Abstract

High energy density lithium metal batteries (LMBs) have garnered significant research interests in the past decades. However, the growth of lithium dendrites and the low Coulombic efficiency (CE) of Li metal anode pose significant challenges for the development of LMBs. Herein, we report a triethyl orthoformate (TEOF)-based localized high-concentration electrolyte (LHCE) that facilitates a highly reversible Li metal anode with dendrite-free deposition morphologies and an average Coulombic efficiency of 99.1% for 450 cycles. Mechanistic study reveal that the steric hindrance caused by the terminal ethyl groups in the TEOF solvent molecule results in a weak solvating ability, leading to the formation of anion-dominant solvation structures. The anion-dominant solvation sheaths play an essential role in the formation of a LiF-rich solid-electrolyte interphase (SEI), which effectively suppresses the growth of Li dendrites. Furthermore, the TEOF-based electrolyte demonstrates the stable cycling of high-voltage Li||NMC811 cells. These results provide insights into understanding of steric hindrance effect on electrolyte solvation structure and offer valuable guidance for the design of electrolyte solvents in the development of lithium metal batteries.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Lithium metal batteries (LMBs) hold significant promise as next-generation rechargeable storage devices capable of delivering high energy densities > 500 Wh kg−1 [1,2,3]. However, the development of LMBs is greatly hindered by the low Coulombic efficiency (CE) and the serious dendrite growth of lithium metal anode [4,5,6,7]. During the repeated Li plating/stripping processes, the vigorous and uncontrollable chemical/electrochemical reactions between Li metal anode and electrolytes lead to the constant growth of solid-electrolyte interphase (SEI) [8,9,10,11,12]. The resulting unstable SEI not only continuously consumes the active Li and electrolytes, but also results in low CE and the growth of dendritic Li, which accelerates the failures of Li metal anode [13,14,15,16]. Also, the uncontrollable Li dendrite may penetrate through the separators, leading to short circuits and serious safety issues.

Optimizing electrolytes plays an essential role in improving the cycling stability of Li metal anode [17,18,19]. While traditional carbonate-based electrolytes match well with the graphite anode [20], they exhibit high reactivity with Li metal anode [21,22,23], leading to poor reversibility and a shorten lifespan of Li metal anode. In contrast, ether-based electrolytes exhibit higher compatibility with Li metal anode, which can greatly improve the CE and suppress the dendrite growth [24, 25]. Unfortunately, the ether-based electrolytes show incompatibility with the high-voltage cathode due to their poor anodic ability [26]. Recently, many electrolyte strategies have been developed to further improve the compatibility of ether-based electrolytes with Li metal anode and high-voltage cathode, including solvent fluorination [27,28,29], weakly solvating electrolytes (WSEs) [30,31,32,33,34] and localized high-concentration electrolytes (LHCEs) [35,36,37]. Among these, LHCEs are currently one of the most advanced electrolytes for high-voltage LMBs [38,39,40]. In LHCEs, the non-solvating diluents can further enhance the anion-dominant solvation structures [41, 42], which facilitate the formation of inorganic-rich SEI to improve the cycling stability of Li metal anode [43]. However, most efforts regarding LHCEs focus on the development of new diluents [37, 44], with little attention given to the design of new ether molecules [45]. Therefore, there is an urgent need to explore the solvent structure effect in LHCEs for high-voltage LMBs.

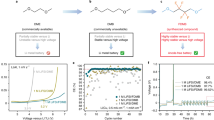

In this work, we present the steric hindrance effect of solvent molecules in LHCEs by systematically comparing triethyl orthoformate (TEOF) and trimethyl orthoformate (TMOF) as weakly solvating solvents for high-voltage LMBs. We found that the TEOF molecules with ethyl groups can significantly increase steric hindrance and weaken the solvation ability, thus facilitating the formation of suitable SEI on Li metal anode and also enhancing the anodic stability on high-voltage NCM811 cathode. Raman spectra and theoretical simulations reveal that the weakly solvating TEOF solvent contributes to an anion-dominant solvation structure. Such solvation structures facilitate the formation of LiF-rich SEI, which enables a high reversible Li metal anode with dendrite-free Li deposition morphologies and a high CE of ~ 99.1% for 450 cycles. In addition, the TEOF-based electrolyte enables stable cycling of high-voltage Li||NMC811 cells, with a high capacity retention of ~ 95.6% for 150 cycles. More importantly, our work provides new sights for the rational design of high-performance electrolytes for high energy density LMBs.

2 Experimental section

2.1 Materials and electrolytes preparations

Lithium Bis(fluorosulfonyl)imide (LiFSI) (≥ 99.8%) salt was purchased from Ningde Guotai Huarong New Material Co., Ltd and dried at 80 ℃ overnight in a vacuum chamber. Trimethyl orthoformate (TMOF) (≥ 98%) and Triethyl orthoformate (TEOF) (≥ 98%) were purchased from Aladdin. 1,1,2,2-Tetrafluoroethyl-2,2,3,3-tetrafluoropropylether (TTE) (≥ 99.5%) was purchased from Shang Fluoro Co., Ltd. Before use, TMOF, TEOF, and TTE solvents were dried with activated molecule sieves for 2 days. The working electrolytes used in this work were LiFSI/TMOF/TTE and LiFSI/TEOF/TTE (1:1.2:3, by molar ratio).

2.2 Cell assembly and electrochemical tests

All electrochemical tests in this work were carried out using 2032-type coin cells, which were assembled in the Ar-filled glove box (< 0.1 ppm H2O and < 0.1 ppm O2). Li||Cu cells were assembled with one piece of lithium metal foil (450 μm, Φ = 14 mm) and one piece of copper foil (25 μm, Φ = 19.1 mm). Li||Li cells were assembled with two pieces of lithium metal foils. For the long-term cycling of Li||Cu cells, Li metal was firstly deposited on the Cu substrate at a current density of 0.5 mA cm−2 or 1 mA cm−2 for 1 mAh cm−2, then stripped to 1 V. For the preparation of NMC811 electrode, NMC811 cathode materials, super P and poly(vinylidene fluoride) (PVDF) were mixed with a mass ratio of 85:7.5:7.5 using N-methyl-2-pyrrolidone (NMP) as a solvent, the as-prepared mixture was stirred to get a slurry. The slurry was further coated on the carbon-coated Al foil and dried at 60 ℃ overnight under vacuum, then cut into pieces (Φ = 14 mm). Before use, the NMC811 cathode was dried at 110 ℃ overnight and transferred into the glovebox. The loading of cathode material in this work was ~ 3 mAh cm−2. In Li||NMC811 cells, one piece of thin lithium metal foil (50 μm, Φ = 16 mm) and one piece of NMC811 electrode were used. In Li||LCO cells, one piece of thin lithium metal foil (450 μm, Φ = 15.6 mm) and one piece of LCO electrode were used. In each cell, Celgard 2325 (25 μm, Φ = 19.1 mm) was used as separator and 80 µL of electrolyte was applied. The cells were tested on a Neware battery testing system (CT-3000n). Linear sweep voltammetry (LSV), cyclic voltammetry (CV) and electrochemical impedance spectroscopy (EIS) measurements were tested in Li||Carbon paper cells, Li||Cu cells, and Li||Li cells, respectively. Both LSV, CV, and EIS measurements were conducted on a CHI760e electrochemical station.

2.3 Characterizations

The Li deposition morphologies were observed using scanning electron microscopy (SEM, FEI Apreo) operated with a working voltage of 2 kV. The modulus of deposited Li was tested by atomic force microscopy (AFM, Bruker Dimension Icon). The modulus measurements were operated in the peak-force quantitative nano-mechanical mapping (QNM) mode. Before SEM and AFM measurements, the samples were washed with DME for several times to clean the residues and dried naturally. The surface chemistry of the Li deposits was characterized by X-ray photoelectron spectroscopy (XPS, KRATOS AXIS SUPRA+). The samples were washed with DME beforehand, and loaded on the XPS transfer holder to avoid exposure to air environment. The depth profiling sputtering was carried out with an Ar-ion gun (5 kV, 2 mm × 2 mm). The sputtering time was 4 min for Li metal samples and 2 min for NMC811 samples, respectively. Raman microscope (Raman, Renishaw inVia) and nuclear magnetic resonance spectrometer (NMR, JNM-ECZ600R/S1) were used to characterize the solvation behaviors in the two electrolytes.

2.4 Theoretical simulations

Density function theory (DFT) calculations were performed to optimize molecular geometries of TEOF and TMOF molecules using the Jaguar 8.8 software package at the level of B3LYP level with the 6-311 + G(d,p) basis sets [46]. Dipole moment and electrostatic potential (ESP) were calculated using at B3LYP/6-311 + G(d) level, which has been reported to well predict the formation charge. The binding energy (△Ebinding) was calculated as follows:

Where E(sol) and E(sol-Li+) are the potential energies of the solvent and Li+ together with solvent, respectively. E(Li+) represents the energy of the Li+.

The dielectric constant of electrolytes, solvation structures and radial distribution function (RDF) were obtained from classical molecular dynamics (cMD) simulations. All cMD simulations were conducted with the GROMACS 2020 program [47]. The simulation of TMOF consists of 100 LiFSI, 120 TTE, and 360 TMOF molecules. The size of the simulation cell of the TMOF system is 109.39 nm3. The simulation of TEOF consists of 100 LiFSI, 120 TTE, and 360 TEOF molecules. The size of the simulation cell of the TEOF system is 142.00 nm3. The electrolyte concentrations were simulated in consistent with experiments. The systems were firstly equilibrated under the isothermal-isobaric (NPT) ensemble. In 2 ns NPT simulations, the temperature was kept at 300 K using a V-rescale thermostat with a relaxation time of 0.1 ps and the pressure was kept at 1 bar using a Berendsen barostat with a relaxation time of 0.5 ps. Thereafter, the systems were simulated in the canonical (NVT) ensemble for 1 ns. In 1 ns NVT simulations, the temperature was kept at 300 K using a V-rescale thermostat with a relaxation time of 0.1 ps.

3 Results and discussion

3.1 Steric hindrance effect on solvation structures

We selected the commercially available solvent, trimethyl orthoformate (TMOF), as a foundational solvent, owing to its distinct open-chain structure, as depicted in Fig. 1a. However, the multiple coordination sites result in strong solvation ability of TMOF, which may generate solvent-dominated solvation structures that have poor compatibility with Li metal anode. We expect that increasing the steric hindrance by lengthening the terminal alkyl group could decrease the solvation ability of TMOF. Under this design principle, we introduced triethyl orthoformate (TEOF) as a weakly solvating solvent. Both TMOF and TEOF molecules have three O atoms that can serve as the Li+ binding sites, leading to the highly centralized negative charge density center indicated from the DFT-derived electrostatic potentials (ESPs) (Fig. 1b, c). Compared with TMOF, the larger ethoxy groups on TEOF provide a stronger steric hindrance. The steric effects of terminal alkyl groups could hinder the interactions between TEOF and Li+, resulting in a lower solvation ability of TEOF than TMOF [30, 33]. In order to substantiate this hypothesis, we have constructed the LHCEs utilizing TMOF and TEOF as equivalent solvents, selecting LiFSI as the salt, and employing non-solvation solvent TTE as the diluent.

Molecular dynamics (MD) simulations and Raman spectroscopy were conducted to elucidate the Li+ solvation structures in both electrolytes. Diverse solvation structures in the electrolytes can be identified based on the differing coordination states of FSI− anions. These structures can be categorized into separated solvated ion pairs (SSIP), contact ion pairs (CIP), and aggregates (AGG), as illustrated in Fig. S1. In both electrolytes, a typical AGG structure consists of two anions and one solvent molecule directly coordinating with one Li+. As depicted in Fig. 2a, b, the increased steric hindrance affected the interactions between Li+ and FSI− anions in two electrolytes, which aligns well with our electrolyte design principles. The Raman signals detected in the 1200–1250 cm−1 range correspond to the vibrations of the S = O stretching mode of FSI− anions [48]. Notably, both LiFSI-1.2TMOF-3TTE and LiFSI-1.2TEOF-3TTE electrolytes manifest an overlapping peak within this range, which can be further vested into three characteristic peaks of SSIP, CIP, and AGG (Fig. S2). A noteworthy contrast in the solvation structures is evident when comparing the LiFSI-1.2TMOF-3TTE and LiFSI-1.2TEOF-3TTE electrolytes. The latter exhibits an increased intensity of AGG and a simultaneous decrease in SSIP intensity (Fig. 2c), suggesting that more FSI− anions are incorporated into the solvation sheaths. Statistical calculations further corroborate this observation, indicating that the LiFSI-1.2TEOF-3TTE electrolyte (~ 78%) has a broader distribution of coordinated anions compared to the LiFSI-1.2TMOF-3TTE (~ 73%) (Fig. 2d). This divergence in solvation structures between the two electrolytes can be attributed to the molecular differences between TMOF and TEOF. MD simulations are carried out for a more profound understanding of these solvation structures (Fig. 2e-f). For the LiFSI-1.2TMOF-3TTE electrolyte, the TMOF solvent primarily resides in the first solvation sheath of Li+ (Fig. 2g, Fig. S3). Conversely, the LiFSI-1.2TEOF-3TTE electrolyte shows an enhanced signal of Li+-O(FSI−) pairs in the first solvation sheaths, indicative of increased interactions between Li+ and anions. These anion-dominant solvation structures in LiFSI-1.2TEOF-3TTE may promote a prior decomposition of anions, potentially leading to the formation of an inorganic-rich SEI.

DFT optimized AGG solvation structure in the a LiFSI-1.2TMOF-3TTE and b LiFSI-1.2TEOF-3TTE electrolytes. c Raman spectra of these two electrolytes. d The corresponding statistics of disassociated and solvated FSI− anions based on the Raman results. Snapshots of the MD simulations boxes in e LiFSI-1.2TMOF-3TTE and f LiFSI-1.2TEOF-3TTE. Radical distribution function g(r) from the MD results of g LiFSI-1.2TMOF-3TTE and h LiFSI-1.2TEOF-3TTE

3.2 Reversibility of Li metal anode

SEM images of the deposited Li with a capacity of a, d 0.5 mAh cm−2 and b, e 1 mAh cm−2 in the LiFSI-1.2TMOF-3TTE andLiFSI-1.2TEOF-3TTE electrolyte at 0.5 mA cm−2. c, f Cross-sectional SEM images of the deposited Li with a capacity of 1 mAh cm−2. AFM observations of the deposited Li in g LiFSI-1.2TMOF-3TTE and h LiFSI-1.2TEOF-3TTE. i The corresponding values of the modulus of SEI formed in two electrolytes

The Li deposition morphologies in these two electrolytes were observed by scanning electron microscopy (SEM). At a deposition capacity of 0.5 mAh cm−2, the LiFSI-1.2TMOF-3TTE electrolyte exhibits the growth of dendritic Li (Fig. 3a, Fig. S4a-c). With a deposition capacity of 1 mAh cm−2, dendritic Li with lengths ranging from 5 to 10 μm can be observed (Fig. 3b, Fig. S4d-i). As shown in the cross-sectional SEM images, the Li deposits exhibit loose structures, with a thickness of ~ 12 μm (Fig. 3c). The dendritic Li and loose structure with high specific surface areas may cause serious parasitic reactions, accelerating the consumption of electrolytes and decreasing the cycling stability of Li metal anode. In contrast, the Li deposits in LiFSI-1.2TEOF-3TTE show closely packed and dendrite-free morphologies (Fig. 3d, e, Fig. S5). With a deposition of 1 mAh cm−2, the deposited Li in LiFSI-1.2TEOF-3TTE exhibits a thickness of ~ 7.2 μm (Fig. 3f), indicating a better compatibility between the electrolyte and Li metal anode. Atomic force microscopy (AFM) characterizations were further conducted to investigate the mechanical properties of SEI formed on the Li metal surface. As shown by the quantitative nanomechanical mapping-AFM images, the modulus distribution of the SEI formed in LiFSI-1.2TMOF-3TTE is inhomogeneous (Fig. 3g), which potentially leads to Li dendrite growth. By contrast, the SEI formed in LiFSI-1.2TEOF-3TTE show a smooth and uniform distribution of modulus (Fig. 3h), leading to an average modulus of ~ 6.28 GPa, which is much higher than that formed in LiFSI-1.2TMOF-3TTE (~ 4.39 GPa, Fig. 3i). The higher modulus of SEI formed in LiFSI-1.2TEOF-3TTE verifies its inorganic-rich feature, which is beneficial in suppressing the Li dendrite growth and improving the reversibility of Li metal anode [49].

To evaluate the compatibility of two electrolytes with Li metal anode, Li||Cu cells were assembled to determine the Coulombic efficiencies (CEs) of Li plating/stripping processes. As shown in Fig. 4a, the LiFSI-1.2TMOF-3TTE electrolyte exhibits an average CE of 99.1% for 380 cycles at 0.5 mA cm−2 and 1 mAh cm−2. However, the CEs after 380 cycles show significant fluctuations (Fig. S6a). In contrast, the Li||Cu cell cycled in LiFSI-1.2TEOF-3TTE shows improved cycling stability, with an average CE of 99.1% for 450 cycles without short circuits (Fig. S6b). Furthermore, when cycled at 1 mA cm−2 and 1 mAh cm−2, the LiFSI-1.2TEOF-3TTE electrolyte also exhibits an enhanced cycling stability of Li||Cu cells than LiFSI-1.2TMOF-3TTE (Fig. 4b, Fig. S7). The former can enable stable cycling of Li||Cu cells for 450 cycles while only 320 cycles for the latter. Although the two electrolytes show similar values of CEs (Fig. S8), the improved kinetics of Li plating/stripping processes and the enhanced lifespan of long-term cycling both verify the higher compatibility of LiFSI-1.2TEOF-3TTE electrolyte with Li metal anode (Fig. S9). Furthermore, electrochemical impedance spectra (EIS) measurements were conducted in Li||Li symmetric cells to compare the electrochemical kinetics of the Li metal anode in two electrolytes. The EIS results of Li||Li cells after 1 cycle and 10 cycles were shown in Fig. 4c and d, respectively. Two semicircles can be observed from the EIS spectra, where the semicircle at high frequency can be assigned to the SEI resistance (RSEI) and the semicircle at middle frequency represents the charge transfer resistance (Rct). After 1 cycle, the RSEI and Rct of the Li||Li cell cycled in LiFSI-1.2TEOF-3TTE (8 Ω and 18 Ω) were lower than that cycled in LiFSI-1.2TMOF-3TTE (12 Ω and 20 Ω). The RSEI of Li||Li cell cycled in LiFSI-1.2TEOF-3TTE decreased to only 3 Ω after 10 cycles, while the LiFSI-1.2TMOF-3TTE shows a much higher value of RSEI (18 Ω), which suggests that the former has better electrochemical kinetics [50].

3.3 Electrochemical performances of Li||NMC811 cells

To compare the high-voltage tolerance of these two electrolytes, linear sweep voltammetry (LSV) measurements were performed in Li||carbon paper cells to investigate the oxidation stability. Compared with LiFSI-1.2TMOF-3TTE, the LiFSI-1.2TEOF-3TTE electrolyte exhibits a broadened electrochemical stability window (> 4.5 V vs. Li/Li+) (Fig. S10), indicating its enhanced anti-oxidation ability. Furthermore, Li (50 μm)||NMC811 (3 mAh cm−2) full cells were assembled to evaluate the cycling performances under high-voltage conditions. The cells were tested within the voltage range between 2.6 and 4.3 V, with a charge rate of 0.2 C and a discharge rate of 0.33 C after three formation cycles of 0.1 C. As shown in Fig. 5, the Li||NMC811 cell cycled in LiFSI-1.2TMOF-3TTE released an initial discharge capacity of ~ 175 mAh g−1, which rapidly decreased to 150 mAh g−1 after 70 cycles, followed by a drop almost to no capacity release after 120 cycles (Fig. 5c). By contrast, the LiFSI-1.2TEOF-3TTE electrolyte exhibits improved cycling stability of Li||NMC811 cells. With a high initial discharge capacity of ~ 182 mAh g−1, the cell remains a stable discharge capacity release of ~ 180 mAh g−1 in the following cycles, with a capacity retention of ~ 95.6% after 150 cycles (Fig. 5b). More importantly, the cell cycled in LiFSI-1.2TMOF-3TTE exhibits an obvious reduction of the CE after 90 cycles, which indicates serious side reactions, while the CE of cell cycled in LiFSI-1.2TEOF-3TTE maintains stable during cycling. In addition, the LiFSI-1.2TEOF-3TTE electrolyte also shows improved cycling stability of Li (450 μm)||LCO (1.4 mAh cm−2) cells cycled within 2.7–4.4 V (Fig. S11). These results suggest that the anion-dominant solvation structures in the LiFSI-1.2TEOF-3TTE electrolyte show improved compatibility with the high-voltage cathodes compared to LiFSI-1.2TMOF-3TTE.

3.4 Interfacial chemistry and understanding

SEM and X-ray photoelectron spectroscopy (XPS) characterizations were conducted to investigate the morphology evolution and interfacial chemistry of the Li metal anode cycled in Li||NMC811 cells after 50 cycles. The cycled Li metal in the LiFSI-1.2TMOF-3TTE electrolyte presents extensive cracks (Fig. 6a, Fig. S12), which results in the continuous penetration of electrolyte to occur in continuous side reactions with fresh Li metal. By contrast, the Li metal anode cycled in LiFSI-1.2TEOF-3TTE exhibits a uniform and smooth surface without any cracks (Fig. 6b). The distinct morphologies of the cycled Li metal origin from the different properties of SEI, which were regulated by the different solvation structures in two electrolytes [51,52,53]. XPS characterizations were further applied to investigate the compositions of SEI. As shown in Fig. 6c, although the similar atomic ratio of C element can be observed in the outer layer of SEI formed in two electrolytes (30% for LiFSI-1.2TMOF-3TTE, 31% for LiFSI-1.2TEOF-3TTE), after argon ion cluster sputtering for 4 min, more content of C can be detected in the inner layer of SEI formed in LiFSI-1.2TMOF-3TTE (21%) than LiFSI-1.2TEOF-3TTE (13%). Furthermore, apparent signals of C-C (~ 284.8 eV), C-O (~ 286 eV), C = O (~ 288.5 eV), and CO32− (~ 289.8 eV) can be observed in the SEI formed in two electrolytes (Fig. 6d h). The increased content of C-containing organic species in the SEI formed in LiFSI-1.2TMOF-3TTE indicates the major contribution of solvent molecules on interfacial reactions, which matches well with the results of solvation structures. More importantly, the Li metal anode cycled in the LiFSI-1.2TEOF-3TTE (7% and 14%) electrolyte shows an increase in the atomic ratio of F element in the outer and inner layer of SEI than that cycled in LiFSI-1.2TMOF-3TTE (4% and 8%). In the F 1s spectra, higher intensity of LiF signal (~ 684.7 eV) and S-F species (~ 687.8 eV) can be detected in the SEI formed in LiFSI-1.2TEOF-3TTE (Fig. 6e and i), which matches with the trend of LiF signal in the Li 1s spectra (Fig. 6f and j). After 4 min sputtering, the Li2O (~ 528.2 eV) peak intensity in the O 1s spectra in LiFSI-1.2TEFO-3TTE is slightly higher than that in LiFSI-1.2TMOF-3TTE (Fig. 6g and k). The enrichments of LiF and Li2O are critical to improving the compatibility of LiFSI-1.2TEOF-3TTE towards the Li metal anode. In addition, the interfacial chemistry of cathode cycled in Li||NMC811 cells after 50 cycles were also characterized (Figs. S13, S14). The cathode cycled in LiFSI-1.2TEOF-3TTE shows an increased peak intensity of the LiF signal, which improves the cycling stability of the high-voltage NMC cathode. Combined with the steric hindrance effect, we found that the anion-dominant solvation structures in the LiFSI-1.2TEOF-3TTE electrolyte contribute to the formation of inorganic-rich SEI and CEI, which are beneficial in improving the cycling stability of high-voltage Li||NMC811 cells.

SEM images of the Li metal anode cycled in Li||NMC811 full cells for 50 cycles using the a LiFSI-1.2TMOF-3TTE and b LiFSI-1.2TEOF-3TTE electrolytes. c Elemental ratios of the SEI on Li metal surface. XPS characterizations of the Li metal anode cycled in d-g LiFSI-1.2TMOF-3TTE and h-k LiFSI-1.2TEOF-3TTE

4 Conclusion

In summary, by regulating the steric hindrance of the TMOF molecule, we developed a novel LHCE that greatly enhanced the cycling stability of high-voltage LMBs. The TEOF molecule, with a lengthened terminal alkyl group than TMOF, has a larger steric hindrance and, therefore, a weakened solvation ability. Raman characterizations and theoretical simulations reveal that the weak solvation ability of TEOF contributes to an anion-dominant solvation structure, which facilitates the formation of a LiF-rich SEI. Therefore, the LiFSI-1.2TEOF-3TTE electrolyte enables dendrite-free Li deposition morphologies and high reversible Li metal anode with a high CE of 99.1% for 450 cycles. In addition, the electrolyte delivers stable cycling of high-voltage Li||NMC811 full cells with a high capacity retention of 95.6% after 150 cycles. The research demonstrates the potential of rational molecular design of electrolytes and provides important implications for the development of high-performance LMBs.

Availability of data and materials

The data and materials are available upon reasonable request.

Abbreviations

- LMBs:

-

Lithium metal batteries

- CE:

-

Coulombic efficiency

- SEI:

-

solid-electrolyte interphase

- LiFSI:

-

Lithium Bis(fluorosulfonyl)imide

- TMOF:

-

Thrimethyl orthoformate

- TEOF:

-

Triethyl orthoformate

- TTE:

-

1,1,2,2-Tetrafluoroethyl-2,2,3,3-tetrafluoropropylether

- ESPs:

-

Electrostatic potentials

- MD:

-

Molecular dynamics

- SSIP:

-

Separated solvated ion pairs

- CIP:

-

Contact ion pairs

- AGG:

-

Aggregates

- RDF:

-

Radical distribution function

- LHCEs:

-

Localized high-concentration electrolytes

- SEM:

-

Scanning electron microscopy

- AFM:

-

Atomic force microscopy

- EIS:

-

Electrochemical impedance spectra

- LSV:

-

Linear sweep voltammetry

- XPS:

-

X-ray photoelectron spectroscopy

References

Cheng XB, Zhang R, Zhao CZ, Zhang Q (2017) Toward safe lithium metal anode in rechargeable batteries: a review. Chem Rev 117(15):10403–10473. https://doi.org/10.1021/acs.chemrev.7b00115

Liu B, Zhang JG, Xu W (2018) Advancing lithium metal batteries. Joule 2(5):833–845. https://doi.org/10.1016/j.joule.2018.03.008

Liu J, Bao ZN, Cui Y, Dufek EJ, Goodenough JB, Khalifah P, Li QY, Liaw BY, Liu P, Manthiram A, Meng YS, Subramanian VR, Toney MF, Viswanathan VV, Whittingham MS, Xiao J, Xu W, Yang JH, Yang XQ, Zhang JG (2019) Pathways for practical high-energy long-cycling lithium metal batteries. Nat Energy 4(3):180–186. https://doi.org/10.1038/s41560-019-0338-x

Lin DC, Liu YY, Cui Y (2017) Reviving the lithium metal anode for high-energy batteries. Nat Nanotechnol 12(3):194–206. https://doi.org/10.1038/nnano.2017.16

Louli AJ, Eldesoky A, Weber R, Genovese M, Coon M, deGooyer J, Deng Z, White RT, Lee J, Rodgers T, Petibon R, Hy S, Cheng SJH, Dahn JR (2020) Diagnosing and correcting anode-free cell failure via electrolyte and morphological analysis. Nat Energy 5(9):693–702. https://doi.org/10.1038/s41560-020-0668-8

Liu H, Sun X, Cheng XB, Guo C, Yu F, Bao WZ, Wang T, Li JF, Zhang Q (2022) Working Principles of Lithium Metal Anode in Pouch cells. Adv Energy Mater 12(47):2202518. https://doi.org/10.1002/aenm.202202518

Zhang JM, Li QP, Zeng YP, Tang Z, Sun D, Huang D, Peng ZG, Tang YG, Wang HY (2022) Non-flammable ultralow concentration mixed ether electrolyte for advanced lithium metal batteries. Energy Storage Mater 51:660–670. https://doi.org/10.1016/j.ensm.2022.07.014

Tikekar MD, Choudhury S, Tu Z, Archer LA (2016) Design principles for electrolytes and interfaces for stable lithium-metal batteries. Nat Energy 1(9):1–7. https://doi.org/10.1038/nenergy.2016.114

Tu ZY, Choudhury S, Zachman MJ, Wei SY, Zhang KH, Kourkoutis LF, Archer LA (2017) Designing artificial solid-electrolyte interphases for single-ion and high-efficiency transport in batteries. Joule 1(2):394–406. https://doi.org/10.1016/j.joule.2017.06.002

Li M, Wang CS, Chen ZW, Xu K, Lu J (2020) New concepts in electrolytes. Chem Rev 120(14):6783–6819. https://doi.org/10.1021/acs.chemrev.9b00531

Zhao Q, Stalin S, Archer LA (2021) Stabilizing metal battery anodes through the design of solid electrolyte interphases. Joule 5(5):1119–1142. https://doi.org/10.1016/j.joule.2021.03.024

Adenusi H, Chass GA, Passerini S, Tian KV, Chen GH (2023) Lithium batteries and the solid electrolyte interphase (SEI)—progress and outlook. Adv Energy Mater 13(10):2203307. https://doi.org/10.1002/aenm.202203307

Li YZ, Li YB, Pei A, Yan K, Sun YM, Wu CL, Joubert L-M, Chin R, Koh AL, Yu Y, Perrino J, Butz B, Chu S, Cui Y (2017) Atomic structure of sensitive Battery materials and interfaces revealed by cryo–electron microscopy. Science 358(6362):506–510

Li YZ, Huang W, Li YB, Pei A, Boyle DT, Cui Y (2018) Correlating structure and function of battery interphases at atomic resolution using cryoelectron microscopy. Joule 2(10):2167–2177. https://doi.org/10.1016/j.joule.2018.08.004

Hobold GM, Kim K-H, Gallant BM (2023) Beneficial vs. inhibiting passivation by the native lithium solid electrolyte interphase revealed by electrochemical Li+ exchange. Energy Environ Sci 16(5):2247–2261. https://doi.org/10.1039/d2ee04203g

Mao ML, Ji X, Wang QY, Lin ZJ, Li MY, Liu T, Wang CL, Hu YS, Li H, Huang XJ, Chen LQ, Suo LM (2023) Anion-enrichment interface enables high-voltage anode-free lithium metal batteries. Nat Commun 14(1):1082. https://doi.org/10.1038/s41467-023-36853-x

Borodin O, Self J, Persson KA, Wang CS, Xu K (2020) Uncharted waters: super-concentrated Electrolytes. Joule 4(1):69–100. https://doi.org/10.1016/j.joule.2019.12.007

Yu ZA, Rudnicki PE, Zhang ZW, Huang ZJ, Celik H, Oyakhire ST, Chen YL, Kong X, Kim SC, Xiao X, Wang HS, Zheng Y, Kamat GA, Kim MS, Bent SF, Qin J, Cui Y, Bao ZN (2022) Rational solvent molecule tuning for high-performance lithium metal battery electrolytes. Nat Energy 7(1):94–106. https://doi.org/10.1038/s41560-021-00962-y

Li MJ, Hicks RP, Chen ZF, Luo C, Guo JC, Wang CS, Xu YH (2023) Electrolytes in organic batteries. Chem Rev 123(4):1712–1773. https://doi.org/10.1021/acs.chemrev.2c00374

Nan B, Chen L, Rodrigo ND, Borodin O, Piao N, Xia J, Pollard T, Hou S, Zhang JX, Ji X, Xu JJ, Zhang XY, Ma L, He XZ, Liu SF, Wan HL, Hu EY, Zhang WR, Xu K, Yang XQ, Lucht B, Wang CS (2022) Enhancing Li+ Transport in NMC811||graphite lithium-ion batteries at low temperatures by using low-polarity-solvent electrolytes. Angew Chem Int Ed 61(35):e202205967. https://doi.org/10.1002/anie.202205967

Zhang WD, Shen ZY, Li SY, Fan L, Wang XY, Chen F, Zang XX, Wu T, Ma FY, Lu YY (2020) Engineering Wavy-nanostructured anode interphases with fast ion transfer kinetics: toward practical Li-metal full batteries. Adv Funct Mater 30(39):2003800. https://doi.org/10.1002/adfm.202003800

Zhang WD, Wu Q, Huang JX, Fan L, Shen ZY, He Y, Feng Q, Zhu GN, Lu YY (2020) Colossal granular lithium deposits enabled by the grain-coarsening effect for high-efficiency lithium metal full batteries. Adv Mater 32(24):2001740. https://doi.org/10.1002/adma.202001740

Jiang ZP, Zeng ZQ, Zhai BY, Li X, Hu W, Zhang H, Cheng SJ, Xie J (2021) Fluorobenzene-based diluted highly concentrated carbonate electrolyte for practical high-voltage lithium metal batteries. J Power Sources 506:230086. https://doi.org/10.1016/j.jpowsour.2021.230086

Qian JF, Henderson WA, Xu W, Bhattacharya P, Engelhard M, Borodin O, Zhang JG (2015) High rate and stable cycling of lithium metal anode. Nat Commun 6:6362. https://doi.org/10.1038/ncomms7362

Chen SQ, Fan JJ, Cui ZZ, Tan LJ, Ruan DG, Zhao X, Jiang JY, Jiao SH, Ren XD (2023) Unveiling the critical role of ion coordination configuration of ether electrolytes for high voltage lithium metal batteries. Angew Chem Int Ed 62(23):e202219310. https://doi.org/10.1002/anie.202219310

Zhang GZ, Chang J, Wang LG, Li JW, Wang CY, Wang R, Shi GL, Yu K, Huang W, Zheng HH, Wu TP, Deng YH, Lu J (2023) A monofluoride ether-based electrolyte solution for fast-charging and low-temperature non-aqueous lithium metal batteries. Nat Commun 14(1):1081. https://doi.org/10.1038/s41467-023-36793-6

Zhao Y, Zhou TH, Ashirov T, Kazzi ME, Cancellieri C, Jeurgens LPH, Choi JW, Coskun A (2022) Fluorinated ether electrolyte with controlled solvation structure for high voltage lithium metal batteries. Nat Commun 13(1):2575. https://doi.org/10.1038/s41467-022-29199-3

Zhao Y, Zhou TH, Baster D, El Kazzi M, Choi JW, Coskun A (2023) Targeted functionalization of cyclic ether solvents for controlled reactivity in high-voltage Lithium Metal batteries. ACS Energy Lett 8:3180–3187. https://doi.org/10.1021/acsenergylett.3c01004

Zhao Y, Zhou TH, Jeurgens LPH, Kong X, Choi JW, Coskun A (2023) Electrolyte engineering for highly inorganic solid electrolyte interphase in high-performance lithium metal batteries. Chem 9(3):682–697. https://doi.org/10.1016/j.chempr.2022.12.005

Chen YL, Yu ZA, Rudnicki P, Gong HX, Huang ZJ, Kim SC, Lai JC, Kong X, Qin J, Cui Y, Bao ZN (2021) Steric effect tuned Ion Solvation enabling stable cycling of high-voltage lithium metal battery. J Am Chem Soc 143(44):18703–18713. https://doi.org/10.1021/jacs.1c09006

Park E, Park J, Lee K, Zhao Y, Zhou T, Park G, Jeong M-G, Choi M, Yoo D-J, Jung HG, Coskun A, Choi JW (2022) Exploiting the steric effect and low dielectric constant of 1,2-dimethoxypropane for 4.3 v lithium metal batteries. ACS Energy Lett 8(1):179–188. https://doi.org/10.1021/acsenergylett.2c02003

Pham TD, Bin Faheem A, Kim J, Oh HM, Lee KK (2022) Practical high-voltage lithium metal batteries enabled by tuning the solvation structure in weakly solvating electrolyte. Small 18(14):2107492. https://doi.org/10.1002/smll.202107492

Wang ZJ, Chen CS, Wang DN, Zhu Y, Zhang B (2023) Stabilizing interfaces in High-Temperature NCM811-Li batteries via tuning terminal Alkyl chains of Ether solvents. Angew Chem Int Ed 62(28):e202303950. https://doi.org/10.1002/anie.202303950

Zhang JM, Li QP, Zeng YP, Tang Z, Sun D, Huang D, Tang YG, Wang HY (2023) Weakly solvating cyclic ether Electrolyte for High-Voltage Lithium Metal batteries. ACS Energy Lett 8(4):1752–1761. https://doi.org/10.1021/acsenergylett.3c00181

Ren XD, Zou LF, Cao X, Engelhard MH, Liu W, Burton SD, Lee H, Niu CJ, Matthews BE, Zhu ZH, Wang CM, Arey BW, Xiao J, Liu J, Zhang JG, Xu W (2019) Enabling high-voltage Lithium-metal batteries under practical conditions. Joule 3(7):1662–1676. https://doi.org/10.1016/j.joule.2019.05.006

Wu JR, Gao ZY, Wang Y, Yang X, Liu Q, Zhou D, Wang XS, Kang FY, Li BH (2022) Electrostatic Interaction tailored Anion-Rich Solvation Sheath stabilizing high-voltage Lithium Metal batteries. Nano-Micro Lett 14(1):147. https://doi.org/10.1007/s40820-022-00896-4

Wu ZC, Li RH, Zhang SQ, lv L, Deng T, Zhang H, Zhang RX, Liu JJ, Ding SH, Fan LW, Chen LX, Fan XL (2023) Deciphering and modulating energetics of solvation structure enables aggressive high-voltage chemistry of Li metal batteries. Chem 9(3):650–664. https://doi.org/10.1016/j.chempr.2022.10.027

Jie Y, Ren X, Cao R, Cai W, Jiao S (2020) Advanced liquid electrolytes for rechargeable Li metal batteries. Adv Funct Mater 30(25):1910777. https://doi.org/10.1002/adfm.201910777

Li W, Jie Y, Chen Y, Yang M, Chen Y, Li X, Guo Y, Meng X, Cao R, Jiao S (2022) Crossover effects of transition metal ions in high-voltage lithium metal batteries. Nano Res 16(6):8417–8424. https://doi.org/10.1007/s12274-022-5334-y

Jie Y, Tang C, Xu Y, Guo Y, Li W, Chen Y, Jia H, Zhang J, Yang M, Cao R, Lu Y, Cho J, Jiao S (2023) Progress and perspectives on the development of pouch-type lithium metal batteries. Angew Chem Int Ed e202307802. https://doi.org/10.1002/anie.202307802

Chen X, Zhang Q (2020) Atomic insights into the fundamental interactions in lithium battery electrolytes. Acc Chem Res 53(9):1992–2002. https://doi.org/10.1021/acs.accounts.0c00412

Ren XD, Gao PY, Zou LF, Jiao SH, Cao X, Zhang XH, Jia H, Engelhard MH, Matthews BE, Wu HP, Lee H, Niu CJ, Wang CM, Arey BW, Xiao J, Liu J, Zhang JG, Xu W (2020) Role of inner solvation sheath within salt-solvent complexes in tailoring electrode/electrolyte interphases for lithium metal batteries. Proc Natl Acad Sci U S A 117(46):28603–28613. https://doi.org/10.1073/pnas.2010852117

Huang ZD, Li XL, Chen Z, Li P, Ji XL, Zhi CY (2023) Anion chemistry in energy storage devices. Nat Rev Chem 14:1–16. https://doi.org/10.1038/s41570-023-00506-w

Amanchukwu CV, Yu ZA, Kong X, Qin J, Cui Y, Bao ZN (2020) A new class of ionically conducting fluorinated ether electrolytes with high electrochemical stability. J Am Chem Soc 142(16):7393–7403. https://doi.org/10.1021/jacs.9b11056

Wang Z, Hou L-P, Zhang Q-K, Yao N, Chen A, Huang J-Q, Zhang X-Q (2023) High-performance localized high-concentration electrolytes by diluent design for long-cycling lithium metal batteries. Chin Chem Lett. https://doi.org/10.1016/j.cclet.2023.108570

Gibson LD, Pfaendtner J (2020) Solvent oligomerization pathways facilitated by electrolyte additives during solid-electrolyte interphase formation. Phys Chem Chem Phys 22(37):21494–21503. https://doi.org/10.1039/d0cp03286g

Abraham MJ, Murtola T, Schulz R, Páll S, Smith JC, Hess B, Lindahl E (2015) Gromacs: high performance molecular simulations through multi-level parallelism from laptops to supercomputers. SoftwareX 1–2:19–25. https://doi.org/10.1016/j.softx.2015.06.001

Liu XW, Shen XH, Zhong FP, Feng XM, Chen WH, Ai XP, Yang HX, Cao YL (2020) Enabling electrochemical compatibility of non-flammable phosphate electrolytes for lithium-ion batteries by tuning their molar ratios of salt to solvent. Chem Commun 56(48):6559–6562. https://doi.org/10.1039/d0cc02940h

Zhang QK, Zhang XQ, Wan J, Yao N, Song TL, Xie J, Hou LP, Zhou MY, Chen X, Li BQ, Wen R, Peng HJ, Zhang Q, Huang JQ (2023) Homogeneous and mechanically stable solid–electrolyte interphase enabled by trioxane-modulated electrolytes for lithium metal batteries. Nat Energy 1–11. https://doi.org/10.1038/s41560-023-01275-y

Yao YX, Chen X, Yan C, Zhang XQ, Cai WL, Huang JQ, Zhang Q (2021) Regulating interfacial chemistry in lithium-ion batteries by a weakly solvating electrolyte. Angew Chem Int Ed 60(8):4090–4097. https://doi.org/10.1002/anie.202011482

He Z, Chen Y, Huang F, Jie Y, Li X, Cao R, Jiao S (2022) Fluorinated solvents for lithium metal batteries. Acta Phys Chim Sinica 0(0):2205005–2205000. https://doi.org/10.3866/pku.Whxb202205005

Jie Y, Xu Y, Chen Y, Xie M, Liu Y, Huang F, Kochovski Z, Lei Z, Zheng L, Song P, Hu C, Qi Z, Li X, Wang S, Shen Y, Chen L, You Y, Ren X, Goddard WA, Cao R, Lu Y, Cheng T, Xu K, Jiao S (2022) Molecular understanding of interphase formation via operando polymerization on lithium metal anode. Cell Rep Phys Sci 3(10). https://doi.org/10.1016/j.xcrp.2022.101057

Chen Y, Li M, Liu Y, Jie Y, Li W, Huang F, Li X, He Z, Ren X, Chen Y, Meng X, Cheng T, Gu M, Jiao S, Cao R (2023) Origin of dendrite-free lithium deposition in concentrated electrolytes. Nat Commun 14(1):2655. https://doi.org/10.1038/s41467-023-38387-8

Acknowledgements

Thanks for the support from department of materials science and engineering of USTC. Thanks for the battery testing supporting form Neware (China).

Funding

Open access funding provided by Shanghai Jiao Tong University. This work was supported by the National Key Research and Development Program of China (Grant No. 2022YFA1504102 and 2022YFB2502200), the Strategic Priority Research Program of the Chinese Academy of Sciences (Grant No. XDB0450302), the National Natural Science Foundation of China (Grant Nos. 52225105, 22279127, 52072358, U21A2082). T. C. thanks the support from Suzhou Key Laboratory of Functional Nano & Soft Materials, the Collaborative Innovation Center of Suzhou Nano Science & Technology, the Priority Academic Program Development of Jiangsu Higher Education Institutions (PAPD), the 111 Project.

Author information

Authors and Affiliations

Contributions

XPL and YXP conducted the experiments; YL conducted the theoretical simulations under the supervision of TC; SQC, SYW, ZXH, YLJ and XDR contributed to the experiment design; XPL, YXP, SYW and YLJ analyzed the data; XPL and YXP wrote the manuscript; XPL, YLJ and RGC revised the manuscript; SHJ and RGC conceived the work and revised the manuscript; All authors read and approved the final manuscript.

Corresponding authors

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

All authors declare that there are no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Additional file 1: Fig. S1.

DFT optimized solvation structures in the (a-c) LiFSI-1.2TMOF-3TTE and (d-f) LiFSI1.2TEOF-3TTE electrolytes. Fig. S2. Raman spectra of the (a) TMOF-based and (b) TEOF-based electrolytes. Fig. S3. Integrated coordination number calculated from MD simulations of the (a) TMOFbased and (b) TEOF-based electrolyte. Fig. S4. SEM images of the deposits in LiFSI-1.2TMOF-3TTE electrolyte with a deposition capacity of (a-c) 0.5 mAh cm-2, (d-f) 1 mAh cm-2 and (g-i) 2 mAh cm-2 at a current density of 0.5 mA cm-2. Fig. S5. SEM images of the deposits in LiFSI-1.2TMOF-3TTE electrolyte with a deposition capacity of (a-c) 0.5 mAh cm-2, (d-f) 1 mAh cm-2 and (g-i) 2 mAh cm-2 at a current density of 0.5 mA cm-2. Fig. S6. Voltage profiles of Li||Cu cells cycled at 0.5 mA cm-2 and 1 mAh cm-2 in the (a) LiFSI1.2TMOF-3TTE and (b) LiFSI-1.2TEOF-3TTE electrolyte. Fig. S7. Voltage profiles of Li||Cu cells cycled at 1 mA cm-2 and 1 mAh cm-2 in the (a) LiFSI1.2TMOF-3TTE and (b) LiFSI-1.2TEOF-3TTE elect. Fig. S8. Coulombic efficiency of Li||Cu cells tested using the Aurbach method. Fig. S9. Cyclic voltammetry (CV) results of Li||Cu cells cycled in two electrolytes. Fig. S10. Linear sweep voltammetry (LSV) measurements of Li||carbon paper cells cycled in two electrolytes. Fig. S11. (a) Long-term cycling performances of Li||LCO cells in the two electrolytes. The corresponding capacity-voltage profiles of the cell cycled in the (b) LiFSI-1.2TEOF-3TTE and (c) LiFSI-1.2TMOF-3TTE electrolyte. Fig. S12. The morphology of Li metal anode cycled in Li||NMC811 cells for 50 cycles using the (a) LiFSI-1.2TMOF-3TTE and (b) LiFSI-1.2TEOF-3TTE electrolyte. Fig. S13. XPS analysis of the NMC811 cathodes cycled in Li||NMC811 cells after 50 cycles using the (a-c) LiFSI-1.2TMOF-3TTE and (d-f) LiFSI-1.2TEOF-3TTE electrolyte. (a,d) C 1s, (b,e) F 1s and (c,f) O 1s XPS spectra are shown. Fig. S14. Elemental ratios of the CEI formed on the cathode cycled in Li||NMC811 cells for 50 cycles.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Li, X., Pan, Y., Liu, Y. et al. Understanding steric hindrance effect of solvent molecule in localized high-concentration electrolyte for lithium metal batteries. Carb Neutrality 2, 34 (2023). https://doi.org/10.1007/s43979-023-00074-4

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s43979-023-00074-4