Abstract

Multi-stage reverse electrodialysis (MSRED) offers a promising way for efficient salinity gradient energy harvesting. Here, an improved model of the MSRED system under serial control strategy is proposed. The technical–economic analysis is conducted with considering discount, depreciation and different regional tax and electricity price levels under the maximum net power output conditions. Results reveal that net power output and energy efficiency both increase first with increasing stage numbers, reach their maximum values, and then decrease. For 5 M/0.05 M solutions, the optimal net power output of 4.98 kW is obtained at the stage number n = 12. The optimal stage number corresponding to the maximum net power increases with increasing feed solution concentrations. Due to the compromise between net power generation and capital cost, there exist optimal stage numbers leading to the lowest LCOE and largest NPV, respectively. Higher feed solution concentration can significantly decrease the system LCOE and increase the NPV. The optimal stage number corresponding to the maximum NPV increases with increasing feed solution concentrations. In Germany, for 5 M/0.05 M solutions, the lowest LCOE of 0.061 €·kWh−1 is achieved at n = 3 while the highest NPV over the system lifecycle of 52,005 € is obtained at n = 8. Lower tax, higher electricity price, appropriate membrane price and stage numbers, and high salinity gradient sources can significantly accelerate the commercial completeness of the MSRED systems.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Rising energy demand and great dependence on fossil fuels have led to severe environmental and social problems. It is imperative to exploit and develop renewable and pollution-free energy substitutes. Salinity gradient energy (SGE) is a kind of sustainable and clean energy resource generated from the reversible mixing of two solutions with different concentrations, also known as “blue energy” [1-3]. It is estimated that the global theoretical potential based on the annual river and ocean flows is 1.4–2.6 TW [4], and approximately 1 TW is technically available [5, 6], indicating that SGE has great development potential and application prospects. Reverse electrodialysis (RED) can serve as a promising technique to effectively harvest SGE due to its relatively high efficiency and low operating requirements [7, 8]. The RED system mainly consists of ion exchange membranes (IEMs) and electrodes. IEMs are classified as cation exchange membranes (CEMs) and anion exchange membranes (AEMs). The alternately stacked IEMs and the mesh spacers between the membranes form RED cell pairs, where the high and low concentration solution (HC, LC) compartments are constructed by spacers.

With advances in stack configuration design and membrane materials [9-13], RED has gradually matured and some pilot-scale plants have been established [14, 15]. Despite the huge potential of global natural SGE for power generation, the application and promotion of RED are still limited. The adverse effects of multivalent ions and the lower salinity gradient between natural seawater and river water lead to a relatively low power generation performance of the RED system [16, 17]. The high pretreatment and anti-fouling costs of natural flows further reduce the economics of the RED stack [18]. In addition, the uneven distribution of natural salinity gradient sources also hinders the system implementation [19].

Recently, attention has been attracted to the multi-stage RED (MSRED). The application of MSRED systems is not limited to natural salinity gradient sources. High salinity solutions such as brine discharged from salt fields and desalination plants as well as treated domestic wastewater can be applied [20]. Compared to single-stage RED stacks, MSRED systems can extract SGE of high salinity gradient sources more completely while maintaining higher output power density [21]. The concept of MSRED was first introduced as a cascade operation by Veerman et al. [22]. Compared to the single-stage stack, the energy efficiency of a three-stage RED system was relatively improved by over 50%. Tedesco et al. [23] investigated the performance of different three-stage configurations, revealing the layout of MSRED worked best with more than 1.1 kW output power obtained. Catarina et al. [24] tested a two-stage RED configuration experimentally and found that MSRED is a viable concept to enhance power and energy efficiency, and the gross overall performance of the two-stage system is improved by 17%. Wang et al. [25] conducted an experiment based on SGE extraction between brine and seawater, and found that the energy conversion efficiency of the MSRED system increased from 2 to 18% at a stage number of 22. There are two main strategies to harvest SGE by MSRED: independent control for each RED stack and series control with equal electric current. Hu et al. [26] compared the two strategies by mathematical modeling and found that the serial control strategy is more feasible in practice and easier to manage the output power.

The assessment of cost and economic aspects is pivotal for the practical application and promotion of the MSRED system. Turek et al. [27] conducted the cost estimation for a RED stack with an experimental power density of 0.92 W·m−2 with an investment cost of 100 $·m−2 for installing membranes. Post et al. [5] designed a 200 kW RED system, which reduced the installed membrane price to 2 €·m−2, resulting in a very low prospective cost of 0.08 €·kWh−1. However, these estimates were either based on obsolete experimental data before RED performance improvements or made overly idealized power and cost assumptions [28]. Giacalone et al. [29] contributed to the field by presenting an improved techno-economic analysis of the RED system. The levelized cost of electricity (LCOE) based on natural and artificial salinity gradient scenarios is estimated, revealing that the RED system demonstrates commercial potential in specific scenarios owing to competitive LCOE values.

In this paper, an enhanced mathematical model for the MSRED system employing the serial control strategy is proposed. This model takes into account variations in volume flow rate and concentration-dependent density along the flow direction. Unlike in previous models where the maximum power of each calculation interval was considered to calculate the overall electric power, here output voltage and electric current are introduced as variables to describe the RED stack more practically. Particle Swarm Optimization (PSO) is applied to identify optimal conditions for maximum output power under different serial stages and salinity gradient sources. Subsequently, a comprehensive technical–economic analysis model of the MSRED system is developed with considering discount, depreciation and different regional tax and electricity price levels. The levelized cost of electricity and net present value (NPV) of the MSRED system are systematically analyzed and discussed, thus evaluating the commercialization potential and feasibility of the serial control MSRED power plant.

2 Model development

2.1 Serial control MSRED system

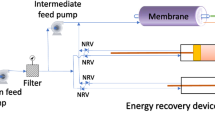

As shown in Fig. 1, an improved mathematical model of the RED stack is developed to describe transmembrane ion and water transportation characteristics with the following assumptions employed: 1) Only changes of properties (e.g., voltage, concentration, flux, and resistance) along the flow direction are considered; 2) Ideal flow distribution and composition are assumed; 3) The concentration polarization and the parasitic current are ignored [30].

The equivalent circuit of a single RED stack is presented in Fig. 2. The stack is divided into several calculation intervals through the numerical discretization of the flow domain along the channel length. Figure 3 shows the serial control strategy of the MSRED system with n identical RED stacks. The total output voltage of the stack is a summation of each stack’s voltage, and the current of each stack is the same to form a serial configuration. The concentration difference of the solutions gradually decreases with the flow and mass transfer proceeding. In the downstream stacks, electrodialysis may occur due to the electromotive force [31].

In a RED cell pair, the electric potential is the sum of the Nernst potential difference across the CEM and AEM [32]:

where α is the permselectivity of the IEM. R is the universal gas constant, 8.314 J·mol−1·K−1. T is the temperature (K). F is the Faraday constant, 96,485 C·mol−1. C is the concentration (mol·m−3). γ is the activity coefficient used in thermodynamics to account for deviations from ideal behavior, which can be determined by Pitzer’s virial equation [33]:

where M is the molality of the electrolyte (mol·kg−1). A is the modified Debye-Hückel slope, A = 0.3915 at 25 ℃. b is a constant, b = 1.2 for NaCl. Bγ and Cγ are functions of the electrolyte nature which can be found in Ref. [33]. I is the ionic strength (mol·L−1), which can be calculated based on pure NaCl solutions:

The RED cell resistance is the sum of the solution compartment resistances and the membrane area resistances [32]:

where RCEM and RAEM are the membrane area resistances (Ω·m2).

The solution compartment resistances vary along the flow direction, which can be calculated as:

where f is the obstruction factor, which illustrates the increase of the electrical resistance due to the negative effects of the spacer. δ is the thickness of the solution compartment (m). Λm is the molar conductivity of the electrolyte solution (S·m2·mol−1).

According to Ohm's law, the current density of each RED stack is calculated as:

where N is the number of cell pairs in each RED stack. U is the output voltage (V). Rel is the area resistance of the electrodes and their compartment (Ω·m2), which can be ignored when a large number of cell pairs are adopted [34].

The electric current can be calculated as:

where W and L are the width and length of the IEM (m), respectively.

The gross output power of the RED stack is:

The pumping energy cannot be ignored and the pressure drop over each solution channel is calculated as [35]:

where μ is the solution viscosity (Pa·s) [36]; Q is the volume flow rate (m3·s−1).

The total hydraulic loss of the RED stack is:

where ζ is the correlation factor considering the geometric effect [31].

Therefore, the net power output of each RED stack is:

The maximum power available is the variation of Gibbs free energy of the mixing process [37], which can be calculated as:

where CM is the concentration of the mixed HC and LC solutions.

The energy efficiency is the ratio of the net power generated by the RED stack relative to the maximum power:

For the transmembrane ion transportation, the total salt flux from the HC to the LC compartment consists of the Coulombic part and the Co-ion transport part [31]:

where DNaCl is the permeability coefficient of salt (m2·s−1). δm is the thickness of the membrane (m). “2” is a factor that indicates two membranes contained in a cell pair.

The total water flux consists of the Osmotic part and the Electro-osmotic part:

where Lp is the average water permeability of the membrane (m·Pa−1·s−1). m is the number of ions produced by the ionization of the electrolyte. φ is the osmotic coefficient. nh is the total hydration number [30].

In the HC compartment, the total mass change arises from the decrease in the NaCl mass and the increase in water mass due to the osmosis effect. The equations of the mass balance are given by:

Similarly, the mass transfer process in the LC compartment follows the mass balance equation:

where M is the molar mass (kg·mol−1). ρ is the concentration-dependent density of the NaCl-water mixture (kg·m−3) [38]:

where ω is the mass fraction, ρapp,NaCl is the apparent density of NaCl. t is the temperature (℃). c0-c4 are the fitted parameters [38].

The boundary conditions of the numerical model are as follows (the inlet volume flow rate and concentration of the HC and LC solutions):

In our previous work [39, 40], the maximum power of each calculation interval was considered to simplify the calculation. In this study, the output voltage and electric current are introduced as variables to model the RED stack more practically. The calculation process is depicted in Fig. 4. The simulation is carried out via Matlab. The ordinary differential Eqs. (19) - (22) are solved by the 4th order five-level Runge–Kutta algorithm. The particle swarm optimization (PSO) is a population-based stochastic approach inspired by flocking birds or fishes representing particles that sail across the problem’s hyperspace [41]. The method starts with the selection of random particles and the generations update iteratively to seek optimization. PSO is generally applicable to optimization problems of multiple local extrema without very high precision, and has widespread applications due to its advantages of simplicity and rapid convergence. The PSO algorithm is adopted to search for the optimal assigned I in Fig. 4 that maximizes the net power output of the serial control MSRED system, and the solver parameters are set as: particle population size of NPSO = 20, personal learning coefficient and social learning coefficient of c1 = c2 = 2, inertia coefficient of w = 0.6, and iteration counter of nPSO = 50.

The validation of the present model is conducted under various concentration ratios. As shown in the Supplementary Information, a good agreement between the model calculation results and experimental data can be observed. In the studied MSRED system, each RED stack is equipped with 1000 cell pairs to simulate actual commercial applications. The effective size of a single IEM is 1 m × 0.1 m, where the flow channel length is 0.1 m [19, 26]. The operating flow rate across IEM has a significant effect on RED performance and is fixed to 1 cm·s−1, which was widely chosen in previous studies on RED [19, 21, 26, 42, 43] and showed great performance with a similar stack size. In addition, The low concentration is fixed at 50 mM according to relevant investigations [19, 25, 26, 42, 43]. The detailed input parameters of the MSRED system are shown in Table 1, and a wide range of concentration ratios (100, 80, 60, 40) are chosen to simulate different brine/freshwater pairs. Relevant membrane properties are listed in Table 2 [26].

2.2 Economic analysis

To assess the commercialization potential and feasibility of the serial control MSRED power plant, a complete technical–economic analysis model is developed to compute capital and operational expenditures and evaluate the LCOE and NPV, considering discount, depreciation and different regional tax and electricity price levels. The relevant factory capacity factors and financial parameters are given in Table 3 [29, 44].

2.2.1 Economic criteria

The net present value (NPV) and the levelized cost of electricity (LCOE) are the two main economic indicators to assess commercial viability [45]. NPV (€) is the difference between the discounted value of net cash flow generated by the plant and the present value of the original investment [44]. A larger NPV indicates a higher benefit for the plant. NPV can be calculated as follows:

where Crep is the total levelized cost of membrane replacement over the plant lifecycle (€) which can be calculated by Eq. (28), and the membrane replacement occurs at i = 10 and 20. CAPEX is the capital expenditure (€). i and t denote year and plant lifetime (y), respectively. r is the discount rate. Cres is the product of capital cost and the residual rate i.e., the fixed asset residual value (€). CFLi is the annual after-tax cash flow (€) computed by Eq. (29).

where n is the number of stages of the MSRED system. A is the area of each membrane and electrode (m2). Cmem is the price of the membrane (€·m−2).

where β is the corporate income tax rate. CFL0i and Ii are the pre-tax cash flow per year (€) and the taxable income per year (€), Which can be calculated by the following equations:

where Ei is annual power generation (kWh), which can be calculated based on plant capacity factor and net power generation. OPEX is the operational expenditure (€). Cdep is the product of capital cost and the depreciation rate i.e., the annual depreciation value (€·y−1), representing tax-deductible gains. Ce is the selling price of electricity (€·kWh−1).

LCOE (€·kWh−1) represents the lowest electricity price at which a power plant can break even over its lifecycle. LCOE is the specific cost calculated after discounting the total investment and power generation during the plant lifecycle at a certain discount rate, i.e., the ratio of the present value of total costs to the present value of total power generation over the plant lifecycle [46], which can be calculated as:

2.2.2 Capital expenditure

The capital expenditure (CAPEX) mainly includes the following components: 1) RED stack cost, 2) intake and outfall infrastructure cost, 3) pretreatment cost, and 4) other costs.

RED stack cost (€) is the main part of the capital expenditure and consists of membrane cost, electrode cost and spacer cost, which can be calculated as:

where Cele and Cspa are the prices of electrode and spacer, respectively (€·m−2).

The intake and outfall cost depends on the actual application conditions, and different operating scenarios (e.g., seawater/river water, brine/brackish water) have different requirements for the intake and outfall infrastructure. Considering the high salinity gradient feed of the MSRED system, a factor equal to 0.35 is introduced to estimate the intake and outfall infrastructure cost (€) of the MSRED plant according to that of the reverse osmosis (RO) desalination plant [29, 47], which can be calculated as:

where Qd is the total inlet flow of the plant per day (m3·d−1).

The pretreatment cost (€) can be estimated as Ref. [5]:

where Pnet is the rated net power (kW).

The other costs include: 1) pump and piping costs, 2) inverter cost, and 3) civil and electrical infrastructure cost. The pump and piping costs (€) can be calculated based on the market prices of components with different specifications and capacities according to the following equations [48]:

where Ppump is the pumping power (W). dpip and Lpip are the pipe diameter and length (mm) based on the specific flow rate and stage number.

According to the market research for both single-phase and three-phase inverters [29], the inverter cost (€) is given as a function of gross power (kW):

The civil and electrical infrastructure cost is fixed at 250 €·kW−1 referring to the gross power output [29].

2.2.3 Operational expenditure

The operational expenditure (OPEX) includes the operational and maintenance cost, the pumping cost, and the membrane replacement cost. The annual fixed operating cost (€·y−1) is assumed to be 4% of the capital cost for the MSRED plant based on the economic structure of the reverse osmosis desalination plants [49]. The membrane replacement cost depends on the lifetime, quantity, and area of the membranes, where the membrane lifetime is assumed to be 10 years and the related cost is described in the previous section.

Here the economic indicators and the cost of power generation at different regional tax and electricity price levels are analyzed to assess the commercialization potential and feasibility of the MSRED plant. The relevant parameters of different regions are listed in Table 4, the electricity price is collected in the ENTSO-E transparency platform [50] and the average historical electricity price throughout the year is used, and the corporate income tax rate is available in the Trading Economics platform [51].

3 Results and discussion

In this section, the performance of serial control MSRED is first investigated, and the optimal serial stages rendering to the optimal maximum net power operation condition are identified by the PSO method. Then a complete technical–economic analysis model is adopted to analyze the power generation performance, LCOE, and NPV of the serial control MSRED system. The influences of stage count, salinity gradient, regional tax, and electricity price are systematically analyzed.

3.1 Performance of serial control MSRED

To assess the influence of variable flow channel lengths, the performance under different system configurations is systematically investigated. As shown in Fig. 5A, Cases 1–4 are serial control MSRED systems with various effective IEM sizes, while Case 5 is a system of 10 separate stacks with parallel flow distribution. Each stack is equipped with 1000 cell pairs with the same total membrane area and total volume flow rate. For each case, 4 M/0.05 M solution pairs are applied and the optimal net power is obtained by the PSO method. Figure 5B shows the net power and energy efficiency of different systems and the contribution of each RED stack. The current and total voltage for each case is listed in Table 5. Figure 5B indicates that multiple shorter stacks can generate more power than a single stack with the same equivalent membrane area, showing great accordance with Ref. [31]. The greatest net power output and energy efficiency are obtained in Case 4. The contribution of each RED pair regarding net power output decreases with increasing stage numbers. Therefore, the RED stack of 1 m × 0.1 m is adopted for further analysis in the performance and economics of the serial control MSRED system, and the corresponding solution concentration of each stage in Case 4 is reported in Supplementary Information.

Subsequently, the performance of the MSRED system with different serial stages for harvesting various salinity gradient sources is investigated. Figure 6 shows the variations of the net power output and hydraulic loss of the MSRED system with the number of serial stages under the maximum net power output conditions. The gross power increases rapidly with the increasing stage numbers as a larger stage number means a larger area of IEMs, which contributes to the transmembrane ion transportation and more completed extraction of the SGE. The transmembrane concentration difference decreases along the flow direction, leading to decreased inlet salinity gradient of downstream RED stacks, thus weakening the increased magnitude of the gross power at larger stage numbers. During the RED process, the transmembrane ion and water fluxes present no obvious effect on the solution volumes in the HC and LC compartments. Therefore, the hydraulic loss of each stack keeps almost the same and the total pump power of the system increases linearly with stage numbers. The net power output of the MSRED system increases first with increasing stage numbers, reaches the maximum value, then decreases. This phenomenon was also reported in Refs. [26, 43]. The optimal stage number increases with increasing feed solution concentrations since more RED stacks are required for efficient energy conversion with larger concentration gradients available. For 5 M/0.05 M solutions, the system generates a maximum net power of 4.98 kW and consumes a pump power of 2.10 kW at n = 12; For 4 M/0.05 M solutions, the system generates a maximum net power of 4.14 kW and consumes a pump power of 1.77 kW at n = 11; For 3 M/0.05 M solutions, the system generates a maximum net power of 3.15 kW and consumes a pump power of 1.34 kW at n = 9; For 2 M/0.05 M solutions, the system generates a maximum net power of 2.04 kW and consumes a pump power of 0.98 kW at n = 7.

Figure 7 shows the variations of the energy efficiency of the MSRED system with the number of serial stages when operating at the maximum net power output conditions. At the given solution concentration and flow rate, the Gibbs free energy is certain. Thus, the total energy efficiency presents the same trend as the net power output under various stage numbers. As shown in Fig. 8, the energy efficiency increases first with increasing stage numbers, reaches the maximum value, and then decreases. At small stage numbers, lower feed solution concentration renders higher energy efficiency due to less Gibbs free energy of mixing consumed. At larger stage numbers, due to significantly decreased net power output at lower feed solution concentration, the energy efficiency is significantly hindered. The optimal stage number of the serial control MSRED system increases with increasing feed solution concentrations. For 5 M/0.05 M solutions, the maximum system energy efficiency of 31.36% is achieved at n = 12; For 4 M/0.05 M solutions, the maximum energy efficiency of 32.99% is achieved at n = 11; For 3 M/0.05 M solutions, the maximum energy efficiency of 34.27% is achieved at n = 9; For 2 M/0.05 M solutions, the maximum energy efficiency of 34.73% is achieved at n = 7. Although lower feed solution concentration leads to higher energy conversion efficiency, it results in decreased maximum net power output. Energy efficiency is associated with various factors such as flow rate, RED stack configuration, and IEMs performance. Adjusting operational conditions and utilizing alternative upgraded IEMs may enhance the efficiency of the MSRED system in extracting salinity gradients from high salinity feed scenarios.

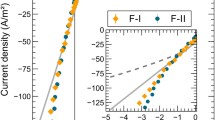

Figure 8 shows the polarization and power curves of the MSRED system under the maximum net power condition for each evaluated high-salinity concentration. The output voltage of the MSRED system decreases as the load current increases in a nonlinear trend since the variation of the solution concentration in HC and LC compartments is significantly impacted by the external electrical current, which can result in subtle changes in the internal resistance of the MSRED system. The LC compartment resistance accounts for a large proportion of the total stack resistance. According to Eqs. (17)- (18), the ionic and water fluxes across membranes increase as the current increases, promoting the solution concentration balance and enhancing the conductivity of the LC solution, thus leading to a gradual decrease in the total stack resistance and the slope of the polarization curve. The gross and net power of the MSRED system increase with increasing current, reach their maximum values, then decrease, which has also been reported in Refs. [21, 24, 25]. The larger current will lead to a rapid decrease in the salinity gradient, thus weakening the output performance of downstream stacks and even resulting in energy loss due to the phenomenon of electrodialysis. There exists an optimal output current leading to the maximum net power output. Figure 9 shows the variations of output voltage and load current with the number of RED stacks for each high salinity concentration under maximum net power conditions. As the stage number increases, the optimal current decreases meanwhile the corresponding total voltage increases. Higher feeding concentration renders larger output voltage and current due to more salinity gradient available.

3.2 Economic analysis

3.2.1 Levelized cost of electricity

The LCOE is typically used in cross-comparison with established conventional and renewable energy to assess the power generation potential and market competitiveness. LCOE of the MSRED system is influenced by the system scale and feed solutions at a given membrane unit price and discount rate level. A larger stage number augments the effective membrane area thus enhancing energy production and energy efficiency. However, it leads to higher equipment costs. Figure 10 shows the variations of LCOE of the serial control MSRED system with stage numbers at different regional tax and electricity price levels under the maximum net power output conditions. Higher feed solution concentration can significantly decrease the system LCOE. The LCOE first decreases with increasing stage numbers, reaches its minimum value, then increases. At small stage numbers, lower net power generation hinders the LCOE. Increasing the stage numbers significantly improves the annual power generation, which decreases the LCOE. At larger stage numbers, augmenting stage numbers induces a significant increase in capital cost. The marginal growth in annual production is insufficient to cover the capital expenditure, resulting in increased LCOE. The lowest LCOE occurs at n = 3 due to the compromise between net power generation and capital cost, while the corporate tax rate and high-salinity concentration present no obvious contribution to the optimal stage number. The LCOE decreases with increasing feed solution concentrations due to augmented net power generation, which is in accordance with Ref. [29]. This decreasing trend weakens at higher concentrations since LCOE is mainly influenced by power generation when the stage number is fixed according to Eq. (32). Larger power generation leads to a smaller value of LCOE. Therefore, the differences in LCOE become less significant as the concentration increases. As shown in Fig. 10A, in Germany, for 5 M/0.05 M solutions, the lowest system LCOE is 0.061 €·kWh−1; For 4 M/0.05 M solutions, the lowest system LCOE is 0.067 €·kWh−1; For 3 M/0.05 M solutions, the lowest system LCOE is 0.076 €·kWh−1; For 2 M/0.05 M solutions, the lowest system LCOE is 0.097 €·kWh−1. The lowest LCOEs under the studied solution concentrations are all lower than the actual electricity price benchmark, which indicates that the serial control MSRED plant presents considerable commercial competitiveness when determining reasonable construction scale and operating conditions.

3.2.2 Net present value

The NPV is an economic indicator that reflects the profitability of the MSRED system, containing funds and net cash flow over the plant lifecycle thus evaluating the economic feasibility. At a specific discount rate, NPV depends on multiple factors such as the corporate income tax rate, electricity price, MSRED plant scale, and annual power generation. Figure 11 shows the variations of NPV of the serial control MSRED system with stage numbers at different regional tax and electricity price levels under the maximum net power output conditions. The NPV over the system lifecycle is positively correlated with the feed solution concentration. With the increase of stage numbers, the NPV increases first as enlarging the scale of the MSRED system can significantly increase the electricity sales revenue despite the higher corresponding investment cost. Large stage numbers lead to decreased NPV as the slight growth in annual production is insufficient to offset the increased capital expenditure, especially at lower feed solution concentrations. Negative NPVs exist at larger stage numbers, indicating that the system cannot achieve the expected revenue. The peak value of NPV is significantly affected by the selling price of electricity. As shown in Fig. 11, for 5 M/0.05 M solutions, the highest NPV over the system lifecycle of 52,005 € is obtained at n = 8 in Germany; the highest NPV over the system lifecycle of 73,413 € is obtained at n = 8 in France; the highest NPV over the system lifecycle of 90,487 € is obtained at n = 9 in Italy; the highest NPV over the system lifecycle of 34,256 € is obtained at n = 7 in Spain. Figure 11 also shows that the NPV increases with increasing feed solution concentrations due to augmented net power generation. For example, in Germany, the optimal stage numbers are 4, 5, 7, and 8, respectively, under the involved concentration ratios.

Figure 12 shows the variations of the annual revenue of serial control MSRED system at the minimum LCOE and maximum NPV conditions. There is a slight decline in the net revenue in years 11 and 21 since the membrane lifetime has been reached and the membrane replacement cost computed by Eq. (27) raises the maintenance cost. This phenomenon is more prevailing under the maximum NPV condition. The turning point for a positive NPV increases with decreasing feed solution concentrations. At the maximum NPV condition, the earnings over the system lifecycle are higher than that at the minimum LCOE condition. However, this difference gradually narrows as the feed solution concentration decreases since the stage numbers corresponding to the optimal NPV and optimal LCOE are the same.

3.2.3 Impacts of regional tax and electricity price

Here the serial control MSRED system is fed with 4 M/0.05 M solutions. Figure 13 illustrates the variations of LCOE of the serial control MSRED system with stage numbers at different regional tax levels and tax uncertainty range. The tax has relatively little impact on LCOE at a single stage. However, the effect of the tax variation on LCOE gradually strengthens as the scale of the MSRED system extends. Figure 14 shows the variations of NPV of the serial control MSRED system with stage numbers at the tax rate uncertainty interval of different regions. The effect of the tax variation on NPV over the system lifecycle becomes more significant when the scale of the MSRED system is closer to that at the maximum NPV. The fluctuation of NPV is more obvious at a higher tax rate. Figure 15 shows the variations of NPV of the serial control MSRED system with stage numbers at the electricity price uncertainty interval of different regions. The electricity price has a significant impact on NPV over the system lifecycle. The effect of the electricity price change on NPV gradually strengthens as the scale of the MSRED system is enlarged. The fluctuation of NPV is more remarkable at a higher electricity price level. Lower tax and higher electricity price can significantly accelerate the commercial competitiveness of the MSRED systems.

4 Conclusions

In this study, an improved mathematical model of the MSRED system under serial control strategy is proposed, which considered the changes of volume flow rate and concentration-depended density along the flow direction. Based on the proposed model, particle swarm optimization is adopted to identify the maximum output power situations under various serial stages and salinity gradient sources. And a complete technical–economic analysis is conducted with considering discount, depreciation and different regional tax and electricity price levels. The main findings are listed below:

-

(1)

The serial control MSRED system presents much greater output power and energy efficiency compared to a single-stage RED stack. The net power output and energy efficiency of the MSRED system increase first with increasing stage numbers, reach their maximum values, then decrease. The optimal stage number corresponding to maximum net power output increases with increasing feed solution concentrations. For 5 M/0.05 M solutions, the optimal net power output of 4.98 kW is available at n = 12; For 2 M/0.05 M solutions, the optimal net power output of 2.04 kW is available at n = 7.

-

(2)

Higher feed solution concentration can significantly decrease the system LCOE. The LCOE first decreases with increasing stage numbers, reaches its minimum value, then increases. Due to the compromise between net power generation and capital cost, the lowest LCOE occurs at n = 3. For 5 M/0.05 M solutions, the lowest system LCOE of 0.061 €·kWh−1 is obtained in Germany.

-

(3)

The NPV increases first with increasing stage numbers, reaches the maximum value, and then decreases. The optimal stage number corresponding to the maximum NPV increases with increasing feed solution concentrations. In Germany, for 5 M/0.05 M solutions, the highest NPV over the system lifecycle of 52,005 € is obtained at n = 8; For 2 M/0.05 M solutions, the highest NPV over the system lifecycle of 13,463 € is obtained at n = 4.

-

(4)

Lower tax, higher electricity price, appropriate membrane price (lower than 4 €·m−2) and high salinity gradient sources (e.g., brine/freshwater) can significantly accelerate the commercial competitiveness of the MSRED systems. For 5 M/0.05 M solutions, with the reduction in tax rate from 0.3 to 0.24 and the increase in electricity price from 228.131 €·kWh−1 to 302.653 €·kWh−1, the optimal LCOE and NPV are increased by 5.3% and 74.0%, respectively.

This paper could serve as guidance for the design and operation of the MSRED system for actual applications. It should be also addressed that there is room for further improvement in many aspects. As membrane-base technologies, Membranes are crucial items in the MSRED system, further efforts by researchers and manufacturers are needed to enhance their performance at an affordable cost. Improving membrane lifespan and system maintenance deserves in-depth research. Stable and reliable SGE sources are also important for the operation of the MSRED system. Employing the MSRED system for efficient SGE extraction could contribute to the transformation of the global energy structure and facilitate the replacement of traditional fossil fuels with “blue energy”, thus to reduce greenhouse gas emission and alleviate the induced environmental issues in the fossil energy utilization process. In addition, coupled technological, economic and environmental assessments should be conducted to evaluate the commercial competitiveness of the MSRED system under different scenarios.

Availability of data and materials

The original data are available from corresponding authors upon reasonable request.

Abbreviations

- AEM:

-

Anion exchange membrane

- CAPEX:

-

Capital expenditure

- CEM:

-

Cation exchange membrane

- HC:

-

High concentration

- IEM:

-

Ion exchange membrane

- LC:

-

Low concentration

- LCOE:

-

Levelized Cost of Electricity

- MSRED:

-

Multi-stage reverse electrodialysis

- NPV:

-

Net Present Value (€)

- OPEX:

-

Operational expenditure

- PRO:

-

Pressure retarded osmosis

- PSO:

-

Particle Swarm Optimization

- RED:

-

Reverse electrodialysis

- RO:

-

Reverse osmosis

- SGE:

-

Salinity gradient energy

References

Ortiz-Imedio R, Gomez-Coma L, Fallanza M, Ortiz A, Ibañez R, Ortiz I (2019) Comparative performance of salinity gradient power-reverse electrodialysis under different operating conditions. Desalination 457:8–21

Long R, Kuang Z, Liu Z, Liu W (2019) Ionic thermal up-diffusion in nanofluidic salinity-gradient energy harvesting. Natl Sci Rev 6(6):1266–1273

Long R, Luo Z, Kuang Z, Liu Z, Liu W (2019) Effects of heat transfer and the membrane thermal conductivity on the thermally nanofluidic salinity gradient energy conversion. Nano Energy. 67:104284

Weinstein JN, Leitz FB (1976) Electric power from differences in salinity. Dialytic Battery 191(4227):557–559

Post JW, Goeting CH, Valk J, Goinga S, Veerman J, Hamelers HVM et al (2010) Towards implementation of reverse electrodialysis for power generation from salinity gradients. Desalination Water Treat 16(1–3):182–193

Kuleszo J, Kroeze C, Post J, Fekete BM (2010) The potential of blue energy for reducing emissions of CO2 and non-CO2 greenhouse gases. J Integr Environ Sci 7(sup1):89–96

Wick GL (1978) Power from salinity gradients. Energy 3(1):95–100

Brogioli D, Ziano R, Rica RA, Salerno D, Kozynchenko O, Hamelers HVM et al (2012) Exploiting the spontaneous potential of the electrodes used in the capacitive mixing technique for the extraction of energy from salinity difference. Energy Environ Sci 5(12):9870–9880

Jang J, Kang Y, Han JH, Jang K, Kim CM, Kim IS (2020) Developments and future prospects of reverse electrodialysis for salinity gradient power generation: influence of ion exchange membranes and electrodes. Desalination. 491:114540

Abidin MNZ, Nasef MM, Veerman J (2022) Towards the development of new generation of ion exchange membranes for reverse electrodialysis: a review. Desalination. 537:115854

Tian H, Wang Y, Pei Y, Crittenden JC (2020) Unique applications and improvements of reverse electrodialysis: a review and outlook. Appl Energy. 262:114482

Nazif A, Karkhanechi H, Saljoughi E, Mousavi SM, Matsuyama H (2022) Recent progress in membrane development, affecting parameters, and applications of reverse electrodialysis: a review. J Water Process Eng 47:102706

Zoungrana A, Çakmakci M (2021) From non-renewable energy to renewable by harvesting salinity gradient power by reverse electrodialysis: a review. Int J Energy Res 45(3):3495–3522

Mehdizadeh S, Yasukawa M, Abo T, Kuno M, Noguchi Y (2019) Higa M The effect of feed solution temperature on the power output performance of a pilot-scale reverse electrodialysis (RED) system with different intermediate distance. Membranes 9(6):73

Nam J-Y, Hwang K-S, Kim H-C, Jeong H, Kim H, Jwa E et al (2019) Assessing the behavior of the feed-water constituents of a pilot-scale 1000-cell-pair reverse electrodialysis with seawater and municipal wastewater effluent. Water Res 148:261–271

Moreno J, Díez V, Saakes M, Nijmeijer K (2018) Mitigation of the effects of multivalent ion transport in reverse electrodialysis. J Membr Sci 550:155–162

Vermaas DA, Veerman J, Saakes M, Nijmeijer K (2014) Influence of multivalent ions on renewable energy generation in reverse electrodialysis. Energy Environ Sci 7: 1434-1445

Weiner AM, McGovern RK, Lienhard VJH (2015) A new reverse electrodialysis design strategy which significantly reduces the levelized cost of electricity. J Membr Sci 493:605–614

Giacalone F, Catrini P, Tamburini A, Cipollina A, Piacentino A, Micale G (2018) Exergy analysis of reverse electrodialysis. Energ Convers Manage 164:588–602

Tedesco M, Cipollina A, Tamburini A, Micale G (2017) Towards 1 kW power production in a reverse electrodialysis pilot plant with saline waters and concentrated brines. J Membr Sci 522:226–236

Simões C, Vital B, Sleutels T, Saakes M, Brilman W (2022) Scaled-up multistage reverse electrodialysis pilot study with natural waters. Chem Eng J 450:138412

Veerman J, Saakes M, Metz SJ, Harmsen GJ (2009) Reverse electrodialysis: performance of a stack with 50 cells on the mixing of sea and river water. J Membr Sci 327(1):136–144

Tedesco M, Mazzola P, Tamburini A, Micale G, Bogle IDL, Papapetrou M et al (2015) Analysis and simulation of scale-up potentials in reverse electrodialysis. Desalination Water Treat 55(12):3391–3403

Simões C, Pintossi D, Saakes M, Brilman W (2021) Optimizing multistage reverse electrodialysis for enhanced energy recovery from river water and seawater: experimental and modeling investigation. Adv Appl Energy 2:100023

Wang Z, Li J, Zhang C, Wang H, Kong X (2022) Power production from seawater and discharge brine of thermal desalination units by reverse electrodialysis. Appl Energy 314:118977

Hu J, Xu S, Wu X, Wu D, Jin D, wang P et al (2019) Multi-stage reverse electrodialysis: strategies to harvest salinity gradient energy. Energy Conv Manag 183:803–815

Turek M, Bandura B (2007) Renewable energy by reverse electrodialysis. Desalination 205(1):67–74

Daniilidis A, Herber R, Vermaas DA (2014) Upscale potential and financial feasibility of a reverse electrodialysis power plant. Appl Energy 119:257–265

Giacalone F, Papapetrou M, Kosmadakis G, Tamburini A, Micale G, Cipollina A (2019) Application of reverse electrodialysis to site-specific types of saline solutions: a techno-economic assessment. Energy 181:532–547

Tedesco M, Cipollina A, Tamburini A, Bogle IDL, Micale G (2015) A simulation tool for analysis and design of reverse electrodialysis using concentrated brines. Chem Eng Res Des 93:441–456

Veerman J, Saakes M, Metz SJ, Harmsen GJ (2011) Reverse electrodialysis: a validated process model for design and optimization. Chem Eng J 166(1):256–268

Veerman J, Post JW, Saakes M, Metz SJ, Harmsen GJ (2008) Reducing power losses caused by ionic shortcut currents in reverse electrodialysis stacks by a validated model. J Membr Sci 310(1):418–430

Pitzer KS, Peiper JC, Busey RH (1984) Thermodynamic properties of aqueous sodium chloride solutions. J Phys Chem Ref Data 13(1):1–102

Tedesco M, Brauns E, Cipollina A, Micale G, Modica P, Russo G et al (2015) Reverse electrodialysis with saline waters and concentrated brines: a laboratory investigation towards technology scale-up. J Membr Sci 492:9–20

Vermaas DA, Saakes M, Nijmeijer K (2011) Power generation using profiled membranes in reverse electrodialysis. J Membrane Sci 385–386:234–242

Laliberté M (2007) Model for calculating the viscosity of aqueous solutions. J Chem Eng Data 52(2):321–335

Choi J, Kim W-S, Kim HK, Yang S, Jeong NJ (2021) Ultra-thin pore-filling membranes with mirror-image wave patterns for improved power density and reduced pressure drops in stacks of reverse electrodialysis. J Membr Sci 620:118885

Veerman J, de Jong RM, Saakes M, Metz SJ, Harmsen GJ (2009) Reverse electrodialysis: comparison of six commercial membrane pairs on the thermodynamic efficiency and power density. J Membr Sci 343(1):7–15

Long R, Li B, Liu Z, Liu W (2018) Reverse electrodialysis: modelling and performance analysis based on multi-objective optimization. Energy 151:1–10

Long R, Li B, Liu Z, Liu W (2018) Performance analysis of reverse electrodialysis stacks: channel geometry and flow rate optimization. Energy 158:427–436

Kennedy J, Eberhart R (1995) Particle swarm optimization. Proceedings of International Conference on Neural Networks (ICNN’95). Perth: IEEE, 1995. 1942–1948.

Micari M, Bevacqua M, Cipollina A, Tamburini A, Van Baak W, Putts T et al (2018) Effect of different aqueous solutions of pure salts and salt mixtures in reverse electrodialysis systems for closed-loop applications. J Membr Sci 551:315–325

Hu J, Xu S, Wu X, Wang S, Zhang X, Yang S et al (2020) Experimental investigation on the performance of series control multi-stage reverse electrodialysis. Energy Conv Manag 204:112284

Glenk G, Reichelstein S (2019) Economics of converting renewable power to hydrogen. Nat Energy 4(3):216–222

Zhao Y, Li M, Long R, Liu Z, Liu W (2023) Techno-economic analysis of converting low-grade heat into electricity and hydrogen. Carbon Neutrality 2(1):19

Duncan C, Roche R, Jemei S, Pera M-C (2022) Techno-economical modelling of a power-to-gas system for plant configuration evaluation in a local context. Appl Energy 315:118930

Malek A, Hawlader MNA, Ho JC (1996) Design and economics of RO seawater desalination. Desalination 105(3):245–261

Quoilin S, Declaye S, Tchanche BF, Lemort V (2011) Thermo-economic optimization of waste heat recovery Organic Rankine Cycles. Appl Therm Eng 31(14):2885–2893

Caldera U, Bogdanov D, Breyer C (2018) Chapter 8 - desalination costs using renewable energy technologies. In: Gude VG (ed) Renewable energy powered desalination handbook. Butterworth-Heinemann, pp 287–329

ENTSO-E. Transparency Platform (2022) https://transparency.entsoe.eu

Trading Economics Platform (2022) https://zh.tradingeconomics.com/

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (52176070)

Funding

National Natural Science Foundation of China (52176070).

Author information

Authors and Affiliations

Contributions

LW: Investigation, Visualization, Writing-original draft; YZ: Investigation; RL: Conceptualization, Methodology, Supervision, Writing-review & editing, Funding acquisition; ZL: Conceptualization; WL: Conceptualization. The authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors have no competing interests to declare that are relevant to the content of this article.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Wang, L., Zhao, Y., Long, R. et al. Techno-economics of multi-stage reverse electrodialysis for blue energy harvesting. Carb Neutrality 3, 12 (2024). https://doi.org/10.1007/s43979-024-00087-7

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s43979-024-00087-7