Abstract

This paper aims to develop a probabilistic approach for robust design with orthogonal experimental methodology in case of target the best on basis of the probabilistic multi-objective optimization. In the treatment, the difference of the target value and the arithmetic mean value of performance indicators of the alternatives is taken one objective to be minimum, and the square root of mean squared error of actual value of performance indicators from the target value of the alternatives is taken as the second objective to be minimum, which contribute their partial preferable probabilities to the alternative individually. As an application example, the probabilistic method for multi-objective optimization is combined with orthogonal experimental methodology to conduct the optimum design, range analysis is used to total preferable probability subsequently, and ranking sequence of total preferable probability of alternatives is used to complete the optimization option.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Quality of product is the life of enterprises, it is also the key to win competition in the increasingly fierce market. Thus the design and production of high-quality, low-cost and short-cycle products by using quality engineering technology has become a challenge problem to academic and engineering circles [1]. The quality of product or process can not only be characterized by the average value of quality characteristics, but also needs to take into account its fluctuation. In the 1960s, Taguchi put forward a robust parameter design method (RPD) on basis of the internal appearance and signal-to-noise ratio (SNR), which attempts to consider the mean and variance of quality characteristics at the same time, and cast them into the sole response — signal-to-noise ratio (SNR), so as to reduce the performance fluctuation of the whole system and improve the quality of product or process by decreasing the sensitivity of products or processes to noise factors through selecting the combination of proper controllable parameters [2]. There formed some mature RPD methods, such as Taguchi method, response surface method, double response surface model, etc. Although the idea of Taguchi method has been widely recognized in academic and engineering circles, there are disputes on the technology and methods to realize robust design, such as the lack of strict statistical theory support, this is the point that is often criticized by statisticians [3]; The internal and external design leads to too many experiments and increased costs; The response can only be optimized within the existing level, and the optimal value cannot be determined [3,4,5].

According to Taguchi [6, 7], there are two types of factors that influence the functional characteristic of product: controllable input parameters and uncontrollable parameters (noise factors). The controllable factors include those parameters that can be easily controlled by experimenter or producer, such as selection of material, mold temperature in an injecting molding process, or cycle time, etc. While noise factors are those not easy or very expensive or impossible to control.

The noise factors could be the main cause of the deviation of product’s performance from its target value. Thus, a robust design is to seek a set of the controllable input parameters which make the product’s performance insensitive to variations of noise factors, i.e., the product’s performance is with good robustness at the specific controllable input parameters without removing the causes of variations of external factors actually.

In Taguchi’s method [6, 7], the sole response “signal-to-noise ratio” (SNR) is employed to conduct the optimum design, the optimal factor levels correspond to set of specific input parameters, which make the appropriate SNR maximum. He suggested three types of SNR which depend on the desired performance response:

-

Target being the best,

$$SN_{T} = 10{\text{long}} \left( {\frac{{\overline{y}^{2} }}{{S^{2} }}} \right).$$(1) -

Smaller the better,

$$SN_{s} = - 10{\text{long}} \left( {\frac{1}{k}\sum\limits_{i = 1}^{k} {y_{i}^{2} } } \right).$$(2) -

Larger the better,

$$SN_{L} = - 10{\text{long}} \left( {\frac{1}{k}\sum\limits_{i = 1}^{k} {\frac{1}{{y_{i}^{2} }}} } \right).$$(3)

In above expressions, k is the number of each experimental test, and \(\overline{y}\) is the arithmetic mean value of a response with k data of the experimental tests; S is the standard deviation of the corresponding response.

In fact, for a set of actual experiments or processes, the mean value \(\overline{y}\) and the standard error S of an experimental scheme are independent responses in general.

While, in Eq. (1), the SNR solids the two responses (i.e., mean value \(\overline{y}\) and the standard error S) of an experimental response into one performance index, the optimization of the maximum of the SNR is not equivalent to the optimizations of the both minima of S and \(\overline{y}\) closing to the target simultaneously.

Besides, the more serious cases are those of “smaller the better” and “larger the better”, says Eq. (2) and Eq. (3) of SNRs for cases of smaller the better and larger the better, the response of the standard deviation S is even excluded by Taguchi. This point was criticized by many statisticians [3, 8,9,10,11]. Statisticians further advised take both mean and variance of response into account by using separate models.

In view of the defects of Taguchi method in statistical theory, some approaches were put forward. The response surface method establishes the quantitative relationship between experimental responses and various factors through reasonable experimental design, which uses the optimization method to find the optimal level combination of controllable factors [12]. Because the response surface method is supported by rigorous statistical theory, this method is even seen as potential approach, therefore extensive attention has been paid. A robust parameter design method for multi-response surfaces based on M estimation is proposed in considering that the least square method is very sensitive to outliers, correlation responses and non-normal errors [13]. A response surface model based on Bayesian multiple regression method is proposed to solve the problems of correlation between multi-responses, conflict of multi-objective optimization and uncertainty of model parameters in considering the design of multi-response robust parameters [14]. A dual response surface method is proposed by combining Taguchi's robust parameter design idea with response surface design [15]. The dual response surface model expects to optimize the mean and variance of quality characteristics at the same time, but it seems to ε—restraint approach, which selects only one objective response as the optimal objective, while the remaining (k-1) objectives as restraint conditions [15,16,17].

Therefore, in order to conduct robust optimization, the optimization of the both minima of S and \(\overline{y}\) closing to the target should be treated with individual models at the same time, so that the essence of robust design can be reflected rationally.

Recently, a probabilistic method for multi – objective optimization (PMOO) was developed to solve the inherent problems of personal and subjective factors in previous multi–objective optimizations [17]. The new concept of preferable probability was proposed to represent a preferable degree of a response of a scheme in the optimization. In this new approach, all performance utility indicators of alternatives are divided into two types preliminarily, i.e., beneficial or unbeneficial types according to their roles and preferences in the optimization; each performance utility indicator of the alternative contributes to a partial preferable probability quantitatively; furthermore, the product of all partial preferable probabilities makes the total preferable probability of a scheme in the viewpoint of probability theory, which forms the uniquely decisive index in the optimization process and thus transfers the multi – objective optimization problem into a single – objective optimization one.

In the cases of smaller the better and larger the better, the arithmetic mean value of performance indicators of the alternatives and their deviations, can be taken as the representatives of the alternatives in the treatment, which contribute their partial preferable probabilities to the alternative individually according to their roles and functions in the assessment, furthermore the total preferable probability is the product of all partial preferable probabilities to the alternative correspondingly, and the total preferable probability is used to conduct the optimal assessment directly [17].

However, in the case of target the best, the mean squared error of actual value of performance indicators from the target value of the alternatives is the essential response [16], which could be used to characterize the real deviation of actual value of performance indicators from their target values.

In this paper, a new approach for robust design in case of target the best is developed, which is further combined with orthogonal experimental methodology to conduct actual optimum design. Detailed illumination is given to show the optimum design with an example.

2 Probabilistic approach of robust design with orthogonal experimental methodology in case of target the best on basis of method for multi-objective optimization

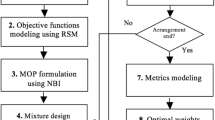

In considering the rationality of the probabilistic method for multi – objective optimization (PMOO) [17], and essence of actual value of performance indicators from the target value of the alternatives [16], the procedure of the robust design with orthogonal experimental methodology in case of target the best is on basis of probabilistic method for multi—objective optimization, which is as follows.

-

(a)

The difference of the target value and the arithmetic mean value of performance indicators of the alternatives is taken one objective to be minimum;

-

(b)

The square root of mean squared error of actual value of performance indicators from the target value of the alternatives is taken as the second objective to be minimum, which contributes its partial preferable probabilities to the alternative;

-

(c)

The total preferable probability is the product of all partial preferable probabilities to the alternative correspondingly;

-

(d)

Range analysis is used to total preferable probability to conduct the robust optimum with the orthogonal experimental design to complete the robust optimum;

-

(e)

Ranking sequence of total preferable probability of alternatives can be used to complete the robust optimum with uniform experimental design directly.

3 Application in the design of scraper conveyor’s lingual plate

The application example is given here to illuminate the procedures in details.

3.1 Selection for effective dwelling house walls in respect of technique view

A scraper conveyor’s lingual plate was studied to illustrate the robust design in case of target the best of discrete tolerance in [18]. Here it is restudied with the approach of robust design on basis of probabilistic method for multi – objective optimization.

Table 1 cited the design and results of the scraper conveyor’s lingual plate by means of orthogonal experimental methodology with L9(34) [18].

According to the requirement of the assembly parts, the desirable value of the closed circle size y is 200 ± 0.07 mm, so a utility \(\varepsilon \equiv |200 - \overline{y} |\) is introduced to represent the gap of actual mean value \(\overline{y}\) of y and its desirable value (200 mm) in the evaluation, which possesses the characteristic of unbeneficial index; while the deviation of actual value of performance indicators from the target value of the alternatives is the square root of mean squared error, which is the second objective and is expressed as γ ≡ [ε2 + δ2]0.5, δ is the standard deviation of actual value of y, it has the characteristic of unbeneficial index; and the total financial cost F is another objective, which has the characteristic of unbeneficial indexes. All data are cited in Table 1.

Table 2 shows the assessed results of preferable probability and total preferable probability in respect of technique view only for the robust design. Table 3 gives the result of range analysis of corresponding total preferable probability, which indicates that the optimum configuration with robustness is A1B1C1, and the impact order of input variables is B > A > C.

3.2 Option of effective dwelling house walls in respects of both technique and financial cost

In considering both technique and financial cost, following treatment is given.

Table 4 shows the assessed results of preferable probability and range analysis for total preferable probability in case of considering both machining process and total financial cost, Table 5 gives the result of range analysis of the corresponding total preferable probability, which indicates that the optimum configuration with robustness is A1B1C2, and the impact order of input variables is B > A > C.

As to this problem, it indicates that there is little difference of above robust configurations in considering respects of pure technique view only and taking both machining process and financial cost together.

4 Conclusion

From above discussion, the approach of robust design with orthogonal experimental methodology in case of target the best on basis of probabilistic method for multi-objective optimization is well developed. The combination of the probabilistic robust design in case of target the best with orthogonal experimental methodology is successful to conduct the optimum design. The range analysis is used to total preferable probability to conduct the robust optimum with orthogonal experimental design to complete the robust optimum.

Availability of data and materials

All data and materials are available as required.

References

Myers R, Montgomery D, Vining G, Borror C, Kowalski S (2004) Response surface methodology: a retrospective and literature survey. J Qual Technol 36(1):53–78

Taguchi G (1987) The system of experimental design engineering methods to optimize quality and minimize cost. Productivity Press, New York, USA

Nair VN, Abraham B, MacKay J, Box G, Kacker RN, Lorenzen TJ, Lucas JM, Myers RH, Vining GG, Nelder JA, Phadke MS, Sacks J, Welch WJ, Shoemaker AC, Tsui KL, Taguchi S, Jeff Wu (1992) Taguchi’s parameter design: a panel discussion. Technometrics 34(2):127–161. https://doi.org/10.2307/1269231

Castillo DE, Colossimo MB, Alshraaideh H (2012) Bayesian modeling and optimization of functional responses affected by noise factors. J Qual Technol 44(2):117–135

Gu XG, Ma YZ, Liu J, Wang J (2017) Robust parameter design for multivariate quality characteristic based on process capability index with individual observations. Syst Eng Electron 39(2):362–368

Roy RK (2010) A primer on the Taguchi method, 2nd edn. Society of Manufacturing Engineers, Michigan, USA

Mori T (2011) Taguchi methods: benefits, impacts, mathematics, statistics, and applications. ASME Press, New York, USA. https://doi.org/10.1115/1.859698

Box G (1988) Signal-to-noise ratios, performance criteria, and transformations. Technometrics 30(1):1–17. https://doi.org/10.2307/1270311

Box GEP, Meyer RD (1986) Dispersion effects from fractional designs. Technometrics 28(1):19–27. https://doi.org/10.1080/00401706.1986.10488094

Welch WJ, Yu T-K, Kang SM, Sacks J (1990) Computer experiments for quality control by parameter design. J Qual Technol 22(1):15–22. https://doi.org/10.1080/00224065.1990.1197920

Welch WJ, Buck RJ, Sacks J, Wynn HP, Mitchell TJ, Morris MD (1992) Screening, predicting, and computer experiments. Technometrics 34(1):15–25. https://doi.org/10.2307/1269548

Anderson MJ, Whitcomb PJ (2016) RSM simplified: optimizing processes using response surface methods for design of experiments. Chapman and Hall/CRC, Boca Raton

Moslemi A, Seyyed-Esfahani M, Niaki STA (2017) Robust surface estimation in multi-response multi stage statistical optimization problems. Commun Stat Simul Comput 47(3):762–782

Wang JJ, Ma YZ, Ouyang LH, Sun JS, Liu J (2016) Bayesian modeling and optimization of multi-response robust parameter design. J Manag Sci China 19(2):85–94

Vining GG, Myers RH (1990) Combining Taguchi and response surface philosophies: a dual response approach. J Qual Technol 22(1):38–45

Lin DKJ, Tu W (1995) Dual response surface optimization. J Qual Technol 27(1):34–39

Zheng M, Yu J, Teng HP et al (2023) Probability-based multi-objective optimization for material selection, 2nd edn. Springer, Singapore

Li JH, Zhou JF (2014) Robust design of discrete tolerance based on DOE. Coal Mine Mach 35(6):121–123

Acknowledgements

Not applicable.

Funding

The author declared that that there is no funding involved.

Author information

Authors and Affiliations

Contributions

Zheng conducted things of this article including preliminary sketch, data treatment and original writing. Yu conducted things of some data treatment and improvement of the revised version.

Corresponding author

Ethics declarations

Conflict of interest

The author declared that that there is no competing interest involved.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Zheng, M., Yu, J. Probabilistic approach for robust design with orthogonal experimental methodology in case of target the best. J. Umm Al-Qura Univ. Eng.Archit. 15, 55–59 (2024). https://doi.org/10.1007/s43995-023-00040-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s43995-023-00040-2