Abstract

The sugarcane (Saccharum officinarum L.) juice, a beverage with fascinating track record of health promoting potential, loaded with phenolics, flavonoids, the bioactives, is capable of high antioxidant activities. The mint is a reliable herbal plant, with loads of phytochemicals and hundreds of food applications. However, sugarcane juice added with mint is normally consumed without any processing and preservation. Therefore, it is important to employ green processing technologies on sugarcane-mint juice blend, in order to process and preserve this nutritional juice with optimum retention of bioactives. In the current study sugarcane-mint blend juice was developed to study the synergistic effect of sonication (20 kHz, 70% amplitude, 5, 10 and 15 min) and microwave (90 °C, 400 W, 120 s) on pH, titratable acidity, total soluble solids (TSS), total phenolics (TPC), total flavonoids (TFC) and antioxidant activity of developed beverage, at 7 days interval, during 21 days of storage period. Increment in sonication time and advancement in storage days, both resulted in an increase in pH, and decrease in titratable acidity and TSS of blend juice. Sonication for 15 min along with microwave exhibited significant (p ≤ 0.05) results in terms of rise in TPC, TFC and antioxidant ability of blend juice, as compared to 10 and 5 min, sonication. Whereas, untreated juice samples exhibited significantly (p ≤ 0.05) less contents of TPC, TFC and antioxidant capacity, which were further significantly (p ≤ 0.05) decreased during 21 days of storage. Our results highlighted the significance of synergism of sonication and microwave in improvement of physicochemical and phytochemical quality of sugarcane-mint blend juice.

Highlights

-

Sugarcane-mint blend juice, and exotic drink loaded with phytochemicals.

-

Synergism of sonication and microwave, innovative technology for juices processing.

-

Sonication for 15 min, 20 kHz, retained maximum polyphenols during 21 days storage.

-

Juice treated with sonication and microwave was superior in quality.

-

Higher antioxidant activities of treated blend juices during storage.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The phytochemistry of fruits and vegetables provides the foundation for blending their parts and produced value-added products, which are high in antioxidants and are responsible for preventing pathogen attack [1]. The sugarcane (Saccharum officinarum) juice, a nutrient-dense beverage, contains a high concentration of polyphenols, antioxidants and other useful components. Its robust nutritional profile and alkaline composition have recently acquired appeal among consumers. Juice, on the other hand, tends to deteriorate enzymatically and ferment microbially due to its elevated polyphenolics and sugars, that impart it a black hue [2]. The nutritional value and shelf life of sugarcane juice have recently been increased utilising modern techniques. The use of such processing techniques is preferable to present practices and essential for the creation of premium, fresh juices free from chemicals [3]. Due to its low cost and high yield, sugarcane, a perennial grass of the Poaceae family, is planted all over the world in more than 90 different nations. Due to its lower cost and greater glucose and fructose contents, it is the crop that provides the most energy [4]. Presence of phenolics acids, flavonoids and other antioxidants contribute towards medicinal potential of sugarcane beverage, a pharma drink with high acceptability [5]. The sugarcane juice has been known to be taken for cure of a diversity of medical ailments, with potential of promoting body abilities to tackle abnormal conditions [6].

Mint (Menth piperita) has excellent nutritional profile, due to the presence of phenolics, and treatment of mint leaves with sonication and microwave proved useful tools in retaining maximum bioactives during processing [7]. Naemeh et al. [8] studied the development of probiotic beverages based on whey and yogurt, that also included mint for its antioxidant qualities. Ingredients derived from mint leaves are frequently used in the culinary industry as food additives and natural flavours. The traditional methods for producing mint extracts are steam distillation or solvent extraction, both of which are time and energy intensive processes. Significant results for phytochemicals were obtained from the extraction of mint leaves using microwave and ultrasonic assistance at room temperature [9]. Ultrasound assisted microwave treated juices retain good quality and acceptability [10]. Sonication, a non-thermal food processing technology, has grabbed the interest of many because it does not alter the sensory characteristics of the food, but changes its nutritional value in positive direction [11]. Ultrasound technology is an alternate of thermal processing, with low energy utilization. Ultrasound waves are, sound waves with limit above the detection level of humans (above 16 kHz), and these varying frequencies create energy for food processing. This innovative and green processing technology improves and ensures product quality, while at the same time reducing processing time and cost. When used with microwave technology, it has numerous advantages, as food quality has been significantly influenced by elements such as texture, colour, antioxidants and polyphenolic properties [11]. Therefore, a huge potential of application of microwaves and sonication on juices, has attracted the food processers.

Fruit juices are normally served to the customers under unhygienic conditions of fresh juice stalls, leading towards microbial food contamination. That is why fruit processing, including frozen, canned, sweets, drinks, fresh juices and dehydration, is critical [12]. Ultrasound treatment has been shown to increase the polyphenols and bioactives, related to the raised antioxidant activity of fresh juices, while at the same time minimizing the quality loss [13]. Sonication of melon drink increased its microbiological cleanliness, bioactive profiles and appearance of the drink [14]. Sonication treatment was found to be effective in terms of increasing numerous quality aspects as well as microbiological decontamination [15, 16]. Ultrasound and microwave processing offer a lot of potential in food applications as green processing methods [17]. Thermosonication with the unique parameter combination, might increase the potential for commercialization of juices [18, 19].

According to Song and Kang [20], microwave method has been applied to prepare, heat, defrost and process different foods. Microwave processing technique is based on mechanical energy produced by dielectric warming produced from waves of microwave ranging from MHz to GHz. It generates a superior product with less heating time [21]. According to Patel et al. [22], microwave applications were effective in retaining the most phenolic components and killing the microorganisms in traditional sugarcane juice, however that study was limited to only sugarcane juice. The nutritional composition of food is important since it has a large impact on acceptance from consumer as well as product conformance to the quality standards. Combining ultrasonic treatments and heat sterilisation allows the production of high-nutritional-value fruit and vegetable juices. According to Golmohamadi et al. [23], the use of ultrasound technology in the food business holds a lot of promise. Non thermal techniques as an alternate of pasteurization, could be utilized at small and industrial scales, for improvement of fruit juices quality, safety and nutritional contents [23,24,25]. It has been demonstrated that combining ultrasound and microwaves provided beneficial effect to sugarcane juice with elevated antioxidant activities [26].

Sugarcane, one of the world’s most significant commercial crops, is a basic raw material of sugar, alcohol and sugarcane juice. The juice is an affordable, sweet beverage that is a potential source of bioactive compounds, especially phenolic acids and flavonoids [27]. Earlier investigations by Sangma et al. [28] provided optimized beverage blend of sugarcane and mint. Because of microbial contamination and enzymatic reactions, sugarcane juice degrades quickly. Synthetic preservatives are typically used to preserve its quality while being stored. Their use has been connected to potential health risks, though. Natural preservatives derived from the mint plant and the use of green processing techniques can be used as secure alternatives in this regard [29]. For the same purpose, Brochier et al. [30] used non thermal and electric heating to process sugarcane juice and observed positive indications. Although several studies have been conducted on processing the juices and beverages, however synergism of microwave and sonication have limited examples in the literature, the reason behind setting this experimental design in a new fashion.

Heat is commonly employed to destroy spoilage bacteria and food-degrading enzymes, but it can also produce adverse changes in the food’s sensory and nutritional properties. Because sonication preserves the nutritional and sensory quality, while increasing heating efficiency and speed, it could be proved as an appropriate method for sugarcane juice processing. However, this product is mostly consumed fresh, without application of any processing and preservation techniques. So, it is necessary to process this nutritious blend juice through application of sonication and microwave, which could help in improving the shelf life, maintaining physicochemical quality and bioactive contents. Therefore, keeping the preceding information in mind, the goals of the present investigations were to apply the combination of microwave at constant time and temperature, along with sonication at three variable times, with 20 kHz frequency, on sugarcane-mint juice blend, in order to study the variations on the physicochemical and antioxidant quality of the juice, during a 21-day trial period. Different treatments of blend juice were studied for the changes in pH, titratable acidity, total soluble solids, total phenolic contents, total flavonoid contents and total antioxidant capacity, to find out the optimum combination of microwave and sonication for maximum retention of bioactive contents with minimum physicochemical variations.

2 Materials and methods

2.1 Chemicals and plant materials for juice

The chemicals and reagents used for these trials were acquired from Merck chemicals, Germany, and same trade chemicals were used for each trial. To make mint juice, mint leaves from indoor plants of Menth piperita (variety peppermint), were manually plucked and mashed in a mixer. Fresh sugarcane samples (variety Tritan 44) were also harvested from the fields directly, from the Punjab native market in Pakistan. High Technologies Laboratories of Punjab were visited for analysis of juices. Collection of the plants used in this study complied with local or national guidelines.

2.2 Preparatory operations of raw materials

Sugarcane, that were healthy and uniform in size, free of illness, were separated from any connected green plant components and other objects, washed, and utilised to extract juice. Healthy and full green mature mint leaves were also cleaned, washed with distilled water and crushed for juice extraction.

2.3 Extraction of juices for blend

After cleaning and rinsing, mint leaves were extracted using a laboratory blender (P105-Panasonic Japan). Sugarcane samples were crushed with the help of a helical presser and juice was obtained, that was kept under refrigerated conditions in airtight plastic bottles. Then the juice was recorded for TSS using digital refractometer (HT-555, Biobase China), and after adding mint juice (2 mL mint juice in 98 mL sugarcane juice) the 15 Brix was selected as the norm for the control juice blend. No chemical additives or preservatives were used in the juice samples. Filtration process of juices was carried out through a sieve with 0.8 mm holes to remove any extraneous contaminants. Following that, the juices were subjected to different combinations of microwave and sonication, while being stored in an aseptic environment. The processed juices were kept in the refrigerator at 4 °C and used for various analyses on occasion. The approach provided by Khandpur and Gogate [25] was utilized for the entirety of the juice preparation and storage methods, with the necessary adjustments. Treatment strategy for treating blend juice before analysis was: T0 (control), T1 (sonication for 5 min and microwave for 120 s), T2 (sonication for 10 min and microwave for 120 s) and T3 (sonication for 15 min and microwave for 120 s). Parameters of sonication (20 kHz frequency and 70% amplitude) and microwave (temperature 90 °C, power 400 W and time 120 s) were remained constant during all processing.

2.4 Thermosonication of sugarcane-mint blend juice

Each treatment juice was processed by ultrasonography. A 0.5 inches probe of 3 mm diameter equipped ultrasonic processor (Hitachi, Japan) was used to sonicate the juice material. The probe was immersed into 20 mm of 100 mL juice sample and 5 s cut off duration was fixed. As previous studies using similar conditions produced promising results for phytochemical retention, this study used sonication of blended juice samples using 70% amplitude for three different time periods i.e., 5, 10 and 15 min at a frequency of 20 kHz with a pulse length of 5 s on and 5 s off. Sonication came right after juice extraction, by following the protocols of earlier research work by Sasikumar et al. [10].

2.5 Microwaves application of sugarcane-mint blend juice

As previously reported by Zia et al. [26], blend juice samples, right after sonication, were microwaved for 120 s at 90 °C and 400 W, using commercial laboratory microwave (OR-303, Orient, Pakistan). 100 mL juice sample was subjected to microwave processing by placing the juice in a glass flask in microwave oven. After that, the processed juices were shifted into airtight plastic bottles. To avoid heat-related bottle shrinkage, the 200 mL plastic bottles were first filled with ice-cold water before adding the beverage. The standard was made up of fresh samples that had not been subjected to any treatments. All the samples were maintained in a refrigerator.

2.6 Storage of juices

Untreated, microwaved and sonicated at different time periods, juice samples packed in airtight plastic bottles, were stored at 4 °C for 21 days right after processing. Juice samples were collected on a regular basis to examine the shelf life of processed juice.

2.7 Physicochemical analysis

Physicochemical analyses including pH, titratable acidity and TSS were performed to study the synergistic effect of thermosonication and microwave at sugarcane-mint blend juice, as these parameters have significant impact on the juice quality.

2.7.1 pH analysis

pH was determined using a digital pH meter (AD 1040 Benchtop meter, Adwa, Hungary) according to method 981.12 of Association of Official Agricultural Chemists (AOAC) [31]. Briefly explaining, the sample to be analyzed was directly dipped into the electrode of the pH meter, and after three analyses, the result on the meter, which showed the pH of the sample, which was recorded.

2.7.2 Titratable acidity

The titratable acidity was calculated using method 942.15 of AOAC [31]. In summary, 500 mL of distilled water were used to dissolve 2 g of NaOH in order to create a 0.1 N NaOH solution. Similar to this, 100 mL of ethanol were used to dissolve 1 g of phenolphthalein to create a phenolphthalein indicator. Next, a sample of 10 mL of each treatment’s blend juice was obtained, and two to three drops of indicator were added. The sample was titrated up to a pink hue using a 0.1 N NaOH solution. Titratable acidity was calculated using the following formula, with the acidity factor of 0.064 being employed for the acidity determination.

2.7.3 Total soluble solids (TSS)

TSS was determined in the form of Brix using a hand refractometer (RHB-32ATC Atago, Japan) under method 932.12 of AOAC [31]. By introducing a few drops of each blend juice treatment to the refractometer’s prism, which measures 0–32°B, Brix was achieved. The refractometer was held perpendicular to a light source in order to view the internal scale. Where the light and dark regions of the scale converge, the Brix reading was easily visible.

2.8 Total phenolic contents (TPC)

As Hussain et al. [32] previously used a modified Folin-Ciocalteu reagent test to determine the TPC, the same was used to determine the TPC of sugarcane-mint juice samples. Briefly explaining, each juice sample was diluted with 0.5 mL 0.5 N Folin-Ciocalteu reagent at ambient temperature, and then NaCO3 (75 g/L) was added to make the medium alkaline due to the oxidation–reduction reaction between the phenolic compounds and the Folin reagent. These mixtures were then kept at 23 °C for a time period of 2 h before measuring absorbance. The absorbance at 760 nm was measured with a spectrophotometer (U 2900 Hitachi, Japan). Total phenolic contents were calculated as mg gallic acid equivalents (GAE) per 100 mL juice using gallic acid as a reference. Three replicates of absorption values were recorded, and mean was calculated.

2.9 Total flavonoid contents (TFC)

The TFC of all the treatment juices were analysed using aluminium chloride assay, as earlier the modifications were provided by Wang et al. [13]. One mL of each juice and catechin as standard solution were put into 15 mL conical tubes, each of which had 2 mL of double distilled water, after that 0.15 mL from 5% NaNO2 was mixed to it. Five mints later, we added 0.15 mL of 10% AlCl3 in it and mixture was allowed to stand for another 5 min. Then after 1 min, 1 mL 1 N NaOH was added and with the help of double distilled water total volume was made up to 10 mL. Then homogenous mixing of solution was done and kept for 15 min before measuring the absorbance. The absorbance was measured at 695 nm, using a spectrophotometer (HT-900, Panasonic, Japan). Total flavonoid concentration was reported as mg of catechin equivalent (CE)/100 mL juice with consistency, using catechin as a reference. Samples were analyzed in triplicates and mean values were calculated.

2.10 Total antioxidant capacity

With some adjustments, the method utilized to assess the sugarcane-mint juice mixture’s overall antioxidant capability was adapted from Rodriguez-Rico et al. [14] instructions. An amount of 0.01 g of 2,2-diphenyl-1-picrylhydrazyl (DPPH) was taken after weighing and transferred into a 25-mL volumetric flask having solvent (80:20 methanol/water (v/v). The flask was filled with solvent, up to the marking level. A calibration curve for ascorbic acid was also developed. An amount of 100 μL from each type of juice was collected in microplates, then an amount of 2 mL solvent and 250 μL DPPH reagent were added. These microplates were shaken and kept in darkness at ambient temperature for a time period of 20 min. Reduction in DPPH absorbance by spectrophotometer (Hitachi U-2900 Japan) at 520 nm was witnessed every 5 min intervals unless this absorbance was stabilized after a time period of 30 min. The findings were given as mg of ascorbic acid equivalent (AAE) per 100 mL of juice, with ascorbic acid used as the standard calibration curves. Each analysis was performed in triplicate.

2.11 Statistical analysis

Each analysis was performed in triplicate to obtain the mean values. Minitab 16 software was used to perform the statistical analysis of the collected data, by following the protocols of Steel and Torrie [33], using the one-way ANOVA test to demonstrate significant differences in mean values at a significance threshold of p ≤ 0.05. Further, Tukey’s was used to find the significant difference among values.

3 Results and discussion

3.1 pH analysis of sugarcane-mint blend juice

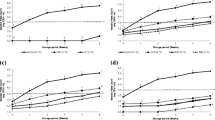

From the value presented in Table 1, it was clear that pH of all treatments was found in increasing mode, both with increasing storage duration and sonication time, during 21 days trial. T0 presented the lowest values, whereas T3 presented the highest values for pH of sugarcane-mint blend juice.

Sonication has been proved useful method for inactivation of bacterial strains without any significant alteration in the physicochemical parameters of the juice [34]. Functionalities of the juices are increased as a result of high pressure and low frequency processing generated by sonication, a well-known non thermal technique [3]. Bag et al. [29] provided a similar pH of sugarcane juice added with mint extract during the optimisation of sugarcane beverage with addition of mint extract. Adulvitayakorn et al. [35] reported a minor reduction in pH of sugarcane juice, which was treated with thermosonication and microwave. Variation in temperature of the juice was linked with variation in pH. According to Khandpur and Gogate [25] pH is one of the important parameters defining the quality and safety of the juices. Sonication’s antibacterial activity is enhanced in low pH or acidic conditions, possibly due to generation of OH radicals. Sonication has been found to impose more influence on juice having low pH.

Further investigations have also provided similar findings as ultrasonic processing of banana juice provided non-significant variation in pH and acidity, (at frequency 40 kHz, power 50 W, time 0–30 min) [36], strawberry juice (sonication treatments; 0, 15 and 30 min at 20 °C, 25 kHz frequency) [37], and carrot-grape juice (sonication treatments; 20 kHz frequency, 70% amplitude level (525 W power). In current study extended ultrasonic treatment (15 min) resulted in a small increase in pH, possibly due to an increase in generation of organic acids, due to the significant cavitation impact of prolonged sonication along with microwave. According to Brochier et al. [30], electricity has significant non-thermal impacts on the enzymatic inactivation kinetics of peroxidase (POD) and the degradation of phenolic compounds in sugarcane juice, just as provided by sonication in current study.

3.2 Analysis of titratable acidity of sugarcane-mint blend juice

Table 2 showed that the titratable acidity was found in decreasing manner within the treatments and during 21 days of storage period. T0 had the highest acidity at the start of the trial, followed by T1, and T3 had the lowest acidity. Titratable acidity of treatments reduced with storage time, according to the influence of storage length. Table 2 reveals that the greatest mean value was observed on the starting day and the lowest titratable acidity was observed at 21st day. The acidity of the untreated juice mixture, on the other hand, rose following storage.

Bag et al. [29] formulated sugarcane beverage by adding mint extracts at different concentrations and found that adding mint resulted decrease in acidity of sugarcane juice, due to increase in pH, while values were much similar to present findings. Sonication had non-significant influence on grapefruit juice, according to Aadil et al. [38], even after treatments lasting 60 and 90 min. Instead, these variables remained constant. They indicated that more research would be beneficial in analysing the effects of sonication on juice nutritional quality and optimising sonication conditions.

Mukhtar et al. [3], during processing of sugarcane juice provided non-significant variation in titratable acidity of the juice, just reporting in line results with the current ones. Adulvitayakorn et al. [35] discovered a considerable increase in titratable acidity (40.62%) in sugarcane juice treated at 700 W, which they linked to temperature loss. While, Adulvitayakorn et al. [35] assessed the acidity of juice from sugarcane samples that had been traditionally heat-treated, microwaved and thermosonicated. Thermosonication had non-significant effect on sugarcane juices, however microwave heat treatment increased titratable acidity significantly. Understanding how both pH and acidity fluctuate might help you recognise the consequences of the actions on the appearance and quality of the juice. Thai and Doherty [39] speculate that the decline in titratable acidity generated by sonication for extended periods of time in this investigation, could be due to the decomposition of aconitic acid, liberating other organic acids in juice. These findings were found to be closely related to ours, because the acidity and pH have a reverse relationship, and increment in pH was found responsible for decline in titratable acidity of the juices [40], as a result of synergism of sonication and microwave. Yikmis [41] concluded from their research that ultrasound treatment has no influence on the titratable acidity and pH of processed juices. One more justification of this happening, found reported in literature, was acidic hydrolysis occurring of polysaccharides, which might have used the acids to convert non-reducing sugars to reducing sugars, resulting in a significant decrease in titratable acidity [42].

3.3 Analysis of total soluble solids (Brix) of sugarcane-mint blend juice

As has been presented in Table 3, sonication at different time periods, while keeping microwave parameters same, there was a significant variation on TSS of the treated juice samples. T3 had the highest Brix value, followed by T2, and T0 had the lowest Brix value, according to statistical findings (Table 3). Total soluble solids in sugarcane-mint juice decreased during a 21-day period, with untreated samples losing the most and T3 losing the least.

Thermosonicated drinks exhibited a favourable physicochemical quality and a prolonged shelf life of 4 weeks at 4 °C, with no quality alterations [18]. Mukhtar et al. [3] showed a small rise in total sugars, reducing sugars, and TSS after processing sugarcane juice with ultrasonication, applying similar parameters as in current study. They went on to say that the increase was due to ultrasounds’ improved extraction ability, which could have resulted in the conversion of disaccharides to monosaccharides. Microwave heating enhanced the shelf life of sugarcane juice by up to 56 days and caused a large increase in TSS, possibly due to evaporation of moisture as a result of high power used. Sonication at high temperatures was when compared with untreated and heat-treated juice trials, resulted in a significant increment in TSS of juice. On the other hand, microwave heating caused more significant effect on TSS of sugarcane juice [35]. These findings are significant to the current study results since microwave settings remained unchanged while changing the sonication duration for three different times, which resulted no change effect on TSS. The addition of mint extracts to sugarcane beverage resulted in a minor decrease in TSS, which was not retained.

Combination of sonication and microwave technology for processing of the juices had presented no change on TSS of the juices, whereas, when these treatments were applied individually and compared with control samples changes were significant [26]. By conducting other similar studies, Bora et al. [36] reported similar results, where sonication period had no effect on the TSS of banana juice.

TSS was reduced during storage due to carbohydrate fermentation, resulting in production of water, carbon dioxide and ethyl alcohol, the compounds responsible for low TSS of liquids. Use of sonication at 70% amplitude was witnessed by Bhat and Sharma [37] as they treated juice of bottle gourd for 20 min and reported maximal TSS, validating the current protocols for optimum results. Yeast and lactic acid bacteria, present in both treated and untreated control juice samples convert carbohydrates into respective alcohols and acids, resultantly reduction in TSS of the juices. Synergism of sonication and microwave resulted small reduction in TSS, as compared to the untreated samples, possibly due to the increased microbiological reactions occurred, which were inhibited by microwave significantly [26].

3.4 Analysis of total phenolic contents of sugarcane-mint blend juice

The thermo-sonication and microwave treatments had significantly changed the TPC of treated juice samples, as presented in Table 4. T0 presented the lowest, whereas T3 presented the highest values of TPC. Storage studies revealed that TPC of untreated juices were significantly reduced during 21 days of storage, whereas synergism of sonication and microwave retained maximum TPC, with samples treated with 15 min of ultrasound retaining the most TPC, as indicated in Table 4.

Green processing approaches for juices such as ultrasound and microwave have been developed as a learning factor in the arena of alternative processing and preservation of juices for optimum phytochemical retention. Synergism of these two novel processing methods have been found successful for retention of maximum phenolics of treated juices [43]. Phenolic chemicals are recognized to play a significant part in the production of colour and flavour, as well as antioxidant and antibacterial capabilities in fruit juices. They are secondary metabolites found in plants [16]. Addition of mint to sugarcane juice contributes towards increment of phenolics and antioxidants of blends, was found in previous investigations of Sangma et al. [28]. Values of TPC of sugarcane beverage added with mint extracts were lower than current values, in the study of Bag et al. [29], possibly due to untreated juice and lower levels of mint addition.

Investigations of Demirok and Yikmis [44], during application of sonication and microwave on tangerine juice, provided results, which were found in line with current findings. In another similar technology application investigation, Patel et al. [22] found the well increment in phenolic contents of jaggery cooked with microwaves at 700 W for 60 s during storage days, supporting microwaves beneficial effects on fruit items. According to research by Brochier et al. [30], the highest phenolics and flavonoids degradation throughout ohmic heating of sugarcane juice were about 23 and 39%, respectively, which was possibly a disadvantage of conventional processing. Current experiments were found useful in overcoming the possible degradation of phytochemicals, triggered by heat treatments. Golmohamadi et al. [23] previously evaluated the effect of ultrasonic frequency on the antioxidant capacity, phenolic and anthocyanin contents of red raspberry puree. Ultrasonic therapy, 20 kHz ultrasonic therapy for 10 min was shown to be the optimum parameters in extraction and retention of bioactive components from raspberry. Similarly, by using different amplitudes, the results at higher frequencies can be comparable.

When compared to the control group, Wang et al. [13] discovered that high intensity ultrasound treated kiwifruit juice exhibited a 108.65% increase in phenolic compounds. Similar to our findings, the total phenolic content of ultrasound-preserved vegetable and fruit juices increased immediately after ultrasound processing, whereas storage of treated and untreated juice showed gradual reduction in phenolics [25]. De Medeiros et al. [45] showed that phenolic compounds deteriorated more slowly when sugarcane juice was stored at refrigerated temperature after ultrasonic therapy.

The current study’s findings were consistent with previous research by Adulvitayakorn et al. [35], who discovered that increasing the microwave temperature of sugarcane juice from 30 to 80 °C significantly reduced TPC. TPC in T1 and T2 may have grown due to the low temperature microwave’s breakdown of different macromolecules, releasing the bounded phenolic contents, as well as the cavitation influence of sonication. According to Aadil et al. [38], hydroxyl groups generated by sonication might have been added with the aromatic rings of the phenolic compounds, increasing the number of total phenolics.

Sugarcane juice has been found to be high in phenolics and flavonoids, two antioxidant molecules known to scavenge free radicals. In their study of sugarcane juice samples processed in various ways, Adulvitayakorn et al. [35] reported that thermosonicated juice samples significantly increased in TPC at lower temperatures. Ultrasonic treatments at 15 min, 40 kHz and 240 W power significantly increased the TPC of sugarcane juice samples, according to Mukhtar et al. [3]. This increase in TPC could be related to phenolic release from unfiltered juice cell wall particles. To summarise, utilising ultrasonic treatment to boost the nutritional worth of sugarcane juice is successful.

3.5 Total flavonoids contents of sugarcane-mint blend juice

Table 5 delves into the sugarcane-mint blend juice samples treated with synergism of sonication and microwave, while comparing with control. The overall flavonoid concentration in the combination juice different treatments varied significantly between treatments and storage days. At the outset of the trial, T3 had the highest flavonoid content, followed by T2, and T0 had the lowest flavonoid level. The flavonoid content declined considerably over a 21-day storage period, with maximum decrease in untreated and minimum decrease in 15 min sonication along with microwave treatment juice samples.

It has been discovered that the retention of bioactive components in treated juices is strongly correlated with the simultaneous optimisation of different ultrasonic power intensities, processing temperatures, and processing times [46]. Similar reports about TFC of tangerine juices treated with microwave and ultrasound by Demirok and Yikmis [44], were provided earlier. Another study by Patel et al. [22] found that microwaves at 700 W for 60 s improved the flavonoids of sugarcane based traditional product “jaggery”. Abid et al. [47] studied how sonication affects apple juice in a relevant study, and results were in line with current ones. Sonication treatments improved bioactive components of strawberry juice, as previously was described by Bhat and Goh [48], and was found to be highly connected to current findings.

According to Wang et al. [13], ultrasound waves of high intensity for 16 min duration, at 400 W power and 25 kHz frequency raised flavonoids of kiwifruit juice by 105.56% as compared to an untreated sample. Mukhtar et al. [3] discovered that ultrasonic treatments at slightly different parameters were also resulted in a significant increase in flavonoids in sugarcane juices. Khandpur and Gogate [25] discovered that juice processed by ultrasound retained the majority of phytochemicals, when comparison was made with juices processed by pasteurization. In a study conducted by De Medeiros et al. [45], inactivation of peroxidase enzyme as a result of ultrasonication caused the maximum retention of TFC of sugarcane juice stored at refrigerated temperature even for 5 weeks.

Sugarcane juice has been discovered to be an excellent therapy of the body, due to high flavonoids, the antioxidants responsible for body defensive role against cancer and malignant cells. Alkaline environments help the body maintain electrolyte equilibrium. Human bodies benefit from its anti-allergic, hepatoprotective, anti-inflammatory, and cardioprotective properties [3].

3.6 Total antioxidant capacity of sugarcane-mint blend juice

Table 6 showed how microwave and thermosonic treatment altered the overall antioxidant activity of the sugarcane-mint juice blend. When compared to the untreated samples, T3 retained the maximum degree of antioxidant activity even after 21 days of storage, while T0 had the lowest antioxidant activity, which was also considerably lowered during storage. Table 6 further showed that during the synergy of microwaves and ultrasounds, as the length of sonication was increased from 5 to 15 min, the antioxidant activity of the blend juice increased significantly.

Dietary antioxidants have received increased attention due to their link to health benefits against a variety of oxidative damage-related illnesses. The development of new thermal and nonthermal food processing processes has made it possible to obtain healthier and safer food items. To achieve these goals, it has been discovered that non-thermal processing methods such as pulsed electric field, high pressure processing, and sonication, as well as thermal processing methods such as ohmic, microwave and infrared heating, are suitable [49]. The use of sonication as a non-thermal processing technology was discovered to be an excellent strategy in keeping maximum antioxidant components in natural fruits and their applications [50]. The investigation of green processing technologies (microwave and ultrasound) has gained pace in the juice processing business. The impacts of the integrated technologies are manifested chemically (free radicals) and mechanically (cavitation and shock waves). Using ultrasound and microwaves combined to treat juices yields superior results because juices have stronger antioxidant capacities and retain more bioactive compounds [43].

Demirok and Yikmis [44] used microwave and ultrasonic techniques to prepare and preserve tangerine juice samples and found similar antioxidant activity results. A comparable study found that the antioxidant capacity of untreated, pasteurised and high intensity pulsed electric filed processed juices decreased during storage, correlating with the current work’s findings of nutritional potential decrement of mix juices after storage.

According to earlier research on strawberry juice, sonication for longer time periods resulted liberation of more bioactives from the different molecules, which boosted the antioxidant capacity of the juice [48], and increasing the sonication time in the current study produced similar results. According to Ali et al. [51], high-intensity sonication treatments greatly enhanced the spinach juice’s antioxidant activity and phenolic and anthocyanin bioavailability. According to study findings, the rise in antioxidants has given sonication technology excellent potential for eradicating free radicals. Dai et al. [9] discovered that sonicated and microwave-treated mint extracts showed stronger antioxidant activity than other traditional mint extracts due to significant changes in the extraction of menthone, menthofuran and menthol from peppermint leaves.

Because ultrasonic induces the liberation of phytochemicals from cells and tissues matrixes, the reason behind the increases of antioxidant activity, when used. Inactivation of several enzymes such as polyphenol oxidases, also contribute towards lowering enzymatic browning [52]. Some recent studies have showed a beneficial relationship among the polyphenol’s quantity, quality and antioxidant strength of the sonicated juices [25]. Ultrasonics enhances the extraction of antioxidant compounds including ascorbic acids, phenolic acids and other organic acids from the treated juices, due to the mechanical effects cavitations and bubble implosions [15, 38, 47].

Adulvitayakorn et al. [35] examined the overall antioxidant capacity (% inhibition) of processed sugarcane drink samples. Antioxidant activity of untreated samples was lower as compared to the treated samples, which was increased in the microwaved samples, whereas, sonicated samples exhibited a more significant increase in the antioxidant activity. The increased antioxidant capacity of sugarcane juice samples could be related to an increase in antioxidant components, specifically phenolics and flavonoids, as well as a decrease in vitamin C loss after thermosonication. Zia et al. [26] discovered that the synergism of both treatments outperformed solo ultrasonics or microwaves in keeping sugarcane juice colour features, while raising its antioxidant agents. Further, effect of microwave alone, on the antioxidant activity of juices was discovered by the investigations of Malik et al. [53], as they reported increasing trend of antioxidant activity of microwaved juice samples.

4 Conclusion

Present study provided scientific knowledge about the synergism of thermosonication and microwave as a novel method for processing and preserving juices blends, that can offer improved nutritional values, with health promoting potential. Treatment with 15 min of sonication and 120 s of microwave provided best results in terms of TPC, TFC and total antioxidant capacity of the sugarcane-mint blend juice, with slight changes in pH, acidity and TSS. Significantly high (p ≤ 0.05) total phenolic contents (298.30 ± 3.10 mg GAE/100 mL), total flavonoid contents (205.72 ± 2.40 mg CE/100 mL) and total antioxidant activity (240.10 ± 2.10 mg AAE/100 mL) were found in the juice sample that were applied 15 min sonication along with microwave heating for 120 s at 90 °C. Storage analysis of the treated juice blends revealed that even after 21 days of storage, treated samples retained maximum phenolics and flavonoids and also exhibited maximum antioxidant activity, as compared to the untreated juice samples, as they were found lower in these bioactives during storage. Sonication for 15 min boosted the physical and chemical qualities of the sugarcane-mint juice, while also extending their shelf life without significantly reducing their nutritional value. This synergistic application of two techniques resulted in the highest retention of TPC, TFC and antioxidant capability during storage. Therefore, use of these techniques could be promoted as alternate of conventional thermal processing for processing of fruits and vegetable juices. However, future challenges in terms of high cost, availability of equipment and training of processors, are required to be tackled effectively in order to provide safe, nutritional and health promoting juices to the consumers.

5 Recommendations

Green processing technologies have been proved the best and reliable alternatives of the conventional and old processing techniques used for juices. Synergism of these novel processing technologies by setting different parameters can be tested in further studies of a variety of beverages to investigate the impact of these methods on juice quality, while comparing with the thermally processed and untreated juices. Variations in microbiological and other food safety parameters could be considered in future studies, with clinical trials of the treated products. This will provide great knowledge to the scientific community, along with benefit to humanity.

6 Practical applications

Mint extracts are expected to give sugarcane juice exceptional anti-microbial and anti-browning stability since they include a variety of bioactive components and are linked to several medicinal characteristics. Sugarcane juice preserved with natural plant-based additives and the use of green processing technology would be a healthy offering, particularly for consumers who prefer minimally processed products with a fresh taste. The results of microwave and sonication synergy would allow for the optimisation of process settings to retain and improve blend juice quality at both fresh and storage analysis.

Data availability

Data relevant to this study can be provided upon request.

References

Hussain A, Kausar T, Sehar S, Sarwar A, Quddoos MY, Aslam J, Liaqat A, Siddique T, An QU, Kauser S, Rehman A, Nisar R. A review on biochemical constituents of pumpkin and their role as pharma foods; a key strategy to improve health in post COVID 19 period. Food Prod Process Nutr. 2023;5(1):22. https://doi.org/10.1186/s43014-023-00138-z.

Panigrahi C, Shaikh AEY, Bag BB, Mishra HN, De S. A technological review on processing of sugarcane juice: spoilage, preservation, storage, and packaging aspects. J Food Process Eng. 2021. https://doi.org/10.1111/jfpe.13706.

Mukhtar K, Nabi BG, Arshad RN, Roobab U, Yaseen B, Ranjha M, Aadil RM, Ibrahim SA. Potential impact of ultrasound, pulsed electric field, high-pressure processing and microfludization against thermal treatments preservation regarding sugarcane juice (Saccharum officinarum). Ultrason Sonochem. 2022;90: 106194. https://doi.org/10.1016/j.ultsonch.2022.106194.

Yadav RL, Solomon S. Potential of developing sugarcane by-product based industries in India. Sugar Tech. 2006;8:104–11.

Payet B, Shum Cheong Sing A, Smadja J. Comparison of the concentrations of phenolic constituents in cane sugar manufacturing products with their antioxidant activities. J Agric Food Chem. 2006;54(19):7270–6. https://doi.org/10.1021/jf060808o.

Akber M, Seraj S, Islam F, Ferdausi D, Ahmed R, Nasrin D, Nahar N, Ahsan S, Jamal F, Rahmatullah M. A survey of medicinal plants used by the traditional medicinal practitioners of Khulna City, Bangladesh. Am Eurasian J Sustain Agric. 2011;5:177–95.

Safaiee P, Taghipour A, Vahdatkhoram F, Movagharnejad K. Extraction of phenolic compounds from Mentha aquatica: the effects of sonication time, temperature and drying method. Chem Pap. 2019;73:3067–73.

Naemeh K, Ali MS, Elham M, Akram A. Production of the whey protein-based probiotic beverages incorporated with Bifidobacterium bifidum, Lactobacillus acidophilus, and peppermint essence nanoliposomes. J Food Meas Charact. 2023. https://doi.org/10.1007/s11694-022-01770-y.

Dai J, Orsat V, Raghavan GV, Yaylayan V. Investigation of various factors for the extraction of peppermint (Mentha piperita L.) leaves. J Food Eng. 2010;96(4):540–3.

Sasikumar R, Vivek K, Deka S. Sensory evaluation of ultrasound assisted microwave treated fruit (Haematocarpus validus) juice through fuzzy logic approach. Int Food Res J. 2019;26(4):1229–36.

Salehi F. Physico-chemical properties of fruit and vegetable juices as affected by pulsed electric field: a review. Int J Food Prop. 2020;23(1):1036–50.

Leon S, Priya VV, Somasundaram J. Assessment of microbial load in fruit juices. HIV Nursing. 2023;23(3):97–104.

Wang J, Vanga SK, Raghavan V. High-intensity ultrasound processing of kiwifruit juice: effects on the ascorbic acid, total phenolics, flavonoids and antioxidant capacity. Lwt. 2019;107:299–307.

Rodríguez-Rico D, MdlÁ S-E, Meza-Velázquez JA, Martínez-García JJ, Quezada-Rivera JJ, Umaña MM, Minjares-Fuentes R. High-intensity ultrasound processing enhances the bioactive compounds, antioxidant capacity and microbiological quality of melon (Cucumis melo) juice. Foods. 2022;11(17):2648.

Bhat R, Kamaruddin NSBC, Min-Tze L, Karim A. Sonication improves kasturi lime (Citrus microcarpa) juice quality. Ultrason Sonochem. 2011;18(6):1295–300.

Rawson A, Tiwari B, Patras A, Brunton N, Brennan C, Cullen P, O’donnell C. Effect of thermosonication on bioactive compounds in watermelon juice. Food Res Int. 2011;44(5):1168–73.

Taha A, Mehany T, Pandiselvam R, Anusha Siddiqui S, Mir NA, Malik MA, Sujayasree O, Alamuru KC, Khanashyam AC, Casanova F. Sonoprocessing: mechanisms and recent applications of power ultrasound in food. Crit Rev Food Sci Nutr. 2022. https://doi.org/10.1080/10408398.2022.2161464.

Sasikumar R, Jaiswal AK. Effect of thermosonication on physicochemical and anti-nutritional properties of blood fruit beverage. J Food Process Preserv. 2022;46(12): e17268.

Singh SS, Sasikumar R, Sami R. Consumer preference study on combined ultrasound and sodium hypochlorite treated freshcut kiwifruits coated with chitosan using the fuzzy logic approach: sensory study of chitosan coated fresh-cut kiwi fruits. J Microbiol Biotechnol Food Sci. 2021;11(1):e4054–e4054.

Song W-J, Kang D-H. Influence of water activity on inactivation of Escherichia coli O157: H7, Salmonella typhimurium and Listeria monocytogenes in peanut butter by microwave heating. Food Microbiol. 2016;60:104–11.

Shaheen MS, El-Massry KF, El-Ghorab AH, Anjum FM. Microwave applications in thermal food processing. In: Cao W, editor. The development and application of microwave heating. Rijeka: Intech; 2012. p. 3–16.

Patel AM, Dhar R, Chakraborty S. Pulsed light, microwave, and infrared treatments of jaggery: comparing the microbial decontamination and other quality attributes. Food Control. 2023;149: 109695.

Golmohamadi A, Möller G, Powers J, Nindo C. Effect of ultrasound frequency on antioxidant activity, total phenolic and anthocyanin content of red raspberry puree. Ultrason Sonochem. 2013;20(5):1316–23.

Odriozola-Serrano I, Soliva-Fortuny R, Martín-Belloso O. Changes of health-related compounds throughout cold storage of tomato juice stabilized by thermal or high intensity pulsed electric field treatments. Innov Food Sci Emerg Technol. 2008;9(3):272–9.

Khandpur P, Gogate PR. Effect of novel ultrasound based processing on the nutrition quality of different fruit and vegetable juices. Ultrason Sonochem. 2015;27:125–36.

Zia S, Khan MR, Zeng XA, Sehrish SMA, Aadil RM. Combined effect of microwave and ultrasonication treatments on the quality and stability of sugarcane juice during cold storage. Int J Food Sci Technol. 2019;54(8):2563–9.

Brochier B, Mercali GD, Marczak LDF. Effect of ohmic heating parameters on peroxidase inactivation, phenolic compounds degradation and color changes of sugarcane juice. Food Bioprod Process. 2018;111:62–71.

Sangma C, Kumar V, Gat Y, Kaushal M, Suri S, Panghal A. Optimization of preparation process for a blended beverage developed from chayote, sugarcane, and mint and coriander extract. Int J Veg Sci. 2018;24(5):432–44.

Bag BB, Panigrahi C, Gupta S, Mishra HN. Efficacy of plant-based natural preservatives in extending shelf life of sugarcane juice: formulation optimization by MOGA and correlation study by principal component analysis. Appl Food Res. 2022;2(2): 100164.

Brochier B, Mercali GD, Marczak LDF. Influence of moderate electric field on inactivation kinetics of peroxidase and polyphenol oxidase and on phenolic compounds of sugarcane juice treated by ohmic heating. LWT. 2016;74:396–403.

AOAC. The official methods of analysis of AOAC International. 20th ed. Gaithersburg: AOAC; 2016.

Hussain A, Kausar T, Din A, Murtaza MA, Jamil MA, Noreen S, Rehman HU, Shabbir H, Ramzan MA. Determination of total phenolic, flavonoid, carotenoid, and mineral contents in peel, flesh, and seeds of pumpkin (Cucurbita maxima). J Food Process Preserv. 2021;45(6): e15542.

Steel RGD, Torrie JH. Principles and procedures of statistics: a biometrical approach. New York: McGraw-Hill; 1986.

Sasikumar R, Jaiswal AK. Influence of pediocin-assisted thermosonication treatment on phytonutrients, microbial, and sensory qualities of blood fruit juice. J Food Process Preserv. 2022;46(11): e17105.

Adulvitayakorn S, Azhari SH, Hasan H. The effects of conventional thermal, microwave heating, and thermosonication treatments on the quality of sugarcane juice. J Food Process Preserv. 2020;44(2): e14322.

Bora SJ, Handique J, Sit N. Effect of ultrasound and enzymatic pre-treatment on yield and properties of banana juice. Ultrason Sonochem. 2017;37:445–51.

Bhat S, Sharma HK. Combined effect of blanching and sonication on quality parameters of bottle gourd (Lagenaria siceraria) juice. Ultrason Sonochem. 2016;33:182–9.

Aadil RM, Zeng X-A, Han Z, Sun D-W. Effects of ultrasound treatments on quality of grapefruit juice. Food Chem. 2013;141(3):3201–6.

Thai C, Doherty W. The composition of sugarcane juices derived from burnt cane and whole green cane crop. In: Bruce RC, editor. Proceedings of the 33rd Annual Conference of the Australian Society of Sugar Cane Technologists 2011. Cairns: Australian Society of Sugar Cane Technologists/Curran Associates Inc; 2011. p. 368–76.

Sasikumar R, Pradhan D, Deka SC. Effects of thermosonication process on inactivation of Escherichia coli and Saccharomyces cerevisiae and its survival kinetics modeling in khoonphal (Haematocarpus validus) juice to extend its shelf life. J Food Process Preserv. 2019;43(11): e14220.

Yikmiş S. Investigation of the effects of non-thermal, combined and thermal treatments on the physicochemical parameters of pomegranate (Punica granatum L.) juice. Food Sci Technol Res. 2019;25(3):341–50.

Bhardwaj RL, Pandey S. Juice blends—a way of utilization of under-utilized fruits, vegetables, and spices: a review. Crit Rev Food Sci Nutr. 2011;51(6):563–70.

Farmani B, Mohammadkhani S, Andabjadid FH. Synergistic effects of sonication and microwave in juice processing. In: Nayik GA, Ranjha M, Zeng XA, Irfan S, Zahra SM, editors. Ultrasound and microwave for food processing. Amsterdam: Elsevier; 2023. p. 157–87.

Demirok NT, Yıkmış S. Combined effect of ultrasound and microwave power in tangerine juice processing: bioactive compounds, amino acids, minerals, and pathogens. Processes. 2022;10(10):2100.

de Medeiros JK, Sarkis JR, Jaeschke DP, Mercali GD. Thermosonication for peroxidase inactivation in sugarcane juice. Lwt. 2021;140: 110730.

Sasikumar R, Chutia H, Deka S. Thermosonication assisted extraction of blood fruit (Haematocarpus validus) juice and process optimization through response surface methodology. J Microbiol Biotechnol Food Sci. 2019;9(2):228.

Abid M, Jabbar S, Wu T, Hashim MM, Hu B, Saeeduddin M, Zeng X. Qualitative assessment of sonicated apple juice during storage. J Food Process Preserv. 2015;39(6):1299–308.

Bhat R, Goh KM. Sonication treatment convalesce the overall quality of hand-pressed strawberry juice. Food Chem. 2017;215:470–6.

Ozkan G, Guldiken B, Capanoglu E. Effect of novel food processing technologies on beverage antioxidants. Process Sustain Beverages. 2019;2:413–49.

Sasikumar R, Mangang IB, Vivek K, Jaiswal AK. Effect of ultrasound-assisted thin bed drying for retaining the quality of red bell pepper and compare the predictive ability of the mathematical model with artificial neural network. J Food Process Eng. 2023;46(12): e14468.

Ali M, Manzoor MF, Goksen G, Aadil RM, Zeng X-A, Iqbal MW, Lorenzo JM. High-intensity ultrasonication impact on the chlorothalonil fungicide and its reduction pathway in spinach juice. Ultrason Sonochem. 2023;94: 106303.

Siddique F, Hussain A, Noreen S, Arif MR, Yaqub S, Batool SA, Iqbal A, Fatima H, Gorsi FI, Iqbal A. Impact of different processing techniques (chemical, heating and sonication) on physicochemical and microbial characterization of kinnow-whey based beverage. Discover Food. 2023;3(1):18.

Malik F, Nadeem M, Ainee A, Kanwal R, Sultan M, Iqbal A, Mahmoud SF, Alshehry GA, Al-Jumayi HA, Algarni EHA. Quality evaluation of lemon cordial stored at different times with microwave heating (pasteurization). Sustainability. 2022;14(4):1953.

Acknowledgements

The goal of this scientific project was to see how synergism of ultrasonic waves and microwave treatments affected the quality of sugarcane-mint blend juice. Blend juice samples were tested qualitatively and chemically at High performance Centers of the Scientific Laboratories of Pakistan.

Funding

No Funds in any form were availed for this research work.

Author information

Authors and Affiliations

Contributions

AH, conceptualization; AAM and SAK, data curation; TS, formal analysis; KK, funding acquisition, investigation; SAB, methodology, project administration; S, resources; SY, software; AAM, supervision; SAK, validation; MRA, visualization; AH and SAK, roles/writing—original draft; AH, SAK and AS, writing—review and editing; AA and SK, conceptualization, visualization, writing—review and editing.

Corresponding authors

Ethics declarations

Ethics approval and consent to participate

Collection of the plants used in this study, complied with local or national guidelines. Guidelines for safety of plants were strictly followed during cultivation of plants. No permissions/license was required for cultivation of plants, as the plants used in current study are commonly harvested in the country.

Competing interests

The authors have declared no competing interests for this article.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Hussain, A., Batool, S.A., Sidrah et al. Synergism of sonication and microwave on phytochemical and physicochemical capacity of sugarcane-mint blend juice. Discov Food 4, 18 (2024). https://doi.org/10.1007/s44187-024-00086-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s44187-024-00086-8