Abstract

Three liquid crystalline monomers were systematically designed, synthesised and characterised. Methyl methacrylic unit was linked to the mesogenic compound, 4′-Undecycloxybiphenyl-4-yl 4-octyloxy-2-(pent-4-en-1-yloxy) benzoate, (Me), using disiloxane, ester and siloxane units respectively. In the first compound, 4′-(undecyloxy)-[1,1′-biphenyl]-4-yl 2-((5-(3-(4-(methacryloyloxy)butyl)-1,1,3,3-tetramethyldisiloxanyl)pentyl)oxy)-4-(octyloxy)benzoate, (M1), the methyl methacrylic unit was linked to the mesogen by disiloxane group, (Si–O–Si), while ester group, (COOC), was used in the second compound, 4′-(undecyloxy)-[1,1′-biphenyl]-4-yl 2-((5-(methacryloyloxy)pentyl)oxy)-4-(octyloxy)benzoate, (M2), and siloxane unit, (Si–O), in the third compound, 4′-(undecyloxy)-[1,1′-biphenyl]-4-yl 2-((5-((4-(methacryloyloxy)butyl)dimethylsilyl)pentyl)oxy)-4-(octyloxy)benzoate, (M3). The introduction of the methyl methacrylic unit caused the melting point of the compounds to reduce with Me melting at 53.3 °C, M1 at −8.1 °C and M2 at −12.5 °C. The three compounds showed characteristic nematic textures when observed under POM and when compared to the mesogenic compound (Me, 71.7 °C), there were remarkable reduction in the clearing points of the compounds, with M1 clearing at 18.6 °C, M2 at 68.8 °C and M3 at 10.3 °C. Finally, there was appreciable increment in the nematic phase range for the compounds when compared to the mesogen, Me, 18.4 °C. The range was 26.7 °C for M1, 81.3 °C for M2 and since there was no observable crystallization point for M3, the range was not determined.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The side chain liquid crystal polymers (SCLCPs) are of paramount importance and have attracted enormous attentions due to harmonization of their special anisotropy liquid crystalline properties with their outstanding mechano-performances [1]. To understand the behaviour of this class of compounds, the molecular architectures of their corresponding monomeric units must be studied [2].

Methyl methacrylate polymers outstand others with comparatively low glass transition temperature (Tg), viscosity, and good mechanical, thermal stabilities, high silicon–oxygen bond angles mobility [3]. These properties rendered them useful in liquid crystal display (LCD), smart soft materials [4,5,6], information storage, non-linear optics and other applications as liquid crystal polymers with low phase transition temperature.

Inspite the above advantages of SCLCPs, little or no attention is being paid to the LC properties and characterisation of the monomers from which they are formed (synthesised).

Here, we present the synthesis and characterisation of methyl methacrylic monomers, taken into consideration the simplicity and more efficient synthetic methods, availability of materials, easy reaction monitoring and characterisation. The detailed synthesis of the intermediates and the products are given in the supporting information.

2 Description of the syntheses

Three methyl methacrylic liquid crystal monomers were designed and systematically synthesised and characterised. The polymeric unit/end chosen was methyl methacrylic to induce flexibility and because of its high polymerization power/ability, while the liquid crystalline moiety used was 4′-Undecycloxybiphenyl-4-yl 4-octyloxy-2-(pent-4-en-1-yloxy) benzoate (Me) [7, 8] with phase transition of Cr 53.3 N 71.7 I. The methyl methacrylic unit, iii, was systematically synthesised by the reaction between 3-buten-1-ol, i, and methacryloyl chloride, ii, with yield of 84% (Scheme 1). In this work, various chemical reactions were used to link the methyl methacrylic unit to the previously reported mesogen, Me (Scheme 1).

The first monomer M1, C55H86O8Si2 (MW = 931.45), was synthesised using hydrosilylation [9] of the mesogen, Me, using 1,1,3,3-tetramethyl disiloxane in the presence of platinum catalyst to achieve the first intermediate (iv) in quantitative yield, 92% (Scheme 2).

The targeted monomer M1 (86%) was finally synthesised by the second hydrosilylation reaction between the intermediates iii and iv.

For the synthesis of the second monomer, M2, C47H66O7 (MW = 742), the hydroboration–oxidation sequence [10,11,12,13,14,15], was carried out on mesogen, Me, to afford intermediate hydroxyl compound, v. The esterification [16, 17] of the resulted intermediated hydroxyl compound gave M2 in quantitative yield (Scheme 3).

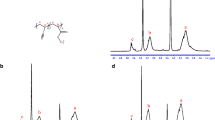

The lateral alkene end of the mesogen, Me, was subjected to hydroboration by 9-BBN and subsequently oxidised by sodium perborate to afford hydroxyl intermediate compound, v, 54 %. The hydroboration by BH3.THF followed by NaOH/H2O2 oxidation was also investigated and gave yield of 44%. The disappearance of the signals due to methylene protons at 4.9 and 5.7 ppm in 1H NMR spectrum of the compound, v, confirmed the reaction. The hydroxyl functional end of the intermediate v was modified by esterification with methacryloyl chloride, ii, to yield the targeted monomer, M2, quantitatively, 98 %.

The third monomer, M3, C51H74O8 (MW = 814), was systematic synthesised as shown in Scheme 4.

One hydroxyl group of 1,4-butanediol, vi, was esterified with methacrylic acid, iii, to obtain the first hydroxyl methacrylate intermediate, vii, in 58% yield [18]. 1H NMR confirm the conversion in which there was emergence of signals due to methylene of methyl methacrylic end at 5.5 and 6.0 ppm. The second intermediate, viii, was synthesised by silylation of the mesogen, Me, by chlorodimethylsilane in the presence of platinum catalyst. From the 1H NMR spectrum, the disappearance of the signals due to methylene protons at 4.9 and 5.7 ppm found in the compound Me, confirm the product, viii. The condensation of compounds vii and viii using imidazole yielded the targeted monomer, M3, in 67 % yield.

3 Results and discussion

3.1 Liquid crystals properties

The liquid crystal properties were obtained using polarizing optical microscope (POM) and differential scanning calorimeter (DSC). The textures were obtained from POM while the transition properties were confirmed by DSC. Table 1 shows the liquid crystalline properties of the intermediates and monomer.

The textures of the intermediates and monomers are as show in Fig. 1.

The mesogen Me and the corresponding intermediates v, shows nematic texture (Fig. 1a, b) from the melting point (53 and 51 °C respectively) to the clearing point (~72 °C). The monomer M2 also shows nematic texture (Fig. 1c). The schlieren texture characteristic of nematic phase was seen for intermediate compound iv (d). An oil streaks texture of nematic is observed for compound iv at room temperature (Fig. 1e) in which lines show up and swim with thermal motion. Monomer M1 showed marble sheared nematic texture (f), while monomer M3 also showed nematic texture at low temperature, 10 °C (g).

3.2 Thermal properties

The thermal behaviour [19] of the intermediates and the monomers were investigated using DSC and the heating and cooling curves as obtained are shown in Fig. 2.

DSC curves of a Compound iv at 20 °C/min, b Compound M1 at 5 °C/min, c Compound M1 at 20 °C/min, d Compound v at 10 °C/min, e Monomer M2 at 10 °C /min, f Monomer M3 at 10 °C /min (Red curve = first heating; Green curve = second heating; Brown curve = third heating; Blue curve = first cooling; Pink curve = second cooling)

Me melted to nematic phase at 53.3 °C with enthalpy of 71.92 J/g and turning isotropy at 71.7 °C with enthalpy of 1.5 J/g. Compounds M1 and M2 melted to nematic phase at −8.1 and −12.5 °C respectively with enthalpy of 0.2 and 1.93 J/g. M1 turned isotropic at 18.6 °C with energy of 0.009 J/g while M2 turned isotropy at 68.2 °C with energy of 0.44 J/g.

For M3, there was no crystallization phase and the clearing point from nematic to isotropy was 10.3 °C with energy of 0.15 J/g.

The range of nematic phase for the mesogen was 18.4 °C. Comparing the compounds, it is clear that the introduction of the methyl methacrylic unit increases the nematic phase range (Table 1). For compound M1, the nematic phase range was 26.7 and 81.3 °C for the compound M2. The range for the compound M3 could not be determined since there was no crystallization observed.

Also, worthy of note is the reduction in the clearing point of the compounds with the introduction of methyl methacrylic unit. This is expected for the compounds M1 and M3 with Si–O– and Si–O–Si linkages respectively [20, 21]. The compound M2, though without silicon-oxygen bond (linkage), still exhibited lower clearing point when compare to the mesogen, Me.

4 Conclusion

Three methyl methacrylic mesogenic monomers, with different linking units between the mesogenic unit and the polymerizable methyl methacrylate end, were successfully synthesised and characterised. The monomers were liquid crystalline with nematic mesophase below the room temperature. The introduction of the methyl methacrylic unit through siloxane, ester and disiloxane linker units causes reduction in the clearing points of the nematic phase of the mesogenic compound and also increment in the stability and temperature range of the nematic phase. The thermal behaviour of the monomers reveals that those with siloxane (Si–O– and Si–O–Si) linker exhibits very low clearing, disiloxane having the lower value.

Note: The experimental procedures are as contained in the additional information and are abstracted from reference [22].

Data availability

The data are available if needed.

References

Wei W, Xiong H (2022) Liquid-crystalline polymers: molecular engineering, hierarchical structures, and applications. Langmuir 38:11514–11520

Imrie CT, Henderson PA (2007) Liquid crystal dimers and higher oligomers: between monomers and polymers. Chem Soc Rev 36:2096

Portugall M, Ringsdorf H, Zentel R (1982) Die Makromolekulare Chemie. Makromol Chem 183:2311–2321

Bisoyi HK, Li Q (2022) Liquid crystals: versatile self-organized smart soft materials. Chem Rev 122(5):4887–4926

Saed MO, Gablier A, Terentjev EM (2022) Exchangeable liquid crystalline elastomers and their applications. Chem Rev 122(5):4927–4945

Banerjee S, Kar KK (2020) Introduction to liquid crystalline polymers. Polymers and polymeric composites: a reference series. Springer, Berlin, Heidelberg, pp 1–26

Karahaliou PK, Kouwer PHJ, Meyer T, Mehl GH, Photinos DJ (2008) Long- and short-range order in the mesophases of laterally substituted calamitic mesogens and their radial octapodes. J Phys Chem B 112(21):6550–6556

Diez S, Dunmur DA, De La Fuente MR, Karahaliou PK, Mehl GH, Meyer T, PerézJubindo MÁ, Photinos D (2003) Dielectric studies of a laterally-linked siloxane ester dimer. J Liquid Crystal 30:1021–1030

Naganawa Y, Inomata K, Sato K, Nakajima Y (2020) Hydrosilylation reactions of functionalized alkenes. Tetrahedron Lett 61:151513

Bergbreiter DE, Rainville DP (1976) Stereochemistry of hydroboration-oxidation of terminal alkenes. J Org Chem 41(18):3031–3033

Brown HC, Zaidlewicz M (2007) From boron hydrides, Inorganic Reactions and Methods, pp 35–86

Makabe H, Kong LK, Hirota M (2003) Total synthesis of (−)-cassine. Org Lett 5:27–29

Kabalka GW, Shoup TM, Goudgaon NM (1989) Sodium perborate: a mild and convenient reagent for efficiently oxidizing organoboranes. J Org Chem 54:5930–5933

Kabalka GW, Maddox JT, Shoup T, Bowers KR (2003) A Simple and Convenient Method for the Oxidation of Organoboranes Using Sodium Perborate: (+)‐Isopinocampheol Organic Syntheses. 116–116. https://doi.org/10.1002/0471264180.Os073.12

Kabalka GW, Maddox JT, Shoup T, Bowers KR (1996) Preparation of Crystalline (Diisopinocampheyl)borane. Org Syn Coll 73:116

Hughes G, Kimura M, Buchwald SL (2003) Catalytic enantioselective conjugate reduction of lactones and lactams. J Am Chem Soc 125:11253–11258

D’Annibale A, Ciaralli L, Basseti M, Pasquini C (2007) Synthesis of alkyl-substituted six-membered lactones through ring-closing metathesis of homoallyl acrylates. an easy route to pyran-2-ones, constituents of tobacco flavor. J Org Chem 72:6067–6074

Sharrett Z, Gamsey S, Hirayama L, Vilozny B, Suri JT, Wessling RA, Singaram B (2009) Exploring the use of APTS as a fluorescent reporter dye for continuous glucose sensing. Org Biomol Chem 7:1461–1470

Chruściel JJ, Janowska G, Fejdyś M (2012) Thermal properties of polymethylvinylborosiloxanes. J Therm Anal Calorim 109:1049–1058

Gao S, Liu Y, Feng S, Lu Z (2019) Reprocessable and degradable thermoset with high Tg cross-linked via Si–O–Ph bonds. J Mater Chem A 7:17498–17504

Weinhold F, West R (2011) The nature of the silicon–oxygen bond. Organometallics 30(21):5815–5824

Amos O (2015) Thesis submitted to University of Hull, UK. Available on https://hydra.hull.ac.uk/assets/hull:13065a/content

Funding

The authors declared that no special fund was made available for this work.

Author information

Authors and Affiliations

Contributions

The research conception and design were done by OA and GM. Material synthesis, analysis, data collection and interpretations were performed by all authors. The first draft of the manuscript was written by OA. The final manuscript was read and approved by all authors.

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Amos, O., Mehl, G.H. & Pashameah, R.A. Synthesis and characterization of liquid crystal methyl methacrylic monomers. J.Umm Al-Qura Univ. Appll. Sci. 10, 129–135 (2024). https://doi.org/10.1007/s43994-023-00086-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s43994-023-00086-x