Abstract

The automotive parts industry cluster is a complex operating system, and it is no longer possible to use a simple theory to make a scientific and reasonable explanation for the parts industry cluster. In view of this, the study takes the automotive parts industry cluster as the research object, innovatively invokes the theory of organizational ecology and constructs a competitiveness analysis mechanism based on population co-evolution. The study conducts performance analysis and simulation tests on the constructed model, integrating the CS–AHP evaluation method to evaluate the competitiveness of the parts industry cluster. The performance comparison results show that the research method has a minimum training error of 0.0108, when the number of iterations of the system is 69th. This method has a stable loss function value at the fifth iteration, which is a stable convergence state earlier than the GA algorithm, differential evolution and distribution estimation algorithm. The A-level index score of the off-line platform auto parts industry cluster is 0.5174, which is significantly greater than 0.5. The competitive cooperation effect, technological innovation effect and cluster culture scores of the e-commerce platform are 0.5885, 0.6899 and 0.5329, respectively, which are significantly higher than those of the off-line. The above results show that the accuracy of the research algorithm is higher than that of the off-line industry. The above results show that the accuracy of the research algorithm is better, which can make a reasonable scientific basis for the auto parts industry and carry out competitiveness evaluation. To a certain extent, it can provide technical reference for the future development of the auto field industry.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

1.1 Research Background and Motivation

At the beginning of the twentieth century, China’s automobile and auto parts industry gradually arose. However, because it started late, the overall level is relatively backward. With the rapid development of China’s economy and the continuous improvement of people’s living standards, the scale of the automobile consumption market is expanding. This has laid a solid economic foundation for the development of China’s automobile and auto parts industry [1, 2]. At the same time, the country has also issued corresponding policies, creating favorable conditions for APIC. In addition, the current relationship between energy resources and environmental transportation has led to more and more social constraints on the development of the automobile industry, and a new round of industrial technology innovation is emerging in the world. Industrial clusters are also receiving widespread attention as a new and effective way of regional economic growth. The low-cost labor force and great potential of the Chinese market have also attracted a number of foreign manufacturers to invest in China. This has further promoted the development and expansion of China’s auto parts manufacturing industry [3, 4]. But the auto parts industry also faces a series of outstanding problems since its development. For example, the industrial cluster structure is unreasonable, the production of parts and components is less profitable, and the development of parts and components industry falls behind. Facing the opportunities and challenges brought by these external factors, it is particularly important for APIC to develop rapidly on the existing basis, innovate product technology, promote industrial progress and ultimately improve the competitiveness of industrial clusters [5]. Therefore, the system concepts of organizational ecology and Lotka–Volterra model are innovatively introduced in the experiment. The mathematical model of APIC evolution dynamics mechanism based on population co-evolution is constructed and simulated, and the characteristics of co-evolution among auto parts enterprises are analyzed. In the experiment, the combination of analytic hierarchy process (AHP) and cuckoo search (CS) is used as a CS–AHP evaluation method to study the competitiveness of the parts industry. It is expected to improve the competitiveness of APIC and provide more reference for the development of APIC in China.

1.2 Innovative Points of the Study

The innovation points of the research can be mainly divided into two points. The first point is that the research innovatively proposes a mathematical model of the evolution mechanism of auto parts industry cluster based on co-evolution. The second point is that based on this model, the experiment conducted a systematic research on the connotation, evaluation system and research paradigm of automobile industry cluster competitiveness. The experiment applied the improved co-evolutionary evaluation method combining the traditional decision-making method of complex systems and the new meta-heuristic optimization algorithm, which has promoted the forward development of the theoretical system of industry cluster competitiveness. As the global economic structures and automobile industry patterns are rapidly changing and reshaping, the road of cluster development is an inevitable choice for China's automobile industry to obtain core competitiveness. Through in-depth and systematic empirical research on the competitiveness of auto parts industry cluster, it is of great practical significance for China's regional automobile industry to realize transformation and upgrading, to help solve the dilemmas encountered in the current development and enhance the competitiveness level of the automobile industry.

1.3 Research Ideas

Based on the research results at home and abroad, the experiment takes China's auto parts industry cluster as the research object and constructs a system analysis model with network attributes to carry out a systematic, dynamic and comprehensive research on auto parts industry cluster. On this basis, a multi-dimensional, dynamic and comprehensive automotive cluster competitiveness evaluation index system combining qualitative and quantitative aspects and taking into account the current development strength and future growth capacity was constructed. The CS–AHP evaluation method is constructed by combining the traditional complex system decision-making method AHP with a new meta-heuristic optimization algorithm cuckoo search. The off-line platform and the e-commerce platform auto parts industry cluster are selected as the experimental objects for comparison, so as to know the healthy development of China's auto parts industry cluster and the improvement of the competitive advantage of the regional economy.

1.4 Research Content

The main content of this paper is divided into sections. The first chapter mainly introduces the significance and background of the research, and the importance of the research on the competitiveness of auto parts industry cluster. The second chapter mainly focuses on the development of auto parts industry cluster and its competitiveness level of domestic and international research. The third chapter analyzes the network attributes of China's auto parts industry cluster and evaluate the competitiveness. Firstly, the first section constructs a mathematical model of the competitiveness mechanism of auto parts industry cluster based on co-evolution. Based on this model, the dynamic evolution mechanism and characteristics of China's auto parts industry cluster are analyzed. Then in the second section, on the basis of the previous experiments, the traditional complex system decision-making method AHP and a new meta-heuristic optimization algorithm cuckoo search are combined with each other to form a CS–AHP evaluation method to evaluate the competitiveness of automotive parts and components industrial clusters. Chapter 4 is a simulation experiment on the performance and application effect of co-evolution in auto parts industry clusters, to explore the weight scores of the three indexes of competitive cooperation effect, technological innovation effect and culture of auto parts industry clusters in China's off-line platforms and e-commerce platforms, and to better evaluate the competitiveness of auto parts industry clusters in terms of network attributes. Chapter 5 is a discussion of the whole article, identifying that the article has a high experimental value and can point out the direction for the development of China's auto parts industry cluster. Chapter 6 is a concluding statement of the whole article.

2 Related Works

APIC is one of the most popular research issues in the current manufacturing industry. With the development of the manufacturing industry, domestic and foreign scholars have begun to conduct extensive and in-depth research on the development competitiveness of the components industry cluster. Through the collection of 242 entities in the physical automobile industry in Malaysia, researchers such as Al-Shami use confirmatory factors and structural equation models to conduct specific analysis of environmental sustainability data. The innovation and sustainability of ecological products of parts and components are linked to each other. They can play an obvious regulatory role in the green development of automobile industry clusters [6]. Aimed at the problem of a large number of customer complaints (VoC) from the automobile industry cluster in Iran, Amoozad and other researchers proposed a multi-criteria decision-making method based on hybrid clustering. Through the collection and analysis of customer complaints, they found that most complaints were related to the service process. Finally, a comprehensive qualitative and decision-making method was obtained to conduct critical analysis of customer complaints [7]. To enrich the existing knowledge space of social cluster benefits, the team of Pavelkova and Zizka carried out a benefit impact analysis on cluster localization. They took the Czech traditional industrial sector as the object to discuss. The enterprise data from 2002 to 2016 did not prove that the localization of cluster enterprises would have an impact on enterprises and industries [8]. Based on the competitiveness evaluation index system, Zheng et al. analyzed the development level of new energy vehicles in Jiangsu, China, by using the method of gray correlation and tripartite decision-making. It selected samples from provinces with the better development of China’s new energy automobile industry cluster for empirical analysis. The overall results show that the overall development level of Jiangsu is the first in the country, showing an obvious upward trend [9]. Intarakumnerd analyzed the development of Thailand’s automobile industry cluster. Through collecting the government policies and the strategies of various partners, it found that the focus of the development of the local automobile industry lied in the innovation of new technologies. Combined with multi-dimensional strategies and efforts, it could effectively promote the status of the global value chain [10].

Valdez-de discussed the independent variables and competitiveness dependent variables that affected the development of automobile industry clusters. A new tool to measure the competitiveness of automobile manufacturing was designed in the experiment. The study found that there was a significant causal relationship between process quality and product innovation and automobile manufacturing clusters. Enterprises in the parts industry should ensure product quality and innovate the product technology to improve market competitiveness [11]. To improve the sustainable and innovative development of the business performance of the Indian automobile industry, Gouda G K and others proposed a new digital conceptual framework model for empirical testing. Knowledge management, office atmosphere, learning enthusiasm and enterprise personnel communication had a significant positive impact on the innovation and performance of the automobile industry [12]. To meet the challenges faced by localized small automobile companies, Joshi A proposed to use the failure mode and effect analysis (FMEA) to reduce the errors in the production process. During the process, he observed the spot-welding failures. Finally, it was found that regular maintenance tools and inspection of safety sensors could effectively reduce the occurrence of failures in the production process of the automobile industry cluster, thus improving the product quality [13]. To reduce the impact of parts defects on the production of automobile industry clusters, Sundaramali and others proposed adopting the six sigma principle to monitor and identify the source of defects. The data showed that the proposed method could effectively reduce the failure rate and the defect percentage by nearly 16.0% [14]. To realize sustainable development and automation of automobile industry manufacturing, Ethiraj’s research team proposed a decision support system based on machine learning. It used decision tree and artificial neural network to diagnose the possible failure of parts in the automobile industry, and the final product could obtain high customer satisfaction [15].

To sum up, many researchers have carried out extensive research on automobile industry clusters. Most of these studies focused on machine learning algorithms to improve vehicle performance. Few studies have analyzed the competitiveness of APIC using organizational ecology. In view of this, the research puts forward the dynamic mechanism model and the CS–AHP method for the evolution of parts industry cluster based on co-evolution. It is expected to provide more research references for China’s automobile industry by evaluating the competitiveness of the components industry cluster.

3 APIC’s Network Attribute Analysis and Competitiveness Evaluation

3.1 Analysis of APIC Competitiveness Mechanism Based on Co-evolution

With the interaction and penetration between ecology and the development of the automobile industry, a relatively novel APIC-based ecological theory has been generated. This theory can explain the competitive mechanism of industrial clusters more comprehensively. There are many forms of co-evolution among different species in the ecological environment. It can be divided into five forms: predatory competition, non-predatory competition, mutual-beneficial symbiosis, partial-benefit cooperation, and primitive cooperation [16]. Table 1 shows the main forms and contents of the co-evolution of the ecosystem and APIC.

"A" and "B" refer to two populations participating in co-evolution in the APIC ecosystem in Table 1. " + ", "−" and "0", respectively, indicate that the current population is promoted, suppressed or unaffected in the co-evolutionary exercise. Generally speaking, the automobile industry cluster is a cluster formed by specialized cooperation of relevant enterprises in the fields of production, manufacturing and parts. Therefore, in the process of competition, there will not be a predatory relationship of "you die and I die", but a non-predatory competition relationship. Through this competitive relationship, they cooperate and evolve with each other. The classic model for predicting the growth of a single population is Logistic. Based on this, this paper studies the construction of the competition mechanism model between the main bodies of industrial clusters. In the APIC with limited resources, the development of all structural parts will be restricted to varying degrees. Therefore, the growth of a single innovation population in the APIC ecosystem must follow a certain Logistic law, as shown in formula (1).

In formula (1), \(N\) represents the innovation output value corresponding to a single competitor in the industrial cluster at the current moment. \(r\) refers to the inherent growth rate of competitiveness growth contained in the main body of competition (related to the industry characteristics and attributes, which is a constant generally). \(K\) represents the maximum value of all the output of the competitor under the premise of sufficient resources. \(\left( {1 - N/K} \right)\) is a coefficient. This coefficient has a braking effect on the competitive ability of the main body of competition. So, the competitiveness of the main body can always be close to the environmental capacity in the cluster ecosystem, and an S-shaped growth curve is formed, as shown in Fig. 1.

The competitiveness of APIC can be divided into three types of co-evolutionary competition mechanisms, including unpredictable competition. In the non-predatory competition mechanism, organizations will fight for resources in the cluster and create obstacles to each other. Therefore, based on the Logistic model, the growth Lotka–Volterra model is constructed, as shown in formula (2).

where \(n_{1} ,n_{2}\) represent the organizations in formula (2). \(N_{1} ,N_{2}\) represent the competitiveness output values of the corresponding organizations. \(r_{1} ,r_{2}\) represent the natural growth rates of the competitiveness outputs of the corresponding organizations. \(K_{1} ,K_{2}\) represent the maximum output values of competitiveness under the premise of sufficient resources. \(\alpha \left( \beta \right)\) represents the inhibition coefficient of competitiveness growth between cluster organizations. The resources used by the component enterprise organization are related not only to their own development potential, but also to the ability of competitors to use the resources of similar clusters. When two organizational populations compete to a state of equilibrium, Eq. (3) can be obtained.

Through formula (3), formula (4) can be obtained.

According to the above formula (4), four different sets of competitiveness output value growth models can be obtained, as shown in Fig. 2.

By solving the growth model in Fig. 2, four different corresponding equilibrium points can be obtained, and formula (5) is the specific expression.

In formula (5), because the competitiveness output values \(N_{1} ,N_{2}\) cannot be equal to 0, the balance points \(P_{1} ,P_{2} ,P_{3}\) have no practical significance, except the balance point \(P_{4}\). Equation (6) can get the balance point coordinates of innovation capacity growth between organizations.

In addition, the model also includes the co-evolution innovation mechanism under the original cooperation mode. In this mode, due to the positive interaction between parts organizations and enterprises, it can get the growth model of competitiveness under the original collaborative competition mode between organizations, as shown in formula (7).

In the same way as formula (3), let \(f\left( {N_{1} ,N_{2} } \right) = 0,g\left( {N_{1} ,N_{2} } \right) = 0\), so the stable balance point of innovation benefits can be obtained under the original cooperation mode between organizations. Formula (8) is the specific expression.

The research model also incorporates the co-evolution innovation competition mechanism under the symbiosis mode of partial benefit. In this mode, one organization can promote the growth of other organizations’ competitiveness. However, the other organization has no promotion effect on the growth of the competitiveness of other organizations. Based on all the above formulas, the growth model is constructed as shown in formula (9).

In the same way, it is supposed that \(f\left( {N_{1} ,N_{2} } \right) = 0,g\left( {N_{1} ,N_{2} } \right) = 0\). So it can get the stable equilibrium point of competitive benefits under the symbiosis mode of partial benefits among organizations. Formula (10) is the expression.

The relationship between APICs is analyzed based on the co-deductive evolution. In the manufacturing industry cluster, there is no contradiction between the co-evolutionary innovation and competitive activities among enterprises. Figure 3 is the cooperation and competition relationship between different parts industry clusters.

3.2 Construction of APIC Competitiveness Evaluation Index System

Relevant information about industrial clusters in China is lacking and the majority of industrial clusters is in the development stage. Therefore, the administrative division closest to the industrial cluster is selected to define the cluster so as to maintain the maximum consistency with the real cluster. Before evaluating the competitiveness of industrial clusters, a scientific evaluation index system must be established to evaluate and compare them [17, 18]. The research focuses on the overall comprehensive competitiveness of the parts industry cluster. The comprehensive evaluation index system of the competitiveness of the components industry cluster is established by holding a special meeting, as shown in Table 2.

In the process of APIC, the reasonable allocation of index weights is the key to the evaluation and quantification process. To avoid AHP falling into the local optimum, a CS–AHP algorithm based on AHP is proposed. The CS–AHP method is applied to the optimization calculation of the weight value of the competitiveness evaluation index of APIC, and a CS–AHP model is constructed. In the process, the hierarchy model of the evaluation system is established first. The whole evaluation system is recorded as A, B, C, and D indicator layers from the top to the bottom, corresponding to the total indicator layer, primary indicator layer, secondary indicator layer, and tertiary indicator layer (the number of elements in each layer is \(n_{b} ,n_{c} ,n_{d}\)). The obtained B-level judgment matrix is shown in formula (11).

where \(a_{ij}\) represents the element, and actually represents the importance of element \(B_{i}\) to element \(B_{j}\) from the perspective of layer A in formula (11). \(n_{b}\) represents the number of elements corresponding to layer B. In the same way, the judgment matrices of layer C and layer D are obtained as shown in formula (12).

The value of element \(a_{ij}\) in the paired matrix is taken from "1–9", corresponding to the reciprocal in Eq. (12). The ranges are \(a_{ij} > 0,a_{ij} = 1,a_{ij} = \left( {\frac{1}{{a_{ij} }}} \right)\). When \(i = j\), \(a_{ij} = 1\). To determine the objective function of the matrix, the weight value optimization contained in the judgment matrix \(A_{k}\) is explained. When the elements in the matrix satisfy \(a_{ij} = \frac{{\omega_{i} }}{{\omega_{j} }},\left( {i,j = 1 \sim n_{b} } \right)\), a completely consistent expression of \(A_{k}\) is obtained, as shown in formula (13).

where \(\omega_{k}\) represents the single ranking weight (\(k = 1 \sim n_{b}\)) of each element index in layer B in formula (13). When the value at the left end of the equation is small, the consistency of matrix \(A_{k}\) is higher, and the assumption is true. Then formula (14) shows the objective function corresponding to the calculation and optimization of the weight values of all factor indicators included in level B.

where \(CIF\left( {n_{b} } \right)\) represents the consistency index function in formula (14). The optimal weight of matrix \(A_{k}\) is solved, that is, the weight value corresponding to the minimum value of the consistency index function. In addition, in the process of optimizing the weight, the constraints of conditions are also required, and formula (15) is the expression of the constraints.

In actual evaluation operation, different data have different dimensions. Therefore, how to deal with the data dimensionless has become the key to evaluate the competitiveness of industrial clusters. The normalization method is used to transform the positive term sequence to obtain a new sequence. The dimensionless operation is performed on the new sequence to obtain the specific expression as shown in Formula (16).

where \(x_{i}\) represents the positive term sequence (\(x_{i} = x_{1} ,x_{2} , \cdots ,x_{n}\)). \(y_{i}\) represents a new sequence (\(y_{i} = y_{1} ,y_{2} , \cdots ,y_{n}\)). The resulting schematic representation of the mechanism used to construct the method is shown in Fig. 4.

4 Performance Analysis and Simulation Evaluation of Co-evolution in Parts Industry Cluster

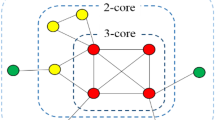

The research innovatively introduces organizational ecology into APIC and constructs a co-evolutionary competitiveness dynamics model. The research takes Windows7 as the operating system and MATLAB as the running platform [19, 20]. The simulation structure model of co-evolution among populations in APIC is observed in Fig. 5.

To prove the performance superiority of the proposed algorithm, four learning evolutionary algorithms are applied to the competitiveness analysis of APIC (Fig. 5). First, the convergence and fitness of the model are verified, as shown in Fig. 6.

At the 95th iteration, the minimum training error of the genetic algorithm model is 0.0346 in Fig. 6a. The differential evolution algorithm tends to be stable after the 70th iteration, with a minimum error of 0.0156. The distribution estimation algorithm converges at the 83th iteration with a minimum error of 0.0218. The research algorithm starts to find the global optimal solution after reducing the short-term iteration period, avoiding the occurrence of the local optimal situation. Finally, it converges at the 69th iteration, and the minimum training error is 0.0108. In Fig. 6b, the research method and differential evolution algorithm reached stable fitness values at the 5th and 29th iterations, respectively. This means that the research algorithm can effectively balance the global and local optimal performance in the training process. It enters the convergence state earlier, reducing the convergence speed of the algorithm. In addition, the PR curve of the algorithm is analyzed, as shown in Fig. 7.

From the comparison of PR curves in Fig. 7, the algorithm is applied to the competitiveness statistics of the parts industry cluster. When the accuracy rate of each algorithm is 0.8 and 0.9, respectively, the corresponding recall rate is different. The recall rates of the distribution estimation algorithm are 0.678 and 0.524, respectively. The recall rate of genetic algorithm is 0.675 and 0.471, respectively. The recall rates of differential evolution are 0.699 and 0.576, respectively. When the accuracy rate of the research algorithm is 0.8 and 0.9, respectively, the corresponding recall rate is 0.798 and 0.661, respectively. This shows that under the same conditions, the accuracy rate and recall rate of the proposed algorithm are higher than those of other algorithms. It has a higher accuracy and recall rate in the optimization of the competitiveness of the parts industry cluster, which can better serve the automobile industry. The variation of the loss function for the four different algorithms is also analyzed, as shown in Fig. 8.

In Fig. 8, all four algorithms are iterated 80 times. When the iterations proceed to about the 63rd iteration, the research method begins to have a minimum loss function value that converges infinitely to the objective function value. At this point, the other algorithms all have significantly higher function values than the study method. By the 72nd iteration, the remaining three methods begin to stabilize. In comparison, the research method converges more quickly and the loss values throughout the process are significantly better than the other algorithms. Then two different populations are selected from APIC for algorithm simulation. Without changing the external environmental factors, the competitiveness output values of population 1 and population 2 are defined as \(N1\) and \(N2\) (that is, the industrial output value of the scale output index commonly used by auto parts clusters). The competitiveness capacity in the corresponding industrial clusters is 5 × 10.3 billion yuan. The growth rate of population 1 is \(r_{1}\) = 0.5, and that of population 2 is \(r_{2}\) = 0.5. The competitiveness growth (inhibition) coefficient \(\alpha \left( \beta \right)\) between the cluster organizations is given different values, and the co-evolutionary deduction results between the two groups are shown in Fig. 9.

Figure 9 shows the different deductive evolution simulation results of the proposed algorithm. In the original collaboration model in Fig. 9, it is supposed that \(\alpha\)(\(\beta\)) = 0.6(0.2), which shows that population 1 and population 2 interact and benefit together. Because \(\alpha\) > \(\beta\), the cooperative promotion effect of population 2 on population 1 is greater than that of population 1 on population 2. The final result of competition is that the outputs of population 1 and population 2 are both improved. The total output value of population 1 is more obvious and finally reaches an equilibrium and stable state. \(\alpha\)(\(\beta\)) is set to 0.6 (0.4) in the non-prey competition model in Fig. 7, which shows that the two populations inhibit each other. Because \(\alpha\) > \(\beta\), it is obtained that the competitive inhibition of population 2 on population 1 is higher than that of population 1 on population 2. The final competition result is expressed as the output result of both population 1 and population 2, both of which have decreased. However, the scale of total industrial output value of population 1 decreased more significantly, and finally reached a stable balance. \(\alpha\)(\(\beta\)) is set to 0 (0.5) under the partial benefit symbiosis relationship in Fig. 9, only \(\beta\) > 0. Population 2 is the partial benefit acquirer, and population 1 does not benefit from the interaction between the two populations, and the total output value does not change. The total output value of population 2 increased. Finally, it reaches a balanced and stable state. Then the sensitivity of the co-evolution competition of the auto industry parts cluster is simulated, as shown in Fig. 10.

In Fig. 10a, \(\beta\) was set to 0.5 and the range of variation of \(\alpha\) was set to [0,0.9], and a total of nine simulations were conducted. It can be found that there is a significant negative correlation between the upper limit of the total output size and the average growth rate of population one and \(\alpha\), while there is a significant positive correlation between the upper limit and the average growth rate of population two. The two populations are in competition with each other, so that the upper limit of their population's gross industrial output value size is lower than the initial 500 billion yuan. When \(\alpha\) is less than 0.5, because the competition coefficient between population one and population two is the largest, population two suffers more damage and the upper limit of the scale of gross industrial output is lower than that of population one; while the growth rate of population one is greater than that of population two because population one suffers less damage and the initial growth rate is higher. When \(\alpha\) = 0.5 and \(\alpha\) = \(\beta\), the impact of damage caused by both sides is the same. When \(\alpha\) is greater than 0.5, population one suffers more damage as the competition coefficient between population one and population two is greater. This means that the greater the competition between the two populations, the lower the upper limit of gross industrial output, the slower the rate of population growth, and the greater the damage caused by the larger competition coefficient.

In Fig. 10b, \(\beta\) is also set to 0.5. It can be seen that the two populations are in a mutually beneficial relationship, so that the upper limit of the size of their total population industrial output is higher than the initial 500 billion yuan, and increases with \(\alpha\). When \(\alpha\) is less than 0.5, population two gains more because population one has a greater coefficient of cooperation with population two. When the value of \(\alpha\) is 0.5, at which point \(\alpha\) = \(\beta\), both parties cause equal impact; however, the growth rate of population one is slightly greater than that of population two because the original growth rate of population one is greater than the original rate of population two. The value of \(\beta\) in Fig. 10c is always in a state of flux and the range of variation of \(\beta\) was set at [0.0.9] for nine consecutive simulations. It can be seen that there is a positive correlation between the upper limit of the size of the gross industrial output and the average growth rate of population II and \(\beta\). As \(\beta\) increased, the upper limit and rate of the population's total industrial output value size also increased. It can be seen that for the biased symbiotic clusters, the beneficiary side is able to obtain a larger upper limit of industrial output and a faster growth rate, both of which are influenced by \(\beta\).

The research selects the e-commerce platform APIC and off-line platform APIC as the empirical research objects. The selected data are from 2012 to 2022, and are all obtained by the relevant government departments. According to the data obtained, the D-level indicators of the auto parts industry are sorted out, and the D-level indicators are dimensionless to obtain \(\alpha_{DI}\). Then the dimensionless value \(\alpha_{CI}\) of the C-level index is obtained by weight calculation. By analogy, \(\alpha_{BI}\) is obtained, and the dimensionless value of A-level index is 0.4821. Table 3 is the final score of the competitiveness evaluation of the e-commerce platform APIC.

Similarly, the relevant indicators of the off-line platform APIC are dimensionless, and the final value of the A-level indicator is 0.5174. That is, the final score of the competitiveness evaluation of the off-line platform parts industry cluster. Table 4 shows the details.

By comparing Table 3 with Table 4, the scores of competitive cooperation effect, technological innovation effect and cluster culture of e-commerce platforms are 0.5885, 0.6899 and 0.5329, respectively. The scores of off-line platforms are 0.4118, 0.3104, and 0.4651, respectively. Indicators C and D are subordinate to each other. In terms of the cluster network attribute advantage (B), the competitiveness of e-commerce platform is significantly better than that of off-line platform. The first reason may be that the e-commerce platform parts industry cluster has a strong demonstration and driving effect on the local parts industry. This can work closely with the relevant enterprises formed in the cluster. Secondly, the e-commerce platform has a large network layout, and the production capacity of supporting enterprises is relatively high. The third is strong resource integration ability and high industrial scale ability. In general, the APIC competitiveness cluster network attribute of e-commerce platform (0.6149) is significantly better than the off-line platform components industry cluster competitiveness network attribute (0.3849).

5 Discussion

On the basis of a large amount of literature and relevant research theories, the study analyses in depth the development status and characteristics of auto parts industry clusters at home and abroad, and uses a combination of qualitative and quantitative methods to analyze the synergistic evolution and competitiveness of China's auto parts industry clusters from multiple perspectives, and obtains specific measures to enhance the competitiveness of China's auto parts industry clusters through detailed analysis. Through the above research, the following conclusions are obtained.

First, based on the theory of auto parts industry clusters, the meaning and characteristics of auto parts industry clusters and the concept of competitiveness of auto parts industry clusters are defined, and the dynamic competitiveness evaluation system of auto parts industry clusters is constructed. Combined with the analysis of the current development situation of China's auto parts industry, an in-depth and systematic analysis of the competitiveness of auto parts was conducted. Secondly, ecology and co-evolutionary theory are introduced into the evaluation of network attributes of the competitiveness of auto parts industry clusters, revealing the dynamic mechanism and systematic evolutionary law of the formation of competitiveness of auto parts industry clusters in China. Based on the data of the total industrial output value of an auto parts industry in China, it is verified that the development pattern of the auto parts industry is basically consistent with the co-evolution mechanism of industrial clusters in ecology. Through simulation experiments, it is found that, on the whole, a more beneficial synergistic evolution mechanism has been established among the component enterprises in the auto parts industry cluster in China. However, the synergistic cooperation among the component enterprises still shows a more obvious asymmetry, and in the future, China's component industry still needs to further enhance the innovation capability of self-technology. Thirdly, using the CS–AHP evaluation method to empirically analyze an auto parts industry cluster in China, there are significant differences between auto parts industries in different regions, and these issues will be the main directions for future strategy.

Overall, this paper puts forward very informative and operational specific measures and suggestions to enhance the competitiveness of China's auto parts industry clusters, pointing out the direction for the future development of China's parts industry clusters.

6 Conclusions

To effectively evaluate the competitiveness of automotive parts industry clusters in e-commerce platforms, the study proposes a co-evolutionary-based approach and incorporates the CS–AHP method to evaluate competitiveness. The process combines the disciplinary knowledge of different theories to conduct theoretical and empirical research on the evaluation of the competitiveness of automotive parts industry clusters. The data show that when the algorithms undergo a convergence stabilization period, the minimum errors of the research method, the genetic algorithm, the differential evolution method and the distribution estimation method are 0.0108, 0.0346, 0.0156, and 0.0218, respectively, with the research method having the fastest stabilization error. Meanwhile, in the PR curve comparison, when the precision rates of the algorithms are 0.8 and 0.9, respectively, the corresponding recall rates of the research algorithm are 0.798 and 0.661, respectively; the recall rates of the differential evolution algorithm are 0.699 and 0.576, respectively. When the system is iterated up to 63 times, the research method is the first to have a stable loss function value and infinitely converges to the objective function value. The competitive network relationship between different enterprises is consistent with the co-evolutionary innovation mechanism under the non-predatory competition model; the evolutionary mechanism between enterprises and weaker parts enterprises in the region is consistent with the original collaboration model. This indicates that in the future, China's auto parts enterprises need to further enhance their own technological innovation capability and supporting capability for the transformation and upgrading of enterprises. In addition, the cluster network attribute of the e-commerce platform (0.6149) is significantly better than the off-line platform network attribute (0.3849) in the evaluation model of auto parts cluster competitiveness. The comprehensive results show that the research method has the best comprehensive performance, with high convergence speed and accuracy rate, and can make a better evaluation of the network attributes and competitiveness of auto parts industry clusters.

However, there are still some limitations of the experiment. Firstly, there is still a shortage in the collection of data related to the auto parts industry clusters. Secondly, the scope of the automotive parts industry clusters involved in the experiment is relatively small in China. Future research should expand the depth and breadth of the experiment and select more regional automotive parts industry clusters to further enrich the research results. Thirdly, the research and application of co-evolutionary-ecological theory in the development of automotive industry clusters is still at a preliminary stage, and the research borrows ecological models to analyze the network attributes of the competitiveness of steep tea parts industry clusters, and more empirical data need to be collected in future research to further improve the relevant theoretical system.

Availability of data and materials

The datasets generated during the current study are available from the corresponding author on reasonable request.

Change history

27 March 2024

This article has been retracted. Please see the Retraction Notice for more detail: https://doi.org/10.1007/s44196-024-00471-2

References

A new approach to solve MADM problems by Logarithmic operation laws in interval neutrosophic environment", T.S Haque, A. Chakraborty, H. Alrabaiah, S. Alam, Granular Computing, 2021, https://doi.org/10.1007/s41066-021-00299-7.

Jatobá, M.N., Franco, M., Rodrigues, M.: The role of communication between partners in the process of strategic alliances: a systematic literature review. J. Busin. Ind. Marketing 38(7), 1511–1531 (2023)

Haque, T.S., Chakraborty, A., Alam, S.: A novel scheme to detect the best cloud service provider using logarithmic operational law in generalized spherical fuzzy environment. Knowl. Inf. Syst. (2023). https://doi.org/10.1007/s10115-023-01873-y

Albayrak Ünal, Ö., Erkayman, B., Usanmaz, B.: Applications of artificial intelligence in inventory management: a systematic review of the literature. Arch. Comput. Methods Eng. 30(4), 2605–2625 (2023)

Yu, P., Cai, Z., Jiang, F., Sun, Y.: Evaluation and analysis of leading position in hydrogen fuel cell vehicle innovation network and the influential factors: a case of patent citations in China. Environ. Sci. Pollut. Res. 30(18), 53339–53354 (2023)

Al-Shami, S., Rashid, N.: A holistic model of dynamic capabilities and environment management system towards eco-product innovation and sustainability in automobile firms. J. Busin. Ind. Marketing 37(2), 402–416 (2022)

Amoozad Mahdiraji, H., Hafeez, K., Kord, H., Abbasi, K.A.: Analysing the voice of customers by a hybrid fuzzy decision-making approach in a developing country’s automotive market. Manag. Decis. 60(2), 399–425 (2022)

Pavelkova, D., Zizka, M., Homolka, L., Knapkova, A., Pelloneova, N.: Do clustered firms outperform the non-clustered? Evidence of financial performance in traditional industries. Econ. Res.-Ekonomska Istraživanja 34(1), 3270–3292 (2021)

Zheng, Q., Zhao, H., He, R.: The competitiveness measurement of new energy vehicle industry based on grey relational analysis. Math. Biosci. Eng. 20(2), 3146–3176 (2023)

Intarakumnerd, P.: Technological upgrading and challenges in the Thai automotive industry. J. Southeast Asian Econ. 38(2), 207–222 (2021)

Valdez-de la Rosa L M, Villarreal-Villarreal L A, Alarcón-Martínez G. Quality and innovation as drivers for manufacturing competitiveness of automotive parts suppliers. TQM J. 2021, 33(5): 966–986.

Gouda, G.K., Tiwari, B.: Talent agility, innovation adoption and sustainable business performance: empirical evidences from Indian automobile industry. Int. J. Product. Perform. Manag. 71(6), 2582–2604 (2022)

Joshi A, Amrutha H, Surabhi M. Application of failure modes and effects analysis (FMEA) in automated spot-welding process of an automobile industry: a case study. J. Eng. Educ. Transform. 2021, 34(Special Issue):281–289.

Sundaramali, G., Santhosh, R.K., Anirudh, S., Mahadharsan, R., Selvaraj, S.K.: Application of dmaic to reduce the rejection rate of starter motor shaft assembly in the automobile industry: a case study. Int. J. Ind. Eng. Manag. 32(3), 1–18 (2021)

Ethiraj, N., Srinivasan, R., Manivannan, S., Devi, S.P., Nallusamy, S.: Predictive analysis of time to failure for sustainable development in an automobile component manufacturing industry. J. Green Eng. 11(2), 1088–1105 (2021)

Selection of most effective COVID-19 virus protector using a novel MCGDM technique under linguistic generalised spherical fuzzy environment", T.S Haque, S. Alam, A. Chakraborty, Computational and Applied Mathematics, Vol- 41, pp: 84, (2022), https://doi.org/10.1007/s40314-022-01776-8

Banik, B., Alam, S., Chakraborty, A.: Comparative study between GRA and MEREC technique on an agricultural-based MCGDM problem in pentagonal neutrosophic environment. Int. J. Environ. Sci. Technol. (2023). https://doi.org/10.1007/s13762-023-04768-1

Chakraborty, A., Mondal, S. P., Alam, S., Pamucar, D., & Marinkovic, D. (2022). A new idea to evaluate networking problem and MCGDM problem in parametric interval valued pythagorean arena. Discrete Dynamics in Nature and Society, 2022.

Westman, L., Luederitz, C., Kundurpi, A., Mercado, A.J., Burch, S.L.: Market transformations as collaborative change: Institutional co-evolution through small business entrepreneurship. Bus. Strateg. Environ. 32(2), 936–957 (2023)

Sahu, A.K., Sharma, M., Raut, R.D., Sahu, A.K., Sahu, N.K., Antony, J., Tortorella, G.L.: Decision-making framework for supplier selection using an integrated MCDM approach in a lean-agile-resilient-green environment: Evidence from Indian automotive sector. TQM J. 35(4), 964–1006 (2023)

Acknowledgements

None.

Funding

The research is supported by: Humanities and Social Science Research Project of Education Department of Jilin Province, Research on the construction path of auto parts Industrial Cluster in Jilin Province, (NO. JJKH20221308SK).

Author information

Authors and Affiliations

Contributions

XM writing—original draft preparation, review and editing.

Corresponding author

Ethics declarations

Conflict of Interest

The author declares that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This article has been retracted. Please see the retraction notice for more detail: https://doi.org/10.1007/s44196-024-00471-2

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Meng, X. RETRACTED ARTICLE: Network Attribute Analysis and Competitiveness Evaluation of Auto Parts Industry Cluster for e-Commerce Platform. Int J Comput Intell Syst 16, 133 (2023). https://doi.org/10.1007/s44196-023-00308-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s44196-023-00308-4