Abstract

To evaluate the influence distance and evolution law of the jet blast under the full thrust state of the aircraft engine, we constructed a refined single-engine nozzle model in this study. Using a specific B737-800 engine as an illustrative example, this model takes into account both the internal combustion of the engine and the shearing effect of the tail cone on the airflow; based on a structured grid, the grid and far-field independence of the numerical solution were verified. The numerical simulation results obtained via the Fluent software were compared with the data outlined in the Boeing aircraft characteristics manual for a thorough analysis. Our results indicated that the calculated jet influence distance from the refined nozzle model aligns more closely with the data in the aircraft characteristics manual, albeit with superior accuracy compared to the simplified nozzle model employed in previous studies. The findings of this study can serve as a valuable reference for computing jet influence distances across various aircraft types and engine models, providing data support for the study of safety intervals for aircraft crossing the runway behind the takeoff point.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

As of January 2024, 24 airports in China have adopted multi-runway simultaneous operations by means of expansion and renovation, aiming to alleviate operational pressure and enhance the overall capacity. Nevertheless, such airports have intricate layouts, inevitably giving rise to challenges associated with runway crossings during practical operations. Effectively utilizing airport space and time resources, and allocating runway usage rationally, are crucial for improving the operational efficiency of multi-runway airports in China's civil aviation industry, thus becoming a key factor for sustained high-speed development. Implementing a more efficient runway crossing operation model at multi-runway airports is one effective method to enhance runway utilization efficiency and reduce flight delays. Presently, the runway crossing procedures at major Chinese airports predominantly involve crossing in front of the takeoff point and executing a big U-turn [1], which introduces risks of runway incursions and operational inefficiency. To address these concerns, He et al. suggested a novel operational mode of takeoff point backside crossing [2]. Aircraft crossing the runway behind the takeoff point is where a crossing aircraft can cross the runway behind its takeoff point when it meets the non-full-length takeoff. This approach helps reduce the risk of accidents, decrease aircraft taxiing time on the ground, lower fuel consumption, and significantly enhance air traffic control operational efficiency. The movement and dissipation characteristics of engine jet flows, as well as their influence distances, constitute an important focal point of global research endeavors. Keiichi et al. investigated the far-field jet-flow velocity distributions during aircraft takeoff on intersecting runways, utilizing numerical simulations based on the Reynolds-Averaged Navier–Stokes (RANS) governing equations and demonstrated a high degree of agreement with experimental data [3]. Rembold studied the flow-field development in the near-nozzle region of aircraft engines through a high-order simulation code and direct numerical simulations [4]. Francisco et al. utilized non-intrusive uncertainty quantification (UQ) in three-dimensional (3D) RANS simulations of aircraft jet flows by employing the Spalart–Allmaras (S–A) turbulence model [5]. Their findings suggested that variations in physical and turbulence model parameters significantly impacted specific jet flow-field regions. Synylo et al. investigated the influence of pavement friction coefficients on (i) jet-flow parameters, (ii) height, and (iii) longitudinal component of buoyancy effects [6]. Nima et al. performed large-eddy simulations of jet flows using unstructured grids and verified the reliability of computational fluid dynamics (CFD) numerical simulations for turbulent flow calculations for these grid conditions [7]. Simon Eastwood and colleagues employed a combined approach of large-eddy simulation (LES) and RANS simulation to solve a jet engine jet-flow model with an aspect ratio of 8:1 and a Reynolds number of 300,000 [8]. Qi et al. conducted a study on the tailpipe model of a dual-duct engine using numerical simulation methods and experimental validation [9]. Liu et al. utilized the numerical simulation method to study the flow-field and temperature-field of the internal and external flow integrated engine jet based on the density solution, and employed the Radiative Transfer Equation (RTE) method to study the infrared radiation characteristics of the engine jet [10]. Wang et al. numerically simulated the spatial evolution of engine jet flows by solving the fully compressible 3D Navier–Stokes equations utilizing high-order explicit spatial differentiation and Runge–Kutta time integration methods [11]. Hu investigated the takeoff influence distance on aircraft engine jet flows utilizing first- and second-order S–A and shear stress transport (SST) turbulence models based on unstructured grids [12]. Wu et al. simulated jet flow for a two-dimensional (2D) cylindrical aircraft under high-altitude and high Mach number inflow conditions [13].

Although the above-mentioned studies provide excellent insights, they primarily investigate the jet-flow dissipation and evolution laws near the engine nozzle, with a limited focus on far-field flows. Even the few studies concerning far-field jet flows often utilize simplified engine nozzle models, establishing static temperature and Mach number boundary conditions [2, 12]. However, a considerable disparity is observed between the nozzle model and the real engine configurations as the above-mentioned static boundary conditions differ vastly from the real operating conditions of the engine, unavoidably introducing significant errors in the numerical simulation results.

This paper focuses on a methodological reference for examining the jet impact range across various aircraft types and to explore the application of structured grid and twin-engine nozzle model in numerical simulation of jet flow. Provide new research ideas and methods for jet influence distance of takeoff aircraft, and data support for the study of safety intervals for aircraft crossing the runway behind the takeoff point.

The remainder of this paper is organized as follows: Sect. 2 reviews the existing practical engine jet calculation models used in engineering. Section 3 selects a popular type of B737-800 engine (representing the largest proportion of 37.9% in China) for a 1:1 scale model reconstruction [14]. The computational domain for fluid dynamics, encompassing the inner and outer ducts of the nozzle and the outer flow field. Then, Sect. 4 establishes the computational domain covering the internal and external flow fields of the duct and nozzle. An integrated structural grid was implemented, followed by grid independence verification. Section 5 selects the optimal grid to calculate the influence distance of B737-800 engine. The calculated results have a superior fit, lower deviation rate, and heightened accuracy. Finally, Sect. 6 summarizes the meaning and importance of the results in practice and limitations of the study.

2 Engine Jet Calculation Model

2.1 Reynolds Mean N–S Equation Model

The RANS equation model is an engineering practical turbulent flow simulation method. It assumes that the turbulent structure of the flow field is random and establishes the transport process of turbulence based on the mean flow field [15, 16]. The RANS equation model is widely used in engineering problems, offering fast computation and being more suitable for turbulent flows at high Reynolds numbers. The N–S equation in Cartesian coordinates is as follows:

Continuity equation:

Momentum equation:

In the equations, \(u_{i}\) represents the Reynolds mean velocity component with the mean symbol omitted; ρ is the density; p is the pressure; \(u^{\prime}_{i} u^{\prime}_{j}\) is the pulsating velocity; and \(\sigma_{ij}\) is the stress tensor component [17].

The N–S equations describe the fundamental laws of fluid motion and constitute a set of partial differential equations. By employing the Finite Volume Method (FVM), the engine jet flow field is divided into a finite number of small control volumes, with the N–S equations for mass, momentum, and energy conservation being solved for each control volume.

2.2 Turbulence Model

We selected the SST k–ω model was used for numerical simulation of the engine jet flows. The model was built at the Standard k–ω model is improved using two equations and a dissipation rate conversion function [18]. The transport equations of the SST k–ω model are divided into three parts: the k-equation, the ω-equation, and the dissipation rate conversion function. The transport equations for k and ω in the SST k–ω model are as follows:

In the equations: the k-equation and the standard k–ω model consistency, The orthogonal divergence term \(D_{\omega }\) is added to the ω equation.

The effective diffusion coefficients are as follows:

In the equations: \(\sigma_{k}\) and \(\sigma_{\omega }\) are the turbulence energy Prandtl coefficients.

The turbulence viscosity \({\upmu }_{\text{t}}\) is as follows:

The dissipation rate conversion function in the SST k–ω model is an empirical formula used to improve the prediction of turbulent structures at larger scales. This function adjusts the distribution of eddy viscosity, making it smaller near the walls and larger away from the walls. It accurately captures the phenomenon of flow reversal in the flow field, predicts turbulent structures at larger scales, and is suitable for numerical simulation of jet blast in aeroengines.

3 Numerical Calculation Methods

3.1 Geometric Model

3.1.1 Engine Geometric Model

The B737-800 engine nozzle in Fig. 1 exhibits a diameter of D = 1735 mm and a length of L = 3046 mm, with L:D = 1.76. The outer and inner annular ducts of the nozzle have exit areas of S1 = 884,410 mm2 and S2 = 273,920 mm2, respectively, with S1:S2 = 3.23.

3.1.2 Fluid Computing Domain Construction

The outflow domain refers to the region in numerical simulation where the internal physical field of the model extends to the external space of the model. Within this region, the computational results interact with the surrounding environment through boundary conditions, simulating the evolution of the physical field. The subject of this study is the jet flow from an aircraft engine, considering the internal flow within the engine nozzle to accurately replicate the aerodynamic behavior of the engine. Therefore, the fluid computational domain includes the internal and external ducts of the nozzle and the outflow domain.

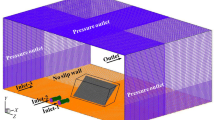

We excluded ground effects and employed a structured grid and a cylindrical far field, enhancing the grid quality and minimizing its impact on the computational results. Consistent with previous studies [19,20,21,22] the circumferential and axial domains were set at 40 and 80 times that of the nozzle diameter. As we primarily focused on the far-field impact range of the jet, the flow field diameter in Fig. 2 was fixed at 40D (69.4 m) in the plane perpendicular to the incoming flow; and along the streamline direction, the flow field length was fixed at 350D.

3.2 Numerical Simulations

The numerical simulation calculations were exclusively performed using a structured mesh, with the ICEM CFD grid generation software. Grid refinement was applied to the inner and outer surfaces of the nozzle. A total of 3.03 million grids in Fig. 3 were used for a single nozzle and its far-field.

We employed the Fluent software for the CFD numerical simulations. The density-based solver was employed to solve the RANS equations and the SST k–ω model was employed to account for the turbulence [23]. The spatial discretization of the viscous terms in all equations utilized a central differentiation scheme, the temporal terms utilized a second-order Euler implicit scheme, and the flux calculation utilized the Advection Upstream Splitting Method (AUSB) scheme [23]. The gradient calculations were performed using a mesh cell-based least squares method [24]. For the computation of the jet flow, turbulent kinetic energy, and dissipation rate, a first-order upwind scheme was used for the initial 15,000 iterations, followed by a second-order upwind scheme for continuance [25].

3.3 Boundary Conditions

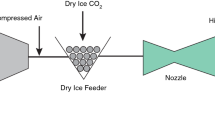

The far-field numerical simulation boundary conditions are as follows: For the far-field inflow, we set the far-field Mach number to Ma = 0.01, static pressure to P0 = 101,325 Pa, and static temperature to T0 = 303.15 K. The inflow direction was set parallel to the central axis of the nozzle. The engine had a maximum takeoff thrust of 13,360 daN, air mass flow rate of 386.5 kg/s, the bypass ratio of the air flow rate in the engine's outer duct to the inner duct is 5.7, diameter of 1735 mm, and outlet temperature of 377 °C. Using these parameters, the GasTurb engine performance calculation software [26] was employed to compute the total temperature and total pressure of the inner and outer annular ducts. We fixed the wall boundary to be adiabatic and noN-Slip.

The numerical simulation boundary conditions for the engine model are provided in Table 1.

3.4 Convergence Judgment of Numerical Simulation

In the Fluent software solution, residuals are the differences between the simulated results and the real ones, and are important indicators to measure the accuracy and convergence of the numerical solution. We would discrete each control equation (mass, momentum, energy, etc.) at each time step, and then solved using an iterative method. During each iteration, the Fluent software calculates the residuals of each control equation and compares them to the convergence criteria to determine if the simulation has converged.

The smaller the value of the residuals, the smaller the error between the numerical solution and the real solution, and the better the convergence. Typically, simulations can be considered to have converged when the rate of change of the residuals is less than a preset threshold [27, 28]. For simulations of engine jet, the numerical results can be considered to have converged when the values of the energy residuals converge below 1E − 06 and the other detection residuals below 1E − 03. Convergence is calculated when each monitored value has reached below the preset residual value. The residual results of velocity and other values are depicted in Fig. 4.

However, residuals are one of the important metrics to measure the accuracy and convergence of numerical solution, but not the only metrics. In practical applications, whether the numerical solution converges or not requires comprehensive evaluation and judgment combined with other indicators and practical problems. We set up air flow monitoring points on the exit surfaces of the inner and outer duct of the nozzle, and the monitoring data are output as a coordinate curve. When the resulting monitoring curve shows that the flow values remain constant, the numerical solution is considered to have converged. The numerical solution is seen to have converged from the air flow monitoring coordinate plots of the inner and outer ducts in Fig. 5.

4 Algorithm Validation

4.1 Grid Independence Verification

For the same model, fewer grids make the results grid-dependent and lead to convergence issues, whereas more grids make the results grid-independent, but lead to difficulties in achieving convergence [29]. Following a preliminary convergence analysis of the numerical simulations, grids were generated for the nozzle and its far-field using a growth rate value of 1.5, resulting in four models with grid sizes of 2, 3, 4.5, and 6.75 million [30].

Both the grid quality and determinant exceeded a value of 0.5, with grids having 0.8 < quality < 1.0 accounting for 93.07% of the total number of grids. The overall quality of the angle was maintained above 35°to ensure good grid quality.

We utilized engine jet-flow velocity profile data extracted from the Boeing Airplane Characteristics for Airport Planning manual. We used the engine jet-flow velocity profile data extracted from the Boeing Airport Planning Characteristics Manual shown in Fig. 6 [31]. We selected velocity values of 16, 22, 44, 50, and 70 m/s, considering speed conversion, and explored variations in the engine nozzle velocity contours in response to changes in the grid quantity.

In the grid independence verification process as shown in Fig. 7, the velocity contours at 16 and 22 m/s exhibited noticeable changes from 2 to 3 million grids. However, between 3 and 6.75 million grids, the contours for the five different velocities remained relatively stable.

In summary, the shape of the velocity contour map of the engine jet-flow influence distance stabilized as the grid quantity surpassed a threshold (irrespective of variations above the threshold). We further analyzed the decay curve of nozzle axial velocity in Fig. 8 and, in particular, the variation of velocity at 16 m/s for varying grid quantities.

Noticeably, for 3 and 4.5 million grids, the axial velocity decay curves of the nozzle in Fig. 8 essentially overlapped. With the increasing grid quantity, the influence distance of the nozzle axial velocity in Fig. 9 decay at 16 m/s was gradually stabilized. For 3 million grids, the deviation of the calculation results was within 5 m, with an error rate of 0.49%. We concluded that the numerical solution becomes independent of the grid quantity for ≥ 3 million grids.

4.2 Far-Field Independence Verification

To validate the far-field impact of the jet flows through numerical simulations, far-field lengths of 300D (520.5 m), 350D (607.25 m), and 500D (867.5 m) were individually set parallel to the incoming flow direction, based on the B737-800 model manual and relevant research experience [32, 33]. The corresponding numbers of grids were 2.82, 3.12, and 3.20 million, respectively. The employed nozzle model (Sect. 2.1) and the structure and parameter settings of the far-field remained consistent.

For the three different far-field lengths, the axial influence distances in Fig. 10 for the speeds of 70, 50, 44, and 22 m/s were essentially the same. The motion patterns of all velocity contour maps for the far-field lengths of 350D and 500D were completely identical, with minimal differences in the influence distance. It indicating that the results were independent of the far-field length.

5 Jet Influence Distance Calculation

After verifying grid and far-field independence, the jet influence distance was computed using 3 million. Considering the influence range of the jet, the far-field length should be set to 350D (Figs. 11, 12).

As shown in Figs. 1 and 2, the impact ranges along the X-axis for speeds of 44, 22, and 16 m/s for the B737-800 aircraft engine were determined to be 110, 310, and 546 m, respectively. For the same speeds, the aircraft characteristics manual in Fig. 6 reports impact ranges of 52, 305, and 549 m, respectively; and the simplified nozzle numerical simulation results indicate impact ranges of 111, 312, and 475 m, respectively. In comparison to the aircraft characteristics manual data, the calculation errors in this study decreased. At a far-field distance of 500 m, the error rate for the speed of 16 m/s was 0.55%, whereas that of the simplified nozzle is 13.48%. This represents a decrease of 12.93%, reducing the error rate below 1% and enhancing the reliability of our calculation results (Fig. 13).

We took six cross-sections on the Y–Z plane at X = 50, 100, 200, 300, 400, and 500 m, to examine the lateral impact range of the tail jet along the X-axis for different speeds. The comparison of the values is illustrated in Table 2.

Upon comparison in Fig. 14, the computed axial velocity decay curve of the nozzle aligned quite closely with the simulation results of the simplified nozzle and the processed data from the aircraft operations manual [1]. The decay curve was the most pronounced in the range of 0–200 m, and exhibited a better fit than the simplified nozzle calculation results beyond 300 m in the far-field range, with a smaller error and higher accuracy.

6 Conclusions

Focusing on the widely employed B737-800 aircraft engine, we conducted numerical simulations of the 3D nozzle model under total temperature and total pressure boundary conditions, utilizing the RANS equations and the SST k–ω turbulence model. The internal combustion of the nozzle and the shear effect of the nozzle tail on the airflow were fully considered. The findings indicate an enhanced model accuracy compared to the simplified nozzle model. Analysis of the nozzle axial velocity decay curves and velocity contour maps at different speeds led to the following primary conclusions: in comparison to the simplified nozzle model used in previous studies and the data from the Boeing aircraft characteristics manual, (i) the impact ranges calculated by the nozzle model in this study exhibit a lower error rate, and higher accuracy; and (ii) the axial velocity decay curve of the nozzle model exhibits a better fit.

The engine nozzle model constructed in this study, along with the applied numerical simulation methods, can offer insights for constructing models applicable to various aircraft types and engine models, and serve as a reference for calculating the jet influence distances.

We provide (i) highly accurate data references for the impact range and evolution of the jet flow field of the B737-800 model under takeoff thrust conditions; and (ii) data support for the study of safety intervals between aircraft when crossing the runway behind the takeoff point. However, this study has certain limitations as the single-engine model may deviate from the real flow fields of the commercial twin-engine aircraft [23, 34]. Future studies will delve into numerical simulations of jet flows in the dual-engine mode and construct refined models for a variety of conditions.

Data Availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

He, X., Hu, D.F., Liu, Ch., et al.: Research on the influence distance of engine jet flow by improving DES method and SA model. Chin. J. Saf. Sci. 31(04), 81–87 (2021). https://doi.org/10.16265/j.cnki.issn1003-3033.2021.04.011

He, X., Hu, D.F., Ch, Y.Q., et al.: Numerical simulation study of aircraft engine jet flow under rear side crossing takeoff. Aeronaut. Comput. Technol. 50(06), 5–8 (2020)

Ishiko, K., Hashimoto, A., Matsuo, Y., et al.: Numerical study of the effects of cross-wind on the jet blast deformation. In: Proceedings of the 28th International Congress of the Aeronautical Sciences ICAS (2012)

Rembold, B.: Direct and large-eddy simulation of compressible rectangular jet flow. ETH Zurich (2003)

Granados-Ortiz, F.J., Arroyo, C.P., Puigt, G.: On the influence of uncertainty in computational simulations of a high-speed jet flow from an aircraft exhaust. Comput. Fluids 180, 139–158 (2019)

Synylo, K., Krupko, A., Zaporozhets, O., et al.: CFD simulation of exhaust gases jet from aircraft engine. Energy 213, 118610 (2020)

Tajallipour, N., Kumar, V., Paraschivoiu, M.: Large-eddy simulation of a compressible free jet flow on unstructured elements. Int. J. Numer. Methods Heat Fluid Flow 23, 336–354 (2013)

Eastwood, S., Tucker, P., Xia, H., et al.: Large-eddy simulations and measurements of a small-scale high-speed coflowing jet. AIAA J. 48(5), 963–974 (2010)

Qi, H.F., Gao, Y., Hao, X., et al.: Investigation on flow characteristics of a turbofan tail nozzle. Aero Engines 41(01), 48–52 (2015). https://doi.org/10.13477/j.cnki.aeroengine.2015.01.009

Liu, Y.H., Sh, W.R., Zh, J.X.: Numerical simulation of the flow field and infrared characteristics of the engine exhaust system and tail jet. J. Aerodyn. 04, 591–597 (2008). https://doi.org/10.13224/j.cnki.Jasp.2008.04.009

Wang, Z., He, P., Lv, Y., et al.: Direct numerical simulation of subsonic round turbulent jet. Flow Turbul. Combust. 84(4), 669–686 (2010)

Hu, D.F.: A study on the safety interval for crossing the rear runway of takeoff aircraft. Civil Aviation Flight University of China (2020)

Wu, Y., Xu, X., Chen, B., et al.: Numerical study on transverse/ opposing jet interaction flow field under high Mach number. Acta Aeronaut. Astronaut. Sin. 42(S1), 726359 (2021). https://doi.org/10.7527/S1000-6893.2021.26359.(inChinese)

Yang, L.B., Cong, Y.: Modeling and simulation of jet-and wake-flow-induced velocity of aircraft. Infrared Technol. 43(10), 940–948 (2021)

Baldwin, B., Barth, T.: A one-equation turbulence transport model for high Reynolds number wall-bounded flows. In: 29th aerospace sciences meeting, 610 (1991)

Xin, H., Chen, Y.Q., Ma, Y.L., et al.: Hybrid numerical simulation of jet blast distance of a departing aircraft. Math. Probl. Eng. 2021, 5597414 (2021). https://doi.org/10.1155/2021/5597414

Hou, Sh., Cao, Y.H.: Surface heat transfer coefficient calculation based on the Reynolds averaged Navier Stokes equation. J. Aerodyn. 30(6), 1319–1327 (2015)

Gao, H.R., Liu, C., Chen, Y.Q., et al.: Research on wake interval of paired departure at closely spaced parallel runways. Qual. Reliab. Eng. Int. 39, 1935–1951 (2023). https://doi.org/10.1002/qre.3338

Chuang, S.H., Nieh, T.J.: Numerical simulation and analysis of three-dimensional turbulent impinging square t-win-jet flow field with no-crossflow. Int. J. Numer. Methods Fluids 33(4), 475–498 (2000)

Yang, Y., Chen, Zh.S., Pedrycz, W., et al.: Using I-subgroup-based weighted generalized interval t-norms for aggregating basic uncertain information [J]. Fuzzy Sets Sys. (2023). https://doi.org/10.1016/j.fss.2023.108771

Gao, H.R., Xie, Y.B., Yuan, C.H.J., et al.: Prediction of aircraft arrival runway occupancy time based on machine learning. Int. J. Comput. Intell. Syst. 16, 150 (2023). https://doi.org/10.1007/s44196-023-00333-3

Bagis, A., Konar, M.: ABC and DE algorithms based fuzzy modeling of flight data for speed and fuel computation. Int. J. Comput. Intell. Syst. 11, 790–802 (2018). https://doi.org/10.2991/ijcis.11.1.60

Tandra, D.S., Kaliazine, A., Cormack, D.E.: Numerical simulation of supersonic jet flow using a modified k−ε model. Int. J. Comput. Fluid Dyn. 20(1), 19–27 (2006)

Sun, X.L., Wang, Z.X., Zhou, L., et al.: The design method of serpentine stealth nozzle based on coupled parameters. J. Eng. Thermophys. 36(11), 2371–2375 (2015)

Liu, T., Kuang, T.Q., Lai, J.M., Wang, Y.Q., et al.: Numerical simulation of the filling stage of gas-water-assisted injection molding process. J. East China Jiaotong Univ. 38(03), 102–110 (2021)

Joachim, K.: Gas Turb 12 [cp]. https://www.gasturb.com/index.php

Lu, J., Tang, S., Zhou, Y., et al.: Simulation of assembly tolerance and characteristics of high pressure common rail injector. Int. J. Comput. Intell. Syst. 4, 1282–1289 (2011). https://doi.org/10.2991/ijcis.2011.4.6.20

Xin, H., Zhao, R., Gao, H.R., et al.: Prediction of aircraft wake vortices under various crosswind velocities based on convolutional neural networks. Sustainability 15, 13383 (2023). https://doi.org/10.3390/su151813383

An, E.K., Zhang, R., Han, Y.F., et al.: Grid independence analysis of numerical simulation of multiphase turbulent combustion. Boiler Technol. 49(06), 54–58 (2018)

Feng, J.G., Tang, X.G., Wang, W.B., et al.: Reliability verification method of numerical simulation based on grid independence and time independence. J. Shihezi Univ. (Nat. Sci.) 35(01), 52–56 (2017). https://doi.org/10.13880/j.cnki.65-1174/n.2017.01.009

Boeing Commercial Airplanes: Airplane characteristics for airport planning. United States of America (2013)

He, X., Wang, Q., Guo, D.X., et al.: CFD-based analysis of rear-side aircraft forces under the influence of engine jet. Sci. Technol. Eng. 23(33), 14443–14451 (2023)

He, X., Wang, Q., Guo, D.X.: Research on the safety interval of runway crossing behind takeoff point based on CFD. Mod. Comput. 19(04), 64–68 (2023)

Li, G.N.: Numerical solution of three-dimensional N–S equations and application of S–A turbulence model. Northwestern Polytechnical University (2006)

Funding

This research was supported by CAAC Aviation Safety Capacity Building Fund Supported Project, under Grant No. [2022] 186; Research and Innovation Team of Civil Aviation Flight University of China: Flight Efficiency Improvement Research Center, under Grant No. CZKY2023156.

Author information

Authors and Affiliations

Contributions

Conceptualization, H.G. and D.G.; methodology, H.G. and Z.L.; software, D.G.; validation, H.G. and T.N.; formal analysis, H.G. and X.H.; investigation, X.H. and T.N.; data curation, H.G.; writing—original draft preparation, D.G. and Z.L.; writing—review and editing, H.G. and Y.C.; visualization, X.H. and T.N.; supervision, H.G. and Y.C.; project administration, H.G. and Y.C. All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Conflict of Interest

The authors do not have any competing interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Gao, H., Guo, D., Li, Z. et al. Analysis of Jet Blast Distance of a Refined Engine Nozzle Model for Departing Aircraft. Int J Comput Intell Syst 17, 121 (2024). https://doi.org/10.1007/s44196-024-00529-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s44196-024-00529-1