Abstract

In this review, we focus on the fabrication of electrodes, using printing techniques. Generally speaking, electrodes are comprised of a metal conductor with a metal lead (sometimes the same material) for the conduction of electrical current. Different inorganic and organic materials including metal, polymers, carbon, as well as their composites thereof, have been used for electrodes on different substrates. While material-dependent characteristics, including conductivity, optical transparency, corrosion resistance and biocompatibility, determine the choice of material, printing, as the manufacturing method, offers precise control over the geometry and scale of electrodes for selective and sensitive performance. Both 2D- and 3D-printed electrodes have been widely used as sensors for electrochemical applications as well as quantification of biological compounds, establishing contact with biological surfaces and systems, finding application in medical diagnosis, therapy and treatment of various conditions. Costa et al. (Energy Storage Mater 28:216–234, 2020), Mensing et al. (Sustain Mater Technol 25:e00190, 2020) depict the difference between the 2D and 3D printing techniques which can be used for fabrication of 2D and 3D electrodes. The 3D structure of the electrode provides advantages over the 2d electrodes in terms of its catalytic properties through enhancement in its mass transfer process, adsorption efficiency and active exposure sites (Mensing et al. in Sustain Mater Technol 25:e00190, 2020).

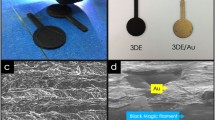

Similar content being viewed by others

Explore related subjects

Find the latest articles, discoveries, and news in related topics.Avoid common mistakes on your manuscript.

Introduction

Electrical conduction is the net movement of electrically charged particles, such as electrons or ions (with either a surplus or deficit of electrons on an atom or molecule), within a transmission medium in response to an electrical field. This movement results in the flow of electric current, the mechanism of which depends on the material used. Metals with empty positions within their valence bands, are good conductors of electricity and typically follow Ohms law. These electrodes are designed to make contact with non-metallic components of the circuit, such as an electrolyte in the case of electrochemical cell, semiconductors in active circuit components or biological cells and tissues in the case of medical devices. The word electrode was coined by William Whewell from two Greek words, electron and hodos, on the request from Michael Faraday [3]. In this review, we focus on electrodes that interface with biological surfaces, particularly those that find application in medical diagnostics and treatments, and their fabrication through the manufacturing route of printing. Medical electrodes have been used for electrical stimulation and electrical recording of the tissue surface. Electrically stimulating electrodes elicit biological response by injecting charge carriers into the tissue surface and polarizing the membrane of electrically excitable tissues through electric potential distribution. Examples within the central nervous system (CNS) that employ electrically stimulating electrodes include brain stimulation for treating Parkinson’s disease [4], psychiatric disorders [5], epilepsy [6], spinal cord stimulation for treating chronic pain [7], cochlea-based nerve cell stimulation for restoration of auditory function [8] and the stimulation of the retina to restore vision [9]. Within the peripheral nervous system (PNS), examples include vagus nerve stimulation for epilepsy [10], occipital nerve stimulation for occipital neuralgia [11] and stimulation of motor neurons to restore lost motor function [12]. Recording electrodes, on the other hand, are used for sensing applications, particularly as wearable devices, for health-monitoring purposes and have been incorporated into clothing and other accessories [13]. The application of these wearable devices for the monitoring of neural signals such as in the collection of electroencephalograms (EEG) [14], electrocardiograms (ECoG) [15] and electromyograms (EMG) [16] has also been demonstrated.

Academic research today is largely focused more on improving the existing electrodes structure and potential through the use of novel materials and fabrication strategies. Depending on the application and materials involved, drop casting [17], spin coating [18] and electrochemical deposition [19] have been some of the simplest ways of depositing materials for fabricating electrodes. Fabrication techniques such as sputter coating [20, 21], thermal evaporation [22] and chemical vapor deposition processes [23] are also used for uniformity control in electrodes. For more controlled feature sizes and geometry, lithographic methods (electron beam [24], nanoimprint [24] and x-ray [25]) and laser ablation [26] have also been used. Electrodes can be manufactured by printing through the synthesis and formulation of conducting inks. Printing has already been established for fabricating various active and passive electronic components including thin-film transistors (TFT)-based display devices, memory devices and sensors [27]. Printing is preferred for the ease of rapid prototyping and scalability [28]. The printing process generally involves deposition of functional inks possessing conducting, semi-conducting and dielectric properties on flexible polymer-based substrates for the fabrication of electronic components. Structures with minimum feature sizes in the micron scale can be made using the process of printing. Depending on application and printing method used, both organic and inorganic material may be chosen as the ink precursor material. In this review, we study the fundamental properties of medical electrodes and explore the printing methods for potential fabrication while reviewing the ink formulation for making electrodes.

Applications

Electrodes may be placed on the skin surface or be surgically implanted within the body in order to measure biological signals (Fig. 1) [29]. On the surface, epidermal electrodes are generally non-invasive and used for wearable applications. They include sensors for simple recording and have found application in health monitoring. These electrodes can be seen in electrical devices including smartphones, smartwatches and smartbands, being configured to measure simple physiological signals (including motion, respiration rate, pressure) and neural signals (such as in EEG, ECoG, EMG). Smart textiles, including sensor laden clothing and footwear and sensor-disguised tattoos, are also available [30,31,32,33]. Some specific sensors can also measure biochemical analytes from bodily fluids (e.g., glucose from sweat and blood) sending signals to mobile devices. These signals, obtained from the electrodes, can also be used to provide remote feedback to medical practitioners, through protocols such as bluetooth, Wi-Fi, 3G, 4G and/or 5G, taking advantage of the internet of things (IoT). Electrodes for wearable health monitoring have been summarized and reviewed recently by Ha et al. [34]. Implantable electrodes on the other hand are invasive, requiring surgical procedures. These implantable electrodes are typically comparatively small in size and designed to be more sensitive, selective and biocompatible. Deep brain stimulators, cochlear implants and cardiac pacemakers, are examples of implants with electrodes for target organ stimulation. Implants and implant electrodes in general are usually expected to last for the lifetime of the patient and are used for treating chronic illnesses. As such the materials chosen should be rather robust, but at the same time, patient compatible for long-term use preventing the need for re-surgery and complications.

Physiological signals (left) and electronic devices (right) for the purpose of health monitoring and treatment of health conditions. The electrodes within these devices can be fabricated using the printing technology through the use of inorganic and organic precursor materials formulated into printing inks

Gao et al. reported a flexible printed circuit board (FPCB) with an integrated sweat sensor array, which selectively and quantitatively analyzes multiple metabolites (glucose and lactate), electrolytes (sodium and potassium ions) skin temperature and wireless data communication module [35]. Mannoor et al. reported a tooth sensor for breath and saliva analysis for monitoring of pathogenic bacteria where the electrode consists of graphene nano-sensors, printed onto silk substrates, and incorporated with a resonant coil for wireless connection [36]. Meanwhile Kim et al. reported a wearable tattoo consisting of multifunctional sensors for temperature, strain and electrophysiological measurements [37]. Similar to wearables, recording electrodes for neural prostheses measure the electric potential generated by the flow of ions across the membrane of an electrically excitable cell (Fig. 1). Branner et al. reported a Utah electrode array, used for stimulation and recording of sciatic nerve in the peripheral region in cats. The array consists of 25 1-mm-long electrodes fabricated on a 2 × 2-mm base with electrodes spaced at 400 μm. The electrode array demonstrated recording and stimulation stability for up to 60 h [38] Similarly, Lu et al. reported a minimally invasive porous graphene-based 64-electrode array fabricated on a polyimide substrate using laser pyrolysis and additional supporting metal interconnects. In vivo cortical stimulation and sensing were conducted on anesthetized rats using the fabricated electrode array. Electrodes show high endurance with no sign of delamination and degradation, even after 1 million biphasic stimulation cycles [39].

Electrode Conduction Mechanics

By controlling the direction of flow of electric current, electrodes can be designed to deliver and receive electrical charge to stimulate biological surfaces and/or monitor their condition [40]. Depending on the mode of operation, they may be classified as stimulating or recording types. Electrodes used for electrical stimulation of neural tissues may be categorized either as microelectrodes or as macroelectrodes depending on their size. Microelectrodes have geometric surface area (GSA), i.e., length times breadth for a rectangular electrode, less than 10,000 μm2, whereas macroelectrodes are larger than 100,000 μm2. Electrodes in between 10,000 and 100,000 μm2 are called mesoelectrodes or intermediate-sized electrodes [41]. In case of stimulation electrodes, larger area of stimulating electrodes has advantages of high current delivery through the larger surface area. However, a higher signal amplitude is also required with large area electrodes to activate neurons at farther distances. For most cases, smaller area stimulating electrodes are preferred over larger area size for localized modulation and clinical merit [42, 43]. For recording electrodes, electrodes with larger area can record low-frequency signals for the neuronal area covered. The smaller recording electrodes detect local field potentials (LPFs) and other high-frequency signals. Microelectrodes have greater selectively and spatial resolution, with the ability to stimulate small and specific volumes of tissue [44]. Table 1 shows the different types of electrodes used as neural interfaces [42].

The schematic diagram for an electrode-tissue interface showing different charge injection mechanisms is shown in Fig. 2a. As the charge is transferred from electrode to the tissue, it changes its form from an electron to an ion. Charge injection mechanism in stimulating electrodes can be capacitive (non-Faradic), Faradic or both with generation of adsorbable species. In capacitive charging, Coulombic forces redistribute equal and opposite charges on the tissue surface, whereas in Faradaic charging electrons are transferred between electrode and tissue via redox reactions [44]. Capacitive charging reactions can be electrostatic or electrolytic involving charging and discharging of electrode–electrolyte layer, while Faradaic charging is based on electrochemical redox reactions between the surrounding media and the electrode. Metals and metal-like compounds, such as titanium nitride, tantalum and platinum, inject charge through the capacitive route [45]. These materials are chemically inert during the reaction process with no chemical species being consumed even with high bias voltage (> 4 V) and are generally regarded as safe in biological systems. Capacitive electrodes also have naturally large reversible charge storage capacities (RCSC), which prevents induction of irreversible reaction at the electrode-tissue interface during the charge transfer. There are however limitations to charge injection and therefore limitations with respect to electrode miniaturization [46]. Rough and porous materials, including those with high dielectric coatings, can improve the charge injection capacity—as this increased roughness and porosity in the material increases the electrochemical surface area (ESA) with respect to the GSA [45].

a Schematic diagram of an electrode-tissue interface showing different charge injection mechanism for stimulating electrodes. Reprinted from [51] Copyright (2015), with permission from Elsevier. b Biphasic symmetric current waveform applied to the stimulating electrodes. Reprinted from [45], Copyright 2008 Annual Review if Biomedical Engineering. c Amplitude vs frequency distribution of bioelectric signals that can be recorded through applying non-invasive on-surface electrodes. Reprinted from [52] Copyright (2019), with permission from Elsevier

Most neural applications employ a series of biphasic current pulses for electrical stimulation. Figure 2b shows a symmetric biphasic current waveform where the flow of electrons takes place from electrode to the tissue during the cathodal phase and in the opposite direction for the anodal phase. The charge delivered (q) at the cathode is given by the product of constant current magnitude (ic) and corresponding pulse width (tc), i.e., q = ic × tc, with analogous behavior at the anode, i.e., q = ia × ta. The system maintains a net zero charge balance with an equal number of charges in the cathodal and anodal phases. Biphasic current waveforms are charge balanced and the electrode potential maintained in a range to prevent any irreversible reactions from occurring, such as electrolysis of water, gas formation, pH changes, corrosion and electrode dissolution that might alter the electrode performance during the charge injection (either directly or by unaccounted alterations to the local environment). In 2008 penetrating microelectrodes with GSA ≤ 2000 μm2, where charge/phase thresholds are in the range of ~ 1 nC∙ph−1, were used by McCreery for safe excitation in feline cochlea and cerebral cortex. Feline cochlear nuclei have been shown to have same cell types as that of the human cochlear nuclei. This study was conducted to determine the feasibility of multichannel auditory prostheses and safe excitation levels within human ventral cortex through experimentation on young adult cats [45, 47]. Stimulating electrodes are generally designed to have low impedance and supply low voltage applied, corresponding to the charge applied for stimulation, as high current input to the target tissue is known to induce tissue damage. An in vitro charge injection capacity of 0.9 mC∙cm−2, with a 0.5 ms pulse-width, has been reported for an array of 4000 μm2 porous TiN electrodes. TiN is interesting material with a columnar structure, where the electrodes fabricated with this material have a resulting high effective area. As such, more electrical charge can be transferred from metal to tissue for stimulation with a small electrode size [48]. Materials including iridium oxide (IrO2), Pt and PtIr alloy conduct through the aforementioned Faradaic route. Activated IrO2 film (AIROF) has reportedly shown intrinsic injection capacities of ~ 1–4 mC∙cm−2 [49]. Recently, intrinsically conducting polymers, including polypyrrole (PPy) and poly(ethylenedioxythiophene) (PEDOT), as well as carbon nanotubes, have emerged as alternatives, which allow chemical surface modification to enhance functionality of the electrodes. PEDOT-modified electrodes have shown to exhibit charge injection of up to ~ 15 mC∙cm−2 [50].

Recording electrodes measure small signals, often in the range of millivolts and below. Action potentials are nerve signals generated and conducted by neurons to transmit information to target tissues, and voltage amplitudes for such central nervous system (CNS) action potentials are typically measured to be in the order of 100 μV. These recorded signals are also often subject to noise. Intrinsic noise can be attributed to the motion of charge carriers and extrinsic noise to atmospheric disturbances including electromagnetic fields from sources such as power lines. Additional sources also include physical disturbances due to physiological processes including respiratory, cardiac processes and muscle contraction along with movement of tissue and electrode relative to each other. As such, recording electrodes are designed so as to minimize all forms of noise so that signals can be recorded with high signal to noise ratio (SNR). These electrodes are also generally designed to operate with low current density and as such have low impedance. This prevents irreversible reactions at the electrode-tissue interface leading to electrode corrosion [44]. Typical impedance of recording electrodes varies between 50 kΩ and 1 MΩ, measured at 1 kHz, which is larger than the impedance of the tissues into which they are embedded [45]. High impedance of a recording electrode, in addition to the network’s distributed capacitance and amplifier, can affect its high-frequency response. The amplitude and corresponding frequency range of some of the bioelectric signals measured by non-invasive electrodes on the surface of the body are shown in Fig. 2c. There is a limitation for spatial resolution and operation frequency band. However, it should be noted that higher electrical impedance does not itself contribute to the noise in the system. Comparatively speaking, implanted electrodes have better-signal reception; however, they typically develop problems in the long run and have risks involving tissue damage. Thus, electrode design for implantable electrodes should accommodate potential risks of tissue trauma that in any way may degrade the electrode performance.

Tissue Interaction

Biocompatibility and Corrosion Resistance

Medical devices implanted underneath the skin or placed on the epidermis to monitor, record and/or stimulate, are susceptible to the intermediate tissue response that arises from the direct or interfacial contact between the electrode and the biological environment. Biocompatible materials are characterized by their non-toxic, non-inflammatory and non-allergenic effects when in contact with biological systems. Often noble metals including gold, platinum, iridium and tantalum, are used as conducting material for electrodes due to their biocompatible nature. For on-surface epidermal electrodes, the use of non-biocompatible materials as the primary material or as an applied decorative finish, increases the potential for reaction at the skin–electrode interface and causes skin irritability. In the case of invasive implant electrodes, biocompatibility issues are normally more severe. The surgical implantation procedure inflames the tissue around the implant leading to the formation of an encapsulation sheath around the foreign body, the direct effects of which includes a decrease in the SNR and increase in electrical impedance at the electrode-tissue interface. This foreign body response may be immediate, occurring within hours of coming in contact with the device or long term that can take from days to months to develop progressively from the initial response [53]. Chronic responses developed over time have also led to the migration of implant [54]. The schematic in Fig. 3a shows the foreign body response for a typical subcutaneous implant, beginning with protein adsorption on the implant surface, followed by adhesion and differentiation of neutrophils and monocytes, which have emigrated from the vasculature resulting in the formation of a collagenous fibrous capsule around the implant. Similarly, Fig. 3b shows foreign body response for an intravascular implant beginning with protein adsorption, followed by adhesion of platelets and leucocytes, generating clotting factors like thrombin. Thrombin converts soluble fibrinogen protein into insoluble fibrin that entraps other platelets, blood cells and plasma in contact. According to the International Organization for Standardization 109993-5, there are three different types of tests, namely extract, direct contact and indirect contact used for quantifying the biocompatibility or checking the cytotoxicity of electrode materials and medical devices [55]. The MMT or the 3-(4,5-dimethyl-2-thiazolyl)-2,5-diphenyl-2H-tetrazolium bromide (methyl thiazolyl tetrazolium assay) is a rapid test for measuring cell metabolism, growth and toxicity through cell proliferation. In the direct contact method, electrodes are placed in direct contact of the cells in vitro and observed for the changes in cell number and other morphological changes. Indirect contact tests include molecular filtration and agar overlay assay. The molecular filtration method is suitable for mildly toxic devices, whereas the agar overlay assay is suitable for small molecular weight and water-soluble particles [55].

Foreign body response (a) of a subcutaneous implant (b) of a intravascular implant. Reprinted from [79] Copyright (2015), with permission from Elsevier

Corrosion of an electrode refers to the degradation of the physical and mechanical properties of electrode materials in response to the harsh body environment that it is exposed to. This is a common issue related to both non-invasive on-surface and implanted electrodes, owing to the ionic compositions of various body fluids [56, 57]. With on-surface applications, wearable electrode materials are subject to biofluids for sensing. These biofluids such as saliva, tears and sweat are often corrosive in nature and may change electrode properties through irreversible chemical reactions and acid attacks. Non-invasive wearable sweat sensors have been used to detect different body analytes like sodium, ammonium and calcium. The electric current applied in the process of detection however makes these sweat sensors prone to galvanic corrosion [58,59,60]. For invasive applications, complications can be more severe with the potential risk of the implant loosening leading to failure. Long-term cytotoxicity in platinum electrodes due to corrosion has been observed in cochlear implants [61]. Corrosion of gold-plated tungsten wire in phosphate buffer saline (PBS) solutions, impacting electrical properties and generating toxic tungsten metal ions, has been observed [62, 63]. Similarly, significantly elevated metal concentrations in blood, with presence in serum and urine, have been reported in total joint replacement patients [64]. Metal ions including cobalt, nickel and chromium in combination with protein available in skin, blood and connective tissues have potential to trigger immune responses [65]. Accumulation of metal ions has also been reported to result from the production of digestive enzymes that degrade the extracellular matrix including cells, morphological change in organs and implant loosening [66]. Dissolved salts and halide ions in the body promote corrosion reactions of invasive electrodes in conjunction with pH and body temperature [57, 67]. Metals, among the extensively used materials to fabricate electrodes, are likely to corrode owing to formation of galvanic cells, with redox electrochemical reactions occurring at the metal/tissue interface [63, 65]. As such corrosion limits the biocompatibility of a material by inducing host reactions through the release of allergenic and toxic species and products during the corrosion process.

Several approaches, both chemical and biological, can be used to improve biocompatibility of electrodes and modulate tissue responses. Electrode surfaces and/or electrode-tissue interface sites can be modified with self-assembling monolayers in order to repel protein adsorption, through the construction of defined surface structures [68] and cell adhesive peptides to promote selective cell adhesion [69]. Alternatively, hydrogel coatings have also shown to improve biocompatibility [70]. Implanted electrodes can also be configured to release therapeutic substances in vivo to prevent the foreign body response from occurring [71,72,73,74]. Hermetic sealing with barrier coatings which are simultaneously biocompatible in composition, defect free, long-life, highly insulating, have low thermal conductivity and mass, high transparency (in the case of an optically responsive electrode), have low mass density, are highly flexible and can resist bio-dissolution can be used [75]. However, careful consideration must be taken as the selection and use of hermetic coatings into the system as coatings may lead to increase in weight, inflexibility and manufacturing challenges [76]. Electrodeposition of conducting polymers like PEDOT with dopants of suitable molecular weight, which may be further oxidized, can also be incorporated in order to minimize corrosion as well as to improve conductivity [77]; however, it is to be noted that thin polymer coatings are often brittle [78]. Polymer and CNT composites can also prevent deposition of species for polarized electrodes through controlled charge injection. This can also be accomplished through application of an AC signal in the electrode for the release of the encapsulated species. Other problems including metal dissolution, deposition and ion migration, common to heterogeneous alloy surfaces, can be prevented by constructing electrodes with homogeneous alloys having transition metals with higher atomic weight.

Flexibility and Mechanical Strength

The mechanical robustness of an electrode, that is, its ability to withstand abrasion and tearing, as well as stretching, is a key feature for reliable performance in an electrode. An electrode should be mechanically robust to continuously transmit signals allowing deformations including bending, twisting, compression and stretching. It should also be flexible enough to avoid substantial mechanical strain on the tissues it is in contact with [80, 81]. Skin tissue has an elastic bilayer structure consisting of outer epidermis with a Young’s modulus 140–600 kPa and inner dermis with Young’s modulus of 2–80 kPa [82,83,84]. Similarly, tissues such as bone, including skeletal muscles, exhibit high elastic moduli in the range of 2–4 GPa. In comparison mechanically static tissues like heart or breast and compliant tissues like the lungs exhibit low elastic moduli of < 1 kPa [85].

The chart from Ashby in Fig. 4 shows the modulus of a material against stress at failure. Such charts provide a good starting point to guide materials selection in the fabrication of electrodes specific to target tissues, as well as the incorporation of materials together in a composite structures for said electrode fabrication [86]. Heavy transition group metals like gold, platinum, iridium including alloys, carbon-based materials like SWCNT and graphene display good conducting properties; however, they are fairly stiff and strong materials. The rigidity of implanted electrodes may induce micro-motion-related mechanical strain in tissue such as brain tissues and result in inflammation and tissue injury, leading, among other things, to device failure [87]. Similarly, the migration of microglia from softer to stiffer areas of the electrode has also been observed [88].

Modulus vs strength Ashby chart for material selection. Reprinted from [86] Copyright 2009 Granta Design Limited, Cambridge

For their implementation in implants, electrodes need to be small in size as well as flexible, such that they can be selective for stimulation and recording purpose. The smaller and compact size also addresses the issue of mechanical mismatch at the abiotic–biotic interface; however, controlling the feature size of the material compromises their intrinsic strength respective to the geometrical design. As such, elastomeric substrates with a low modulus of between 50 and 100 kPa have been employed for the fabrication of devices with metal conductors. An advantage of using elastomers for wearables is the ability to have conformal and intimate integration with the epidermis, which helps to avoid errors introduced by small air gaps or artifacts associated with relative motion that affect their performance significantly. Incorporating electronic components like silicon (Young’s modulus of 160 GPa) with elastomers, comes with the risk of mechanical strain on the low elastic modulus material affected by the high elastic modulus material due to their difference in mechanical properties [89]. As such, effective moduli should be maintained within 100–150 kPa to prevent interfacial cracking and delamination [37].

Together with individual material properties of the electrode, such as the conducting material, the underlying substrate can improve the collective ability to endure mechanical strain as well as avoid mechanical mismatch of electrode subcomponents and geometry. For wearables, placed on the skin surface, the effective moduli of the device in contact should be low. High moduli devices can lead to interfacial cracks, impedance increase and signal loss leading to device failure. Polymers offer tunable conductive and mechanical properties through controlled particle loading [90]. Thus, depending on the placement of an electrode in the body, the flexibility and stretchability of the electrode can (and must) be designed for matching in order to provide reliable performance.

Types of (Semi) Conductors

Materials may be classified as conductors, semiconductors or insulators, depending on their ability to conduct electricity. Insulators (wide band gap materials, with high dielectric constants) are poor conductors of electricity, and as such mostly find application as dielectric components in electronic devices [91]. For example, implanted devices typically use materials with high dielectric constants, such as silicone and Parylene for hermetic sealing of the implant [92].

Metal conductors, with their ordered atom arrangement, are the most widely used electrode materials attributed to property of wire drawing in older electrode preparation processes. Conductors have an energy overlap between their conduction and valence band, meaning charges can migrate without needing to be excited first. Gold and platinum are some of the most common metals to be used as electrodes for interacting with biological systems.

Semiconductors, as the name suggests, are mid-way between conductors and insulators. They have a narrow band gap between their conduction and valence band. This band gap energy is the minimum required to excite a charge carrier to a state in which it can participate in the conduction process. The application of voltage, as well as rise in temperature, can trigger electron flow bridging the narrow energy gap resulting in their high conductivity. Silicon is the archetypal semiconductor and is widely used in electronic applications. Silicon has a network of covalently bonded atoms, where each neighbor shares four valence electrons. Pure semiconductors are called intrinsic semiconductors. Conduction in such types of semiconductors occurs through the movement of both holes and electrons. As such, total current is equal to the sum of electron current and hole current. The conductivity of semiconductors can be increased by the addition of impurities and the process is called doping, creating what is known as an extrinsic semiconductor. In the case of silicon, addition of pentavalent impurities, with 5 electrons in their outermost shell, like arsenic or bismuth, increases the electron charge carriers. These semiconductors with excess electrons due to doping are called N-type semiconductors. The addition of trivalent impurities with 3 electrons in their outermost shell, like boron and aluminum, increases the hole charge carriers. Due to the excess of positive hole carriers, these semiconductors are called P-type semiconductors [93].

For the interfacing of bioelectronics however, silicon tends to have poor suitability in terms of biocompatibility or flexibility and are likely to underperform in in vitro applications [89]. Adding a layer of coating such as a hydrogel onto these materials has however been shown to facilitate improved biocompatibility, rendering them compatible for bioelectronics interfacing [94]. On the other hand, signal transduction across the abiotic–biotic surface face problems due to increase in impedance at the point of contact. This is an underlying problem common to inorganic materials interfacing with the biological systems that limit efficient charge transfer. Conjugated polymer composites, as a class of semiconductor, are often used as coating materials on these inorganic electrodes, in order to decrease the impedance of the electrode structure. Polymers also have unique ionic charge transport capabilities, similar to the conduction process in biological systems. As such polymer materials are favored for bioelectronics application and interfacing as electrodes and coating materials for inorganic electrodes. In contrast to inorganic metals and non-metallic elemental solids such as silicon, polymers can also be flexible in nature and thus are sometimes referred to as ‘soft organic materials’ [95]. Although polymers are intrinsically insulating, they can be made fairly conducting by addition of dopants, which lead to the creation of free charge carriers. N-type dopants partially oxidize the conjugated network, while p-type dopants partially reduce it [96]. A number of biomolecules and therapeutic agents can function as dopants. Furthermore, these may be functionalized into conducting polymers themselves during the polymerization process [97,98,99]. The building blocks of polymers are covalently bonded atoms. These blocks form chains, connected to one another through Van-der Waals force and electrostatic forces. In contrast to the covalently bonded silicon atoms, these bonds can be easily broken, allowing for tunable functionality and opportunities for application-specific materials engineering. A schematic comparing the interaction of inorganic silicon and organic PEDOT:PSS electrode with the biological system is given in Fig. 5 [100]. In the case of a silicon electrode, the formation of silicon oxide on the silicon surface causes ion accumulation at the electrolyte/ion interface, which affects its doping state due to field-effect mechanism. As such, conduction is limited on the surface of the electrode, increasing the impedance of the structure. Organic polymer electrodes on the other hand employ ionic charge transport and utilize the entirety of its material volume for conduction. Other advantages of using polymers for electrodes include low-temperature processing, oxide-free interfacing and facile modification process with tunable functionalities.

Comparing the structural organization of inorganic silicon with organic PEDOT:PSS electrode along with their responses in a biological environment. Reprinted (adapted) with permission from [100].

Printing Techniques

Conventional practices of electrode fabrication range from simple methods like drop casting [17], spin coating [18] and electrodeposition [19]; to more complicated methods including lithography [24, 25] and laser ablation [101, 102]. Depending upon the material choice and application, these methods can yield high resolution with controlled geometry and feature sizes. However, the main interest and advantage of printing as an alternative to conventional practices lies in the ease of prototyping and scalability [28]. The printing process involves deposition of functional materials or pigments with conducting, non-conducting dielectric and semi-conducting properties, fashioned into electronic inks through the incorporation of appropriate solvents, binder polymers, surfactants and/or stabilizers. Suganuma et al. provide an insightful introduction to the field of printed electronics and should be referred to as a starting point for newcomers [103]. In the present work, we review different printed organic and inorganic electrodes and their potential use in biological sensing and stimulation. The construction of these electrodes through different printing techniques is highlighted with an evaluation of electrical properties. Inks can be used singularly for making simple passive structures like resistors, or in combination for constructing active structures such as thin-film transistors, depending on how they are applied. Table 2, adapted from Fukuda et al., provides general specifications of different printing methods for the fabrication of printed thin-film transistors [27]. Different printing methods are listed in the table with required ink viscosity, attainable line resolution (specified through physical dimensions of the print including line width and thickness) and printing speed, based on the printing method selected. Considerations regarding the proper choice of ink, substrate and design of patterned structure determine printing method selection. The results being the yield, quality and production cost for the entire operation. Metals including Ag, Au, Cu, ceramics oxides, carbon-based graphene, nanotubes and organic polymers including poly(3,4-ethylenedioxythiophene) polystyrene sulfonate (PEDOT/PSS) compounds, have been used as conducting pigments in conducting inks for printing interconnects and electrode pads. Interconnects are the connecting wire or conducting line in a circuit. Among the conducting materials, metals feature comparatively higher conductivity and low resistance than their polymer and ceramic counterparts.

Metals

Metals are normally the first choice when it comes to fabricating conducting electrodes. Metals have high conductivity due to the overlap of their conduction and valence bands. For applications in the biomedical field, heavy transition noble metals including iridium, platinum, gold, tungsten, tantalum are generally preferred on account of their biocompatibility, mechanical strength and corrosion resistance [104, 105]. In some cases, more inexpensive options, such as copper and silver, have also been used [106, 107]. Generally, one-dimensional high aspect ratio nanoparticles, nanorods and nanofibers of metals are attractive for ink formulations, given their advanced electrochemical performance, electrical and heat conductivity [108, 109]. Metal nanoparticles, with dimensions between 1 and 100 nm, can be easily suspended in solvents such as short-chain alcohols (ethanol, isopropyl alcohol), glycols, water or toluene in order to form low-viscosity inks, without significant sedimentation over the timeframes required. Such low-viscosity inks can be used in inkjet, flexo and offset gravure printing. Nanoparticles exhibit high surface energy due to the small particle size, which facilitates post-printing annealing/sintering of neighboring individual particles can be accomplished to create a solid, continuous product after printing [110].

Nanoparticles are generally synthesized through chemical routes by the reduction of organometallic compounds in wet-chemical environments [111]. Other methods also include mechanical machining, aided with high energy sources like ultrasound and laser ablation. The chemical synthesis route is normally preferred as it offers better control over the final morphology and higher yields of the metal nanoparticles. Solvents including polyols [112, 113], octyl ether [114], octylamine [115] and toluene [116] have been used for such synthesis procedures. Among the organic solvents used for nanoparticle synthesis, ethylene glycol is the most widely reported [112, 117] and is itself a mild reducing agent, assisting the creation of nanoparticles from electropositive metal salts, including those of silver, gold, palladium and platinum [112]. During the reaction, control of particle growth is facilitated by addition of appropriate surfactants, which further helps prevent nanoparticle agglomeration. Surfactants should have good affinity to the metal nanoparticles to provide electrostatic and steric stabilization of particles in the solvent, avoiding agglomeration and/or uncontrolled growth of the particles. Sulfur-enriched thiol molecules have been widely used to stabilize gold nanoparticles [118, 119]. It has also been observed that the concentration of alkanethiol used as stabilizing agent also affects the particle size of the metal [119, 120].

Poly(N-vinyl-2-pyrrolidone) (PVP) is a common steric stabilizing agent used for Ag- and Cu-based inks[117, 121], with other stabilizers including carboxylic acids [114, 116], cetyltrimethylammonium bromide (CTAB) [112], poly (acrylic acid) salts [122] and poly(ethyleneimine) [123]. Besides the use of stabilizing surfactants, materials like copper may also require to be processed in anaerobic environments, as they are prone to oxidation. Furthermore, polymer binders may also be added for good ink adhesion to the substrate. Organic surfactants including ligand molecules and polymer binders can also be added in the later stage during the ink formulation for metal nanoparticles synthesized without the stabilizers. These organic layers, however, can cause several types of defects, including the formation of an insulating energy barrier that inhibits charge injection and/or altering the work function of the metal [124]. Post-deposition heat treatment of the printed structures can help decompose and remove these organic binder materials, in addition to performing the role of sintering the metal particles [125]. Inorganic inks that utilize polymeric layers for ink formulation, however, may require very high-temperature treatment to improve conductivity, restricting the use of many flexible plastic substrates which may degrade and/or distort at such temperatures. Metal–organic decomposition (MOD) inks are another approach to printing of metallic structures, which utilize metal precursors like metal salts dissolved in solvent. The ink itself is free from nanoparticles and typically transparent or translucent in nature. The molecular nature of the compound allows for low-temperature processing of the printed pattern, in favor of plastic substrates. β-Ketocarboxylate Ag MOD ink decomposes at 100 °C, giving Ag metal features with a resistance of 10−6 Ω at 120 °C [126]. Cu- [127], Au- [128] and Pt [129]-based MOD inks have also been used.

Various printing methods, including high-resolution inkjet, gravure, offset printing and screen printing, as well as less conventional ‘advanced manufacturing processes’ such as transfer and 3D printing, have been used to print metal nanoparticle-based inks. Depending on the printing method used, ink viscosity can be tuned to match the rheological requirement of the printer. Generally, metal loadings of 20–60 wt% are required to obtain high conductivity in an inkjet-printed pattern. Alternatively, inks with high vapor pressure may be used to afford a high density of the metal particles without unwanted organic materials.

In terms of conductivity, Ag nanoparticle-based metal inks are the leaders and widely researched, with resistivities of just a few μΩ∙cm [130, 131], comparable to bulk Ag, which has a resistivity 1.59 μΩ∙cm. Grau et al. reported a high-resolution Ag nanoparticle-based source–drain electrode for TFT application fabricated using a gravure printing process, which is shown in Fig. 6a. The source–drain electrodes are printed at 5 µm distances, called channel lengths for a transistor, with each individual electrode having a 5 µm width. The source–drain electrodes are overlaid with different viscosity semiconductor ink for assessing performance [132]. Kang et al. reported comparable results using gravure printing with a line spacing of 10 μm in a TFT, with optimized ink viscosity and print speed [133]. Meanwhile, Shen et al. have reported inkjet-printed Ag nanoparticle-based electrodes, shown in Fig. 6b with a width of ~ 526 µm, fabricated on paper substrates. The usefulness of these electrodes was demonstrated with them being used as conductive tracks to supply an LED in a circuit [134].

a High-resolution gravure-printed Ag nanoparticle-based source–drain electrodes with equal channel length and electrode width of 5 µm, overlaid with semiconductor inks of different viscosities for TFT application. Reprinted from [132] Copyright 2016 Wiley Advanced Electronic Materials. b Optical image of inkjet-printed silver tracks with (i) different line widths, (ii) a “1.0pt” printing width of 562 µm. Reprinted from [134] Copyright 2014 Nanoscale. c Inkjet-printed Ag nanoparticle-based disposable electrodes for pathogen detection. Reprinted from [135] Copyright 2016 Scientific Reports. d High-resolution line spacing/channel of 1um demonstrated for pentacene-based OTFTs with inkjet-printed Ag electrodes. (i) Schematic cross section of the OTFT. (ii) Optical images of OTFT channel length L = 1, 2 and 5 µm. (iii) Atomic force microscopy (AFM) of OTFT with 5-µm channel length. Reprinted from [136] Copyright 2008 National Academy of Sciences, USA. e Inkjet-printed gold 31-electrode array with minimum feature size of 62 µm for bioelectronics interfacing. Reprinted from [146] Copyright 2016 Wiley Advanced Functional Materials. f Inkjet-printed Au-based MEAs in a 64-electrode configuration with 200 µm pitch and individual electrode measuring ~ 31 µm. Reprinted from [147] Copyright 2017 Flexible and Printed Electronics

With a focus toward biological applications, Ali et al. reported that an interdigitated Ag nanoparticle-based electrode, produced using inkjet printing, is shown in Fig. 6c. This was successfully used for pathogen detection, with Salmonella typhimurium, and the Escherichia coli strains JM109 and DH5-α all identified using this biosensor [135]. The direct write inkjet printing method has been demonstrated to achieve high-resolution line spacing/channel length of 1 μm between the drain and source electrodes for organic TFTs, with sub-femtoliter droplets of a Ag nanoparticle-based ink and a low sintering temperature of 130 °C (see Fig. 6d). For comparison, channel lengths 1, 2 and 5 µm were also reported for pentacene-based OTFTs [136]. The low-viscosity inks utilized by these printing methods are often aqueous-based dispersions. Ink viscosity, metal particle size, wettability and adhesion of the ink to the substrate need to be considered for high resolution and accurately aligned patterns. Recent studies, however, have shown Ag to be less biocompatible and rather toxic with migration effects for in vivo applications [137, 138].

Similar to silver, copper nanoparticle-based inks are attractive due to their low cost and high conductivity. Norita et al. have reported printed Cu nanoparticle ink-based electrodes with resistivities as low as 7 μΩ.cm after photonic sintering using a Xenon (Xe) flash lamp [139]. In the case of copper, the particles themselves are prone to surface oxidation, resulting in the printed structures often having much higher resistance. As such, higher sintering temperatures in inert atmospheres and/or more severe reducing conditions are required to provide good conductivity [140]. Recently, the biomedical prospects of copper oxide nanoparticles have also been investigated, with a few reports on printed electrochemical sensors [106, 141].

Platinum is another attractive metal for biomedical applications, due to its high conductivity, stability and inertness, radiopacity, durability and mechanical strength attributed its high atomic weight [142]. Platinum nanoparticle inks for inkjetting have been developed and the resultant metal patterns have been used as base electrode for applications such as pH sensing [143] and electrodes for dye-sensitized solar cells [144]. Similarly, platinum ink has also been screen printed for electroanalytical applications [145].

Inkjet-printed gold nanoparticle-based electrode arrays, shown in Fig. 6e, consisting of 31 electrodes with features as small as 62 μm, spaced at between 2 and 7 mm and with a conductivity of 5 × 106 S∙m−1, have been realized on a polyethylene naphthalate (PEN) substrate and used to map the impedance of conformal surfaces at 15 kHz for bioelectronic interfacing purposes [146]. Similarly, Fig. 6f shows MEAs with 64 electrodes, which were fabricated using an inkjet printing method on Kapton sheets, and were used for extracellular recording of cardiomyocytes. These MEAs had a 200 μm pitch, with individual electrodes measuring ~ 31 μm in width [147]. Gold nanoparticle-based screen-printed sensor electrodes were also produced for use in DNA detection [148, 149], while high-precision screen-printed gold nanoparticle-based source–drain electrodes produced with a 90-μm line spacing/channel and conductivity of 1.0 × 105 S∙cm−1 for OTFTs have also been demonstrated [150].

Carbon Nanomaterials

Carbon nanomaterials have become a popular choices for electrodes and sensor applications given their low cost, environmentally sustainable nature due to their associated processing steps and excellent electrochemical performances [151]. Carbon materials including graphene, carbon nanotubes (CNT), carbon dots, carbon nanofibers, nanodiamonds and fullerenes exhibit large surface-to-volume ratios, high conductivity and electron mobility, chemical inertness and higher sensitivity for electrochemical analysis resulting in their widespread application. Among them, CNTs and graphene have become the most attractive materials for printed electronic applications, with fabrication of TFTs [152, 153], RFID tags [154], electrochemical and bio-sensing electrodes [155, 156] all being reported. Other larger carbon materials including fibers and particles are also used as resistors and electrodes.

Graphene is a two-dimensional carbon allotrope with sheet thickness of 0.34 nm and sp2-hybridized carbon units [157]. The ideal sheet resistance of graphene is Rs ~ 62.4/N Ω∙cm, where N is the number of layers [158]. Depending on application, graphene of different qualities can be obtained using mechanical or chemical splitting of graphite and carbon nanotubes, liquid phase exfoliation, chemical vapor deposition (CVD), plasma-enhanced CVD, solvothermal synthesis from organic compounds and/or thermal decomposition of SiC [159]. Graphene-based printing inks can be formulated by dispersing graphene flakes in solvents such as water [160, 161], ethanol [162, 163], terpineol [164], N-methylpyrrolidone (NMP) [165, 166] and o-dichlorobenzene [166]. Additionally, stabilizing agents such as poly cyclic aromatic hydrocarbons, surfactants including sodium dodecyl sulfate (SDS) [167], sodium dodecylbenzene sulfonate (NaDDBS) [161], sodium deoxycholate [166], sodium cholate [168] and CTAB [169], as well as polymeric PVP [170], PVA [171] and ethyl cellulose [163] have also been used for maintaining stable dispersions.

Figure 7a shows a schematic representation of processing steps for the preparation of graphene-based inks as used in inkjet printing. Formulated at room temperature, this ink uses ethanol as a solvent and ethyl cellulose as a surfactant. First, the precursor graphite powder is exfoliated in a solution of ethanol with ethyl cellulose by probe ultrasonication process. Ethyl cellulose acts as the stabilizing agent for the exfoliated graphene. The exfoliated ethyl cellulose-encapsulated graphene is then subjected to sedimentation centrifugation for removal of larger particles. Then, an aqueous solution of NaCl is added to the mixture, in order to flocculate the graphene and ethyl cellulose. The obtained solid is then washed, dried and finally dispersed in a variety of solvents to prepare ink for printing [163].

a Schematic representation of graphene ink preparation with graphene flakes and stabilizing polymer; (i) probe sonication exfoliation of graphite powder and simultaneous isolation in ethanol/EC; (ii) removal of residual graphite flakes by sedimentation; (iii) graphene/EC flocculation with salt; (iv) ink with graphene/EC dispersed in 85:15 cyclohexane/terpineol; (v) photograph of the prepared graphene ink. Reprinted (adapted) with permission from [163] Copyright 2013 American Chemical Society. b Porous graphene-based 64-electrode array fabricated on polyimide substrate for cortical stimulation and sensing. Reprinted from [39] Copyright 2016 Scientific Reports. c Screen-printed graphene electrode: (i) single 40-µm-wide track; (ii) implemented as source–drain electrodes for electrolyte-gated transistor (EGT) with a channel length of 90 µm and width of 900 µm; (iii) schematic illustration of EGT with screen-printed graphene electrodes. Reprinted from [173] Copyright 2015 Wiley Advanced Materials. d Screen-printed graphene: (i) rheology characterization of ink through viscosity measurement for 52 mg∙mL−1 concentration ink in dipropylene glycol; (ii) graphene paste on spatula; (iii) screen-printed graphene on PET and folded. Reprinted from [174] Copyright 2016 Advanced Functional Materials. (e) Screen printed: (i) graphene oxide ink-based circuit; (ii) reduced graphene oxide showing printed circuit. Reprinted from [180] Copyright 2017 Wiley Advanced Materials Technologies

Aside from dispersions of graphene itself, graphene oxide (GO) and its chemical derivative (reduced graphene oxide (rGO)) may also be used to prepare inks. Reduction of GO after printing is required in order to improve conductivity to a useful range. Compared to pristine graphene flakes, the hydroxyl, carbonyl and carboxylic groups in GO enable easy dispersion without the need for stabilizing agents. GO has been dispersed in water [165] and other polar organic solvents including NMP, N, N-dimethylformamide (DMF), tetrahydrofuran (THF) and ethylene glycol [172]. Generally, particle loading for low-viscosity graphene-based inks is in the range 0.002–1 wt% [166] and GO-based inks are 0.1–1 wt%, requiring multiple layer prints in order to attain reasonable conductivities. Viscous graphene inks can be prepared by increasing particle concentration [173] or by gelation of graphene dispersions [174]. Apart from the wet-chemical synthesis methods, porous graphene has also been prepared by direct laser writing on carbon materials using CO2 lasers in an ambient environment [175]. Figure 7b shows a 64-electrode array fabricated from graphene, produced by direct laser ablation of a polyimide substrate [39].

CNTs are one-dimensional allotropes of carbon having cylindrical structure with hexagonal honeycomb lattices built by sp2 carbon units. CNTs have been used for different electrochemical and biosensing applications [176, 177]. Two structural groups including single-walled carbon nanotubes (SWNTs) and multi-walled carbon nanotubes (MWNTs) have been identified for CNTs. SWCNTs consists of a hollow rolled up individual graphite sheet with possible diameters between 1 and 2 nm, whereas MWNTs are nested graphite cylinders with diameters between 2 and 25 nm with spacing between tubes of 0.34 nm [176]. Thin films composed of randomly distributed CNT can also be flexible and stretchable, making them very useful for flexible devices. CNTs may have either metallic or semiconducting properties depending on the chirality or lattice symmetry along the sheet. In their metallic configurations, SWCNT and MWCNT are still less conductive than most metals used as electrodes at 10−6 Ω∙cm and 3.10−5 Ω∙cm, respectively, although they do exhibit superior mechanical strength [178]. For use as a conducting element, separation of semiconducting CNTs is an essential requirement. Electric arc discharge, laser ablation and chemical vapor deposition (CVD) are some of the methods used for synthesis of CNTs.

Similar to graphene, CNT-based printing ink can be formulated by dispersing CNTs in organic solvents. Ultrasonication and high-pressure homogenization are used for dissociating agglomerates and preparing homogenous dispersions. Additional stabilizing agents including surfactants with anionic, cationic and non-ionic groups or polymers may also be used in the process. Reported surfactants for stabilizing CNTs include Triton X-100, SDS, Tween 20, Tween 80, sodium cholate, CTAB, dodecyl trimethylammonium bromide (DTAB) and NaDDBS [179]. In the case of dispersion in water-based media or other hydrophilic solvent, surface modification may be needed since CNTs generally have hydrophobic nature. CNT-based inks generally have low particle concentrations, ranging from 0.01 to 10 g∙L−1.

A variety of printing techniques including inkjet [163], gravure [181], screen [174] and flexographic method have been used for printing graphene and CNT-based electrodes. Graphene lines with resolution ~ 30 µm have been gravure printed for large area flexible electronics [181]. High-resolution prints have also been reported with silicon stencil-based screen-printed graphene demonstrating line width of ~ 40 μm, high conductivity of ~ 1.86 × 104 S∙m−1 with a particle concentration of ~ 80 mg∙mL−1. The optical image for the printed line is shown in Fig. 7c.i. This ink was subsequently used for the fabrication of an electrolyte-gated transistor having a channel length 90 µm and channel width 900 µm, as shown in Fig. 7c.ii. A schematic of the full fabricated device is shown in Fig. 7c.iii [173]. Similarly, a highly concentrated (52 mg.mL−1) graphene paste was screen printed to give lines with 40 μm width and 25 μm thickness, exhibiting a sheet resistance of 30 Ω.sq−1 after being dried at 100 °C. The rheological characterization of the ink, shown in Fig. 7d.i, shows shear thinning behavior with high viscosity suitable for screen printing. For screen printing, ink viscosity needs to be high 500–100,000 m∙Nm−1 (as given in Table 1). The viscous ink in a spatula is shown in the photographic image in Fig. 7d.ii. This ink was used to prepare a flexible screen-printed circuit on PET substrate, shown in Fig. 7d.iii [174]. A reasonable resistance of 327 Ω∙sq−1 was also achieved using screen-printed water-based graphene oxide ink, as demonstrated by the as a conductive circuit shown in Fig. 7e.i. The same circuit was also printed using rGO-based ink, screen printed as shown in Fig. 7e.ii. In this case GO was reduced with 1:1 mixture of trifluoroacetic acid and hydroiodic acid, at 80 °C [180]. A slightly lower sheet resistance of 250 Ω∙sq−1 was achieved using an inkjet printer, with a graphene oxide concentration of 3.2 mg∙mL−1 in the ink [182]. Similarly, at a concentration of 3.4 mg∙mL−1, a low resistance of just 4 mΩ∙cm was achieved for 20-μm thick inkjet-printed graphene samples [163]. Aside from graphene, inkjet-printed MWNT electrodes have also been reported to achieve a conductivity up to 30 S∙cm−1 without post-treatment [183]. Similarly, inkjet-printed SWCNT on stretchable substrates with 1- and 5- layers showed respective sheet resistances of 170 and 19 Ω∙sq−1 [184]. For SWNT printed onto paper and plastic substrates using inkjet printing technology, a sheet resistance of ~ 40,000 Ω∙sq−1 was demonstrated [185]. Among screen-printed MWNT inks, sheet resistances of 0.5–13 Ω∙sq−1 have been achieved for 3 successive layers of print [186].

Polymers

Conducting polymers are organic compounds composed of repeating units, linked together by alternating single and double bonds [187]. Despite having lower conductivity than metals, conducting polymers have advantages of being inexpensive [188] and mechanically more flexible and elastic with lower Young’s moduli than metals [189]. Polyaniline (PANI) [190], polypyrrole (PPy) [191] and poly (ethylene dioxythiophene) (PEDOT) [192] are some of the first reported and most commonly used biocompatible polymers. Conducting polymers are compatible with a wide variety of aqueous solvents making them an attractive material for printing and ink formulation, often by dispersion. Conducting polymers have been printed using several printing methods including inkjet [193], gravure [194], screen printing [195] and 3D printing [196], for applications including flexible electronics and energy storage applications [197]. These polymers tend to have narrow bandgaps, allowing easy transfer of electrons from valence band to the conduction band. Most polymers intrinsically lack charge carriers for conduction despite having narrow bandgaps. As such, dopants are required to increase the carrier mobility and improve conductivity. Dopants are agents that either partially oxidize or partially reduce the polymer and are typically added during the synthesis process. Depending on the added dopant, polymers can, similar to inorganic semiconductors, be n-doped or p-doped through the addition and removal of electrons. Within the polymer backbone, electrons can move along the π-bonded network in conjugated molecules to conduct current; however, electron hopping is observed between localized conjugated molecules of the non-conjugated bonds. Conducting polymers can be synthesized generally via chemical and electrochemical processes [198, 199]. Chemical synthesis generally involves mixing the monomer solution with the oxidizing agent, forming bulk powder or thick polymer film. On the other hand, electrochemical polymerization involves application of electrical current to a solution containing a monomer, usually with a dopant resulting in deposition of thin polymer films on another conducting (usually metal) electrode. Electrochemically synthesized polymers have superior properties including higher electrical conductivity and enhanced redox activity compared to their chemically synthesized counterparts, but the process is time-consuming and has low yield. For commercial applications and printing, chemically synthesized polymeric nanoparticles are generally preferred.

Ink formulations for printing polymers may be either include organic solutions [200,201,202] or dispersions of polymer nanoparticles [203, 204] obtained through various chemical synthesis routes. These synthesis routes include deposition of monomer followed by reaction or polymer growth during the deposition process like chemical vapor deposition (CVD). Among the conducting polymers, poly (ethylene dioxythiophene) (PEDOT), doped with oxidative polystyrene sulfonate (PSS) to give PEDOT:PSS, has demonstrated conductivities as high as 103 S∙cm−1 [200] and is widely commercially available. Both electrochemically and environmentally stable, this polymer exhibits excellent biocompatibility and has been used as electromyography (EMG) electrodes [205], electrocorticography (ECoG) electrodes [206, 207], neural electrodes [208, 209] and coatings [210], nerve grafts and heart patches [211,212,213]. Different printing methods including inkjet [214,215,216], aerosol [217], roll-to-roll gravure [218] and 3D printing have been used to fabricate PEDOT:PSS-based electrodes. Recently, inkjet-printed PEDOT:PSS interconnects on elastic substrates having high conductivity of 700 S∙cm−1 and low sheet resistance 75 Ω∙sq−1 have been reported [219]. PEDOT:PSS-based inks have also been 3D printed to realize conducting polymer devices as shown in Fig. 8a. This ink was used to construct high-density flexible circuits patterned using this method, shown in Fig. 8a.i. This circuit was used for lighting an LED, (Fig. 8a.ii). The circuit is bendable and flexible, shown in Fig. 8a.iii and a.iv. A 9-channel soft neural probe using the same construction with magnification is shown in Fig. 8a.iv. The constructed 3D printed PEDOT:PSS soft neural probe was implanted in mouse dorsal hippocampus and used for neural recording [196]. Using inkjet printing, a TIPS pentacene-based OTFT was reported with PEDOT:PSS electrodes. Figure 8b.i shows the schematic of the TFT with channel length 60 µm and channel width of 1050 µm. A photographic image with inset microscopic details of the fabricated OTFT is shown in Fig. 8b.ii. Similarly, Fig. 8c shows a fully printed micro-needle electrode array, based on an ink formulated using PEDOT:PSS and MWNT to create a composite. The micro-needles had diameters of 10 ± 2 μm and were 33 ± 4 μm tall, with demonstrated conductivity of 323 ± 75 S∙m−1. The constructed micro-needles performed stably in an aqueous electrolyte and were used to record extracellular signals from cardiomyocyte-like HL-1 cells [220]. Along with PEDOT, PANI is another printable polymer that is environmentally stable. PANI can be tuned to achieve high conductivity through protonic doping using appropriate dopant [221]. Inkjet-printed PANI nanoparticle inks, doped with dodecylbenzenesulfonic acid (DBSA), have been used in both chemical [203] and biosensing [222] applications. In fact, the printed device showed comparable conductive and electrochemical properties to its electrochemically deposited counterpart, with ink stability demonstrated over several months. An ammonia gas sensor fabricated using the inkjet-printed PANI nano-dispersion showed good sensitivity and rapid response to ammonia (t = 15 s) [223]. High-viscosity PANI nanocomposite inks have also been screen printed to produce pH sensors [224]. Similarly, inkjet-printed PPy has been used as vapor sensor [225], whereas screen-printed PPy electrode has been used as a carbon dioxide gas sensor [226]

a 3D printed PEDOT: PSS-based conducting polymer devices: (i) photographs for high-density circuits fabricated by using conducting polymer; (ii) LED lit using the fabricated high-density circuit pattern; (iii) bending test for the fabricated high-density circuit; (iv) photograph for 9-channel 3D printed neural probe; (v) magnified image of soft neural probe from figure (iv). Reprinted from [196] Copyright 2020 Nature Communications. b All inkjet-printed TIPS pentacene OTFT: (i) schematic structure; (ii) photograph of the OTFT with an inset microscopic image of the fabricated OTFT. Reprinted (adapted) with permission from [215] Copyright 2017, American Chemical Society. c PEDOT: PSS-based μ-needle electrode array construction for bioelectronics application using a combination of inkjet and aerosol-jet printing. Reprinted (adapted) with permission from [220] Copyright 2019 American Chemical Society

Metal Oxides

Metal oxides and other ceramics may also be utilized in the fabrication of conducting electrodes, particularly those heavily doped (termed degenerate semiconductors). Indium tin oxide (ITO), fluorine-doped tin oxide (FTO), Al- and Ga-doped zinc oxide (AZO and GZO), antimony-doped tin oxide (ATO), CdO, Ga2O3 and In2O3 are some commonly used conducting oxides. Degenerate semiconductors are of particular interest as electronic conduction and optical absorption may be decoupled, allowing them to be applied in opto-electronic devices including thin-film solar cells, touch screens, light-emitting devices, display devices along with opto-electronic interfaces. Among these, ITO, with demonstrated resistivities as low as 10−4 Ω.cm−1, with transparency > 80% in visible range, is the industry standard with recorded $6.99 billion in revenue and 97.6% market share in transparent conductive film in 2010 [227]. Typically produced with 90% In2O3 and 10% SnO2, polycrystalline or amorphous ITO can be deposited using various thin-film technologies including ion-assisted plasma evaporation, high-power pulsed magnetron sputtering, radio frequency (RF) magnetron sputtering, electron beam evaporation, thermal evaporation, pulsed layer deposition and printing. The conductivity of transparent conducting oxides (TCO) is highly dependent upon the dopant levels in the oxides.

Gravure-printed ITO films compared to sputter-coated ITO films show comparable performance in addition to mechanical flexibility [228]. These printed films can endure small bending radii and retain their electrical characteristics [228]. Printed metal oxides are thus potential candidates for fabricating flexible electrodes. For implementation in printed electronics, decomposition of inorganic metal complexes in a wet-chemical environment has been the generally favored route to synthesize ITO and other TCO nanocrystal inks. Song et al. reported a generalized batch method for synthesizing different forms of pure and doped TCO nanocrystal ink with yields of up to 10 g. The method is illustrated in Fig. 9a.i, where the process involves two key reactions: the ester elimination reaction and the condensation reaction. First, one or more metal precursor molecules react with 1-dodecanol (DDL) to produce a metal hydroxide M–OH species through the release of ester by-products. The M–OH species then condense forming M–O–M1–OH where M and M1 represent two metal species. These eventually form the doped TCOs. The resultant nanocrystals exhibit high crystallinity, uniform morphology, high ink stability with resultant electrodes having sheet resistances of 110 Ω∙sq−1 and transmittance of 88%. Figure 9a.ii shows the various TCO nanocrystal-based inks dispersed in toluene solvent. The ink may vary from transparent to colored, depending on the identity and concentration of dopants such as Al, Ga, In or Sn. The above-reported ink dispersions are said to be stable for more than a year. Figure 9a.iii shows the UV–Vis spectra of the TCO nanocrystal-based films on glass substrate. The films show > 80% transmittance, only slightly lower than the reference glass. Similarly, Fig. 9a.iv shows the measurement of sheet resistance against dopant concentration used. In a test to measure the dependence of conductivity against dopant concentration, optimal doping ratios for lowest obtained resistance were 1% for AZO, 3% for GZO, 5% for IZO and 5% for ITO, respectively. With a thickness of 300 nm IZO and ITO, sheet resistances of 350 and 110 Ω∙sq−1 were obtained. Figure 9a.v shows the transmittance corresponding to the sheet resistance of the TCO nanocrystal-based films. The films meet the requirements for electrodes in applications including resistive touch panels, windows and displays with high transparency and resistance < 400 Ω∙sq−1 [229].

a A generalized method for synthesis of pure and doped TCOs. (i) Schematic illustration of reaction process; (ii) TCO nanocrystal-based inks dispersed in toluene solvent; (iii) UV–Vis spectra of TCO nanocrystal films on glass substrates; (iv) sheet resistance measurement against dopant concentration; (v) study of integrated transmittance against sheet resistance of TCO nanocrystal films. Reprinted from [229] Copyright 2015 Wiley Angewandte Chemie International Edition. b Inkjet-printed ITO film results: (i) FE-SEM of printed film; (ii) sheet resistance and resistivity of printed ITO film measured by Hall measurement corresponding to annealing temperature; (iii) transmittance graph of the printed film. Reprinted from [230] Copyright 2011, with permission from Elsevier. c (i) organic light-emitting diode (OLED) fabricated with ITO anode (ii) SEM of gravure-printed ITO film on PET substrate. (iii) Optical characterization of fabricated OLED. Reprinted from [231] Copyright 2008, with permission from Elsevier

Traditional methods including shadow masks [232] and sputter deposition [233] have been used significantly for the deposition of TCOs. Various printing methods have also been used for fabricating TCO-based opto-electronic and display devices, with inkjet printing being the most common of these. ITO nanoparticle-based inks have been inkjet printed. Figure 9b.i shows the FE-SEM of the inkjet-printed ITO film after microwave annealing at 400 °C with presence of connected nanoparticles. Figure 9b.ii shows the electrical measurements of the printed device, whereas Fig. 9b.iii shows the optical characterization of the device. The inkjet-printed ITO nanoparticle ink demonstrated sheet resistance of 517 Ω∙sq−1 and 3.0 × 10−2 Ω∙cm−1 at a thickness of ~ 580 nm. The printed film had > 87% transmittance irrespective of the annealing temperature [230]. Similar results sheet resistance of 202.7 Ω∙sq−1 and resistivity of 1.52 × 10−2 Ω∙cm−1 have also been reported earlier [234]. ITO nanoparticle-based inks have also been gravure printed, exhibiting sheet resistances of 3 to 10 kΩ∙sq−1, for thicknesses of solid areas ranging between 300 and 100 nm. This ink was UV curable and resulted in a film of 88% transparency [235]. Another ITO nanoparticle-based ink was gravure printed onto either PET or PEN substrates and applied as an anode for an organic light-emitting diode (OLED, see Fig. 9c.i.). These ITO films demonstrated a sheet resistance of 400 Ω∙sq−1 at thickness from 0.2 to > 1 μm. SEM image of the fabricated ITO film is given in Fig. 9c.ii, showing connected nanoparticles. Similarly, Fig. 9c.iii shows the optical characterization of the fabricated device with > 80% transmittance [231]. Similar works on gravure printing ITO-based electrodes for transparent electrode applications yielded sheet resistances of 23.5 kΩ∙sq−1 for a film thickness of 600 nm, on a PET substrate. This is compared to sputtered ITO coatings, with a sheet resistance of 80 kΩ∙sq−1 for 100 nm thickness. Although the sheet resistance of printed ITO film is 6 times larger than sputter-coated film, printed films have higher transparency of 95% in the visible light region, with electrical performance retained even after bending at small radii of curvature [228]. Water-based ITO nanoparticle inks have also been inkjet printed for fabrication of toluene vapor sensors [236].

The limited availability of indium in the earth’s crust and expense of manufacturing serve as major drawbacks for expansion of the flexible electronics market for ITO. As such, alternative materials including AZO and indium-doped CdO with low indium content are being investigated. In a similar context, aluminum-doped cadmium (ACO) ink was inkjet printed as source–drain electrodes of transistors with sheet resistances of 600 Ω∙sq−1 to 2 kΩ∙sq−1 [237].

Summary and Conclusion

In this review, printing as a manufacturing method for fabricating electrodes for applications in medical diagnostics and therapy has been discussed. Depending upon their surface area and geometry, printed electrodes of different sizes can be constructed for both recording and stimulation in vivo and quantification of biological compounds in vitro. The main advantage of printed electronics is that it is a rapid prototyping platform that can easily be integrated for mass scale production. The diversity of materials like metals, transparent conducting oxides, carbon and polymers used and their tailored ink formulation has overcome challenges relating to device performance, geometry and resolution, reliability and fabrication throughput. Additive manufacturing and the printing process in general shows exciting results and opportunities for fabricating electrodes for integration and biological application.

Table summary for the printed electrodes with different applications

Material | Application | Printing method | Conductivity/resistance | Physical dimensions | Reference |

|---|---|---|---|---|---|

Ag | TFT | Inkjet | 3.7 µΩ∙cm | 527um width, 530 nm thickness | [134] |

TFT | Gravure | 5um width and source–drain electrode spacing | [132] | ||

Biosensor | Inkjet | 144 mΩ.sq−1 on PET | 50um width, 200um electrode spacing, 800 nm thickness | [238] | |

Biosensor | Inkjet | 100um width, 200um electrode spacing | [135] | ||

TFT | Inkjet | < 25 μΩ.cm | 2um width, 1um source–drain electrode spacing, 300 nm thickness | [136] | |

TFT | Gravure | 10um source–drain electrode spacing | [133] | ||

Cu | TFT | Inkjet | 7 μΩ.cm | Width 200um | [139] |

TFT | Inkjet | 12.9 ± 0.2 Ω.cm | 30–350um length, 70um width, 3000um source–drain electrode spacing | [140] | |

Electrochemical sensor | Screen | 3 mm diameter | [141] | ||

Pt | pH sensor | Inkjet | 5.6 ± 0.1 Ω.sq−1 | 300 × 300μm2 | [143] |

Au | Bio-electronic interfacing | Inkjet | 5 × 106 S.m−1 | 62um minimum feature size, 2–7 mm electrode–electrode spacing | [143] |

Extracellular recording of cardiomyocytes | Inkjet | 75 ± 18 Ω.sq−1 | 31um minimum diameter, 200um electrode–electrode spacing | [147] | |

DNA detection sensor | Screen | 1.00 ± 0.05 mm (∼0.785mm2) Diameter | [148] | ||

DNA detection sensor | Screen | 12.6 mm2 diameter | [149] | ||

TFT | Screen | 1.0 × 105. S.cm−1 | 90–400um length, 2000–5000um, width | [150] | |

Graphene | Large area flexible electronics | Gravure | ∼10,000 S.m−1 | ~ 30um width and 100–200 nm thickness | [210] |

Electrode | Inkjet | 4 mΩ·cm | 60um line width, thickness of one printed layer ~ 14 nm | [163] | |

Electrode | Screen | 30 Ω.sq−1 | 40um width25um thick | [174] | |

TFT, Electrode | Screen | 1.86 × 104.S.m−1 | 40um line width | [173] | |

For opto-electronic applications | Inkjet | 4 × 104 S.m−1 | thickness of one printed layer ~ 18 nm | [182] | |

Graphene oxide | Circuits | Screen | 327 Ω.sq−1 | 1.6 × 1.6 cm | [180] |

MWNT | Electrodes | Inkjet | 30 S.cm−1 | Thickness 50 nm | [183] |

Electrodes | Screen | 0.5–13 Ω.sq−1 | Thickness 20–25 μm | [186] | |

SWCNT | Electrodes | Inkjet | 1 print layers − 169.76 Ω.sq−15 print layers − 19.08 Ω.sq−1 | Line width 0.1 × 3.0cm2 and square pads (0.5 × 0.5 cm2) | [184] |

Electrodes | Inkjet | ~ 40,000 Ω.sq−1 (multiple prints) | 36-mm long and 2.5-mm wide | [185] | |

PEDOT:PSS | Electrodes | Inkjet | Thickness of film: 85 ± 5, 170 ± 5, and 280 ± 5 nm, for one, two and three printed layers | [214] | |

TFT, Electrodes | Inkjet | 449–93 Ω.sq −1 | 1 × 1 cm2 area, 105 to 525 nm thickness. Transistor has channel length 60um, width 1050um | [215] | |

Passive electronic components | Inkjet | 4.35 kΩ | Gap between electrodes 400 um and 800um | [216] | |

Transistor | Aerosol | 40um wide | [217] | ||

Thin film | Gravure | [218] | |||

Neural probe and high-density circuits | 3D | 155 S.cm−1 | 30 mm length and 5 mm width, thickness 17um | [196] | |

Interconnects and circuits | Inkjet | 700 S.cm−1/75 Ω.sq−1 | Length 1 cm | [219] | |

PEDOT:PSS + MWNT composite | u-needle for recording extracellular signals from cardiomyocyte HL-1 cells | Inkjet + Aerosol | 323 ± 75 S.m−1 | 10 ± 2um diameter33 ± 4um height | [220] |

PANI | Chemical and biosensing | Inkjet | 0.4 mS.cm−1 | 1 cm2 (20 prints) | [203] |

Ammonia gas sensor | Inkjet | 200um wide lines and 1500um line spaced inter-digited structure | [223] | ||

pH sensor | Screen | 0.4 mm wide, 3.6 mm long lines with 0.4 mm line spaced inter-digited structure | [224] | ||

PPy | Vapor sensor | Inkjet | 1 × 106 Ω.cm | Array of sensing device with each device measuring 10 mm × 4 mm, thickness of film 30um | [225] |

Carbondioxide gas sensor | Screen | 19.9 × 1010 ΩFor PPy-I and 17.9 × 1010 Ωfor PPy-II | 75 mm × 25 mm | [226] | |

ITO | Electrode | Inkjet | 517 Ω.sq−13 × 10−2 Ω.cm−1 | ~ 580 nm thick | [230] |