Abstract

WE43 magnesium alloy was modified using surface mechanical attrition treatment (SMAT) and characterized to evaluate the influence of sub-micron surface modification on degradation rate and in vitro behavior. Modified surface was characterized for wettability, hardness, roughness, degradation rate, in vitro biocompatibility, and antibacterial activity as per the ASTM standards. The treated substrates proved to have a significant decrease in the degradation profile by creating micro pockets of oxidation channels and reducing the total delamination in comparison to the conventional heterogeneous oxide layer formed on the untreated substrate surface. Biocompatibility studies showed that this modification did not induce any toxicity to human fetal osteoblast (hFOB) cells as demonstrated by cell proliferation and enhanced calcium deposition. In fact, results showed that between the 7th day and 14th day of culture, there was an eight time increase in calcium deposition for the surface-treated magnesium alloy. Bacterial adhesion and toxicity studies were carried out using Staphylococcus aureus and methicillin-resistant Staphylococcus aureus. Bacterial toxicity studies showed that both treated and control samples were toxic to the bacteria with more dead cells. Hence, this treatment has developed a highly potential orthopedic surface with decreased biodegradability rate of WE43 and simultaneously enhanced antibacterial properties with good osteoblast cell growth and calcium deposition for faster in vitro bone growth.

Similar content being viewed by others

Data availability

Data will be made available on reasonable request.

References

Gupta M, Wong WLE. Magnesium-based nanocomposites: lightweight materials of the future. Mater Charact. 2015;105:30–46. https://doi.org/10.1016/j.matchar.2015.04.015.

Falcon-Franco L, Rosales I, García-Villarreal S, Curiel FF, Arizmendi-Morquecho A. Synthesis of magnesium metallic matrix composites and the evaluation of aluminum nitride addition effect. J Alloy Compd. 2016;663:407–12. https://doi.org/10.1016/J.JALLCOM.2015.12.078.

Alfrey AC, Miller NL, Butkus D. Evaluation of body magnesium stores. J Lab Clin Med. 1974;84:153–62. https://doi.org/10.5555/uri:pii:0022214374901930.

Sezer N, Evis Z, Kayhan SM, Tahmasebifar A, Koç M. Review of magnesium-based biomaterials and their applications. J Magne Alloys. 2018;6:23–43. https://doi.org/10.1016/j.jma.2018.02.003.

Zeng R, Dietzel W, Witte F, Hort N, Blawert C. Progress and challenge for magnesium alloys as biomaterials. Adv Eng Mater. 2008;10:3–14. https://doi.org/10.1002/adem.200800035.

Witte F. Reprint of: The history of biodegradable magnesium implants: a review. Acta Biomater. 2015;23:S28–40. https://doi.org/10.1016/j.actbio.2015.07.017.

Song G, Atrens A, Wu X, Zhang B. Corrosion behaviour of AZ21, AZ501 and AZ91 in sodium chloride. Corros Sci. 1998;40:1769–91. https://doi.org/10.1016/S0010-938X(98)00078-X.

Gu X, Zheng Y, Cheng Y, Zhong S, Xi T. In vitro corrosion and biocompatibility of binary magnesium alloys. Biomaterials. 2009;30:484–98. https://doi.org/10.1016/j.biomaterials.2008.10.021.

Witte F, Fischer J, Nellesen J, Vogt C, Vogt J, Donath T, Beckmann F. In vivo corrosion and corrosion protection of magnesium alloy LAE442. Acta Biomater. 2010;6:1792–9. https://doi.org/10.1016/j.actbio.2009.10.012.

Gill P, Munroe N. Review on magnesium alloys as biodegradable implant materials. Int J Biomed Eng Technol. 2014;10:383–98. https://doi.org/10.1504/IJBET.2012.052400.

Yamashita A, Horita Z, Langdon TG. Improving the mechanical properties of magnesium and a magnesium alloy through severe plastic deformation. 2001;300:142–147. https://doi.org/10.1016/S0921-5093(00)01660-9.

Nayak S, Bhushan B, Jayaganthan R, Gopinath P. Strengthening of Mg based alloy through grain refinement for orthopaedic application. J Mech Behav Biomed Mater. 2016;59:57–70. https://doi.org/10.1016/j.jmbbm.2015.12.010.

O’ptHoog C, Birbilis N, Estrin Y. Corrosion of pure Mg as a function of grain size and processing route. Adv Eng Mater. 2008;10:579–82.

Ning J, Xu B, Sun MS, Zhao C, Feng Y, Tong W. Strain hardening and tensile behaviors of gradient structure Mg alloys with different orientation relationships. Mater Sci Eng A. 2018;735:275–87. https://doi.org/10.1016/j.msea.2018.08.053.

Wang H, Estrin Y, Zúberová Z. Bio-corrosion of a magnesium alloy with different processing histories. 2008;62:2476–2479. https://doi.org/10.1016/j.matlet.2007.12.052.

Gray-Munro JE, Seguin C, Strong M. Influence of surface modification on the in vitro corrosion rate of magnesium alloy AZ31. J Biomed Mater Res Part A. 2009;91:221–30. https://doi.org/10.1002/JBM.A.32205.

Sheikh Z, Najeeb S, Khurshid Z, Verma V, Rashid H, Glogauer M. Biodegradable materials for bone repair and tissue engineering applications. Materials. 2015;8:5744. https://doi.org/10.3390/MA8095273.

Feyerabend F, Fischer J, Holtz J, Witte F, Willumeit R, Drücker H, Vogt C, Hort N. Evaluation of short-term effects of rare earth and other elements used in magnesium alloys on primary cells and cell lines. Acta Biomater. 2010;6:1834–42. https://doi.org/10.1016/j.actbio.2009.09.024.

Jamesh M, Kumar S, Sankara Narayanan TSN. Electrodeposition of hydroxyapatite coating on magnesium for biomedical applications. J Coat Technol Res. 2012;9:495–502. https://doi.org/10.1007/s11998-011-9382-6.

Sankar M, Suwas S, Balasubramanian S, Manivasagam G. Comparison of electrochemical behavior of hydroxyapatite coated onto WE43 Mg alloy by electrophoretic and pulsed laser deposition. Surf Coat Technol. 2017;309:840–8. https://doi.org/10.1016/j.surfcoat.2016.10.077.

Huan ZG, Leeflang MA, Zhou J, Fratila-Apachitei LE, Duszczyk J. In vitro degradation behavior and cytocompatibility of Mg-Zn-Zr alloys. J Mater Sci Mater Med. 2010;21:2623–35. https://doi.org/10.1007/s10856-010-4111-8.

Song Y, Zhang S, Li J, Zhao C, Zhang X. Electrodeposition of Ca-P coatings on biodegradable Mg alloy: In vitro biomineralization behavior. Acta Biomater. 2010;6:1736–42. https://doi.org/10.1016/j.actbio.2009.12.020.

Wang HX, Guan SK, Wang X, Ren CX, Wang LG. In vitro degradation and mechanical integrity of Mg-Zn-Ca alloy coated with Ca-deficient hydroxyapatite by the pulse electrodeposition process. Acta Biomater. 2010;6:1743–8. https://doi.org/10.1016/j.actbio.2009.12.009.

Gopi D, Murugan N, Ramya S, Kavitha L. Electrodeposition of a porous strontium-substituted hydroxyapatite/zinc oxide duplex layer on AZ91 magnesium alloy for orthopedic applications. J Mater Chem B. 2014;2:5531–40. https://doi.org/10.1039/c4tb00960f.

Dunne CF, Levy GK, Hakimi O, Aghion E, Twomey B, Stanton KT. Corrosion behaviour of biodegradable magnesium alloys with hydroxyapatite coatings. Surf Coat Technol. 2016;289:37–44. https://doi.org/10.1016/j.surfcoat.2016.01.045.

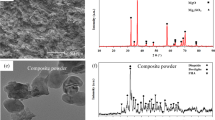

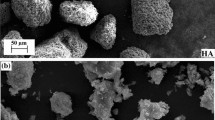

Du H, An Y, Zhang X, Wei Y, Hou L, Liu B, Liu H, Zhang J, Wang N, Umar A, Guo Z. Hydroxyapatite (HA) modified nanocoating enhancement on AZ31 Mg alloy by combined surface mechanical attrition treatment and electrochemical deposition approach. J Nanosci Nanotechnol. 2018;19:810–8. https://doi.org/10.1166/jnn.2019.15746.

Benafia S, Retraint D, YapiBrou S, Panicaud B, GrosseauPoussard JL. Influence of surface mechanical attrition treatment on the oxidation behaviour of 316L stainless steel. Corros Sci. 2018;136:188–200. https://doi.org/10.1016/j.corsci.2018.03.007.

Meng X, Duan M, Luo L, Zhan D, Jin B, Jin Y, Rao X-x, Liu Y, Lu J. The deformation behavior of AZ31 Mg alloy with surface mechanical attrition treatment. Mater Sci Eng A. 2017;707:636–46. https://doi.org/10.1016/j.msea.2017.09.094.

Peng J, Zhang Z, Guo P, Liu Z, Li Y, Zhou W, Wu Y. The effect of surface mechanical attrition treatment on texture evolution and mechanical properties of AZ31 magnesium alloy. Mater Charact. 2019;148:26–34. https://doi.org/10.1016/j.matchar.2018.11.031.

Balusamy T, Sankara Narayanan TSN, Ravichandran K, Park IS, Lee MH. Influence of surface mechanical attrition treatment (SMAT) on the corrosion behaviour of AISI 304 stainless steel. Corros Sci. 2013;74:332–44. https://doi.org/10.1016/j.corsci.2013.04.056.

Avadhani GS, Tapase S, Suwas S. Hot deformation processing and texture in magnesium alloy WE43, in: IFAC Proceedings Volumes (IFAC-PapersOnline), 2013: pp. 208–213. https://doi.org/10.3182/20130825-4-US-2038.00037.

Suresh KS, Gurao NP, Satyaveer Singh D, Suwas S, Chattopadhyay K, Zherebtsov SV, Salishchev GA. Effect of equal channel angular pressing on grain refinement and texture evolution in a biomedical alloy Ti\13Nb\13Zr. Mater Charact. 2013;82:73–85. https://doi.org/10.1016/j.matchar.2013.05.003.

Vishnu J, Manivasagam VK, Gopal V, Bartomeu Garcia C, Hameed P, Manivasagam G, Webster TJ. Hydrothermal treatment of etched titanium: a potential surface nano-modification technique for enhanced biocompatibility. Nanomed: NBM. 2019;20. https://doi.org/10.1016/j.nano.2019.102016.

Manivasagam VK, Popat KC. Hydrothermally treated titanium surfaces for enhanced osteogenic differentiation of adipose derived stem cells. Mat Sci Eng C. 2021:112315. https://doi.org/10.1016/J.MSEC.2021.112315.

Manivasagam VK, Popat KC. In vitro investigation of hemocompatibility of hydrothermally treated titanium and titanium alloy surfaces. ACS Omega. 2020. https://doi.org/10.1021/acsomega.0c00281.

Damiati L, Eales MG, Nobbs AH, Su B, Tsimbouri PM, Salmeron-Sanchez M, Dalby MJ. Impact of surface topography and coating on osteogenesis and bacterial attachment on titanium implants. J Tissue Eng. 2018;9. https://doi.org/10.1177/2041731418790694.

Manivasagam VK, Sabino RM, Kantam Prem, Popat KC. Surface modification strategies to improve titanium hemocompatibility: a comprehensive review. Mater Adv. 2021. https://doi.org/10.1039/D1MA00367D.

Hameed P, Manivasagam VK, Sankar M, Popat KC, Manivasagam G. Nanofibers and nanosurfaces, In: Springer Series in Biomaterials Science and Engineering, Springer Science and Business Media Deutschland GmbH;2021. pp. 107–130. https://doi.org/10.1007/978-981-33-6252-9_4.

Kokubo T, Takadama H. How useful is SBF in predicting in vivo bone bioactivity? Biomaterials. 2006;27:2907–15. https://doi.org/10.1016/j.biomaterials.2006.01.017.

Wei Yh, Liu Bs, Hou Lf, Xu Bs, Liu G. Characterization and properties of nanocrystalline surface layer in Mg alloy induced by surface mechanical attrition treatment. J Alloys Compd. 2008;452:336–42. https://doi.org/10.1016/J.JALLCOM.2006.11.079.

Zheng T, Hu Y, Pan F, Zhang Y, Tang A. Fabrication of corrosion-resistant superhydrophobic coating on magnesium alloy by one-step electrodeposition method. J Magne Alloys. 2019;7:193–202. https://doi.org/10.1016/J.JMA.2019.05.006.

Sun X, Cao ZY, Liu JG, Feng C. Security assessment of magnesium alloys used as biodegradable implant material. Bio-Med Mater Eng. 2015;26:S119–27. https://doi.org/10.3233/BME-151297.

Iwamoto T, Hieda Y, Kogai Y. Effect of hydroxyapatite surface morphology on cell adhesion. Mater Sci Eng C. 2016;69:1263–7. https://doi.org/10.1016/j.msec.2016.07.056.

Denchai A, Tartarini D, Mele E. Cellular response to surface morphology: electrospinning and computational modeling. Front Bioeng Biotechnol. 2018;6. https://doi.org/10.3389/fbioe.2018.00155.

Yang C. The effect of calcium phosphate implant coating on osteoconduction. Oral Surg Oral Med Oral Pathol Oral Radiol Endod. 2001;92:606–9. https://doi.org/10.1067/moe.2001.118477.

Alqhtani NR, Logan NJ, Meghji S, Leeson R, Brett PM. Low dose effect of bisphosphonates on hMSCs osteogenic response to titanium surface in vitro. Bone Reports. 2017;6:64–9. https://doi.org/10.1016/j.bonr.2017.02.002.

Poh CK, Shi Z, Tan XW, Liang ZC, Foo XM, Tan HC, Neoh KG, Wang W. Cobalt chromium alloy with immobilized BMP peptide for enhanced bone growth. J Orthop Res. 2011;29:1424–30. https://doi.org/10.1002/jor.21409.

Stewart C, Akhavan B, Wise SG, Bilek MMM. A review of biomimetic surface functionalization for bone-integrating orthopedic implants: mechanisms, current approaches, and future directions. Prog Mater Sci. 2019;106:100588. https://doi.org/10.1016/J.PMATSCI.2019.100588.

Mariani E, Lisignoli G, Borzì RM, Pulsatelli L. Biomaterials: foreign bodies or tuners for the immune response? Int J Mol Sci. 2019;20:636. https://doi.org/10.3390/IJMS20030636.

Bahl S, Shreyas P, Trishul MA, Suwas S, Chatterjee K. Enhancing the mechanical and biological performance of a metallic biomaterial for orthopedic applications through changes in the surface oxide layer by nanocrystalline surface modification. Nanoscale. 2015;7:7704–16. https://doi.org/10.1039/C5NR00574D.

Rajamaki K, Nordström T, Nurmi K, Åkerman KE, Kovanen PT, Ööeni K, Eklund KK. Extracellular acidosis is a novel danger signal alerting innate immunity via the NLRP3 inflammasome. J Biol Chem. 2013;288:13410–9. https://doi.org/10.1074/JBC.M112.426254.

Riemann A, Ihling A, Thomas J, Schneidr B, Thews O, Gekle M. Acidic environment activates inflammatory programs in fibroblasts via a cAMP-MAPK pathway. Biochim Biophys Acta. 1853;2015:299–307. https://doi.org/10.1016/J.BBAMCR.2014.11.022.

Torroni A, Xiang C, Witek L, Rodriguez ED, Coelho PG, Gupta N. Biocompatibility and degradation properties of WE43 Mg alloys with and without heat treatment: in vivo evaluation and comparison in a cranial bone sheep model. Journal of Cranio-Maxillofacial Surgery. 2017;45:2075–83. https://doi.org/10.1016/j.jcms.2017.09.016.

Ribeiro M, Monteiro FJ, Ferraz MP. Infection of orthopedic implants with emphasis on bacterial adhesion process and techniques used in studying bacterial-material interactions. Biomatter. 2012;2:176–94. https://doi.org/10.4161/biom.22905.

Manivasagam VK, Perumal G, Arora HS, Popat KC. Enhanced antibacterial properties on superhydrophobic micro-nano structured titanium surface. J Biomed Mater Res A. 2022. https://doi.org/10.1002/JBM.A.37375.

Wolk DM, Struelens MJ, Pancholi P, Davis T, Della-Latta P, Fuller D, Picton E, Dickenson R, Denis O, Johnson D, Chapin K. Rapid detection of Staphylococcus aureus and methicillin-resistant S. aureus (MRSA) in wound specimens and blood cultures: multicenter preclinical evaluation of the cepheid Xpert MRSA/SA skin and soft tissue and blood culture assays. J Clin Microbiol. 2009;47:823–6. https://doi.org/10.1128/JCM.01884-08.

Hedin G, Fang H. Evaluation of two new chromogenic media, CHROMagar MRSA and S. aureus ID, for identifying Staphylococcus aureus and screening methicillin-resistant S. aureus. J Clin Microbiol. 2005;43:4242–4. https://doi.org/10.1128/JCM.43.8.4242-4244.2005.

Acknowledgements

The authors would like to thank everyone in the Webster Nanomedicine Lab, specifically Nicole Bassous, Kanny Chang, and Zelong Xie. The authors Geetha Manivasagam and Magesh Sankar would like to thank Sumit Bahl and Srijan Acharya from the Indian Institute of Science for their help with the SMAT equipment.

Funding

This work was supported by Northeastern University and Vellore Institute of Technology.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Rights and permissions

About this article

Cite this article

Manivasagam, V.K., Sankar, M., Garcia, C.B. et al. Surface-modified WE43 magnesium alloys for reduced degradation and superior biocompatibility. In vitro models 1, 273–288 (2022). https://doi.org/10.1007/s44164-022-00016-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s44164-022-00016-x