Abstract

Gluten-free and gum-free breads were developed, with the focus on the impact of raw materials (rice grain or flour) and processing conditions (pre-hydration and mixing time). The evaluation of bread quality primarily involved after the measurement of specific volume (BV), alveolar area (AA), and crumb hardness both before and storage. BV varied within 1.99–2.97 ml/g for rice bread and 2.14–2.26 ml/g for flour bread, with control (containing xanthan gum) values of 2.65 and 3.11 ml/g for rice and flour bread, respectively. An increase in AA was observed (rice: 0.5–1.9 mm2 and flour: 0.76–2.0 mm2) compared to controls with gum (rice: 0.36 and flour: 1.41 mm2). Pre-hydration of ingredients and reduced mixing time improved bread quality: volume of bread from hydrated rice and 4 min of mixing time was comparable to that of gum control. Although the aging process, measured by hardness, was faster than in gum-containing bread, process conditions were identified that delayed aging. This information is essential and valuable for future research.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Due to the unsuitability of wheat bread for individuals with celiac disease, alternative gluten-free grains and hydrocolloids are being used as substitutes for wheat and gluten, respectively [1]. Various hydrocolloids have been examined in the production of gluten-free bread to create a polymer network that mimics the function of gluten protein, thereby enhancing the quality of the bread. These include xanthan gum, guar gum, emulsifiers, cellulose, starches, pectin, and protein isolates [2,3,4,5,6]. In particular, the incorporation of gums into gluten-free products improves the properties of the dough by enhancing water absorption capacity and viscoelasticity, resulting in increased bread volume, a softer texture, and an extended shelf life due to delayed staling [1]. However, there are ongoing efforts to develop high-quality gluten-free breads without the use of hydrocolloids, in particular gums, as some consumers find their inclusion undesirable [6, 7]. For instance, Yano, Fukui [8] focused on stabilizing the batter Pickering emulsion to maintain the bubble structure of gluten-free rice batter during fermentation, while Ziobro, Juszczak [6] studied the impact of protein isolates on the structure and quality of gluten-free bread (corn and potato starch-based) without other structure-forming agents such as guar gum and pectin. Nevertheless, achieving gluten-free dough with structural properties comparable to wheat dough remains a difficult challenge and a significant obstacle in the industry, especially when aiming to avoid the use of hydrocolloid additives. The absence of hydrocolloids also presents a challenge in terms of the accelerated staling observed in these breads, primarily characterized by the hardening of the crumb. Staling involves various physical, chemical, and sensory transformations taking place in bakery products during storage. These transformations include starch retrogradation/crystallization, moisture diffusion and redistribution among the protein-starch components and crumb-crust fractions of the bread. These mechanisms collectively contribute to the overall changes and deterioration observed in the texture, flavor, and quality of the bread over time. As a result, bread staling leads to significant economic losses and a decline in consumer acceptance of the products [2]. For this reason, new anti-aging strategies are constantly being studied. For example, adding starch-hydrolyzing enzymes [9], psyllium [10, 11], cross-linked or chemically modified starch [12], chitosan [13], or potato flakes [14] to bread.

When it comes to gluten-free breads, the processing conditions and production methodology play a crucial role in determining the quality of the final product. Researchers have suggested studying various aspects to optimize the characteristics of gluten-free breads. These include investigating the water absorption properties of ingredients [15, 16], understanding the emulsification mechanism for maintaining the bubble structure during fermentation [8], evaluating the impact of particle size on bread quality [17], and considering factors such as mixing and fermentation time [18], among other processing parameters. By studying and optimizing these parameters, it is possible to enhance the overall quality and characteristics of gluten-free breads.

The objective of this study was to evaluate the influence of raw material selection (rice grain or rice flour), raw material treatment (hydration or non-hydration), and process conditions (mixing time) on the quality of gluten-free and gum-free rice bread. Bread volume, alveolar structure of crumb, and changes in crumb texture after 48 h storage were determined. In addition, the flow behavior and microstructure of batter were also investigated.

2 Materials and methods

2.1 Materials

The following ingredients were utilized in the experiments: white rice flour (Kapac Alimentos Específicos S.A., Argentina) with 10.6% moisture, 4.2% protein, 82% carbohydrates, 1.6% fat and 1.6% fiber [19]; long grain rice (Gallo, Molinos Río de la Plata S.A., Argentina) with 11.5% moisture, 7.8% protein, 79.5% carbohydrates, 0.5% fat, 0.3% fiber, and 0.4% ash [19]; commercially available sunflower oil (Natura, AGD Alimentos Naturales, Argentina); fresh yeast (Calsa, C.A.L.S.A., Argentina); xanthan gum (Onza de Oro, Condiment S.A., Argentina); salt and sugar, all of which were obtained from a local market. Rice flour showed a multimodal particle size distribution (determined by sieving) with a median value of 220 ± 22 µm and a dispersion index of 1.37 ± 0.2.

2.2 Bread making process and experimental design

Breads were prepared using either rice grains (R) or rice flour (F) based on the following recipe: 400 g of rice grains or rice flour, 45 g of sunflower oil, 15 g of sugar, 10 g of salt, 9 g of fresh yeast, and the amount of water specified in Table 1. In order to investigate the impact of three factors—rice ingredient (rice grain or rice flour), prior hydration time of the rice ingredient (0 or 2 h), and batter mixing time (2–6 min) , a factorial design 23 (Table 1) was employed. Table 1 indicates that half of the breads was prepared using rice grains/flour that were previously hydrated (H), while the other half was made with dry ingredients (D). For rice bread, the rice grains were soaked in water for 2 h. After the hydration process, the excess water was drained and hydrated rice grains were obtained for further use in the recipe. In the case of flour breads, the rice flour was soaked with a specific amount of water (350 g) for 2 h. Unlike rice grains, the water used for soaking the flour was included as part of the bread recipe and was not drained. Once all the ingredients were accurately weighed and hydrated (if applicable), they were mixed at maximum power using a Waring blender (Waring Commercial, United States) for varying mixing times (1 and 2, according to Table 1), depending on whether the rice ingredients were hydrated or dry. For dry rice bread, a longer mixing time was applied to eliminate any remaining hard rice particles. The amount of water added, and the addition time varied depending on the consistency of the batter during the mixing process. The specific water addition protocol is provided in detail in Table 1. Each batter sample was then left to ferment at room temperature for approximately 2 h, until it reached the edge of the batter container. Finally, the fermented batter was baked in an electric oven at 180 °C for 35 min. Two control formulations were carried out based on the hydrated rice and flour formulations with the addition of 3 g of xanthan gum and mixing time 1 (2 min): RH + G and FH + G formulations. The quantities of the other ingredients remained unchanged, as well as the bread-making process. All the pan breads were prepared in duplicate.

2.3 Damaged starch extent

Damaged starch in rice and flour batters was determined by a spectrophotometric method (AACC Method 76-30A) using damage starch assay kit (Megazyme Ltd., Bray, 100 Ireland). Samples were prepared by mixing pre-hydrated rice grain or rice flour with water in the ratio shown in Table 1 for RH and FH, respectively. They were mixed at maximum power using a Waring blender for 2 min (mixing time 1). The resultant batters were freeze-dried before measuring damaged starch. The results were reported as g/100 g flour.

2.4 Rheological properties of bread batter

Flow curves of the bread batter were obtained at 25 °C using an Anton Paar rheometer equipped with RheoCompass software (Anton Paar GmbH, Austria). The rheometer was provided with a plate and cone system with a gap distance of 1 mm, where the batter samples (excluding yeast, sugar, and salt) were placed. The obtained data were fitted to the Herschel-Bulkley equation to determine the model parameters, including p (flow behavior index), b (consistency index), and τ0 (yield point). All measurements were performed in triplicate.

2.5 Bread batter microstructure

In order to investigate the microstructural changes taking place within the bread batter during the fermentation process, microscopic images of the bread batter were captured using a Zeiss Axioskop 2 Plus optical microscope (Zeiss, Oberkochen, Germany) equipped with an automatic photo camera. A small sample of the batter at the initial stage of fermentation was positioned between a microscope slide and coverslip. After 30 min of fermentation at room temperature, the samples were examined under the microscope at 40 × magnification.

2.6 Specific bread volume

The specific bread volume was measured using a modified standard rapeseed displacement method 10–05 [19] with flax seeds as a substitute for rapeseeds. The experimental procedure involved submerging the bread in a container filled with flax seeds of known apparent density (AD: 0.6908 g/ml). The weights of the bread and the displaced seeds were determined during the experiment. The specific bread volume was then calculated using the following equation:

2.7 Bread crumb quality

In order to analyze the bread slices, digital images were captured using a Nikon Coolpix L330 digital camera. A reference scale was included in the images for accurate measurements. The acquired images were then analyzed using ImageJ software (v. 1.49, National Institutes of Health, USA). For each bread formulation, three slices of bread were cut and photographed. During the analysis, the edges of the bread were digitally removed to exclude the crust area. The original RGB images were converted to grayscale (8 bit), and the contrast was adjusted using the threshold command to create a binary scale. Once all the images were processed, an exploratory analysis of the cell size in the crumb was conducted. The average size of the crumb cells was reported in square millimeters per cell (mm2/cell).

2.8 Texture profile analysis

Texture profile analysis (TPA) of gluten-free bread was conducted using an Instron Testing Machine model 3345 (Canton, Massachusetts, United States), equipped with a 50 N load cell. For the analysis, a cylindrical probe with a diameter of 30 mm was used to compress a bread crumb cylinder (diameter: 20 mm, thickness: 15 mm) twice at a speed of 50 mm/min until a deformation of 70% was reached. The texture parameters, including hardness, adhesiveness, cohesiveness, springiness, gumminess, and chewiness, were determined using the software provided by the device. TPA measurements were carried out at 0 and 48 h of storage and the average of at least 10 replicates was reported.

2.9 Statistical analysis

Statistical analyses of single ANOVA and Fisher test (LSD) were performed with a confidence level of 95%, using Statgraphics software Centurion version XVI (Statistical graphics Corporation, USA). The effects of treatment and storage time on mechanical and rheological parameters were analyzed by a multivariate analysis of variance (MANOVA), followed by post hoc Hotelling test with Bonferroni correction, using SPSS software v19 (SPSS Inc., Chicago, USA) and Infostat v2009 (Universidad Nacional de Córdoba, Argentina). The significant level was set up at p < 0.05. In order to show the relationship between mechanical parameters and storage time and treatments, a principal component analysis (PCA) was performed. Prior to multivariate analyses, outliers were identified and removed using the Mahalanobis distance.

3 Results and discussion

3.1 Rheological properties of bread batter

The analysis of batter consistency provides information about the impact of its composition and preparation method on the structure of gluten-free bread. According to Hüttner, Bello [20], low viscosity of the batter positively influences bread quality. Specifically, a low viscosity is associated with several desirable characteristics such as increased bread volume and a well-aerated crumb. This effect can be attributed to the improved expansion of gas cells during the fermentation process. However, excessively low viscosity in the batter can lead to weakened structure and reduced gas retention, negatively impacting bread quality. The ideal batter formulation should possess a relatively low viscosity to facilitate gas cell expansion during fermentation but should also have the ability to form a robust structure that can effectively retain gas during proofing. This balance ensures that the resulting bread achieves the desired structure, texture, and volume [6, 21].

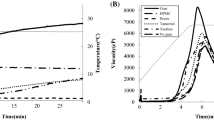

The apparent viscosity of all the samples decreased with the increasing shear rate, indicating that they all displayed shear thinning behavior (Fig. 1). It should be noted that both the experimental design batter samples and the control samples demonstrated asymptotic values of apparent viscosity within the range of 439—1437 mPa.s at a fixed shear rate of 100 s−1. For the controls with xanthan gum and the samples that were hydrated and mixed at mixing time 1, a narrower range of apparent viscosity was observed (Fig. 1c): 392—682 mPa.s at 100 s−1. This suggests a similar level of consistency among all the samples. The highest viscosity values were observed at the lowest shear rate. Longer homogenization times and the addition of gum resulted in higher apparent viscosities, indicating increased resistance to flow. The apparent viscosity values at different shear rates were used to determine the consistency and flow parameters using the Herschel-Bulkley model. The consistency index (b) and yield point (τ0) were found to be higher not only with increased homogenization time but also when rice and flour were used without undergoing a prior hydration step (Table 2). This suggests that the consistency and flow behavior of the batter were influenced by the processing conditions and the hydration status of the rice and flour.

Apparent viscosity of batter samples at 25 °C as function of shear rate. RH: hydrated rice bread, RD: dry rice bread, FH: hydrated flour bread, FD: dry flour bread, RH + G: hydrated rice bread with gum, FH + G: hydrated flour bread with gum, 1 (2–4 min) and 2 (4–6 min): time of homogenization according to Table 1

3.2 Bread volume

Values around 4—5 ml/g are expected for wheat breads, depending on the formulation and the baking method, whereas lower values between 1.3 and 2.4 ml/g are typical in gluten-free bread [22, 23]. The viscoelastic properties of gluten play a crucial role in gas retention during fermentation and baking, contributing to the superior performance of wheat dough compared to gluten-free batters. Unlike gluten-containing doughs, rice batter lacks the necessary consistency, extensibility, and elasticity provided by the protein matrix of gluten. Rice batter lacks the consistency, extensibility, and elasticity associated with the protein matrix of gluten-containing doughs [22]. Consequently, it has limited capacity to retain the gases generated during proofing and early stages of baking, leading to gas leakage. In the absence of proper gas retention, the gases released during fermentation escape through weakly connected particles and channels formed by the expanding gas that pushes the particles apart. This phenomenon contributes to the formation of rigid bread with a reduced volume and a rough crumb texture [24]. However, by the method here proposed, specific volume values of gluten-free and gum-free rice bread ranged from 1.99 to 2.97 ml/g (Fig. 2). These results were similar to those found by Matos and Rosell [25] (1.44–3.03 ml/g) in rice bread with the addition of gums, emulsifiers, enzymes, or dairy products.

Specific bread volume of rice grain and rice flour breads. H: hydrated, D: dry, G: gum, 1 (2–4 min) and 2 (4–6 min): time of homogenization according to Table 1

For formulations without added gum, Fig. 2 shows that breads made from rice grains had higher volume than those made from rice flour, except for D2. This may be related to the fact that rice grain batter showed significantly less starch damage (2.1 ± 0.1%) than rice flour batter (8.71 ± 0.04%), since Yano, Fukui [8] informed a negative linear correlation (R2 = − 0.93) between specific bread volume and starch damage extent.

Regarding the soaking effect, hydrated rice breads (RH1 and RH2) showed specific volume values significantly (p < 0.05) higher than those made with dry rice (RD1 and RD2). Particularly, when comparing RH2 and RD1, both with 4 min of homogenization, the greater volume was obtained in the hydrated one (RH2). These results highlight the benefit of pre-hydration treatment, in agreement with the results obtained by Hamada, Aoki [26] who declared that that soaking and wet-milling yield high-quality rice flour characterized by fine particles and reduced damaged starch content, consequently resulting in greater bread volumes. In recent studies, wet-milling procedure is also used to produce Pickering emulsions for the development of functional foods where the emulsion plays a key role in the product structure [8, 27,28,29].

Moreover, de la Hera, Rosell [17], Cajas Locke, González [30] and Yano, Fukui [8] observed the impact of flour particle size and damaged starch content on the specific volume of rice flour gluten-free breads. They found that using coarser flour and reducing the amount of damaged starch resulted in a significant increase in specific volume. The presence of small flour particles in the batter creates a weak dough structure that struggles to retain the gases released during fermentation. This leads to lower volumes in the final bread product. Moreover, fine flour particles have a larger surface area, requiring more water for hydration and starch granule swelling [17]. This could be the reason why lower specific volume is achieved in rice flour breads in comparison to breads made from rice grains at the same water content and in breads made from dry ingredients. Encina-Zelada, Cadavez [3] and de la Hera, Rosell [17] also found a positive impact of high-water content of the dough on the specific volume of gluten-free breads, which could be explained by the crucial plasticizer effect of water when making gluten-free bread that contributes to the extensional properties of the dough during mixing [17]. Nevertheless, an excessive amount of water could cause overdevelopment of the dough during baking, resulting in large-volume and collapsed loaves with big holes [31].

The use of hydrated rice in the bread-making process resulted in increased volume when the homogenization time was extended. On the other hand, breads made from dry rice showed reduced volume and a collapsed center when subjected to longer homogenization times (Fig. 2). In the case of flour breads, extending the homogenization time did not lead to significant changes in volume. The observed changes in bread volume with different homogenization times can be attributed to the impact on batter consistency. When the homogenization time was increased, the batter became more viscous. Moore, Schober [32] reported a higher consistency of gluten-free batter with high protein content, which resulted in lower bread volumes, and Renzetti and Arendt [33] also found that lower paste viscosities might have reduced the resistance to expansion of brown rice batters during baking, therefore increasing the specific volume. On the contrary, other authors reported that an increase in batter consistency leads to higher bread volume, since higher paste viscosities improve batter development and gas retention, thus increasing loaf volume [34, 35]. Therefore, the relationship between batter viscosity and bread volume depends on several factors: the type and quantity of hydrocolloids added, the amount of water in the formula, and the interactions established between hydrocolloids and batter ingredients, among others [35]. In view of such complexity, further studies are required to understand the effects of formulation and process conditions on final product attributes.

Although the improving effect of gums on bread volume has been reported by several authors [36,37,38], in this case, the addition of xanthan gum was only suitable for breads made from rice flour, since no significant differences were found between rice grain breads H1 and H1 + G. Mezaize, Chevallier [37] also reported no significant differences in bread volume between formulations containing xanthan gum and the gum-free control in breads made from rice flour and corn flour. However, it is essential to evaluate other characteristics of the flour breads in conjunction with the specific volume, since they showed some undesirable characteristics, such as crumbling when cutting.

3.3 Bread and crumb features

Image analysis of crumb features was done based on digital images. Gluten-free bread crust and crumb photos highlight important differences in porosity, slice shape, volume, and bread crust appearance among samples (Fig. 3). All breads presented a cracked surface except for gum-free rice bread obtained from hydrated rice grain. Analyzing the characteristics of the crumb is relevant since pan bread is an aerated product and its mouth feel is known to be strongly influenced by the size and distribution of the gas cells [22, 23]. In the process of mechanical aeration by mixing, air bubbles are incorporated into the gluten-free batter. Further mixing can cause coalescence, which decreases the number of bubbles and increases their size. The opposite effect of numerous smaller bubbles results from bubble breakage through shearing. To produce bread with small and homogeneous pores as well as high volume, it is important to reach the balance in the aeration and prevent gas-loss throughout processing [21]. All the bread samples made with flour showed a collapsed structure, except for the gum-containing sample, which still had a flat and heterogeneous appearance. It can be appreciated that bread samples H2 and D2 showed a more open crumb structure with fewer cells, which were larger in size compared to breads H1 and D1 that, in turn, showed a more regular porosity regardless of whether they were made with rice flour or rice grain. Therefore, with an increase in mixing time, there was an observed increase in cell size (Table 3), which is likely attributable to the higher viscosity of the batter (Fig. 1). However, these characteristics do not fully match the bread volume results, indicating that larger cells do not necessarily create a greater volume. Values of cell area (Table 3) were found in agreement with the alveolar appearance of bread slices (Fig. 3), particularly for RH1 + G (low value of cell area) and RD2, FH2, and FD2 (high values of cell area).

Comparative photos of gluten-free rice bread (left) and rice flour bread (right), hydrated (H) or dry (D), with different homogenization time (1 or 2, according to Table 1) and with or without addition of xanthan gum (+ G)

Figure 4 shows optical microscopic observation of the batter during proofing. Due to the high concentration of solids these systems are opaque, and it is quite difficult to obtain good micrographs. Based on our previous work of Pickering emulsions [19], three samples of hydrated rice flour (8.71% damaged starch) were selected, which facilitated a clear visualization of the batter structure.

Optical microscopic observation of the batter in the fermentation step. FH: hydrated flour bread, FH + G: hydrated flour bread with gum, 1 (2–4 min) and 2 (4–6 min): time of homogenization according to Table 1

Bubble structures of the batter and crumbs of bread slices were consistent with each other. The micrographs suggest that the surfaces of the bubbles were covered by starch granules, which corresponds to the formation of Pickering foam, as Yano, Fukui [8] and González, Santagapita [27] also declare. These authors hypothesized that gluten-free rice bread can develop in the absence of gum due to the stabilizing effect of the Pickering emulsion. In addition, said authors state that starch granules with higher levels of damage tend to absorb more water, leading to the formation of incompletely covered droplets. This phenomenon is less favorable for gluten-free bread production, as it results in breads with reduced volume, as described earlier. Concerning the difference between the presence or absence of the hydration step before bread making, the major appearance difference was seen between RH2 and RD2 (Fig. 3). The most homogeneous crust surfaces in shape and color were obtained for RH1 and RH2. The addition of xanthan gum only had a positive effect on the volume and crumb cell characteristics of the flour bread slices, as it was found in volume results. However, the appearance of the crust was heterogeneous in shape, with large grooves on the surface. The heterogeneity of the surface was also seen in the sample RH1 + G, together with a noticeable dense crumb. The cracks or grooves in the crust were probably caused by further oven-rising after the crust is formed and almost hardened. The outgoing gas from the fermentation bubbles had no place to go so it escaped through the weakest intersections of the crust. This is often a main problem in gluten-free breads because of the weak gas holding ability of batter caused by the abovementioned lack of gluten network [39].

3.4 Texture profile analysis

The hardness, springiness, and cohesiveness results for the TPA analysis of the baked breads and the effect of storage time (48 h) on crumb structure are shown in Fig. 5. Overall, crumb hardness increased with storage time, except in breads containing xanthan gum. As has already been extensively studied [1, 2, 40], this is an indicator that the addition of gum to the formulation delays the aging of the bread and keeps its crumb soft for a longer time by maintaining a steady moisture. However, it should be highlighted that comparisons between the effects of hydrocolloids on hardness values of gluten-free breads found in the literature are quite difficult since there are plenty of different gluten-free flours which vary largely in starch and protein content and other characteristics. Besides, bread characteristics depend on the gum source and the water amount used in the formulation. Staling of gluten-free breads is mainly attributed to the migration of water to crust, the loss of moisture, and the starch retrogradation and recrystallization. The interactions between bread components, even added hydrocolloids, and starch, could intervene the aging rate. Moreover, crumb of starch-based bread, in which there are no gluten-starch interactions and water is bound only by a carbohydrate, hardens much faster than of standard wheat bread containing gluten [6]. The rice-based bread developed in this study was moist and chewy when it was fresh, but it became floury and crumbly after two days of storage at room temperature. This phenomenon was also described by Lu, Donner [39] in potato-based breads and was attributed to lack of a continuous elastic gluten structure surrounding the starch. In instances where such a structure is present, it tends to mask the alterations induced by starch retrogradation [32].

TPA profile of gluten-free rice and rice flour breads at 0 and 48 h post-baking:a crumb hardness,b crumb springiness,c crumb cohesiveness,d MANOVA test: samples labeled with the same letter were not significantly different. H hydrated, D dry, G gum, 1 (2–4 min) and 2 (4–6 min): time of homogenization according to Table 1

Rice formulations RH1, RH2, and RD2 showed notably softest crumb than the same formulations made with flour. In the case of D1 and H1 + G, there were no significant differences between rice and flour breads. When breads were made with rice, the increase in the mixing time (from mixing time 1 to 2) improved aging, achieving a less hard crumb after 48 h than the same breads made under the mixing time 1 condition. Regarding flour breads, the results were the opposite. The best results, in terms of hardness, were obtained for the RH1, RH2, and RD2 loaves, because the softest crumb was obtained immediately after being prepared (2.8, 1.5, and 2.3 N, respectively) and the least hardness was found after storage (7.2, 3.3, and 6.5 N, respectively). It is important to consider that, although RD2 showed similar TPA results to RH1 and RH2, it showed low volume (Fig. 2) and not a good crumb appearance (Fig. 3).

Chewiness followed the same behavior as hardness, which is awaited since this parameter is dependent on hardness, cohesiveness, and springiness. Regarding springiness, the values were similar or slightly lower than the control in the case of rice bread, while they were up to 24% higher than the control for flour breads. However, with the exception of H2, no significant differences were found between values of rice and flour breads both before and after storage. After 48 h of storage, the springiness of the breads with added gum (controls) remained stable, in comparison to the control for rice bread that showed a 17% higher value. Crumb cohesiveness decreased with storage time, except in gum-containing breads (Fig. 5c). Decrease of cohesiveness during storage is related to greater crumbling, which negatively influences consumers’ acceptance of bread [39].

TPA results suggest that the pre-hydrated rice grain may be used in the production of gluten-free breads with a softer crumb structure, a desirable characteristic since gluten-free breads are often characterized by a hard texture [41].

Figure 6 shows the principal component analysis (PCA) bi-plot of mechanical parameters of bread samples. The first two principal components (PC1 and PC2) accounted for about 99% of the total variance: PC1 and PC2 explained 71.3% and 27.8%, respectively. Results from PCA showed that PC1 was mainly related to hardness and showed remarkable differences between samples at 0 and 48 h of storage regardless of the specific bread composition and bread-making procedure, in concordance with the significant differences of the MANOVA test (Fig. 5), except in samples with added gum. Therefore, PC1 reflects bread staling. No classification of mixing times was possible, but there was a tendency of rice breads to contribute less to PC1 than flour samples; in fact, there were significant differences between results of rice and flour breads for 0 and 48 h.

Principal component analysis (PCA) bi-plot of mechanical parameters of breads with different composition and bread-making procedures that were stored for 0 and 48 h at room temperature. RH: hydrated rice bread, RD: dry rice bread, FH: hydrated flour bread, FD: dry flour bread, RH + G: hydrated rice bread with gum, FH + G: hydrated flour bread with gum, 1 and 2: time of homogenization according to Table 1

4 Conclusions

The factors investigated, including the type of rice ingredient, pre-hydration, and mixing times, had varying effects on the flow behavior and microstructure of the batter, as well as the volume, alveolar structure, and texture attributes of the gluten-free and gum-free bread. The optimal formulation included pre-hydrated rice grains with the addition of 62.5% of water. This formulation resulted in a low viscosity emulsion that was well-suited for gas cell expansion during fermentation and could form a high-quality crumb. The batter microstructure observed by optical microscopy during fermentation revealed the bubble surfaces covered by starch granules present in the Pickering emulsion. The bread made from pre-hydrated rice grains (RH1 and RH2) showed a volume comparable or higher to that of the gum control: RH1 + G (Fig. 2). However, based on bread appearance, the gum-free rice bread (RH1) stood out from the gum control (RH1 + G) with its smooth and uniform crust that remained crack-free. In terms of volume and cell area, the bread made from pre-hydrated rice grains resembled the gum control. Although the hardness, elasticity, and cohesiveness values of the recently baked bread were comparable to those of the gum control, hardening and lower cohesiveness were observed after 48 h of storage at room temperature. Hence, additional studies will be required to investigate potential reformulations or modifications to the bread-making process that can help mitigate the quality deterioration observed during product storage.

Data availability

The data that support the findings of this study are available on request from the corresponding author.

References

Awulachew MT. A Review of non-gluten components in gluten-free bread characteristics, dough baking quality and viscoelastic qualities. Int J Food Sci Biotechnol. 2021;6(4):115–20.

Demirkesen I, Campanella OH, Sumnu G, Sahin S, Hamaker BR. A study on staling characteristics of gluten-free breads prepared with chestnut and rice flours. Food Bioprocess Technol. 2014;7(3):806–20.

Encina-Zelada CR, Cadavez V, Monteiro F, Teixeira JA, Gonzales-Barron U. Combined effect of xanthan gum and water content on physicochemical and textural properties of gluten-free batter and bread. Food Res Int. 2018;111:544–55.

Lazaridou A, Duta D, Papageorgiou M, Belc N, Biliaderis CG. Effects of hydrocolloids on dough rheology and bread quality parameters in gluten-free formulations. J Food Eng. 2007;79(3):1033–47.

Salehi F. Improvement of gluten-free bread and cake properties using natural hydrocolloids: a review. Food Sci Nutr. 2019;7(11):3391–402.

Ziobro R, Juszczak L, Witczak M, Korus J. Non-gluten proteins as structure forming agents in gluten free bread. J Food Sci Technol. 2016;53(1):571–80.

Huerta KDM, Alves JDS, Silva AFCd, Kubota EH, Rosa CSD. Sensory response and physical characteristics of gluten-free and gum-free bread with chia flour. Food Sci Technol. 2016; 36: 15–8.

Yano H, Fukui A, Kajiwara K, Kobayashi I, Yoza K-I, Satake A, et al. Development of gluten-free rice bread: Pickering stabilization as a possible batter-swelling mechanism. LWT Food Sci Technol. 2017;79:632–9.

Haghighat-Kharazi S, Reza Kasaai M, Milani JM, Khajeh K. Antistaling properties of encapsulated maltogenic amylase in gluten-free bread. Food Sci Nutr. 2020;8(11):5888–97.

Filipčev B, Pojić M, Šimurina O, Mišan A, Mandić A. Psyllium as an improver in gluten-free breads: effect on volume, crumb texture, moisture binding and staling kinetics. LWT. 2021;151: 112156.

Fratelli C, Santos FG, Muniz DG, Habu S, Braga ARC, Capriles VD. Psyllium improves the quality and shelf life of gluten-free bread. Foods. 2021;10(5):954.

Roman L, Reguilon MP, Martinez MM, Gomez M. The effects of starch cross-linking, stabilization and pre-gelatinization at reducing gluten-free bread staling. LWT. 2020;132: 109908.

Silva HA, Paiva EG, Lisboa HM, Duarte E, Cavalcanti-Mata M, Gusmão T, et al. Role of chitosan and transglutaminase on the elaboration of gluten-free bread. J Food Sci Technol. 2020;57:1877–86.

Witczak M, Ziobro R, Juszczak L, Korus J. Potato flakes (Solanum tuberosum L.) as a factor modifying the rheological properties of dough and limiting the staling of gluten-free bread. Food Bioprocess Technol. 2021;14:65–77.

Horstmann SW, Axel C, Arendt EK. Water absorption as a prediction tool for the application of hydrocolloids in potato starch-based bread. Food Hydrocolloids. 2018;81:129–38.

Sahin AW, Wiertz J, Arendt EK. Evaluation of a new method to determine the water addition level in gluten-free bread systems. J Cereal Sci. 2020;93: 102971.

de la Hera E, Rosell CM, Gomez M. Effect of water content and flour particle size on gluten-free bread quality and digestibility. Food Chem. 2014;151:526–31.

Hong YE, Kweon M. Optimization of the formula and processing factors for gluten-free rice bread with tamarind gum. Foods. 2020;9(2):145.

AACC, American Association of Cereal Chemists. Approved methods of the AACC. 9° ed. St Paul: Association of Cereal Chemists; 2000.

Hüttner EK, Bello FD, Arendt EK. Rheological properties and bread making performance of commercial wholegrain oat flours. J Cereal Sci. 2010;52(1):65–71.

Elgeti D, Peng L, Jekle M, Becker T. Foam stabilization during processing of starch-based dough systems. Innov Food Sci Emerg Technol. 2017;39:267–74.

Hager A-S, Wolter A, Czerny M, Bez J, Zannini E, Arendt EK, et al. Investigation of product quality, sensory profile and ultrastructure of breads made from a range of commercial gluten-free flours compared to their wheat counterparts. Eur Food Res Technol. 2012;235(2):333–44.

Marti A, Marengo M, Bonomi F, Casiraghi MC, Franzetti L, Pagani MA, et al. Molecular features of fermented teff flour relate to its suitability for the production of enriched gluten-free bread. LWT. 2017;78:296–302.

Onyango C, Mutungi C, Unbehend G, Lindhauer MG. Modification of gluten-free sorghum batter and bread using maize, potato, cassava or rice starch. LWT Food Sci Technol. 2011;44(3):681–6.

Matos ME, Rosell CM. Quality indicators of rice-based gluten-free bread-like products: relationships between dough rheology and quality characteristics. Food Bioprocess Technol. 2013;6(9):2331–41.

Hamada S, Aoki N, Suzuki Y. Effects of water soaking on bread-making quality of brown rice flour. Food Sci Technol Res. 2012;18(1):25–30.

González LC, Santagapita PR, Tolaba MP. In-situ production of modified starch and pickering emulsions by planetary ball milling. Starch-Stärke. 2023;75:2300021.

Rawal K, Annamalai PK, Bhandari B, Prakash S. Oat flour as a novel stabiliser for designing plant-based pickering emulsion. J Food Eng. 2023;340: 111300.

Aoki N, Kataoka T, Nishiba Y. Crucial role of amylose in the rising of gluten-and additive-free rice bread. J Cereal Sci. 2020;92: 102905.

Cajas Locke JE, González LC, Loubes MA, Tolaba MP. Optimization of rice bread formulation by mixture design and relationship of bread quality to flour and dough attributes. LWT. 2019;113:108299.

Han HM, Cho JH, Kang HW, Koh BK. Rice varieties in relation to rice bread quality. J Sci Food Agric. 2012;92(7):1462–7.

Moore MM, Schober TJ, Dockery P, Arendt EK. Textural comparisons of gluten-free and wheat-based doughs, batters, and breads. Cereal Chem. 2004;81(5):567–75.

Renzetti S, Arendt EK. Effect of protease treatment on the baking quality of brown rice bread: from textural and rheological properties to biochemistry and microstructure. J Cereal Sci. 2009;50(1):22–8.

Marco C, Rosell CM. Breadmaking performance of protein enriched, gluten-free breads. Eur Food Res Technol. 2008;227(4):1205–13.

Sciarini LS, Ribotta PD, León AE, Pérez GT. Effect of hydrocolloids on gluten-free batter properties and bread quality. Int J Food Sci Technol. 2010;45(11):2306–12.

Demirkesen I, Mert B, Sumnu G, Sahin S. Rheological properties of gluten-free bread formulations. J Food Eng. 2010;96(2):295–303.

Mezaize S, Chevallier S, Le Bail A, De Lamballerie M. Optimization of gluten-free formulations for French-style breads. J Food Sci. 2009;74(3):E140–6.

Mohammadi M, Azizi M-H, Neyestani TR, Hosseini H, Mortazavian AM. Development of gluten-free bread using guar gum and transglutaminase. J Ind Eng Chem. 2015;21:1398–402.

Lu ZH, Donner E, Liu Q. Development and characterisation of gluten-free potato bread. Int J Food Sci Technol. 2021;56(6):3085–98.

Sciarini LS, Pérez GT, de Lamballerie M, León AE, Ribotta PD. Partial-baking process on gluten-free bread: impact of hydrocolloid addition. Food Bioprocess Technol. 2012;5(5):1724–32.

Alvarez-Jubete L, Arendt EK, Gallagher E. Nutritive value of pseudocereals and their increasing use as functional gluten-free ingredients. Trends Food Sci Technol. 2010;21(2):106–13.

Funding

This study was funded by Agencia Nacional de Promoción Científica y Tecnológica (ANPCyT) (PICT 2018–01619), Consejo Nacional de Investigaciones Científicas y Técnicas (CONICET), and Universidad de Buenos Aires (UBACYT 20020220100189BA).

Author information

Authors and Affiliations

Contributions

Luciana C. González: Conceptualization, Methodology, Formal analysis, Writing—Original Draft; Eunice V. Contigiani: Methodology, Formal analysis; Marcela P. Tolaba: Supervision, Writing—Review & Editing, Funding acquisition.

Corresponding author

Ethics declarations

Competing interests

Nothing declared.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

González, L.C., Contigiani, E.V. & Tolaba, M.P. Development of gluten-free and gum-free rice bread: influence of ingredients, hydration and processing time on bread quality. Discov Food 4, 61 (2024). https://doi.org/10.1007/s44187-024-00112-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s44187-024-00112-9