Abstract

This study explores the application of stone columns to improve the bearing capacity of sabkha soil for the construction of a Lattice Communication Tower foundation in the Eastern Province of Saudi Arabia. Geotechnical investigation report, an on-site footing loading test to evaluate the foundation's bearing capacity and settlement behavior following stone column installation, and post-cone penetration tests (CPT) to assess soil densification are all part of the study data. The uppermost 4 m of the soil profile comprise a medium to dense layer of sand with silt, followed by a 12-m layer of weak sabkha soil (SPT, N less than 4). Below the sabkha layer, the strata exhibit varying densities, ranging from medium to dense and very dense layers, extending to the maximum depth of investigation. The comparison of Pre- and Post-CPT data revealed significant improvements in the sand and silt layer above the sabkha layer, as well as moderate improvements in the upper portion of the sabkha layer. However, the majority of the sabkha soils and underlying soil layers did not show significant improvement. Plaxis 3D numerical models were employed to provide insights into the performance of the composite area encompassing stone columns and the surrounding soil. Comparing field tests and numerical models showed that neglecting stone column installation effects in numerical models led to overestimating settlements. However, when examining the field data and numerical results with a raised coefficient of lateral earth pressure when of \({K}_{^\circ }=2\), a distinct alignment between settlement values consistent with those derived from field testing. The findings highlight the importance of including site-specific conditions and installation effects in numerical modeling to accurately predict the behavior of stone columns in sabkha soils.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

This research utilized soil improvement data to build a 90-m-high Lattice Radio Communication Tower at a Gas Complex in Saudi Arabia's Eastern Province. Radio communications are critical for day-to-day operations and emergency response measures for plant employees. The gas plant is in an area characterized by the presence of sabkha deposits, and it is built on a wide recent backfill sand layer situated above sabkha soil. sabkha soil derives its name from an Arabic term that describes saline flats underlain by sand, silt, or clay, often encrusted with salt [1]. Sabkha soil, composed of multiple layers, has distinctive characteristics such as excessive differential settlement and reduced bearing capacity [1,2,3,4]. It also has a high potential for collapse due to salt dissolution from water absorption and leaching of calcium ions [2, 5]. Consequently, structures constructed on sabkha soil encounter various challenges, including excessive settlements and low bearing capacity, leading to an incapability to safely support applied loads.

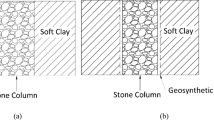

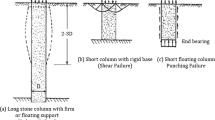

To address these issues, various ground improvement techniques have been employed to improve the sabkha soil, including the installation of stone columns. Stone columns are a cost-effective and environmentally friendly technique for improving used a lot to improve the weak soils[6]. These columns involve replacing soft soil with cylindrical columns made of compressed granular materials. The choice of granular materials and their proportions are carefully selected to ensure optimal performance. Stone column installation is achieved through two primary methods: Vibro- replacement and Vibro-compaction [7, 8]. Vibro-replacement is used to improve cohesive and cohesionless soils by creating cavities, introducing granular fill material, displacing soft soil laterally, and increasing load-bearing capacity[9]. Vibro-compaction is primarily used to improve cohesionless soils by causing densification of the soil mass and rearrangement of soil particles, reducing the void ratio, and increasing the relative density [9, 10]. In this case study, vibro-replacement is the preferred method for stone column installation. It offers several advantages, including being relatively low-cost compared to traditional ground improvement techniques and being known for its speed, enabling rapid progress in construction projects. This efficiency is particularly beneficial for projects with tight schedules or urgent requirements. Numerous studies conducted to date on the use of stone columns on various types of soft soil have demonstrated their effectiveness in enhancing bearing capacity and mitigating settlement issues [11,12,13,14,15,16,17]. However, little is known about the behavior of stone columns in sabkha soils, particularly in terms of installation effects and numerical modeling. Understanding the specific challenges and opportunities associated with stone column installation in sabkha soils is essential for successful and cost-effective soi improvement in these geological settings.

Stone columns on homogeneous soft clay are typically designed using simplified calculations derived from elasticity and plasticity theories. Presently, the same design approach is being applied for stone column design in sabkha soils, despite the distinct characteristics of soft clay soils and sabkha soils [17]. This approach does not consider the complexities associated with the presence of challenges related to the characteristics of sabkha soil. Consequently, there is a pressing need for a more comprehensive examination of the behavior of stone columns when encountering sabkha layers. In such cases, conducting field static load tests and numerical modeling emerge as the most effective methods for analyzing the complex behavior of stone columns and their interaction with various soil layers. Through numerical analysis, it is possible to investigate in detail how the installation of stone columns will affect the surrounding soils and how stone columns will behave as they cross multiple soil layers with varying properties, including the unique challenges presented by sabkha soil. This method provides valuable insights into the load transfer mechanisms, settlement characteristics, and overall performance of composite soil systems consisting of stone columns and existing soil. Conducting field static load tests on composite soil systems is an effective method for validating the accuracy of the numerical model and design assumptions utilized in the design of stone columns for specific site conditions.

In this study, a comprehensive investigation was conducted to examine the efficiency of stone column improvement techniques in enhancing the bearing capacity and settlement behavior of sabkha soil. An on-site footing loading test was achieved to validate the bearing capacity and ensure that the desired settlement criteria were met following the installation of stone columns using the Vibro-Replacement Top Feet method. In addition, Pre- and Post-Cone Penetration Test (CPT) assessments were carried out to evaluate the state of the neighboring soils before and after the installation of the stone columns. The approach of raising the coefficient of lateral earth stress to replicate the effect of stone column installation on the surrounding soil mass was used to model the installation effect of stone columns on surrounding soils. Comparisons were made between the settlement results of the field footing loading tests, numerical models that considering for the installation effect of the stone columns, and a numerical model that does not account for the installation effect of the stone columns.

2 Subsoil soil condition

The project's location is near a coastline with Aeolian dunes, which are made up of sand deposits mixed with silt, salt, and clay to create a loose soil type known as sabkha. A soil investigation program was carried out, with three boreholes drilled at appropriate locations and two Cone Penetration Tests (CPTs). Figure 1 shows a summary of the Standard Penetration Test (SPT) N-values, CPT test results, and subsurface strata identified in the boreholes. The uppermost 4 m consisted of a medium to dense layer of sand with silt, followed by a weak sabkha soil that extended for 12 m (SPT, N within this layer is less than 4). Beneath the sabkha layer, the density of the strata varied between medium, dense, and very dense layers, continuing to the maximum depth of investigation. Groundwater conditions were assessed 48 h after borehole drilling, and the natural groundwater table was found to be approximately 2.7 m below the ground surface in all boreholes.

3 Soil improvement

3.1 Installation of stone columns

The primary goal of the ground improvement work using stone columns is to achieve a design bearing capacity of 200 kPa for the foundation of the Lattice Radio Communication Tower. Geotechnical testing at the location determined that the bearing capacity of the native soil was between 85 and 145 kPa. To overcome this obstacle, the Vibro-replacement top feed-wet installation method was chosen for the project. The selection of the Vibro-replacement top feed-wet method followed a thorough comparative analysis of alternative soil improvement methods. This decision hinged on a set of well-defined criteria, including the site's specific characteristics, equipment availability, and previous experience with similar projects in adjacent areas.

The stone columns were implanted in a regular rectangle grid with center-to-center distances of 1.3 m by 1.3 m; each stone column had a diameter of 0.85 m. The effective length of the stone columns, extending beneath the mat foundation, was determined to be 15 m. In total, 169 stone columns were installed to achieve the desired ground improvement objectives. The Vibro-replacement Top- Feed technique entails the insertion of a vibrating probe into the weak soil, which creates a void space that is subsequently filled with the granular material. The vibration and push of the granular material laterally during installation are anticipated to assist in densifying the soil surrounding the stone columns. The increased bearing capacity provided by the stone columns is anticipated to reduce both total and differential settlements while ensuring that the maximum allowable uniform settlement of 25 mm is not exceeded.

3.2 Assessment of soil due to installation of stone columns

The CPT was used to assess ground conditions before and after the installation of stone columns. It provided valuable insight into changes in soil properties resulting from the stone column installation process. The Pre- and Post-CPT tip resistance testing outcomes are shown in Fig. 2. The analysis of this data is critical for evaluating ground improvement work and validating design assumptions. These results serve as an essential tool for assessing the degree of improvement in surrounding soils due to the installation process of stone columns and provide valuable input for numerical modeling in the study.

The Pre- and Post- CPT data show slight improvement in the first layer above the sabkha stratum after stone columns were implemented. However, some points show higher Pre-CPT values than post-CPT values. This could be due to the presence of a recent backfill approximately 2.5 m from the ground surface, compacted on-site during the construction of the Gas Complex Plant, which may exhibit higher pre-CPT values due to its denser state and improved engineering properties. Furthermore, the discrepancy between Pre-CPT and Post-CPT values could be attributed to soil structure arrangement disruption and loose of cemented bonding in some points during the wet vibro-replacement process [17].

However, a slight improvement is observed in the sabkha layer, particularly in the upper 1.5 m of the layer. According to geotechnical investigations, the sabkha soil in this region is composed of sandy silt with shell fragments. Another factor that may contribute to the improvement of this portion of the sabkha soils is the mixing of sand materials from the top layer caused by the installation process of the vibration prop techniques used in the installation of wet vibro-stone columns. This distinct composition could explain the observed improvement. The sandy nature of the sabkha soil, combined with the presence of a fine content of less than 20%, contributes to the enhanced behavior of the soil. Figure 3 depicts the passage from sieve # 200 with depth in all boreholes, indicating that up to 6 m is less than 20%. Field observations have shown that vibration techniques are ineffective in improving the density of soils when the fine content exceeds 20% [6]. This observation is supported by the findings of previous studies conducted by Hussin (1987) and Mackiewicz (2007), which concluded that vibration techniques have minimal impact when the fine materials reach around 12% [18, 19]. The soil beneath the sabkha layer is typically sand with silt, with Pre-CPT values increasing until refusal at 18–19 m. Post-CPT test results show a significant reduction in refusal depth by over 5 m, suggesting minor modifications due to stone column installation.

These observations highlight the complexity of the soil improvement process and the unique challenges posed by sabkha soil. The current method used to design stone columns in sabkha soils assumes that some improvements are occurring in the soil surrounding the depth of the stone columns; consequently, the evaluation of improvements occurring in the surrounding soils is crucial in this instance. The results demonstrate the significance of considering the unique characteristics of the sabkha soil and adapting the unique design procedure for stone columns accordingly.

To further clarify this concept, the method proposed by Massarsch (1991) is used in this study to assess the compactability of both sand with silt and sabkha soils when vibro-stone columns are installed [20]. Massarsch (1991) developed compactability criteria based on Pre-CPT data to assess the potential for soil compaction via vibratory methods. According to Massarsch (1991), soils can be classified into three categories based on their ability to be compacted: "Compactable," "Marginally Compactable," and "Not Compactable." By assessing the soil's compactability, it becomes possible to predict the extent to which the soil will compact after the installation of stone columns [20, 21].

Figures 4 and 5 show the relationship between the friction ratio and cone resistance for Pre-CPT Nos. 1 and 2. In the case of the upper sand and silt layer, a majority of data points fall into the compactable to marginally compactable range, while only a few falls into the not compactable range. This indicates that this soil layer could be effectively compacted through the installation of stone columns. Conversely, the majority of sabkha soil points fall within the not compactable range, while only a few pointes fall within the marginally compactable and compactable ranges. This indicates that the sabkha soil is less susceptible to compaction during the installation of stone columns. This evaluation's findings provide valuable insight into the densification of soil layers following the installation of stone columns, which could be used to facilitates the determination of the necessary parameters for designing stone columns.

3.3 Footing load tests

Footing load tests were performed to confirm the achievement of the requisite design capacity for the composite area, which included both the improved soils and the stone column. The concrete foundation used in the tests measured 2 m by 2 m and had a thickness of 0.6 m. A hydraulic jack was used in conjunction with a Kentledge platform made up of 120 tons of concrete blocks to impose the required load, as shown in Fig. 6. The applied pressure and accompanying settlement data were meticulously documented using pressure and displacement gauges. The applied pressure schedule, as shown in Table 1. Figure 7 depicts the relationship between applied pressure and associated settlement graphically. Notably, the greatest load applied during testing reached 300 kPa, which exceeded the acceptable bearing capacity by a factor of 1.5 in accordance with the design specifications. The test results indicate that the highest settlement observed was 2.44 mm, which is only 9.8% of the maximum allowable settlement of 25 mm. This displays the exceptional performance of the composite improvement region by presenting the minimal settling obtained under heavy load applications.

3.4 Numerical model

Using the PLAXIS 3D software, a numerical model was created to correctly model the field footing loading test and examine the behavior of the composite region. The model was carefully created to replicate the actual test's geometry, load application, soil layer properties, and stone column characteristics. To mitigate the impact of model boundaries on the analysis results, the numerical model was expanded to 12 m by 12 m. This extension served to mitigate the influence of the model's boundaries on the analysis results by creating a sufficient buffer zone around the area of applied loading and mitigating boundary effects. The height of the numerical model was set to 30 m to prevent undesired deformations at the bottom of the model. This specific height was determined through a series of experimental models in which a variety of heights were evaluated to determine the optimal value. In terms of finite element discretization, the numerical model utilized wedge elements with 15 nodes. To capture the localized effects, a very fine mesh was used for the stone column and the area around it, while a fine mesh was used for the remaining area. Figure 8 depicts the overall geometry of the numerical model, including the footing, soil strata, and stone column.

3.5 Modelling of stone columns

The Mohr–Coulomb model, in combination with the full drain assumption, was used in the numerical model to accurately represent the behavior of the stone columns. The selection of the full drain assumption is supported by the high permeability of the crushed stone used to construct the stone columns [22]. This assumption permits the unrestricted dissipation of excess pore water pressure during loading within the stone column [17].

The parameters governing the behavior of the stone columns were estimated using a combination of previous research results and the Project Geotechnical Design Report. The elastic modulus and Poisson's ratio of the stone columns were derived from the work of done by Hassan (2015) [22], which examined the behavior of stone columns under a water storage tank constructed on medium compacted sand followed by weak sabkha soils. The elastic modulus value used in this study was \(=80 MN/{m}^{2}\), which is similar to the conditions modeled in this case study. The angle of internal friction for the stone columns was chosen to be 42°. The dilatancy angle of the stone columns was estimated using the empirical equation presented by Bolton [23], which relates the dilatancy angle (ψ) to the angle of internal friction (ϕ) as shown in equation No. 1.

In the numerical model, no interface element was used between the stone columns and the surrounding soil. The observation that the crushed stone and the surrounding soil at the edge of stone columns tend to blend during the installation process, resulting in a cohesive interface, supported this choice. Therefore, it was deemed acceptable to consider the stone column and the surrounding soil as composite materials without requiring a distinct interface element. The specific material parameters of the stone column utilized in the numerical model, including elastic modulus, Poisson's ratio, angle of internal friction, and dilatancy angle, are summarized in Table 2.

3.6 Modelling of concrete footing

The precast concrete footing was numerically modeled using a linear elastic, non-porous material model. The loading was implemented in the FEM as a uniformly distributed pressure, simulating the actual field test pressure values. As the applied pressure on the footing is vertical, no interface elements were used to simulate the interface between the rigid precast concrete and the underlying soil surface. This means no relative lateral movement is permitted between the concrete and the soil below it [22, 24,25,26]. Table 2 presents the concrete parameters used in the analysis, which define the mechanical properties of the concrete material.

3.7 Modelling of soil surrounding stone columns

The rate of improvement in the soil surrounding stone columns is a significant factor to consider when assessing the behavior of composite regions that involve stone columns and surrounding soils. The installation process of stone columns, particularly Vibro Top- Feed installation, can have different impacts on various soil types. Some soils exhibit a discernible improvement in their properties as a result of the actions associated with stone column installation, whereas others may not experience a significant improvement [17].

In this study, two different numerical models were used to describe the complex behavior of the soil-stone columns interaction. The first model was created without consideration of the stone column installation effects. The goal of this model was to explore the baseline behavior and offer a reference for comparison. The second model was developed specifically to integrate the stone column installation effects. This model attempted to represent the changes in the surrounding soil caused by the installation process. A comprehensive understanding of how the process of installing stone columns contributes to total soil improvement might be managed by comparing the results of both models and the field footing loading test.

3.8 Numerical model without stone column installation effect

This section focuses on the numerical modeling of the soil-structure system without considering the influence of stone column installation on neighboring soils. The soil profile of the model's layers is displayed in Fig. 1, providing a visual representation of the various soil strata encountered at the site. Various soil parameters were extracted from the Project Geotechnical Investigation Report, including SPT, CPT, and laboratory experiments conducted prior to the installation of stone columns. Table 3 provides a summary of the soil parameters derived from these tests, which serve as inputs for the numerical model.

3.9 Modeling of stone column with installation effects

The comparison of Pre- and Post- CPT data values clearly shows that there are certain improvements occurring in the sand layer above the sabkha soil and slight improvements occurring in the upper part of the sabkha. Modeling stone columns correctly requires considering the impact of this improvement on soil conditions. Numerous researchers have proposed various approaches to modeling this improvement in soft clay, with increasing the coefficient of lateral earth pressure approach [27,28,29,30] being one of the most commonly used methods. This method was utilized in this study to simulate the implementation effects of stone columns. This method involved manually increasing the coefficient of lateral earth stress (\({K}_{^\circ }\)) for the soil layers surrounding the stone columns. The \({K}_{^\circ }\) values were progressively increased by 1 increment. Increasing values of \({K}_{^\circ }\) result in an increase in horizontal stress around stone columns. It is essential to note that this enhancement was only applied to the soil layers that exhibited observable improvement, as demonstrated by the Pre- and Post- CPT results.

3.10 Construction stags

The construction stages were meticulously replicated during the modeling process to correctly simulate the sequential activities that take place during the installation of stone columns and footing load tests. This method in the Plaxis 3D software enabled the activation or deactivation of specific components as well as the modification of geometrical configurations and soil parameters, thereby depicting the realistic process of construction stages. Figure 9 shows a flowchart of the numerical model's construction steps.

4 Result and discussion of numerical model

The study concluded with a comprehensive comparison between numerical modeling results and field test results to evaluate the proposed FEM. This thorough analysis aimed to determine the areas of concordance and disparities. The discussion investigated the exploration of potential factors contributing to variations observed between the model and field test results. Furthermore, the adopted numerical model was used to investigate specific performance aspects of both the stone columns and the surrounding soil, aspects that remained unobservable through conventional field-testing methods.

4.1 Comparison between field and numerical settlement

Load-settlement curves from the footing load test were compared to those obtained through numerical simulations to analyze the differences between the numerical model with and without installation effects, as shown in Fig. 10. In the model without installation effects, the settlement curve exhibited a considerably higher value at a maximum pressure of \(300 kN/{m}^{2}\), reaching 5.449 mm. This value was nearly three times greater than the field test measurement of 2.44 mm. This considerable variance clearly highlights that ignoring the installation effect in the numerical model leads to a substantial overestimation of stone column settlements. It is evident that the integration of the installation effect is imperative for achieving a more precise and realistic representation of stone column behavior in the model.

The approach of increasing the coefficient of lateral earth pressure (\({K}_{^\circ }\)) was used to address the installation effect of stone columns. The \({K}_{^\circ }\) values of the soil strata were increased manually, beginning with \({K}_{^\circ }=1\) and progressing to \({K}_{^\circ }=2\). This increase in \({K}_{^\circ }\) was only applied to soil layers that exhibited an improvement when comparing Pre- CPT and Post-CPT evaluations. Specifically, the sand with silt layer above sabkha soils that extends up to 4 m from the ground surface and to a portion of sabkha soil between 4 and 5.5 m. The value of \({K}_{^\circ }\) in remaining soil layers around stone columns stay unchanged. The comparison curves revealed that the numerical model's predicted settlement values closely match the measured settlement values from field footing tests. The maximum settlement measured in the field tests was 2.44 mm, whereas the numerical simulations predicted 2.585 mm. This slight difference of only 0.145 mm signifies a high degree of agreement between the numerical model and field footing tests, highlighting the effectiveness of integrating the installation effect into the modeling approach.

4.2 Settlement versus stone column depth

In the context of examining the settlement behavior of stone column systems, Fig. 11 illustrates a relationship between vertical settlement and the depth of stone columns. The profile was obtained by measuring the settlement beneath the concrete footing at the midpoint between the four stone columns involved in the loading test to a depth of 15 m, which is the maximum depth of a stone column. The graph displayed in Fig. 11 shows a substantial decrease in settlement as depth increases. The highest settlement values are observed at the surface, and they progressively decrease with increasing depth. When the depth reaches 11 m, the values for settlement are less than 0.5 mm. These findings can be used in the design desired depth of stone columns in sabkha soil conditions.

5 Conclusion

This manuscript offers an in-depth case study on the implementation of stone columns to improve the characteristics of sabkha soils. By conducting a thorough analysis of relevant data related to site soil conditions, foundation systems, construction procedures, field control criteria, footing load tests, and numerical studies, numerous valuable insights and conclusions were obtained. The conclusions resulting from this investigation are outlined below:

The footing load tests conducted on the composite foundation area, which comprises of natural soils and stone columns, have verified the attainment of the needed design capacity. The concrete footing exhibited a settlement of only 2.44 mm, well within the permissible limits, when subjected to a maximum load of 300 kPa. These findings highlight the reliability and efficacy of the stone column technique for ground improvement in mitigating settlements and ensuring the integrity of the foundations of the Lattice Communication Tower on sabkha soil.

The CPT tests conducted prior to and after the installation of stone columns provided valuable insight into the ground conditions and degree of soil improvement. The comparison of pre- and post-CPT data revealed significant improvements in the sand and silt layer above the sabkha and a slight improvement in the upper portion of the sabkha layer. This illustrates that the installation of Vibro-stone columns can result in significant improvements in the topsoil layer only in the situation of sabkha existing beneath the sand layer, and most sabkha soils and layers beneath it have not improved due to vibration. The findings must be considered while designing stone columns.

The study also revealed that the FEM, without considering the installation effects of stone columns, overestimated settlement values compared to field footing load test measurements. This emphasizes the need of considering the installation effect of stone columns while modeling the performance of stone column in sabkha soil. Additionally, when examining the field data and numerical results with a raised coefficient of lateral earth pressure (\({K}_{^\circ }\)) of \({K}_{^\circ }=2\), a distinct alignment between settlement values consistent with those derived from field testing. This increase in \({K}_{^\circ }\) was only applied to soil layers that exhibited an improvement when comparing Pre- CPT and Post-CPT evaluations.

In conclusion, the successful verification of design capacity through footing load tests indicates the reliability of stone columns in mitigating settlements, particularly for structures such as the Lattice Communication Tower on sabkha soil. CPT tests emphasize the selective effectiveness of Vibro-stone columns in improving specific soil layers. The study stresses the importance of considering installation effects in numerical modeling, addressing the overestimation of settlements without this consideration.

Further investigation could examine the long-term performance and durability of stone columns in sabkha soils, considering factors such as cyclic loading and environmental effects. Additionally, exploring advanced numerical modeling techniques that capture intricate installation effects and soil-structure interactions could enhance the accuracy of predictions of the installation effect of stone columns on the surrounding soil layers.

Availability of data and materials

The data and materials for this manuscript have been included and any other data will be available upon request.

References

Abduljauwad SN, Al-Amoudi OSB (1995) Geotechnical behaviour of saline sabkha soils. Geotechnique 45(3):425–445

Al-Amoudi OSB, Abduljauwad SN (1995) Compressibility and collapse characteristics of arid saline sabkha soils. Eng Geol 39(3–4):185–202

Jung C, Ceglarek R, Clauvelin T, Ayeldeen M, Kim D (2020) Deep soil mixing in Sabkha soils for foundation support in United Arab Emirates. Int J Geosynth Ground Eng 6(1):3

Elsawy MB, Lakhouit A (2021) Geotechnical behaviour of sandy sabkha soils based on experimental and numerical investigations. Indian Geotech J. https://doi.org/10.1007/s40098-021-00555-2

Al-Otaibi FA (2023) Effects of long-term soaking on the load-bearing capacity of Bitumen-treated Saline Sabkha soil subgrade. J Eng Res TJER 20(2):23–32

Saleh S (2021) Improving bearing capacity of weak soils: a review. J Constr Res. https://doi.org/10.30564/jcr.v3i1.3262

Raju VR, Sondermann W 2005 “Ground improvement using deep vibro techniques,” in Elsevier Geo-Engineering Book Series, vol. 3, Elsevier, , pp. 601–638

Egan D, Scott W, McCabe BA (2008) Installation effects of vibro replacement stone columns in soft clay. In: Karstunen M, Leoni M (eds) Proceedings of the 2nd International workshop on the geotechnics of soft soils. Taylor & Francis, Glasgow, pp 23–30

. Barksdale RD, Bachus RC (1983) “Design and construction of stone columns volume II, appendixes,” United States. Federal Highway Administration. Office of Engineering and

SoleimaniFard H, Köhler T, Haris A (2021) “Ground improvement with vibro compaction method to mitigate the liquefaction potential, case study”, in ground improvement techniques. In: Sitharam TG, Parthasarathy CR, Kolathayar S (eds) In Lecture Notes in Civil Engineering. Springer Singapore, Singapore, pp 257–273

McCabe BA, Nimmons GJ, Egan D (2009) A review of field performance of stone columns in soft soils. Proc Inst Civ Eng-Geotech Eng 162(6):323–334

Al-Ani W, Wanatowski D, Chan SH, Serridge CJ (2015) “Numerical modelling of stone columns in soft soils,”

Etezad M, Hanna AM, Ayadat T (2015) Bearing capacity of a group of stone columns in soft soil. Int J Geomech 15(2):04014043

Chandrawanshi S, Kumar R (2021) “Settlement behaviour of very soft soil reinforced with stone columns. In: Patel S, Solanki CH et al (eds) Proceeding of the Indian Geotechnical Conference. Springer, Springer Singapore, pp 345–355

Grizi A, Al-Ani W, Wanatowski D (2022) Numerical analysis of the settlement behavior of soft soil improved with stone columns. Appl Sci 12(11):5293

Hamzh A, Mohamad H, Bin Yusof MF (2022) The effect of stone column geometry on soft soil bearing capacity. Int J Geotech En 16(2):200–210. https://doi.org/10.1080/19386362.2019.1666557

Idrus J, Shien NK, Nujid MM, Abdullah N, “A review of stone columns performance in soft soils,” in AIP Conference Proceedings, AIP Publishing, 2023. Accessed: Nov. 13, 2023. [Online]. Available: https://pubs.aip.org/aip/acp/article-abstract/2688/1/040003/2890290

Hussin JD, Ali S (1987) “Soil improvement at the Trident submarine facility,” in Soil Improvement: A Ten Year Update, ASCE, pp. 215–231.

. Mackiewicz SM and Camp III (2007) “Ground modification: how much improvement?,” in Soil Improvement, pp. 1–9

. Massarsch KR (1991) Deep soil compaction using vibratory probes. ASTM International

Massarsch KR, Fellenius BH (2005) Deep vibratory compaction of granular soils. Elseiv Geo-Eng Book Ser 3:539–561

T. Weber, S. M. Springman, M. Gäb, V. Racansky, and H. F. Schweiger, 2008 “Numerical modelling of stone columns in soft clay under an embankment,”In: M Karstunen, M Leoni (eds) Geotechnics of Soft Soils: Focus on Ground Improvement: Proceedings of the 2nd International Workshop held in Glasgow, Scotland, Taylor & Francis

Bolton MD (1986) The strength and dilatancy of sands. Geotechnique 36(1):65–78

Abas HA (2015) “Performance and Design Optimization of Stone Column in Sabkha Soils,” PhD Thesis, King Fahd University of Petroleum and Minerals (Saudi Arabia),

Gäb M, Schweiger HF, Kamrat-Pietraszewska D, Karstunen M (2008) Numerical analysis of a floating stone column foundation using different constitutive models. In: Karstunen M, Leoni M (eds) Geotechnics of soft soils: focus on ground improvement. CRC Press, UK, pp 149–154

Abbas HA (2019) Numerical model of stone column in sabkha soil. Int Res J Innov Eng Technol IRJIET 3(9):8–11

Choobbasti A, Zahmatkesh A, Noorzad R (2011) Performance of stone columns in soft clay: numerical evaluation. Geotech Geol Eng 29(5):675–684

Al Ammari K, Clarke BG (2018) Effect of vibro stone column installation on the performance of reinforced soil. J Geotech Geoenviron Eng. https://doi.org/10.1061/(ASCE)GT.1943-5606.0001914

Castro J, Karstunen M (2010) Numerical simulations of stone column installation. Can Geotech J 47(10):1127–1138

Remadna A, Benmebarek S, Benmebarek N (2020) Numerical analyses of the optimum length for stone column reinforced foundation. Int J Geosynth Ground Eng 6(3):1–12

Acknowledgements

This research was made possible through the generous support of the University of Prince Mugrin (UPM). The authors would like to express their heartfelt appreciation to UPM for their unwavering and continued support throughout this endeavor.

Funding

No Funding was received through this study.

Author information

Authors and Affiliations

Contributions

Conceptualization: HAA, AMM. Methodology: HAA, AMM. Writing, Validation and Discussions: HAA, AMM. The authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

This manuscript has not been published and is not under consideration for publication elsewhere. We have no conflicts of interest to disclose.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Abas, H.A., Medawi, A.M. Investigating stone column effectiveness for sabkha soil improvement: field tests and numerical model. J. Umm Al-Qura Univ. Eng.Archit. 15, 67–77 (2024). https://doi.org/10.1007/s43995-023-00042-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s43995-023-00042-0