Abstract

Metal corrosion leads to severe economic losses and safety hazards to human society. As an energy-efficient and sustainable anticorrosion technique, photocathodic protection (PCP) systems have received growing attention in the past two decades. However, the existing PCP devices barely meet the requirements of adequate metal protection in real-world scenarios. This perspective aims to provide some constructive insights into the rational design of PCP devices and propose “functional module integration” as a new concept for future PCP systems. Similarly to multi-layered solar cells, PCP systems may incorporate multiple modules based on the corresponding functions. These include photoabsorber module (PAM), electron transfer module (ETM), hole transfer module (HTM), hole consumption module (HCM), and electron storage module (ESM). With such a modular design, improved capture of sunlight and fast charge separation, directional transportation, and effective utilization of the photogenerated carriers might be attained. Consequently, the solar-to-electric energy conversion efficiency and operation consistency of PCP devices can be significantly boosted, paving the way for practical application of solar-powered metal protection technology.

Graphical Abstract

This perspective analyses the key issues of current photocathodic protection systems and proposes a unified design composed of functional modules for the next generation systems inspired by the architecture of solar cells. This modular design allows the breaking-down of all reaction steps of the solar-to-electric conversion process onto various modules, which may bring about breakthroughs for green cathodic metal protection.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

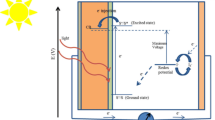

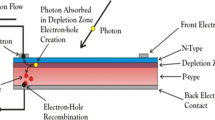

Metal corrosion is causing significant economic loss due to infrastructure failures (for example, in buildings, petroleum pipelines, and ships) on a global scale. In particular, the marine environment, which combines the presence of seawater and waves with wind and sunlight, leads to extremely harsh corrosion conditions for metallic structures. The implementation of conventional cathodic protection methods, including impressed current cathodic protection (ICCP) and sacrificial anode cathodic protection (SACP), in such an environment is primarily limited by their intrinsic drawbacks such as reliance on the grid, high electricity cost for ICCP, continuous anode material consumption, and release of toxicants into the seawater for SACP. In the past two decades, photocathodic protection (PCP) has emerged as a promising alternative technology that harnesses solar energy to produce the photoelectrons used to shift the electrochemical potential of the protected metal negatively. The core component of a PCP system is a light-harvesting material (photoabsorber), which absorbs photons with higher energy than its bandgap. Light absorption generates charge carrier pairs due to the excitation of electrons from the valence band (VB) to the conduction band (CB) and the subsequent generation of holes in the VB [1]. These photogenerated electrons can drive cathodic protection upon transfer to the metals. Such a sustainable and environmental-friendly anti-corrosion strategy opens up new possibilities for electrochemical metal protection in remote areas such as off-shore islands.

The implementation of PCP systems can be grouped into two types: (1) direct coating of the metal substrates with semiconductor photoabsorbers; and (2) a photoanode connected to the protected metal via external wires. Direct coating with semiconductors is generally considered difficult to scale up owing to the large mass of materials required and limitations imposed on the long-term stability of the coating. Thus, an external connection to an independent photoanode has dominated this field. However, the overall efficiency of conventional PCP systems is hindered due to severe recombination of charge carriers, relatively slow rate of hole transfer and surface oxidation reactions, and inadequate stability under prolonged operation. Hence, further development of advanced PCP systems is restricted, as discussed in a previous review article [2].

This perspective discusses a potential design strategy for the next generation of PCP systems, in which various modules with designated functionalities are integrated into a unified device. As several comprehensive reviews on PCP photoanode materials have been published, this perspective mainly focuses on the design details of such a unified device and how the bottlenecks of traditional photoanode-type PCP systems can be overcome. We highlight the significant upgrades brought about by coordinating the architecture of optional modules and employing cutting-edge materials. Our recommendations on module selection criteria and evaluation methods are provided, hoping to primarily promote the application of green metal protection in real-world engineering.

2 Current research status

Semiconductors have been widely used in photo(electro)chemical devices, promoting reactions of environmental importance such as water cleavage, carbon-dioxide reduction, nitrogen fixation, and organic pollutant mineralization. In such scenarios the oppositely charged electrons and holes are spatially separated and employed to drive the redox reactions [3]. In a pioneering work, Yuan et al. found that the illumination of a classical semiconductor, titanium dioxide (TiO2), induced a PCP effect upon a copper substrate [4]. Later, to maintain the cathodic protection functionality of PCP systems, Tatsuma et al. used tungsten trioxide as an “electron pool”, which is claimed to store the electrons generated in the TiO2 under UV irradiation and facilitate the continuous supply of electrons to the metal even during post-illumination operation [5]. Since then, various photoabsorbing materials have been rapidly developed in this field.

Thus far, the reported studies have mainly focused on tuning semiconductors in terms of morphology regulation [6], heterojunction construction [7], and element doping [8]. Nanoscale morphological regulation generally accelerates charge transport to the surface and creates a more extensive semiconductor-electrolyte interface. Heterojunctions induce an internal electric field near the interface, facilitating charge carrier separation between the components formulating the junction. particles of different materials. Element doping introduces mid-gap states. While these new states expand the wide bandgap semiconductors' light absorption range, they often lead to increased charge recombination. Recently, researchers applied more effort to extending the post-illumination metal protection performance of PCP systems by introducing capacitive materials [9].

Despite all the previous efforts to optimize photoanode materials, a few unresolved issues of current PCP technology still hinder its practical application. These include: (1) the protection of carbon steel, a widely used engineering material, remains a challenge due to its higher self-corrosion potential compared to metals such as stainless steel and copper alloys; (2) the cathodic protection effect cannot be sustained once the illumination is ceased; (3) due to the insufficient separation and directional transportation of photogenerated charges, the energy conversion efficiencies of current PCP systems remains low; (4) the low catalytic activities for oxidation reactions (e.g., water oxidation) that occur at the semiconductor surface results with hole accumulation and consequent charge recombination. This problem is often alleviated in academic studies by adding sacrificial hole scavengers to the electrolyte. However, a continuous supply of such hole scavengers is not feasible in practical applications. In particular, as we have pointed out elsewhere [2], the consumption of holes at the semiconductor-electrolyte interface has been largely neglected in previous studies, alongside the promising benefits of utilizing the photoexcited holes to drive significant chemical transformations.

3 Modular design strategy

The bare bones of conventional PCP systems consist of a photoanode (a conductive substrate coated with semiconductor particles) immersed in electrolytes and a metallic subject to be protected that is connected to the photoanode via an electric circuit. During operation, the photoanode is essentially where “everything” happens, from light absorption and the generation of excited charge carriers, electron–hole separation, charge diffusion, to ultimately, electron injection to the protected metal and oxidization of species in the electrolyte (OH− or H2O) with holes. As a result, it is challenging to optimize all of the steps simultaneously. Herein we propose that the next generation of PCP systems will benefit from breaking down all the reaction steps, with independent design of specific modules for each step. This function tailored design will significantly elevate the energy conversion efficiency. To the best of our knowledge, thus far, there have been no reports on such “all-in-one” PCP system, which integrates multiple independent units for separate control and optimization of the various reaction steps.

3.1 Functional independent modules

Systems for solar energy conversion (such as solar cells, photoelectrochemical cells, and photodetectors) necessitate the separation of charge carriers, making vectorial transport of the electrons and holes in different directions a critical aspect for proper operation [10]. The internal electric field formed at the heterojunction interface is often considered to prolong the carrier migration distance, thus improving the charge separation in the PCP system. However, such a migration may only occur between the semiconductor nanoparticles and is somewhat disordered and non-directional at the macroscopic scale. In addition, the short diffusion length and slow diffusion rate of holes, along with unfavorable oxidation reactions at the surface, lead to the retention of holes, thus increasing the probability of their recombination with newly generated electrons. As a result, conventional heterostructured PCP photoanodes, are hindered by short-lived charge separation. Solving these challenges mandates guidance of the electrons and holes, directing flow in opposite directions, considering the separation lifetime compared to charges utilization.

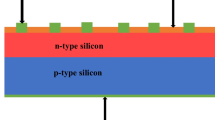

The extensive research on charge separation in [photovoltaic cells perovskite solar cells (PSCs) [11,12,13,14], organic photovoltaics (OPVs), [15, 16] dye-sensitized solar cells (DSSCs), [17, 18] etc.] and light-emitting diodes (LEDs) [19, 20] have demonstrated the huge benefit of modular design, where the collaboration of various function layers drastically improves the directional charge flow and overall efficiency. For instance, as shown in Fig. 1, the classic “n-i-p” model creates selective transport paths for electrons and holes. However, photovoltaic cells are meant to convert solar energy into electric energy, while PCP devices involve much more complicated “solar-electric-chemical” conversion processes. As a result, PCP systems have to be “custom-designed” based on the protected metal (material nature, metal size and shapes, etc.) with more in-depth consideration on the destination and utilization of electrons and holes, rather than just charge extraction and collection, as in solar cells.

Structural design of typical photovoltaic devices (a) PSCs, (b) OPVs, (c) DSSCs and (d) LEDs. Reproduced with permission: Copyright 2019, Springer Nature Limited [11], Copyright 2023, Royal Society of Chemistry, [15] Copyright 2011, American Association for the Advancement of Science, [17] Copyright 2018, Nature [19]

The next generation of PCP systems will be constructed in a bottom-up approach, assembling layer-by-layer with functional modules for an optimized complete architecture. The design principles are illustrated in Fig. 2. First, one selects a photoabsorber module (PAM) with excellent light-capturing characteristics (e.g., broad light absorption region and long carrier diffusion length), an electron transfer module (ETM), and a hole transfer module (HTM), which sandwich the PAM to form opposite diffusion pathways for electrons and holes (respectively), and a hole consumption module (HCM), which promotes rapid oxidation reactions involving the photogenerated holes. These modules are assembled in the order of “ETM-PAM-HTM-HCM”. An electron storage module (ESM), which traps a portion of the photogenerated electrons and keeps the system running in the absence of light, is placed in direct contact with the ETM. Through such a modular design, the flow of photoinduced charge carriers is manipulated and controlled throughout the whole device, improving upon the traditional microscopic diffusion between different phases in a heterostructure junction. It is postulated that proper design will improve the effectiveness of holes participating in oxidation reactions on the surface. In the meantime, solar energy is “stored” to provide effective post-illumination metal protection. Notwithstanding that the proposed modular PCP systems in this perspective still does not exist at the moment, considering the prevalence of similar designs in solar cells and LEDs and the current commercial maturity of their derivative products, we strongly believe that such a new PCP nanoarchitecture will be the future of this field with all its fundamental advantages of macroscopic directional charge transfer, sufficient surface reactivity, efficient photoelectric conversion and sustainable cathodic protection.

3.2 Photoabsorber module (PAM)

When selecting a semiconductor for the PAM module, several aspects should be taken into consideration: (1) broad coverage of the solar spectrum, (2) appropriate energy band positions with respect to the other modules and the reduction potential of the protected metal, and (3) long-term stability. Using abundant and economical materials will be valuable for future global-scale production. The other modules will be selected based on the PAM semiconductor to facilitate favorable thermodynamics and ensure the correct charge flow direction throughout the PCP device. Several of the most promising photoabsorbers with broad optical absorption spectra, such as halide perovskites [21], phosphorene [22], Cu2O [23], and various chalcogenide quantum dots [24], suffer severe instability when exposed to moisture or aqueous media upon illumination, which significantly restricts their applications. The modular-layer-stacking design with the PAM sandwiched in the middle can reduce the contact between the PAM semiconductor and the harmful ambient environment. However, proper post-sealing is expected to enhance long-term performance further. Moreover, one has to consider the transparency of the other modules so that the PAM can receive an adequate flux of incident photons.

3.3 Electron Transfer Module (ETM)

An ETM, which only allows electrons to travel through, is placed next to the PAM. Excited electrons in the PAM will subsequently diffuse to the neighboring ETM and get further directed to the protected metallic structure via external wiring. In addition to high selective conductance (high for electrons and low for holes), a crucial prerequisite for the ETM material is having a Fermi level below that of the PAM semiconductor. Potential candidates for ETM materials include SnO2 [25,26,27], ZnO [28, 29], and TiO2 [30, 31].

3.4 Hole Transfer Module (HTM)

Like the ETM, a HTM can be placed on the other side of the PAM to mediate the photoexcited holes into the next module selectively. Typical HTM materials used in solar cells and light-emitting diodes, including NiO [32, 33], PEDOT:PSS [34], Spiro-OMeTAD [35], and carbon-based materials, may also be considered here.

3.5 Hole Consumption Module (HCM)

Oxidation reactions involving the transfer of multiple charge carriers are often the limiting step of solar conversion applications. For example, the slow kinetics of oxygen evolution reaction (OER) [36] restricts overall photocatalytic water splitting efficiency. The HCM, which sits next to the HTM and is in direct contact with the electrolyte, is designed to receive the photogenerated holes from the HTM and utilize them to oxidize selected species in the electrolyte rapidly. Though the benchmark OER catalyst, ruthenium dioxide, [37, 38] may provide relatively high activity towards water oxidation, materials with lower costs developed lately, such as layered double hydroxides [39, 40] and metal oxyhydroxides [41, 42] represent promising alternative options.

Water oxidation at the surface of conventional PCP photoanodes is supplemented with sacrificial hole scavengers such as sodium sulfide and sodium sulfite, [43] which are added to the electrolyte. This strategy is impractical in real-world scenarios and turns the excited holes into waste. Sound engineering of the HCM may endow the unified PCP device with the capability of catalyzing important oxidation reactions with the holes (Fig. 3), which will lead to extra economic benefits. For example, urea oxidation reaction (UOR) [44] with a relatively low thermodynamic equilibrium potential (0.37 V vs. RHE [45], as compared to 1.23 V vs. RHE for OER) can be potentially used to replace the OER in PCP systems, considering the significant value of UOR for the treatment of urea-rich wastewater generated from industrial synthesis and sanitary sewage [41, 44, 45]. In addition, benzyl alcohol oxidation [46] and C-H halogenation, [47] which are widely used in pharmaceutical synthesis and chemical production processes, can be considered as feasible alternatives for OER.

a a brief overview of the PCP reaction mechanism and the potential pathways for hole consumption: b OER, c C–H halogenation, d oxidation of benzylic alcohols and e UOR. Reproduced with permission: Copyright 2014, The American Association for the Advancement of Science, [36] Copyright 2018, American Chemical Society, [47] Copyright 2021, Springer Nature, [46] Copyright 2022, Elsevier [44]

3.6 Electron Storage Module (ESM)

ESM composed of capacitive materials such as MXenes [48, 49], graphdiyne [50], metal–organic frameworks [51], and Mn-/Co-/W-based composites, are designated to collect and store the photoexcited electrons from the PAM during illumination and keep the device running even with a light source. This significant feature will enable continuous metal protection, even during the nighttime or cloudy days.

4 Selection criteria and efficiency evaluation

Note that the different modules' materials must be carefully selected based on two key factors: the target metal and the anodic reaction. Different types of metals (e.g., carbon steel, stainless steel, aluminum alloys, and copper alloys) possess a broad range of corrosion potentials. Hence, to achieve the injection of excited electrons from the PAM to the metal through ETM and external wiring and protect the metal from electrochemical corrosion, the Fermi levels of PAM and ETM must be located above the corrosion potential of the specific metal. Moreover, the Fermi level of the ETM material is required to be lower than that of the PAM material to guarantee the correct flow direction of photogenerated electrons within the unified PCP device. In addition, depending on the anodic reaction that occurs at its surface, the HCM material should demonstrate excellent activity and selectivity for the specific oxidation reaction while maintaining proper alignment of the energy bands with respect to the PAM and HTM to facilitate hole diffusion from the PAM to the HCM through the HTM. Finally, the ESM material should be determined based on the self-corrosion potential of the target metal and the Fermi levels of PAM and ETM to ensure the adequate inflow and outflow of electrons.

Consequently, the appropriate material selection of all modules helps establish a “traveler’s guide” for the photogenerated charge carriers (with opposite directions for electrons and holes) in such an “ETM(ESM)-PAM-HTM-HCM” architecture. The energy level gradients can guarantee the required vectorial separation and transport of charges at the device level, which is fundamentally different from the traditional heterojunctions. Moreover, all the key steps within the PCP operation are separated and assigned to various functional modules. With independent optimization and integration of all modules, a unified PCP device can potentially break through the limitations of traditional PCP systems.

To evaluate the efficiency of the proposed unified PCP device, one may refer to the evaluation method of photoelectrochemical systems [52, 53], as shown in Eq. 1:

where ηPCP is the overall efficiency of the PCP device, ηLH is the efficiency of the light harvesting (LH) step, ηCS is the efficiency of the charge separation (CS) process, ηHI is the efficiency of the hole injection to the electrolyte at the surface (HI).

As shown in Eq. 2, [54, 55] the measured photocurrent (J PCP photocurrent) of a PCP device is a product of the rate of photon absorption expressed as a current density (JLH), ηCS, and ηHI. In the presence of hole scavengers, ηHI may be optimized close to 1, and so the photocurrent measured with the addition of hole scavengers, J PCP' photocurrent can be seen as a product of only JLH and ηCS (Eq. 3). Thus, the value of ηHI may be determined by dividing Eq. 2 by Eq. 3. Subsequently, substituting the known value into Eq. 2 will give the value of ηCS. Similarly, ηPCP can be acquired through the numerical calculation of Eq. 1.

It is to be noted that the obtained overall efficiency of PCP device is merely the photoelectric conversion efficiency. When it comes to practical application, the cathodic protection potential for the metal, the effective operation duration and the maximum size of metallic structures that can be protected, determine how well a cathodic protection system performs.

5 Conclusion

Conventional PCP systems are inadequate in protecting industrially essential metals such as carbon steel, offer only limited post-illumination protection, and are accompanied by unfavorable surface oxidation reactions. The system efficiency could be improved if issues like non-directional migration and incomplete separation of the photogenerated electron–hole pairs are addressed. In this perspective, we propose a new generation of unified PCP systems composed of layered multiple functional modules that are individually selected and optimized. In the unified “ETM(ESM)-PAM-HTM-HCM” architecture, PAM captures photons and produces excited charge carriers, ETM selectively directs the photogenerated electrons to the cathode for metal protection, HTM selectively accepts the photoexcited holes and guides holes to HCM for rapid surface oxidation reactions, and the electrons are partially stored in ESM for post-illumination metal protection. With such a modular design to disintegrate all the PCP reaction steps, the bottlenecks of conventional devices are expected to be largely, if not all, overcome. However, it should be noted that such precise and complicated nanoarchitecture will require researchers to carefully consider all aspects in the actual implementation process: (1) the energy levels of ETM/ESM being well-matched to the target metal is vital and the very fundamental prerequisite for the proper operation of a PCP system. If the energy level alignment cannot support the electron flow into the metal, or even worse, “backflow” of electrons from the metal to the PCP system will aggravate the corrosion evolution of the protected metal; (2) the interlayer bonding of neighboring modules not only significantly affects the charge migration at the interface, but also determines the mechanical stability of the whole unified device (weak bonding may cause an entire layer to fall off and lose its efficacy); (3) non-ideal density and uniformity of functional layers also constrain the final power output, posing risks of short circuits and localized corrosion of metal. Therefore, elaborate design in terms of band alignment, interlayer bonding, layer packing, light transmittance, electrical conductivities can put forward stringent challenges to material selection and deposition protocols. In this regard, further development of novel functional materials in the future can largely benefit this field. With the proposed modular design, there is an excellent possibility of a giant leap forward for the “green” solar-powered cathodic metal protection technology in terms of energy conversion efficiency, sustainable operation, and tunability, which will primarily benefit the practical application of this technology.

Availability of data and materials

Not applicable.

Abbreviations

- PCP:

-

Photocathodic protection

- PSCs:

-

Perovskite solar cells

- OPVs:

-

Organic photovoltaics

- DSSCs:

-

Dye-sensitized cells

- LEDs:

-

Light-emitting diodes

- PAM:

-

Photoabsorber module

- ETM:

-

Electron transfer module

- HTM:

-

Hole transfer module

- HCM:

-

Hole consumption module

- ESM:

-

Electron storage module

- ICCP:

-

Impressed current cathodic protection

- SACP:

-

Sacrificial anode cathodic protection

- VB:

-

Valence band

- CB:

-

Conduction band

- OER:

-

Oxygen evolution reaction

- UOR:

-

Urea oxidation reaction

References

Bard AJ (1980) Photoelectrochemistry. Science 207:139–144. https://doi.org/10.1126/science.207.4427.139

Xing Z, Wang ZJ, Yang SH (2022) Capturing Solar energy for cathodic protection of metals: the life of photoexcited charge carriers. Adv Energy Sustainability Res 3. https://doi.org/10.1002/aesr.202200134

Sivula K, van de Krol R (2016) Semiconducting materials for photoelectrochemical energy conversion. Nat Rev Mater 1. https://doi.org/10.1038/natrevmats.2015.10

Tsujikawa S, Yuan J (1995) Characterization of sol-gel-derived TiO2 coatings and their photoeffects on copper substrates. Electrochem Soc 142:3444–3450

Tatsuma T, Saitoh S, Ohko Y, Fujishima A (2001) TiO2−WO3 photoelectrochemical anticorrosion system with an energy storage ability. Chem Mater 13:2838–2842

Momeni MM, Motalebian M, Ghayeb Y, Atapour M (2021) Photoelectrochemical cathodic protection of stainless steel using W- and Cr-doped/codoped TiO2 nanotube thin film photoanodes. J Electrochem Soc 168. https://doi.org/10.1149/1945-7111/ac1b05

Feng C, Chen Z, Jing J, Sun M, Lu G, Tian J, Hou J (2020) A novel TiO2 nanotube arrays/MgTixOy multiphase-heterojunction film with high efficiency for photoelectrochemical cathodic protection. Corros Sci 166:108441

Jing J, Chen Z, Bu Y, Sun M, Zheng W, Li W (2019) Significantly enhanced photoelectrochemical cathodic protection performance of hydrogen treated Cr-doped SrTiO3 by Cr6+ reduction and oxygen vacancy modification. Electrochim Acta 304:386–395

Zhang J, Yang H, Wang Y, Cui X, Wen Z, Liu Y, Fan L, Feng J (2020) Facile fabrication of SnO2 modified TiO2 nanorods film for efficient photocathodic protection of 304 stainless steel under simulated solar light. Corros Sci 176:108927

Nielander AC, Shaner MR, Papadantonakis KM, Francis SA, Lewis NS (2015) A taxonomy for solar fuels generators. Energy Environ Sci 8:16–25

Luo D, Su R, Zhang W, Gong Q, Zhu R (2019) Minimizing non-radiative recombination losses in perovskite solar cells. Nat Rev Mater 5(1):44–60

Park NG, Zhu K (2020) Scalable fabrication and coating methods for perovskite solar cells and solar modules. Nat Rev Mater 5(5):333–350

Boschloo G (2023) Can alternative module design help to overcome stability problems of perovskite photovoltaics? ACS Energy Lett 8(2):1147–1151

Werner J, Boyd CC, Moot T, Wolf EJ, France RM, Johnson SA, van Hest MFAM, Luther JM, Zhu K, Berry JJ, McGehee MD (2020) Learning from existing photovoltaic technologies to identify alternative perovskite module designs. Energy Environ Sci 13(10):3393–3403

Yu H, Wang J, Zhou Q, Qin J, Wang Y, Lu X, Cheng P (2023) Semi-transparent organic photovoltaics. Chem Soc Rev 52(13):4132–4148

Hedley GJ, Ruseckas A, Samuel ID (2017) Light harvesting for organic photovoltaics. Chem Rev 117(2):796–837

McGehee MD (2011) Paradigm shifts in dye-sensitized solar cells. Sci 334:607–608

Yella A, Lee HW, Tsao HN, Yi C, Chandiran AK, Nazeeruddin MK, Diau EWG, Yeh CY, Zakeeruddin SM, Gratzel M (2011) Porphyrin-sensitized solar cells with cobalt (II/III)–based redox electrolyte exceed 12 percent efficiency. Science 334:629–634. https://doi.org/10.1126/science.120968

Kusamoto T, Nishihara H (2018) Efficiency breakthrough for radical LEDs. Nat 563:480–481

Meredith P, Armin A (2018) LED technology breaks performance barrier. Nat 562:197–198

Kim JY, Lee JW, Jung HS, Shin H, Park NG (2020) High-efficiency perovskite solar cells. Chem Rev 120:7867–7918

Pang J, Bachmatiuk A, Yin Y, Trzebicka B, Zhao L, Fu L, Mendes RG, Gemming T, Liu Z, Rummeli MH (2018) Applications of phosphorene and black phosphorus in energy conversion and storage devices. Adv Energy Mater 8. https://doi.org/10.1002/aenm.201702093

Caretti M, Lazouni L, Xia M, Wells RA, Nussbaum S, Ren D, Grätzel M, Sivula K (2022) Transparency and morphology control of Cu2O photocathodes via an in situ electroconversion. ACS Energy Lett 7:1618–1625

Duan L, Hu L, Guan X, Lin CH, Chu D, Huang S, Liu X, Yuan J, Wu T (2021) Quantum dots for photovoltaics: a tale of two materials. Adv Energy Mater 11. https://doi.org/10.1002/aenm.202100354

Kim M, Jeong J, Lu H, Lee TK, Eickemeyer FT, Liu Y, Choi IW, Choi SJ, Jo Y, Kim HB, Mo SI, Kim YK, Lee H, An NG, Cho S, Tress WR, Zakeeruddin SM et al (2022) Conformal quantum dot–SnO2 layers as electron transporters for efficient perovskite solar cells. Sci 375:302–306

Zhu Z, Bai Y, Liu X, Chueh CC, Yang S, Jen AK (2016) Enhanced efficiency and stability of inverted perovskite solar cells using highly crystalline SnO2 nanocrystals as the robust electron-transporting layer. Adv Mater 28:6478–6484

Jiang Q, Zhang L, Wang H, Yang X, Meng J, Liu H, Yin Z, Wu J, Zhang X, You J (2016) Enhanced electron extraction using SnO2 for high-efficiency planar-structure HC(NH2)2PbI3-based perovskite solar cells. Nat Energy 2. https://doi.org/10.1038/nenergy.2016.177

Tang X, Chen W, Wu D, Gao A, Li G, Sun J, Yi K, Wang Z, Pang G, Yang H, Guo R, Liu H, Zhong H, Huang M, Chen R, Muller-Buschbaum P, Sun XW, Wang K (2020) In situ growth of all-inorganic perovskite single crystal arrays on electron transport layer. Adv Sci 7:1902767

Chen R, Cao J, Duan Y, Hui Y, Chuong TT, Ou D, Han F, Cheng F, Huang X, Wu B, Zheng N (2019) High-efficiency, hysteresis-less, UV-stable perovskite solar cells with cascade ZnO–ZnS electron transport layer. J Am Chem Soc 141:541–547

Paik MJ, Yoo JW, Park J, Noh E, Kim H, Seok SI (2022) SnO2–TiO2 hybrid electron transport layer for efficient and flexible perovskite solar cells. ACS Energy Lett 7:1864–1870

Lin CT, Hsieh CT, Macdonald TJ, Chang JF, Lin PC, Cha H, Steier L, Wadsworth A, McCulloch I, Chueh CC, Durrant JR (2022) Water-insensitive electron transport and photoactive layers for improved underwater stability of organic photovoltaics. Adv Funct Mater 32. https://doi.org/10.1002/adfm.202203487

Bai Y, Chen H, Xiao S, Xue Q, Zhang T, Zhu Z, Li Q, Hu C, Yang Y, Hu Z, Huang F, Wong KS, Yip HL, Yang S (2016) Effects of a molecular monolayer modification of NiO nanocrystal layer surfaces on perovskite crystallization and interface contact toward faster hole extraction and higher photovoltaic performance. Adv Funct Mater 26:2950–2958

Zhu Z, Bai Y, Zhang T, Liu Z, Long X, Wei Z, Wang Z, Zhang L, Wang J, Yan F, Yang S (2014) High-performance hole-extraction layer of sol–gel-processed NiO nanocrystals for inverted planar perovskite solar cells. Angew Chem Int Ed 53:12571–12575

Mahmud MA, Zheng J, Tang S, Liao C, Wang G, Bing J, Leung TL, Bui AD, Chen H, Yi J, Bremner SP, Nguyen HT, Ho-Baillie AWY (2022) Water-free, conductive hole transport layer for reproducible perovskite–perovskite tandems with record fill factor. ACS Energy Lett 8:21–30

Lou Q, Lou G, Guo H, Sun T, Wang C, Chai G, Chen X, Yang G, Guo Y, Zhou H (2022) Enhanced efficiency and stability of n-i-p perovskite solar cells by incorporation of fluorinated graphene in the spiro-OMeTAD hole transport layer. Adv Energy Mater 12. https://doi.org/10.1002/aenm.202201344

Luo JS, Im JH, Mayer MT, Schreier M, Nazeeruddin MK, Park NG, Tilley SD, Fan HJ, Grätzel M (2014) Water photolysis at 12.3% efficiency via perovskite photovoltaics and earth-abundant catalysts. Sci. 345:593–1597

Shi Q, Zhu C, Du D, Lin Y (2019) Robust noble metal-based electrocatalysts for oxygen evolution reaction. Chem Soc Rev 48:3181–3192

Suen NT, Hung SF, Quan Q, Zhang N, Xu YJ, Chen HM (2017) Electrocatalysis for the oxygen evolution reaction: recent development and future perspectives. Chem Soc Rev 46:337–365

Zhou D, Li P, Lin X, McKinley A, Kuang Y, Liu W, Lin WF, Sun X, Duan X (2021) Layered double hydroxide-based electrocatalysts for the oxygen evolution reaction: identification and tailoring of active sites, and superaerophobic nanoarray electrode assembly. Chem Soc Rev 50:8790–8817

Gong M, Li Y, Wang H, Liang Y, Wu JZ, Zhou J, Wang J, Regier T, Wei F, Dai H (2013) An advanced Ni–Fe layered double hydroxide electrocatalyst for water oxidation. J Am Chem Soc 135:8452–8455

Chung DY, Lopes PP, Martins PFBD, He HY, Kawaguchi T, Zapol P, You H, Tripkovic D, Strmcnik D, Zhu Y, Seifert S, Lee S, Stamenkovic VR, Markovic NM (2020) Dynamic stability of active sites in hydr(oxy)oxides for the oxygen evolution reaction. Nat Energy 5:222–230

Cai M, Zhu Q, Wang X, Shao Z, Yao L, Zeng H, Wu X, Chen J, Huang K, Feng S (2022) Formation and stabilization of NiOOH by introducing α-FeOOH in LDH: composite electrocatalyst for oxygen evolution and urea oxidation reactions. Adv Mater e2209338. https://doi.org/10.1002/adma.202209338

Meng L, He J, Zhou X, Deng K, Xu W, Kidkhunthod P, Long R, Tang Y, Li L (2021) Atomic layer deposition triggered Fe-In-S cluster and gradient energy band in ZnInS photoanode for improved oxygen evolution reaction. Nat Commun 12:5247

Sun H, Li L, Chen HC, Duan D, Humayun M, Qiu Y, Zhang X, Ao X, Wu Y, Pang Y, Huo K, Wang C, Xiong Y (2022) Highly efficient overall urea electrolysis via single-atomically active centers on layered double hydroxide. Sci Bull 67:1763–1775

Lu XF, Zhang SL, Sim WL, Gao S, Lou XWD (2021) Phosphorized CoNi2S4 yolk-shell spheres for highly efficient hydrogen production via water and urea electrolysis. Angew Chem Int Ed 60:22885–22891

Huang H, Yuan H, Janssen KPF, Solís-Fernández G, Wang Y, Tan CYX, Jonckheere D, Debroye E, Long J, Hendrix J, Hofkens J, Steele JA, Roeffaers MBJ (2018) Efficient and selective photocatalytic oxidation of benzylic alcohols with hybrid organic-inorganic perovskite materials. ACS Energy Lett 3:755–759

Li Z, Luo L, Li M, Chen W, Liu Y, Yang J, Xu SM, Zhou H, Ma L, Xu M, Kong X, Duan H (2021) Photoelectrocatalytic C–H halogenation over an oxygen vacancy-rich TiO2 photoanode. Nat Commun 12:6698

Pang J, Mendes RG, Bachmatiuk A, Zhao L, Ta HQ, Gemming T, Liu H, Liu Z, Rummeli MH (2019) Applications of 2D MXenes in energy conversion and storage systems. Chem Soc Rev 48:72–133

Anasori B, Lukatskaya MR, Gogotsi Y (2017) 2D metal carbides and nitrides (MXenes) for energy storage. Nat Rev Mater 2. https://doi.org/10.1038/natrevmats.2016.98

Wang N, He J, Wang K, Zhao Y, Jiu T, Huang C, Li Y (2019) Graphdiyne-based materials: preparation and application for electrochemical energy storage. Adv Mater 31:e1803202

Sheberla D, Bachman JC, Elias JS, Sun CJ, Shao-Horn Y, Dincă M (2017) Conductive MOF electrodes for stable supercapacitors with high areal capacitance. Nat Mater 16:220–224

Zhao X, Luo WJ, Feng JY, Li MX, Li ZS, Yu T, Zou ZG (2014) Quantitative analysis and visualized evidence for high charge separation efficiency in a solid-liquid bulk heterojunction. Adv Energy Mater 4:1301785

Zhao X, Luo W, Feng J, Li M, Li Z, Yu T, Zou Z (2014) Quantitative analysis and visualized evidence for high charge separation efficiency in a solid-liquid bulk heterojunction. Adv Energy Mater 4. https://doi.org/10.1002/aenm.201301785

Hu J, Zhao X, Chen W, Chen Z (2018) Enhanced charge transport and increased active sites on α-Fe2O3 (110) nanorod surface containing oxygen vacancies for improved solar water oxidation performance. ACS Omega 3:14973–14980

Dotan H, Sivula K, Grätzel M, Rothschild A, Warren SC (2011) Probing the photoelectrochemical properties of hematite (α-Fe2O3) electrodes using hydrogen peroxide as a hole scavenger. Energy Environ Sci 4:958–964

Acknowledgements

This work was financially supported by the Natural Science Foundation of China (22202237) and Guangdong Basic and Applied Basic Research Foundation (2021A1515111234, 2023A1515011552).

Funding

Open access funding provided by Shanghai Jiao Tong University. Detailed in the Acknowledgements section.

Author information

Authors and Affiliations

Contributions

Z. X. conceptualize. H.X., L.A., and Z. X. have written this perspective.

Corresponding authors

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Xie, H., Amirav, L. & Xing, Z. Modular design of solar-powered photocathodic metal protection device. Carb Neutrality 2, 29 (2023). https://doi.org/10.1007/s43979-023-00068-2

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s43979-023-00068-2