Abstract

Photovoltaic/thermal (PV/T) utilization has been regarded as a promising technique to efficiently harvest solar energy, but its thermal efficiency highly degrades in cold seasons because of remarkable heat loss. Although various methods, such as using air or vacuum gap, have been used to reduce heat loss of the PV/T, heat radiative loss still exists. In addition, unlike selective solar absorbers, the current PV/T absorber behaves like an infrared blackbody, showing great radiative heat loss. To overcome this drawback, a novel aerogel PV/T (referred to as “A-PV/T” hereinafter) collector based on solar transparent and thermally insulated silica aerogel is proposed, which can reduce the heat loss from both the non-radiative and radiative heat transfer modes. Experimental testing demonstrates that the thermal efficiency improvement of 25.1%-348% can be achieved for PV/T within the collecting temperature range of 35–70 °C when silica aerogel is introduced, indicating a significant efficiency enhancement. Compared with traditional PV/T (referred to as “T-PV/T” hereinafter) collector, the stagnation temperatures of the A-PV/T collector are 96.7 °C and 103.1 °C in outdoor and indoor environments, which are 27.4 °C and 25.8 °C greater, respectively, indicating a heat loss suppression of the aerogel. Moreover, simulation reveals that useful heat can hardly be provided by the T-PV/T collector in cold seasons, but the A-PV/T still exists a high solar thermal performance, showing good seasonal and regional applicability.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Solar energy is a plentiful green energy resource and can alleviate society's dependence on fossil fuels [1,2,3,4]. Photovoltaic/thermal (i.e., PV/T) utilization combines photovoltaic and photothermal processes to generate clean electricity and heat in one device, by converting part of sunlight into electricity and the rest of solar irradiance into heat that is collected by working fluids as the heat source for other purposes [5,6,7,8,9], which exhibits a significant performance improvement in comparison to the standalone photovoltaic module. Reviewing the published papers, PV/T technology has already been used in various applications to establish near-zero energy structures. Souliotis et al. [10] constructed a life cycle assessment analysis of combining PV/T collectors and building roofs to generate more energy, which contrasts vividly with standalone PV and solar thermal panels. Das et al. [11] proposed a new PV/T collector that has a rectangular spiral tube and a phase change materials-based composite, which has a high thermal efficiency of 66.6% and improves electrical power by 18.4%. Liang et al. [12] theoretically evaluated the influence of the PV/T collector installed on the wall on buildings. PV/T collectors not only supply hot water and electricity for buildings but also act as a wind barrier to suppress building thermal loss. The simulation result shows that the heat loss of the external wall is suppressed by approximately 40%, which increases the water supply temperature to 40 °C for buildings. Agrawal and Tiwari [13] optimized PV/T systems under cold weather conditions, and the system after optimization can provide 15,209 kWh of electrical energy and 18,062 kWh of thermal energy in one year with a constant air mass rate.

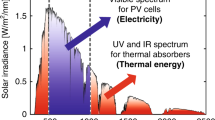

In fact, in the cold season, PV/T collectors show unsatisfactory thermal performance. The main drawback is that the thermal performance dramatically deteriorates as the ambient temperature decreases. The poor thermal performance makes it impossible to provide useful heat for buildings in cold conditions (e.g., cold winter and locations) without an auxiliary heat source [14]. In addition, compared to the solar collector with a spectral selective absorber, the PV/T collector presents a lower capacity for heat generation because the PV/T absorber is generally encapsulated by the optical transparent Tedlar/Polyester/Tedlar (hereinafter referred to as “TPT”) with a high infrared emissivity of approximately 0.9 [15], and the air gap is transparent to infrared radiation, so the radiative heat loss is enormous and thus the thermal efficiency is at a low level.

To solve this issue, many contributions have been made to the topic of radiation heat loss suppression. An aluminum-doped ZnO coating on a glass surface is developed [16], which shows a low infrared emissivity (~ 0.3) and a high solar transmittance (~ 0.79), and a thermal efficiency enhancement of 45% was obtained. Lämmle et al. [17] designed suitable spectrally selective coatings by applying an optical coating consisting of aluminum-doped ZnO and reflective metal film to obtain a solar transmittance (79%) while presenting an ultralow emissivity of 0.13 at 373 K. Our group [18] also reveals that the importance of emissivity of PV cells for PV/T hybrid utilization. Simulation results show that a significant efficiency enhancement with the longwave emissivity dropping from 0.95 to 0.05 is obtained. The above consequences manifest that reducing the longwave emissivity can make a significant thermal efficiency improvement. The above experiments and simulations were carried out by optimizing and regulating the spectral selectivity of the PV/T absorber. However, there are few experimentally verified works, and the relevant coatings exhibit large optical loss so that the PV cell cannot generate electricity efficiently. Therefore, simultaneously suppressing radiative heat loss based on the spectral selective method and maintaining the high optical efficiency for electrical generation is a potential method for PV/T technology to improve harvesting efficiency.

Based on the thermal analysis, introducing a low thermal conductive radiation shield into the gap between PV/T absorbers and glass envelopes is a useful method to reduce heat loss. In our previous studies [19], an aerogel was introduced on the top PV/T absorber surface for heat loss suppression. Aerogels are good materials that can be designed to exhibit ultralow density [20,21,22,23], ultrahigh porosity [24, 25], ultralow thermal conductivity, and ultrahigh-temperature resistance. The greatest advantage is that the silica aerogel can work as an optical filter; it presents opaque to infrared radiation but is transparent to sunlight [19]. Moreover, the aerogel has an ultralow thermal conductivity, which can be designed to be smaller than that of ambient air [26]. The spectral properties and physical properties of the aerogel make it extremely effective in heat loss suppression. Recently, the transparent silica aerogel attracts the researchers’ attention due to its excellent insulation performance. The silica aerogel prevents heat loss while having high sunlight transmit capacity which is mainly determined by its transparency to sunlight, opaque in the IR, and extremely low effective thermal conductivity. Zhao et al. [23] constructed a device that reached over 473 K under realistic weather without the demand of the optical concentrator by combining the silica aerogel with the flat-plate solar receiver. Moreover, Zhao et al. [27] obtained the silica aerogel with an extremely high solar transmittance (95%) by optimizing its microstructure to reduce the scattering of the aerogel. On this basis, they demonstrated a solar thermal device based on silica aerogel, and the device can generate steam at 100 °C with an efficiency of 56% under the 700 W/m2 solar irradiation. Qiu et al. [28] proposed a novel parabolic trough receiver insulated by silica aerogel, reporting the efficiency of the parabolic trough receiver can be improved by 0.32–5.04%. In these applications, aerogel is generally introduced to the solar thermal absorbers, the knowledge gap of aerogel for PV/T applications is being explored. Although few works focus on integrating aerogel with PV/T collectors, such as the aerogel-based PVT-TEG system [29], a detailed radiative heat transfer mechanism is not considered and the existing aerogel-based solar absorbers are designed to improve working temperatures, while aerogel-based PV/T in this work is mainly to improve efficiency in cold conditions and extend the operating temperature region. Compared to the existing heat suppression methods (e.g., vacuum method) of PV/T collector, aerogel can significantly reduce the heat loss of the PV/T absorber from both the heat conduction and heat radiation suppressions, which is a new try for highly efficient PV/T hybrid utilization.

Motivated by the above analysis, this work aims to experimentally explore the performance enhancement after using an aerogel as a radiation shield for PV/T hybrid utilization. Experimental demonstration is performed to explore the performance improvement of the aerogel PV/T (referred to as “A-PV/T” hereinafter) collector. A indoor experiment is carried out based on the solar simulator under unconcentrated solar flux, and the stagnation temperature, thermal and electrical efficiency are tested, compared, and analyzed. In addition, an outdoor experimental platform is constructed to reveal the A-PV/T’s performance in realistic weather conditions. Finally, a validated numerical model is applied to predict the A-PV/T performance in different regions.

2 Description of the experimental setup

2.1 Transparent silica aerogel

The 12.5-mm-thick silica aerogel used in this work is solar transparent (Fig. 1(a)) and the transmittance (Fig. 1(b)) of the aerogel was measured based on a spectrophotometer (SolidSpec-3700) from 0.3 to 2.5 μm and an FT-IR spectrometer (Nicolet iS10) from 2.5 to 20 μm. The aerogel presents a high transmittance to solar irradiance with an AM 1.5 weighted transmittance of up to 87%. In addition, the aerogel has ultralow transmittance in the infrared band, which greatly reduces the radiative heat loss. Moreover, the thermal conductivity of the aerogel was tested by a laser thermal conductivity testing instrument (NETZSCH LFA457). The aerogel exhibits an ultralow thermal conductivity of approximately 0.0254 W·m−1·K−1, which is lower than ambient air (~ 0.026 W·m−1·K−1 [30]), and this property mainly benefits from the highly porous structure [31]. Besides, the silica aerogel is lightweight with a density of about 0.09 g·cm−3 and this is also contributed by the highly porous structure.

2.2 The prototype of the A-PV/T

Figure 2(a) shows a photo and schematic diagram of the A-PV/T collector which consists of a transparent silica aerogel, an encapsulated PV/T absorber, and an insulation material. The dimension of the collector is 170 mm × 170 mm × 55 mm, and the dimension of the PV/T absorber and aerogel is 50 mm × 50 mm. During the experiment, a T-PV/T is set up for reference (Fig. 2(b)), and the difference between them is only the transparent silica aerogel in Fig. 2(a) substituted with the glass cover. Notably, additional protective layers, such as glass, will be optionally added on top of silica to protect the aerogel depending on its mechanical strength. Here, silica aerogel exposes to the sky directly. The amorphous silicon (a-Si) solar cell is employed for the PV/T absorber because of its low-temperature coefficient [32]. As shown in Fig. 3, the AM 1.5 solar spectrum weighted absorptivity of the cell is 0.77. The a-Si cell is fixed in an aperture, and the silica aerogel is attached to the top of the a-Si cell. The insulation material is applied to decrease the heat transfer between the absorber and ambient air.

2.3 Efficiency and stagnation temperature measurement

Thermal/electrical efficiency and stagnation temperature are important indicators for the performance evaluation of the PV/T utilization. A testing system is designed and established to measure the thermal efficiency of the fabricated prototype and the schematic is shown in Fig. 4. A Peltier device with a PID control device is used to provide heating/cooling power for the a-Si cell to control temperature. A heat flux sensor is attached between the a-Si cell and the Peltier device to measure the input and output heat flux of the a-Si cell. To control the solar power under relatively stable conditions, a solar simulator (Oriel Sol3A Model 90943A, as shown in Fig. 5) is used for thermal efficiency testing. When the system is stabilized, the heat flux from solar irradiance (downward heat flux) equals the heat flux supplied by the Peltier device, and the value of the flux is monitored by the flux sensor. Thus, thermal efficiency is calculated by:

where P is a heat flux correction factor, which is used to eliminate the effect of the conductivity difference between the glass and heat flux sensors. Shf and Vhf are the sensitivity and voltage output of the heat flux sensor, respectively.

To measure the electrical efficiency, I-V testing is performed under the solar simulator. Photo and schematic of the I-V testing system are displayed in Fig. 5. To obtain the electrical efficiency under various temperatures, a heater is attached to the backside of the cell, and the temperature control uncertainty is about ± 0.5 °C.

The stagnation temperature is tested under steady-state conditions. A T-type thermocouple is fixed between the a-Si cell and insulation layer to measure the transient temperature with an uncertainty of ± 0.5 °C. To comprehensively test the stagnation temperature of the two PV/T collectors, two conditions, the indoor solar simulator condition (Fig. 5(a)) and the outdoor weather condition are selected. In the outdoor condition (Fig. 6), two PV/T collectors are fixed on mechanical support and arranged toward the south direction with a slope angle of approximately 30° to obtain maximum solar irradiance. In addition, the solar irradiance reaching the collector’s surface is monitored by a solar pyranometer (TBQ-2) with an uncertainty of ± 2%. The experimental data are saved by a data acquisition (HIOKI LR8402-21).

Due to the accuracy of the monitors in experiments, a general uncertainty analysis of the testing results is conducted, including thermal efficiency, stagnation temperature, and electrical efficiency. The root sum-of-the-squares method is selected for uncertainty analysis, which can be presented by:

where Uf is the uncertainty of the parameter f, xi and △xi are the ith variable and its uncertainty.

3 Mathematical model

The energy flow process of the A-PV/T is presented in Fig. 7. Sunlight is transmitted through the silica aerogel and absorbed by the PV/T absorber with the generation of electricity and heat. Meanwhile, thermal loss occurs from the absorber to the environment. Generally, the energy control equation can be described by:

where Qth is the collected heat flux, Qabs denotes the absorbed solar irradiance, Qloss denotes the overall heat flux loss, and Qpv represents the electrical power. The determination of the collected heat flux Qth is related to the optical performance of the bulk aerogel. The PV/T total heat loss of consists of two parts that include the heat dissipation power at the top surface (i.e., Qloss1) and bottom surface (i.e., Qloss2). The generated electricity can be calculated by applying an empirical correlation that involves the referenced electrical efficiency, PV cell temperature coefficient, and operating temperature. The detailed equations are described in Appendix.

Thermal efficiency (ηth), electrical efficiency (ηe), and overall exergy efficiency (ηov) are used as indicators to evaluate the performance of the A-PV/T, which are described by Eqs. (4), (5), and (6), respectively [33]:

where Isol denotes the total solar irradiance, T and Tamb represent the PV/T absorber temperature and ambient air temperature, respectively. Esol is the exergy of solar irradiance [34], which is related to sun temperature (Tsun), ambient temperature, and total solar irradiance:

4 Results and discussions

Experiments demonstration of the A-PV/T and T-PV/T collectors are performed. Besides, the behavior of the two types of collectors under different conditions is further predicted and compared.

4.1 Thermal efficiency

Thermal efficiency of the A-PV/T and T-PV/T with different operating temperatures are measured using the system described in Fig. 4. Due to the difference in thermal conductivity between the glass and heat flux sensors, the value detected by the heat flux sensor is not the actual heat flux. Thus, calibration testing of the thermal efficiency testing system is conducted. The calibration testing system is illustrated in Fig. 8(a). A heater plate is placed on the surface of the a-Si cell and is thermally insulated to avert extra heat loss. Figure 8(b) presents the voltage output of the heat flux sensor under disparate heat power supplies, which shows that the system reaches a steady state quickly. As illustrated in Fig. 8(c), ratio P is used to eliminate the effect of the conductivity difference and obtain an accurate and steady heat flux value that has no connection with the supplied heating powers. The fitting result shows that the ratio P is approximately 1.11.

Figure 9 exhibits the variation in the two devices under different PV/T absorber temperatures. Compared with the T-PV/T, A-PV/T always exhibits higher thermal efficiency, regardless of the operating temperature. Because of the strong thermal loss suppression by aerogel, the A-PV/T expresses a better thermal performance than T-PV/T. The typical operating temperature range of previously reported PV/T collectors is approximately 35 °C (low solar irradiance [35]) -70 °C (high ambient temperature and high solar irradiance [36, 37]), and the A-PV/T exhibits nearly 25.1% and 348% enhancement in thermal performance within this temperature range when compared with the T-PV/T. In addition, the T-PV/T possesses a stagnation temperature of 77 °C, which indicates that there is no potential for further heat collection. However, the A-PV/T can still possess a high thermal efficiency of 25.4% at 77 °C, which can provide a heat source for more applications. The main reason is that heat loss, especially radiative heat loss, increases rapidly when the surface temperature arises, and the thermal efficiency tends to zero after a rapid decline. In addition, the maximum uncertainties of thermal efficiency and electrical efficiency for A-PV/T are evaluated as 1.36% and 0.089%, respectively, and those for T-PV/T are evaluated as 1.28% and 0.10%, respectively.

4.2 Stagnation temperature, electrical efficiency, and overall exergy efficiency

To further explore the operating temperature region of the A-PV/T and T-PV/T, stagnation temperature and electrical efficiency are first measured under the solar simulator and the results are presented in Fig. 10. The temperature of the cell increases rapidly in the initial testing stage and eventually reaches a steady value. It is found that the temperature of the a-Si cell in the A-PV/T is always greater than that in T-PV/T. Specifically, the cell in the A-PV/T and T-PV/T reaches 103.1 °C and 77.3 °C after 20 min from the testing start, which indicates that the heat loss power of the T-PV/T is higher than that of the A-PV/T, showing a potential of aerogel for the efficiency improvement for solar energy harvesting.

It is found from Fig. 10(b) that the electrical efficiency of the a-Si cell with silica aerogel attached is relatively lower than the a-Si cell with a glass cover attached because the effective solar transmittance of the silica aerogel used in this study is slightly lower than that of the glass, which means that there exists an extra optical loss in the T-PV/T collector. Notably, the solar transmittance of the silica aerogel is being improved as manufacturing techniques developed. At present, solar transmittance of the silica aerogel is improved to 0.95 and this is experimentally proven and reported in ref. [27]. Also, it is found that the electrical efficiency drops slightly with increasing temperature because the solar cell has a negative temperature coefficient. However, the a-Si cells used in this study possess a low-temperature coefficient with a value of -0.24%/°C, which means that the sensitivity of the a-Si cell to temperature is lower than that of widely used Si cells. Notably, the temperature coefficient of PV cells could be theoretically positive and was successfully reported using the InGaN solar cell [38], which provides a new pathway for PV/T applications.

As shown in Fig. 11, compared with T-PV/T collectors, A-PV/T collectors can obtain a higher overall exergy efficiency when the operating temperature exceeds 45 °C. The exergy efficiency of A-PV/T is lower than that of T-PV/T when the working temperature was lower due to optical loss caused by aerogel. At an operating temperature of 60 °C, the exergy efficiency of the A-PV/T collector is 1.21 times that of the T-PV/T collector. This ratio increases to 1.45 as operating temperatures rise to 70 °C. It is worth noting that the best operating temperature of A-PV/T is 74 °C with an exergy efficiency of 8.29%. Compared with the T-PV/T collector (the optimal working temperature of 48 °C, and the maximum exergy efficiency of exergy was 6.97%), A-PV/T has a higher optimal working temperature and a greater exergy efficiency, which is conducive to the application of PV/T technology in more scenes. Importantly, when the solar transmittance of the silica aerogel is increased to the level of the glass, the exergy efficiency will be higher than that of the T-PV/T at all working temperatures, and this is what needs to do in the future.

Outdoor experimental testing was also performed and constructed on November 12th, 2020, from 9:00 to 15:00 to further explore the behavior of the A-PV/T in actual sky conditions. Meteorological parameters, including ambient air temperature and solar irradiance, are presented in Fig. 12(a). Figure 12(b) describes the variations in the a-Si cell temperature under different PV/T collectors. The trend of the cell temperature in the two PV/T collectors is highly correlated with the variation in solar irradiance. It can be observed that the A-PV/T collector always presents supernal temperatures than the T-PV/T. For instance, the solar cell in the A-PV/T and T-PV/T reach maximum temperatures of 96.7 °C and 70.7 °C, respectively. In addition, the maximal temperature difference reaches 27.4 °C. The high stagnation temperature of the A-PV/T benefits from the ability of the aerogel to reduce heat loss. The same results are obtained in both indoor and outdoor experiments, which demonstrate the feasibility of the PV/T collector combined with aerogel. Notably, such a high stagnation temperature does not mean that the PV cell will reach this temperature in actual work. In actual work, the cell temperature can be controlled by the operation condition of the working fluid, such as using highly effective nano-fluid or improving flow rates of the working fluid.

4.3 Numerical analysis

Distinct performance of the PV/T utilization in different regions occurs due to distinct weather conditions. To clarify the annual performance behavior in different regions, a theoretical model is carried out for simulation study.

4.3.1 Model validation

Model validation is conducted with the practical data obtained from the experimental setup. The meteorological boundary parameters are from the experiment in Sect. 4.1. As plotted in Fig. 13, the predicted thermal efficiency is consistent with the experimental results, which shows the simulation and experimental results present a similar trend and the RMSD is 3.81% over the whole temperature range. This tiny distinction shows that this model is credible for the performance prediction in this study.

4.3.2 Performance in different regions

The annual performance of the A-PV/T and T-PV/T in Beijing, Fuzhou, Urumqi, and Hefei are explored by the mathematical model. The thermal and electrical energy gains are presented in Figs. 14 and 15. During the simulation, a 20-mm-thick aerogel is applied to the collector, the operating temperature is set as 60 °C, the PV/T absorber exhibits an emissivity of 0.95, and the areas of the two types of collectors are assumed to be 1 × 1 m2, the daily operation time of Beijing, Fuzhou, Hefei is set from 8:00 to 16:00, while the operation time of Urumqi is located from 10:00 to 18:00. All weather condition data are obtained from EnergyPlus [39].

As displayed in Fig. 14, the A-PV/T possesses a higher monthly heat gain than that of the T-PV/T, especially in cold seasons. For example, in Urumqi and Beijing, the T-PV/T cannot work properly in winter due to the ultralow ambient temperature. In January, the A-PV/T can provide 27.7 kWh and 8.3 kWh thermal energy gain in Beijing and Urumqi, respectively, while the T-PV/T produces only 0.9 kWh and 0.027 kWh, respectively. The annual thermal energy gain and electricity gain of the four regions are summarized in Table 1, which shows the A-PV/T in Beijing, Fuzhou, Urumqi, and Hefei can obtain total thermal energy of 638.7 kWh, 547.3 kWh, 634.1 kWh, and 545.0 kWh, respectively, which are 1.9, 1.5, 1.8, and 1.7 times those of the T-PV/T, respectively. The great thermal performance of A-PV/T is benefit from thermal loss suppression of the aerogel. Specifically, during the month when the heat demand is greatest, the A-PV/T can provide thermal energy continuously. These predicted results indicate that A-PV/T is more suitable for year-round operation than T-PV/T, especially in cold regions.

As presented in Fig. 15, the monthly electrical energy gains of the A-PV/T are slightly lower. The annual electrical energy gains of the A-PV/T in Beijing, Fuzhou, Urumqi, and Hefei are 58.6 kWh, 50.4 kWh, 57.3 kWh, and 49.9 kWh, respectively, which are 1.01%, 1.18%, 1.04%, and 1.19% lower than those of the T-PV/T collector, respectively. The electrical reduction is caused by the optical loss of the aerogel. However, with the optimization of the manufacturing process, the silica aerogel can be fabricated with a high transmissivity and low optical loss for solar irradiance, and this viewpoint was experimentally proven [27]. Although the electrical energy gains of the A-PV/T decreased throughout the year, the decrease in electrical performance was negligible compared to the enhancement in thermal energy gains. Most importantly, in the season when heat is most needed in cold regions, the T-PV/T collector can hardly work normally, but the A-PV/T still has a high heat output, which makes up for the lack of seasonal inability to supply useful heat for end-use (e.g., space heating).

5 Conclusions

In summary, an innovative A-PV/T was proposed and investigated based on the feature that silica aerogel with ultra-low thermal conductivity is solar transparent and thermally insulated. Indoor and outdoor experimental tests were conducted for performance evaluation. In addition, a mathematical model is developed and validated for performance prediction in different regions. Some main conclusions are summarized as follows:

-

(1)

The thermal efficiency of the A-PV/T collector is 25.1%-348% greater than that of the T-PV/T collector when the collection temperature is within the typical operating temperature range of 35 °C-70°C, indicating that silica aerogel can significantly improve its thermal efficiency.

-

(2)

The stagnation temperature of the A-PV/T and T-PV/T can reach 103.1 °C and 77.3 °C, respectively, which shows that silica aerogel can significantly suppress the radiative heat loss of the PV/T collector.

-

(3)

Annual thermal energy gains of the A-PV/T collector in Beijing, Fuzhou, Urumqi, and Hefei are 638.7 kWh, 547.3 kWh, 634.1 kWh, and 545.0 kWh, respectively, which are 1.9, 1.5, 1.8, and 1.7 times those of the T-PV/T.

-

(4)

The A-PV/T improves the seasonal suitability to provide useful heat in cold seasons for hot water supply and space heating when T-PV/T cannot efficiently provide the required thermal energy.

In the future, more efforts should be paid to improve the performance of the silica aerogel and corresponding PV/T collectors, such as enlarging the solar transmittance of the silica aerogel, improving the mechanical strength of the aerogel, and achieving cost-effective large-scale manufacture.

Availability of data and material

The data that support the findings of this study are available from the corresponding author upon reasonable request.

Abbreviations

- PV:

-

Photovoltaic

- PV/T:

-

Photovoltaic/thermal

- RTE:

-

Radiative transfer equation

- RMSD:

-

Root-mean-square deviation

- TPT:

-

Tedlar-Polyester-Tedlar

- A-PV/T:

-

Aerogel photovoltaic/thermal

- T-PV/T:

-

Traditional photovoltaic/thermal

- AM:

-

Air mass

References

Jia T, Huang J, Li R, He P, Dai Y (2018) Status and prospect of solar heat for industrial processes in China. Renew Sustain Energy Rev. 90:475–489. https://doi.org/10.1016/j.rser.2018.03.077

Zhao B, Lu K, Hu M, Liu J, Wu L, Xu C, Xuan Q, Pei G (2022) Radiative cooling of solar cells with micro-grating photonic cooler. Renew Energy 191:662–668. https://doi.org/10.1016/j.renene.2022.04.063

Guo J, Liu Z, Du Z, Yu J, Yang X, Yan J (2021) Effect of fin-metal foam structure on thermal energy storage: An experimental study. Renew Energy 172:57–70. https://doi.org/10.1016/j.renene.2021.03.018

Kalogirou SA (2004) Solar thermal collectors and applications. Prog Energy Combust Sci 30:231–295. https://doi.org/10.1016/j.pecs.2004.02.001

Wolf M (1976) Performance analyses of combined heating and photovoltaic power systems for residences. Energy Convers 16:79–90. https://doi.org/10.1016/0013-7480(76)90018-8

Li Z, Ji J, Yuan W, Zhao B, Zhou F, Muin Uddin M, Ren X, Yu B, Song Z (2021) Experimental & numerical investigation and optimization on a novel flat-plate PV/T system using CdfTe thin-film solar modules of sandwich structure. Sol Energy. 223:261–277. https://doi.org/10.1016/j.solener.2021.02.009

Li Z, Ji J, Zhang F, Zhao B, Xu R, Cui Y, Song Z, Wen X (2021) Investigation on the all-day electrical/thermal and antifreeze performance of a new vacuum double-glazing PV/T collector in typical climates — Compared with single-glazing PV/T. Energy. 235:121230. https://doi.org/10.1016/j.energy.2021.121230

Yao J, Xu H, Dai Y, Huang M (2020) Performance analysis of solar assisted heat pump coupled with build-in PCM heat storage based on PV/T panel. Sol Energy 197:279–291. https://doi.org/10.1016/j.solener.2020.01.002

Song Z, Ji J, Cai J, Zhao B, Li Z (2021) Investigation on a direct-expansion solar-assisted heat pump with a novel hybrid compound parabolic concentrator/photovoltaic/fin evaporator. Appl. Energy. 299:117279. https://doi.org/10.1016/j.apenergy.2021.117279

Souliotis M, Arnaoutakis N, Panaras G, Kavga A, Papaefthimiou S (2018) Experimental study and Life Cycle Assessment (LCA) of Hybrid Photovoltaic/Thermal (PV/T) solar systems for domestic applications. Renew Energy 126:708–723. https://doi.org/10.1016/j.renene.2018.04.011

Das D, Bordoloi U, Kamble AD, Muigai HH, Pai RK, Kalita P (2021) Performance investigation of a rectangular spiral flow PV/T collector with a novel form-stable composite material. Appl. Therm. Eng. 182:116035. https://doi.org/10.1016/j.applthermaleng.2020.116035

Liang R, Wang P, Zhou C, Pan Q, Riaz A, Zhang J (2020) Thermal performance study of an active solar building façade with specific PV/T hybrid modules. Energy. 191:116532. https://doi.org/10.1016/j.energy.2019.116532

Agrawal B, Tiwari GN (2010) Optimizing the energy and exergy of building integrated photovoltaic thermal (BIPVT) systems under cold climatic conditions. Appl Energy 87:417–426. https://doi.org/10.1016/j.apenergy.2009.06.011

Cao C, Li H, Feng G, Zhang R, Huang K (2016) Research on PV/T – Air Source Heat Pump Integrated Heating System in Severe Cold Region. Procedia Eng 146:410–414. https://doi.org/10.1016/j.proeng.2016.06.422

Ahmad EZ, Sopian K, Jarimi H, Fazlizan A, Elbreki A, Abd Hamid AS, Rostami S, Ibrahim A (2021) Recent advances in passive cooling methods for photovoltaic performance enhancement. Int J Electr Comput Eng. 11:146. https://doi.org/10.11591/ijece.v11i1.pp146-154

Ehrmann N, Reineke-Koch R, Föste S, Giovannetti F (2013) The influence of process parameters and coating properties of double glazing coated with transparent conducting oxides on the efficiency of solar-thermal flat-plate collectors. Thin Solid Films 532:132–140. https://doi.org/10.1016/j.tsf.2012.11.145

Lämmle M, Kroyer T, Fortuin S, Wiese M, Hermann M (2016) Development and modelling of highly-efficient PVT collectors with low-emissivity coatings. Sol Energy 130:161–173. https://doi.org/10.1016/j.solener.2016.02.007

Hu M, Guo C, Zhao B, Ao X, Suhendri, Cao J, Wang Q, Riffat S, Su Y, Pei G (2021) A parametric study on the performance characteristics of an evacuated flat-plate photovoltaic/thermal (PV/T) collector, Renew. Energy. 167:884–898. https://doi.org/10.1016/j.renene.2020.12.008

Wu L, Zhao B, Ao X, Yang H, Ren X, Yu Q, Guo K, Hu M, Pei G (2021) Performance analysis of the aerogel-based PV/T collector: A numerical study. Sol Energy 228:339–348. https://doi.org/10.1016/j.solener.2021.09.077

Lu J, Wang J, Hassan KT, Talmantaite A, Xiao Z, Hunt MRC, Šiller L (2020) Morphology control of nickel nanoparticles prepared in situ within silica aerogels produced by novel ambient pressure drying. Sci Rep 10:11743. https://doi.org/10.1038/s41598-020-68510-4

Khedkar MV, Somvanshi SB, Humbe AV, Jadhav KM (2019) Surface modified sodium silicate based superhydrophobic silica aerogels prepared via ambient pressure drying process. J Non Cryst Solids 511:140–146. https://doi.org/10.1016/j.jnoncrysol.2019.02.004

Du D, Jiang Y, Feng J, Li L, Feng J (2020) Facile synthesis of silica aerogel composites via ambient-pressure drying without surface modification or solvent exchange. Vacuum. 173:109117. https://doi.org/10.1016/j.vacuum.2019.109117

Zhao L, Bhatia B, Yang S, Strobach E, Weinstein LA, Cooper TA, Chen G, Wang EN (2019) Harnessing Heat Beyond 200 °C from Unconcentrated Sunlight with Nonevacuated Transparent Aerogels. ACS Nano 13:7508–7516. https://doi.org/10.1021/acsnano.9b02976

Jiang F, Liu H, Li Y, Kuang Y, Xu X, Chen C, Huang H, Jia C, Zhao X, Hitz E, Zhou Y, Yang R, Cui L, Hu L (2018) Lightweight, Mesoporous, and Highly Absorptive All-Nanofiber Aerogel for Efficient Solar Steam Generation. ACS Appl Mater Interfaces 10:1104–1112. https://doi.org/10.1021/acsami.7b15125

Wang H, Du A, Ji X, Zhang C, Zhou B, Zhang Z, Shen J (2019) Enhanced Photothermal Conversion by Hot-Electron Effect in Ultrablack Carbon Aerogel for Solar Steam Generation. ACS Appl Mater Interfaces 11:42057–42065. https://doi.org/10.1021/acsami.9b12918

Cuce E, Cuce PM, Wood CJ, Riffat SB (2014) Toward aerogel based thermal superinsulation in buildings: A comprehensive review. Renew Sustain Energy Rev 34:273–299. https://doi.org/10.1016/j.rser.2014.03.017

Zhao L, Bhatia B, Zhang L, Strobach E, Leroy A, Yadav MK, Yang S, Cooper TA, Weinstein LA, Modi A, Kedare SB, Chen G, Wang EN (2020) A Passive High-Temperature High-Pressure Solar Steam Generator for Medical Sterilization. Joule 4:2733–2745. https://doi.org/10.1016/j.joule.2020.10.007

Qiu Y, Zhang Y, Li Q, Xu Y, Wen Z-X (2020) A novel parabolic trough receiver enhanced by integrating a transparent aerogel and wing-like mirrors. Appl Energy. 279:115810. https://doi.org/10.1016/j.apenergy.2020.115810

Wen X, Ji J, Song Z (2021) Performance comparison of two micro-channel heat pipe LFPV/T systems plus thermoelectric generators with and without aerogel glazing. Energy. 229:120704. https://doi.org/10.1016/j.energy.2021.120704

Tang A-M, Cui Y-J, Le T-T (2008) A study on the thermal conductivity of compacted bentonites. Appl Clay Sci 41:181–189. https://doi.org/10.1016/j.clay.2007.11.001

Strobach E, Bhatia B, Yang S, Zhao L, Wang EN (2019) High temperature stability of transparent silica aerogels for solar thermal applications. APL Mater. 7:081104. https://doi.org/10.1063/1.5109433

Ren X, Li J, Hu M, Pei G, Jiao D, Zhao X, Ji J (2019) Feasibility of an innovative amorphous silicon photovoltaic/thermal system for medium temperature applications. Appl. Energy. 252:113427. https://doi.org/10.1016/j.apenergy.2019.113427

Hassani S, Saidur R, Mekhilef S, Taylor RA (2016) Environmental and exergy benefit of nanofluid-based hybrid PV/T systems. Energy Convers Manag 123:431–444. https://doi.org/10.1016/j.enconman.2016.06.061

Chow TT, Pei G, Fong KF, Lin Z, Chan ALS, Ji J (2009) Energy and exergy analysis of photovoltaic–thermal collector with and without glass cover. Appl Energy 86:310–316. https://doi.org/10.1016/j.apenergy.2008.04.016

Gaur A, Ménézo C, Giroux-Julien S (2017) Numerical studies on thermal and electrical performance of a fully wetted absorber PVT collector with PCM as a storage medium. Renew. Energy. 109:168–187. https://doi.org/10.1016/j.renene.2017.01.062

Kumar R, Rosen MA (2011) Performance evaluation of a double pass PV/T solar air heater with and without fins. Appl Therm Eng 31:1402–1410. https://doi.org/10.1016/j.applthermaleng.2010.12.037

Terashima K, Sato H, Ikaga T (2020) Development of an environmentally friendly PV/T solar panel. Sol Energy 199:510–520. https://doi.org/10.1016/j.solener.2020.02.051

Huang X, Li W, Fu H, Li D, Zhang C, Chen H, Fang Y, Fu K, DenBaars SP, Nakamura S, Goodnick SM, Ning C-Z, Fan S, Zhao Y (2019) High-Temperature Polarization-Free III-Nitride Solar Cells with Self-Cooling Effects. ACS Photonics 6:2096–2103. https://doi.org/10.1021/acsphotonics.9b00655

Energyplus:weather. https://energyplus.net/weather.

Modest MF (2nd ed) (2003) Radiative Heat Transfer. Academic Press, San Diego

Günay AA, Kim H, Nagarajan N, Lopez M, Kantharaj R, Alsaati A, Marconnet A, Lenert A, Miljkovic N (2018) Optically Transparent Thermally Insulating Silica Aerogels for Solar Thermal Insulation. ACS Appl Mater Interfaces 10:12603–12611. https://doi.org/10.1021/acsami.7b18856

Harrison S, Cruickshank CA (2012) A review of strategies for the control of high temperature stagnation in solar collectors and systems. Energy Procedia 30:793–804. https://doi.org/10.1016/j.egypro.2012.11.090

Bahaidarah H, Subhan A, Gandhidasan P, Rehman S (2013) Performance evaluation of a PV (photovoltaic) module by back surface water cooling for hot climatic conditions. Energy 59:445–453. https://doi.org/10.1016/j.energy.2013.07.050

Acknowledgements

Thanks for the support from the research center for multi-energy complementation and conversion of USTC.

Funding

Open access funding provided by Shanghai Jiao Tong University. This work was supported by the National Key R&D Program of China (2020YFA0710100), National Natural Science Foundation of China (NSFC 52106276 and 52130601), Fundamental Research Funds for the Central Universities (WK2090000038).

Author information

Authors and Affiliations

Contributions

WL proposed the design and performed the testing and simulation. GD, JD, and HM contributed to the analysis and paper review. PG and ZB conceived the study and edit the manuscript. All authors read and approved the final manuscript.

Corresponding authors

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

Gang Pei is an editorial board member for Carbon Neutrality and was not involved in the editorial review, and the decision to publish this article. All authors declare that there are no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

1.1 Theoretical model of the A-PV/T

As shown in Fig. 7, the detailed mathematical model is as follows. The collected heat flux is expressed as:

Qabs and Qpv are expressed as Eqs. (9) and (10), respectively:

where τa and τad are the solar transmittances of the aerogel and adhesive, Isol is total solar irradiance, α is the effective solar absorption, Bpv denotes the power-based temperature coefficient of the cell, and ηe, ref is the referenced PV efficiency (Tref = 25 ℃).

The radiative transfer equation (RTE) is used and coupled with the heat conduction governing equation to calculate the heat flux within the aerogel. The RTE is expressed as [40]:

where Iλ denotes the radiative intensity field, σλ and κλ denote scattering and absorption coefficient, \(\Phi_{\lambda } (\vec{s}^{^{\prime}} ,\vec{s})\) denotes the phase function, Ibλ denotes the blackbody intensity, k denotes the solid thermal conductivity of the silica aerogel, z is the spatial coordinate along with the thickness of the aerogel, T denotes the temperature field within the aerogel, and \(q_{{\lambda { = }0\sim \infty }}^{{\text{r}}}\) denotes the spatial radiative heat flux. When T(z) has been determined, the radiative and conductive heat flux can be then obtained at any z within the aerogel. Therefore, thermal loss of the PV/T absorber to the environment through the silica aerogel can be obtained by summing the radiative and conductive heat flux at the top surface of the aerogel (z = 0) [41].

where \(q_{{\lambda { = }0\sim \infty }}^{{\text{r}}} (z = 0)\) is the spatial radiative heat flux obtained by RTE at the top surface of the aerogel, \(q_{{{\text{cond}}}} (z = 0)\) is the conductive heat flux at the top surface of the aerogel.

Another part of the thermal loss is transferred from the PV/T absorber to the environment through the back-insulation layer, which is expressed by:

where Tamb is ambient temperature, ue is the thermal loss coefficient between the PV/T absorber and environment, which can be determined by:

where L is the thickness of the insulation layer. h is the convection loss coefficient between the insulation layer and the environment and can be estimated by h = 2.8 + 3.0 V, where V is wind speed.

The stagnation temperature is obtained when the thermal efficiency is 0, which is the maximum achievable temperature collector [42]. The PV/T collector can supply useful thermal energy when the operating temperature is lower than the stagnation temperature.

The mathematical model is set up according to the aforementioned mathematical equations. The root mean square deviation (RMSD) is applied to validate the predicted results [43]:

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Wu, L., Zhao, B., Gao, D. et al. Solar transparent and thermally insulated silica aerogel for efficiency improvement of photovoltaic/thermal collectors. Carb Neutrality 2, 6 (2023). https://doi.org/10.1007/s43979-023-00046-8

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s43979-023-00046-8