Abstract

The building sector is one of the three major energy consumption areas and one of the main areas responsible for carbon emissions. In 2019, carbon emissions related to construction and building operations in China accounted for 38% of the total social carbon emissions, of which construction accounted for 16% and operations accounted for 22%. Due to its large volume and high energy consumption per unit area, public buildings account for 38% of the operating energy consumption of all buildings, that is, 8% of the total national energy consumption. At this time, the building industry must take decarbonization actions to avoid a delay in realizing carbon neutrality and an emission peak. We need to form a unified process for the implementation boundary, implementation path, and index system to build a zero-carbon implementation plan for China’s public building sector. Based on bottom-up practical cases, this paper proposes the KAYA model, which is applicable to different scales and different types of public buildings/communities, and proposes specific and feasible plans. Through the implementation of demand reduction, energy efficiency improvement, and the fully-use of renewable energy in all five clear steps, this paper promotes the implementation of decarbonization in China’s building industry.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

On September 22, 2020, President Xi Jinping announced an unprecedented and ambitious climate goal. The carbon peak and neutrality goals represent the greatest positive progress in the global climate governance process since the 2015 Paris Agreement. However, China is also facing huge challenges in achieving its carbon neutralization goal. Today, architecture has become the main location for human activity, and the total building area is continuously growing. In 2019, the annual completed building area reached 4.02 billion square meters and has maintained an annual growth rate of 5% [1]. From the perspective of the entire building life cycle and all types of energy, In 2019, carbon emissions related to construction and building operations in China accounted for 38% of the total social carbon emissions, of which construction accounted for 16% and operations accounted for 22%. Due to their large volume and high energy intensity, public buildings account for 34% of the total building energy consumption and are one of the main contributors to social energy consumption and carbon emissions [2].

A comprehensive, specific, and implementable plan is required to achieve carbon neutrality in the public building sector. At present, most of China’s research on building carbon neutrality are concentrated on the analysis of economic growth and building carbon emissions between industries and regions, as well as the decarbonization effects of specific technologies. Li et al. discussed the overall characteristics and basic laws of building carbon emissions in each province [3, 4]. Wang et al. applied Tapio decoupling model to quantity the decoupling elasticity between China’s economy and CO2 emission [5, 6]. Aiming at the future carbon emissions of the building sector, the CBEM model [7,8,9] developed by Tsinghua University, the DREAM model [10] developed by Lawrence Berkeley Lab, the TIMES model [11], CAS model [12], CBCEM model [13], and PECE-Building model [14] all have carried out trend predictions and research on the carbon emission path of the building sector. Sun Wei et al. used LMDI model to study the influencing factors of carbon emission in Guangzhou, and studied the peak path of Guangzhou under different scenarios based on the influencing factors. The results show that, Under the low economic growth rate, the policy scenario enables Guangzhou to reach the carbon peak in 2020 [15]. Zhou Lina et al. used LEAP model to predict the peak time and carbon emissions in Shandong Province, and put forward corresponding policy suggestions on this basis [16]. Yang Xiu et al. used KAYA model to study the correlation between population, per capita GDP, energy consumption intensity, carbon emission factor of input energy and carbon emission, and estimated the carbon peak time and carbon emission in Beijing [17]. To sum up, the current research is mainly based on the scenario analysis method, adopting different analysis models to carry out prediction and path planning for a variety of scenarios at the national, urban or industrial level. On the whole, it is more of a top-down work path with constraints, and there is a lack of building carbon neutralization programs supported by energy data from actual building decarbonization projects. In this context, this study is based on the community scale and supported with energy data. A bottom-up implementation model, boundary, and path will be discussed for promoting the decarbonization of China’s public building sector and to provide suggestions for additional new/existing building decarbonization. This paper aims to promote the development of energy conservation and emission reduction in the building industry.

2 Research methods and implementation paths

2.1 Boundaries of carbon emission measurements in the public building sector

Building carbon emission models can be divided into top-down and bottom-up methods [18]. The top-down estimation starts with a building’s overall carbon emissions, and then a downscaling analysis of time and space is performed [19]; the bottom-up method starts with the hourly energy consumption of a single building, and then the calculation scale for carbon emissions is enlarged. Kavgic et al. compared the two methods [18]. The top-down method is usually used at the macro level and emphasizes the impact of macro rather than physical factors on building energy consumption. The bottom-up approach is based on architectural details, which is more helpful in focusing on the contribution of the technology itself to the decarbonization of buildings than is the top-down approach. The calculation of public building carbon emissions for China is shown in Fig. 1, which is divided into three parts: carbon emissions from fossil fuel combustion, Carbon emissions from the use of electricity and heat, and Carbon emissions from construction and demolition. The sum represents the carbon emissions of the entire life cycle of the building.

Specifically, the overall carbon emissions of the public building sector can be categorized into energy and material consumption carbon emissions. Energy consumption includes coal, coke, crude oil, gasoline, kerosene, diesel, fuel oil, natural gas, and electricity as statistical objects; material consumption takes cement, steel, glass, wood, and aluminum as the statistical objects [20]. Equation 1 can be used as a model to calculate carbon emissions in the public building sector.

where C is the total carbon emissions of the public building sector; \({C}_{energy}\)is the carbon emissions from the energy consumption side of the public building sector; \({C}_{material}\) is the carbon emissions from the material consumption side of the public building sector; \({E}_{i}\) is the i-th energy consumption; \({\alpha }_{i}\) is the carbon emission coefficient of the i-th energy; \({M}_{j}\) is the consumption of type j-th materials; \({\beta }_{j}\) is the carbon emission coefficient of the j-th material; and \({\mu }_{j}\) is the recycling coefficient of the j-th material.

2.2 Five section model for decarbonization in the public building sector

Based on the research and definition of carbon emissions, they can be divided into the following three categories:

-

1)

Carbon emissions from fossil fuel combustion: direct carbon emissions from the burning of fossil energy in the building operation process;

-

2)

Carbon emissions from the use of electricity and heat: indirect carbon emissions caused by energy consumption during the building operation;

-

3)

Carbon emissions from construction and demolition: indirect carbon emissions during building construction, maintenance and demolition.

The above three categories clarify the specific scope of carbon emissions in the public building sector; however, it is easier to categorize carbon emissions compared to specific implementations. Based on a new perspective and the feasibility of the project’s actual decarbonization operation, starting from the five steps in Fig. 2, each step focuses on reducing demand, improving energy efficiency, and expending the source of energy. Compared with the original carbon emission classification, this method can more directly and effectively describe the decarbonization activities of the public building sector.

2.3 Construction of the KAYA model at the community scale of the public building sector

The KAYA model was proposed by the Japanese scholar Kaya Yoichi to study carbon dioxide emissions and its driving factors, linking carbon dioxide emissions with factors such as population, economy, and energy and exploring the main driving factors of carbon dioxide emissions [21], as shown in Eq. 2:

where \(P\) is the population, \(G\) is the regional GDP, \(E\) is energy consumption, \(\frac{G}{P}\) is the GDP per capita, \(\frac{E}{G}\) is the energy consumption per unit of GDP, and \(\frac{{CO}_{2}}{E}\) is the carbon dioxide emission per unit of energy consumption.

As a black box model, the KAYA model is often used in conjunction with factor analysis to calculate and analyze the main influencing factors of city-scale carbon emissions. Decomposed to the level of the building department, the KAYA model can be changed to guide the decarbonization action of the public building department in the form of a white box model. In the public building sector, the parameters in the model can be changed to building area, production output value per building area, energy consumption per production output value within the building range, and carbon emissions per unit energy consumption, as shown in Eq. 3:

where \(S\) is the built-up area, \(G\) is the GDP within the scope of building, \(E\) is the energy consumption, \(\frac{G}{S}\) is the production output value per unit building area, \(\frac{E}{G}\) is the energy consumption per unit production value within the scope of the building, and \(\frac{{CO}_{2}}{E}\) is the carbon dioxide emission per unit of energy consumption.

This model can not only be used to describe the decarbonization action of single buildings, but it can also expand the dimension to communities/towns and expand the scale range to unit square kilometers or unit square hectares; it can also be based on per capita and unit service volume as main calculation objects, which can help multiple types of buildings in the building sector plan decarbonization paths. In the future, as more types and sizes of buildings embark on decarbonization actions, this enrichment of the index system can help the entire public building sector to unify the measurement and statistical methods and achieve the expected carbon emission reduction goals.

2.3.1 Index Interpretation: building area (\(S\))

The building area is an important indicator of carbon emissions in the affected area. In the case of the same regional economic and technical conditions, changes in building area are generally related to changes in resource and energy demand and directly affect regional carbon emissions.

2.3.2 Index Interpretation: production output value per unit building area (\(\frac{G}{S}\))

The production output value per unit of the building area is the calculation range of the building department. The ratio of the total production output value during the calculation period to the building area within the calculation range is a standard for quantitatively evaluating the development and operation level of public. Generally, the production output value per unit building area is related to the service quality of public buildings. If a high-carbon economic development model is adopted, carbon emissions will change proportionally with the production output value per unit building area; however, under the development of a low-carbon economy, the increase in the production output value per unit building area will not lead to excessive growth in carbon emissions. Low-carbon economic development is a key driver of decarbonization in the building sector.

2.3.3 Index Interpretation: energy consumption per unit production value of the building (\(\frac{E}{G}\))

Energy consumption per unit of production output value within the context of a building refers to the amount of energy consumed per unit of production output. The greater the value, the stronger is the dependence of service quality on energy. For the public building sector, this indicator can also measure the level of energy-saving work. In addition, the total energy consumption can be split into two areas: energy classification and implementation path sub-items. The energy classification is shown in Fig. 3. The first-level indicator is the total energy consumption by item, the second-level index is the total cooling and heating consumption, the third-level index is the energy consumption of each sub-item energy node, and the fourth-level index focuses on the energy consumption of sub-equipment. The indicator level is helpful to the building department to identify key energy consumption links in the production and operation process and to explore the potential of energy saving and emission reduction. At the same time, the implementation of an indicator system that details the equipment, process, and even product levels helps the building department to unify the accounting standards and standardize the verification tool, each of which can be horizontally and vertically benchmarked.

Deviations from the implementation path should be based on the actual operation of the project in accordance with the five levels of decarbonization actions described above. Priority is given to measurements of the main building’s heating, cooling, ventilation, temperature and humidity control, lighting, and heat (steam) energy consumption. Then, statistics are obtained on the energy consumption for specific activities, for vehicle operation, and during production, construction, and demolition. This work can help the building department to unify the decarbonization path and realize a work classification that can be benchmarked, verified, and advanced.

2.3.4 Index Interpretation: carbon dioxide emissions per unit of energy consumption (\(\frac{{CO}_{2}}{E}\))

The amount of carbon dioxide emissions per unit of energy consumption is an important indicator for measuring the carbon energy structure and emission levels of the building sector. Owing to the difference in heat value and combustion efficiency, the carbon dioxide emissions produced by different energy sources are very different. The calculation model of carbon dioxide emissions per unit of energy consumption is as follows (Eq. 4) [17]:

where \({U}_{i}\) is the class \(i\) energy consumption, \({\gamma }_{i}\) is the carbon emission coefficient of class \(i\) energy, and \(n\) is the type of energy.

2.4 Implementation path and indicator system of decarbonization in the public building sector

At present, the construction department should construct a set of implementation paths aimed at achieving the goal of decarbonization. It is used to guide buildings, communities and cities to achieve the near zero carbon goal, and at the same time to achieve the zero-carbon goal by connecting more renewable energy. According to the types of carbon emissions, the total carbon emissions of buildings can be divided into direct carbon emissions generated by using fossil energy, direct carbon emissions and indirect carbon emissions generated by using electricity and heat, and carbon emissions generated by outsourcing energy. The direct carbon emissions generated from the use of fossil energy are mainly related to coal, oil and natural gas. In daily life, these energy sources are mainly used to produce domestic hot water, steam and cooking. For this part of carbon emissions, the direct carbon emissions generated by the use of fossil energy can be made zero through the use of air source heat pumps, electric heat pumps for waste heat recovery, cooking electrification and other technologies. The carbon emissions generated by the purchased energy mainly consist of the carbon emissions generated by the purchased power and the purchased heat. The purchased power can be replaced by the clean power of the power grid, and the purchased heat can be replaced by technologies such as cogeneration and the consumption of clean waste heat, so that the carbon emissions generated by the purchased energy can be zero. As for the direct and indirect carbon emissions generated by the use of electricity and heat in the building itself. As mentioned above, in the process of implementing the 5-section decarbonization model, three main tasks should be considered: demand-side reduction, conversion chain efficiency, and tapping more renewable resources to realize zero-carbon goals.

As shown in Fig. 4, the demand side represents the basic energy demand of buildings. Under the zero-carbon index system, demand-side consumption needs to be reduced. There are three main types of energy requirements in buildings: cooling, heat, and electricity. Cooling and heat are measured at the community scale, and energy consumption is measured by the indicators of unit area and unit square kilometers. In addition to the above two indicators, electric energy should be added to the per capita indicator.

The conversion chain is split into equipment and system, pursuing the highest two parts, the highest equipment energy efficiency ratio, and the highest matching. A seamless and efficient connection needs to be ensured between the demand and supply sides.

The supply side is divided into renewable energy and additional purchased energy, and the proportion of renewable energy should be expanded as much as possible. The additional purchased electricity is only applied in advance in extreme cases (extremely cold, continuous cloudy days), and the trough electricity is purchased from the grid for storage. The additional purchased heat should be supplied or supplemented with cogeneration or clean waste heat, according to local conditions.

KAYA model is a starting point that can well describe and guide the community to carry out decarbonization work. The key lies in reasonable energy consumption and reducing carbon emission factors while the community prospers and develops. This paper takes existing public communities and new public communities as cases to illustrate the application of this view in practical projects.

3 Case study: zero-carbon reconstruction for existing public buildings / communities

This study used a public building community in Qingdao, China, as an example for a specific analysis. This public building community covers an area of 45 ha, with a building area of 227,000 square meters, including conference centers, hotels, office buildings, and other types of businesses, with a total of ten buildings. The typical annual energy cost is 20.81 million yuan, the power consumption is 21.39 million kWh, the heat consumption is 62,000 GJ, and the gas consumption is 340,000 Nm³.

The project was planned in accordance with the above-mentioned work path, starting with high-level energy conservation, comprehensive electrification, upgrading of the zero-carbon operating power energy system with new energy as the main body, and comprehensive and full life cycle decarbonization of public building communities. The specific work is as follows:

-

1)

High-level energy saving: the basis for achieving zero-carbon operation.

-

The building’s winter heating demand/actual cumulative heating: <0.1 GJ/m2·year; building (end) low temperature (water supply temperature < 50 ℃) heating and low return water temperature of the pipe network become the normal operation of the heating pipe network, so that renewable energy (including heat pumps) can be fully utilized;

-

Cooling and electricity: reduce the air-conditioning system cooling and air-conditioning ventilation power consumption: <20 (source) + 10 (terminal fan) kWhe/m2·year; reduce public area lighting power consumption: <10 kWhe/m2·year.

-

2)

Fully electrified: reduce direct carbon emissions to zero.

-

Use electricity to replace coal, oil, and gas; use various types of high-efficiency electricity to drive heat pumps; " Few concentration, most dispersion” and replace gas boilers for building heating and hot water.

-

For steam and hot water occasions, disperse and locally improve energy grades, prepare steam or hot water, and fully recover heat to achieve point-to-point supply with minimal loss.

-

When the carbon emission factor of the municipal heating network heat is close to zero, zero-carbon municipal heating (for example, Yantai City, nuclear wastewater and heat transmission, biomass).

-

3)

Upgrade to a power energy system that uses new energy as the main body and helps cities operate with zero carbon.

-

As far as possible, give priority to the development of the roof, ground, and water surfaces of the site to use photovoltaic power generation and connect it to the nearby low-voltage side DC distribution network.

-

Multi-links and multiple media make the building community park a flexible power load, fully absorbing the grid and local renewable power, reducing the carbon emission factor of its own electricity to zero, and contributing to zero carbon in the power system.

-

4)

Comprehensive and full life cycle:

-

Non-carbon dioxide greenhouse gas emission reduction issues (refrigerant leakage, reclaimed water treatment aeration, meal waste, etc.);

-

Zero-carbon energy regeneration of various building materials in the overall construction, maintenance, and renewal of the building community park, one-time fossil energy consumption, and lifetime repeated use; smart buildings reduce carbon emissions during the use, construction, and demolition of high-carbon building materials.

In the following, Fig. 5 shows the specific implementation plan of the case. It can be seen from the horizontal coordinate axis on the figure that the three types of work can gradually decarbonize the case by combining the reduction of demand side with the efficient conversion chain and the zero carbon resources on the supply side. As can be seen from the left ordinate in the figure, the functions of the building are divided into four types: heating, cooling, user terminal and specific functions. Each type carries out specific work in combination with the above three types of work, which can gradually decarbonize buildings. The specific work content has been shown in the table and will not be described here. For the demand of heating and cooling, the top right corner of the figure shows the zero-carbon energy supply scheme on the basis of energy conservation priority. In a zero-carbon community, the annual demand for buildings is clean electricity, clean cold and clean heat. Ideally, all the energy needed comes from ‘Sky’ and ‘Ground’. The general idea is to drive the heat pump by clean electricity to meet the building’s demand for clean heat and cold. ‘Sky’ provides solar energy and wind energy to meet the basic demand for electricity. ‘Ground’ provides geothermal energy and air sources to meet the basic needs for cold and hot. The lower right corner shows the schematic diagram of the zero-carbon power system, which uses photovoltaic panels laid in the community for solar power generation and power storage. The building electricity system of ‘PEDF’ has been established. The case establishes a building electricity system of ‘PEDF’, which P stands for ‘Photovoltaic’, E stands for ‘Energy storage’, D stands for ‘Direct current’, and ‘F’ stands for ‘Flexibility’. ‘Photovoltaic’ means that the power source of the building is mainly photovoltaic; ‘Energy storage’ and ‘Direct current’ are to establish the ‘Toughness’ of the building power distribution system. As the renewable input energy is subject to the objective factors of weather, it is easy to cause the mismatch between the power generation curve and the actual demand of buildings. Therefore, it is necessary to establish an energy storage system to meet the flexible demand of community electricity.

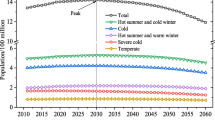

Consider the heating decarbonization of an office building of 12,000 square meters with a municipal heat source in this community project as an example. As shown in Fig. 6, the baseline heat energy consumption should be determined first. The typical annual building heat consumption intensity is about 0.4GJ/m2·year, the total heat consumption of the secondary side of building heating in severe cold season is 41.0GJ, and the heat consumption per unit building area is 958.5Wh/m2·day. The figure shows the 24-hour heat consumption statistics of the building’s heating system on a typical day. Among them, domestic hot water accounts for 3% and heating accounts for 97%. The heat consumption of domestic hot water fluctuates widely, but because the total amount is relatively small, the fluctuation is not obvious. In addition to supplying the building, the energy station shall also supply a 24-hour fire station. The fluctuation of heating consumption of fire station is small, and the heating consumption of the building mainly affects the fluctuation of energy consumption of energy station. The whole day heat consumption of the building reaches its peak between 8:00 A.M. to 13:00 P.M. In the case of no personnel in the building at night, the consumption of heat supply does not change significantly compared with that in the daytime, and the average temperature in the building does not change much compared with that in the daytime neither. Through testing, it is found that in terms of feasibility and profitability, reducing the heat demand is the most profitable and easiest job to achieve. Like most public buildings in northern China, this building works at the same heating temperature (45 °C) throughout the heating season.

Specific attention was paid to the change in heat usage of this building. There are two problems: one is the heating temperature setting on a seasonal scale, and the other is the heating temperature setting on a daily scale. The result of this study was to reduce the heating energy consumption of the building by 30% in the full heating season while meeting the temperature requirements of the entire building. Because the energy station currently needs to be distributed to the fire station, the heating temperature cannot be further reduced. If the fire station is decoupled from the office building and the air source heat pump is supplied independently, the night office building only needs to meet the antifreeze requirements, and the water supply temperature can be further reduced. It is estimated that more than 20% of energy savings will still exist.

During a severe cold period, four working conditions were tested. As shown in Fig. 7, these four working conditions respectively correspond to the reset values of the water supply temperature at the secondary side of the heating system at different outdoor temperatures. The outdoor temperatures are − 1 ~ 5℃, -5 ~ 0℃, -3 ~ 5℃ and − 4 ~ 7℃. The secondary side water supply temperature is manually adjusted from the original fixed 45℃ to 41℃ for whole day, 40℃ for whole day, 40℃ during the day while 35℃ at night and 37℃ for whole day. These different temperatures also correspond to the four groups of experiments in the figure. The results showed that the daily heat consumption index per unit area could be reduced to below 500 Wh/m2·day while ensuring that the temperature of the entire building was within a comfortable temperature range. At the end of cold period, seven sets of experiments were performed. As shown in Fig. 8, these seven experiments are optimization tests based on different outdoor temperatures. Under the outdoor temperatures of 3 ~ 10℃, 6 ~ 14℃, 7 ~ 14℃, 5 ~ 10℃, 5 ~ 10℃, 8 ~ 12℃ and 4 ~ 12℃, the secondary side water supply temperature of the heating system was adjusted from the original fixed 45℃ to 41℃, 40℃, 38℃, 37℃, 35℃ and 33℃ for the whole day. These different temperatures also correspond to the seven groups of experiments in the figure. The results showed that the daily heat consumption per unit area was reduced to less than 300 Wh/m2·day.

Refined time-sharing and zoning energy consumption debugging is an important step to achieve the expected decarbonization goal for the building. Improving the airtightness of the building and reducing its heat loss in winter are also keys to reducing energy consumption. Public buildings in northern China in winter should be blocked from unorganized infiltration wind, including, but not limited to, installing double-layer doors on opposite sides of the indoor and outdoor connecting passages. Measures such as balancing the proportion of internal exhaust and supplementary air in the building and plugging holes in the enclosure structure can effectively reduce the cooling load of the building. This work also contributed approximately 50% to the reduction in building heat demand. On the premise that the demand reduction work is completed, the equipment/system energy efficiency improvement work should be started. The heating system of the building used in this study was simple. The author checked and optimized the working performance of the heating circulation pump, heat exchanger, and thermal balance of the building to ensure that the output performance of the equipment was in the high-efficiency range, the terminal temperature variance was the smallest, and the system resistance was the smallest as well. Taking the thermal balance test of the building as an example, it can be found that there is thermal imbalance between the heating pipes of the building through the measured data. The maximum temperature difference between different floors can be close to 4 K. This current situation can be improved through the thermal balance commissioning, so as to minimize the variance of the supply and return water temperature difference at the end of each pipe end and the pipe resistance coefficient S of the water system. After comprehensive consideration, it is estimated that these works of improving quality and efficiency can reduce energy saving space by about 20%.

Demand-side reduction and efficient work in the conversion chain are important foundations for achieving the expected carbon neutrality goal. To achieve zero from near-zero carbon emissions, an important step in the development of zero-carbon resources on the supply side is also required. Priority should give to the development of space resources such as the roof, ground, and water surfaces of the site, pave photovoltaic power generation, and connection to the nearby low-voltage-side DC distribution network. Normal weather does not require power supply from the power grid. Only in extreme cold weather and continuous cloudy days will the grid fill the gaps, apply in advance, and store electricity during low periods. According to Figs. 9 and 10, the author obtained statistics on the electricity demand of the entire community. Currently, the annual average basic electricity consumption (terminal + cold source electricity consumption) of the community is 58,600 kWh/day. Heating electrification requires the use of heat pumps. Considering the two scenarios, the maximum daily total power consumption of the seawater source heat pump system with a heating energy efficiency ratio of 3.5 is 71,800 kWh/day, and the heating energy efficiency ratio is 6.0, for medium-deep ground source heat pumps, and the maximum total daily power consumption of the system is 41,900 kWh/day.

The area of photovoltaics that could be installed in the community was determined to be 45,400 square meters. Because the optimal height angle arrangement of solar PV panels needs to consider the shielding between the panel arrays, when space resources are limited, the power generation of the horizontally placed unit area space resources is compared with the best power generation at an altitude of 34°. In this study, photovoltaic panels were laid horizontally at 5°.

According to previous content, the energy intensity per square meter required for heating, cooling, ventilation, environmental control, lighting, and thermal energy in the building community is 40.5 kWh/m2 per year. The total building area in the park is 227,000 square meters, and the total power consumption of the entire site is 9.19 million kWh/year. According to Fig. 11, the available photovoltaic area of 45,400 square meters at the site generates 7.36 million kWh per year at present. There are two gaps between the power consumption of the entire site and the photovoltaic power generation capacity: the total amounts and the time difference. These gaps require multiple links and multiple media to make the building community park a flexible electrical load. Fully absorbing the grid and renewable electricity in this field and reducing the carbon emission factor of its own electricity to 0 help the power system to zero carbon and complete the decarbonization action plan of another four scopes in the future.

4 Case study: zero-carbon construction of new public buildings/ communities

The decarbonization plan for new public buildings and communities can also be implemented in accordance with the above-mentioned decarbonization implementation boundary. Taking the regional macro scope as the core and specific public buildings/ communities as the main objects, we constructed a zero-carbon energy system implementation plan with clear boundaries, feasible measures, credible results, and zero-carbon searchable. This plan allows all scope levels (scope 1 photovoltaic supply + scope 2/3 consumption grid and renewable green electricity) to achieve the community’s annual zero-carbonization program and a balance between supply and demand.

New zero-carbon public buildings or communities need to design and build zero-carbon district heating, cooling, ventilation, dehumidification, lighting, and fan systems. The equipment capacity is determined by the operating energy consumption, coupled with DeST simulation results, to obtain the required photovoltaic installed capacity, measure and count the pavement area of photovoltaics in the field, and determine the feasibility of zero-carbon construction in the current scope.

In the realization of zero-carbon work in new public buildings or communities, the building and electromechanical system has two important characteristics: high efficiency and absorbability. The system must be able to coordinate with the regional power grid under the premise of sufficient efficiency. Through fine adjustments of the system, the building and electromechanical system can achieve “flexibility,” and it is easier to solve the coordination between energy and load. The frequency conversion adjustment of fans, water pumps, elevators, and escalators can adjust the power by more than 50% in a short time.

This paper considered the construction of an airport site in central China as an example for a specific analysis. The building area of this site is 500,000 square meters, the annual passenger throughput is 40 million, and the freight throughput is 600,000 tons. The project was planned according to the above-mentioned work path, and the specific work was as follows:

-

Generalized field zero carbon goal: in the construction and operation of the entire airport, all energy comes from renewable energy with no direct and indirect carbon emissions (excluding aviation fuel).

-

Zero carbon emissions caused by energy consumption are realized in the process of ensuring indoor health and a reasonable environment during building operations, including heating, cooling, ventilation, humidity control, indoor healthy environment control, lighting and lighting in public areas, and hot water.

-

The energy consumption for specific functional activities, by absorbing green electricity from the external grid, creates zero carbon emissions. The energy required includes the electricity consumed by elevators, escalators, trails, and luggage transmission required for the movement of people and things, power required for office and various functional equipment, electricity consumption of tenants, and energy consumption of freezing and refrigeration, catering, and cooking.

-

The operation of transportation related to the airport is fully electrified, and the full absorption of green electricity makes carbon emissions zero. This includes the energy consumption of vehicles in the airport and aircraft remaining on the ground.

-

The carbon emission of “building materials containing energy” is zero. This includes carbon emissions from the production process of building materials and carbon emissions from the construction and demolition process, making full use of the dismantled building materials waste after recycling. The carbon emission of “building materials containing energy” is permanently fixed in the building to achieve “near zero,” and plants are used as “carbon sinks.“

-

Other focuses include refrigerant leakage during the operation of buildings and community parks, as well as zero non-carbon dioxide emissions from the treatment of water, garbage, and feces.

The project follows the decarbonization implementation boundary, and the first step is to design the system under the zero-carbon goal. Based on the advanced level of experience and relevant standards, combined with the DeST simulation results, the operating energy consumption is used to determine the range-total energy demand, and then the equipment capacity is determined. This project is designed according to the standards of near-zero carbon energy demand and high-efficiency and energy-saving equipment. As shown in Table 1; Fig. 12 below, the DeST software is used to simulate the annual cooling and heating loads of the buildings in this project, and the loads under different infiltration air times are simulated respectively. Finally, 0.5 times per hour is finally selected as the conclusion based on the project experience. The total energy intensity of the energy station is 20.5 kWh/m2 per year, and the total energy intensity of the fans and lighting equipment in the terminal building is 25 kWh/m2 per year. The intensity is 45.5 kWh/m2 per year, and the annual energy consumption is 22.75 million kWh.

To determine the energy demand of Scope 1, the photovoltaic area required to match the energy demand is calculated and the location selected. The location of distributed photovoltaics needs to follow the following four basic principles: (1) consider the shadow effects of the surrounding buildings; (2) fully investigate the load requirements and configure distributed photovoltaics to match the load characteristics as much as possible; (3) consider the impact of the new load of the PV project on the safety of the original building; and (4) consider the available roof area: a large-area roof is preferred. The application of distributed photovoltaics in the airport field needs to consider the following two basic principles: (1) The reflection of photovoltaic modules: modules with low reflectivity should be selected according to relevant specifications, and the horizontal and vertical viewing angles of the pilot should be avoided during installation; (2) The influence of electromagnetic interference: The scope of China’s civil aviation electromagnetic environmental protection zone is fully considered. In photovoltaic projects, the electromagnetic interference effect of inverters should be considered.

Airport safety and economic considerations are combined based on the above-mentioned basic principles. For this project, the following are selected: the GTC outdoor parking lot in the terminal area, the rainwater storage tank on the land side, the supporting parking lot of each unit on the land side, and the outer area of the flight area. A small number of landside roofs are supplemented with 25.39 MWp solar photovoltaic panels, and annual power generation is expected. The capacity is 24.04 million kWh. The form of distributed electricity and water heat storage solves the problem of “scissors difference” between power generation and electricity supply and demand in large-scale cycles, and heat storage (when the outdoor temperature is low, the indoor temperature is kept at a low level, and cold energy stored is prepared in advance in indoor air. When the passenger load peaks, part of the cooling load is borne by the prepared cold capacity to reduce the pressure on the refrigeration unit), dry air (when the enthalpy of the outside air is low, more dry air is prepared, and the indoor air is maintained at a low humidity level. During passenger peak hours, the upper limit of indoor air humidity is appropriately increased to reduce energy consumption for dehumidification), and clean air is stored (when the outdoor air enthalpy is closer to the indoor state, the ventilation rate is increased, and the indoor CO2 concentration is kept relatively low. During the peak period of passengers, the indoor CO2 concentration increase is limited to not more than 800 ppm) to solve the problem of imbalance between supply and demand on the daily scale.

As shown in Fig. 13, in the design of the project energy scheme, the clean electricity generated by photovoltaics is used to drive the medium-deep ground source heat pump, which is a heat pump with a high energy efficiency ratio, to meet the demand for clean heat in the field. The plan makes full use of the multi-grade renewable energy coupling system, performs intermittent heat storage and release operations according to the characteristics of the grid supply, realizes the “underground rock formation-heat storage device-building” multi-level energy storage, and cooperates with the corresponding power demand side response incentive policy. Thus a “zero electricity bill” operation is essentially realized.

Similar to the zero-carbon renovation of existing public buildings/communities, the zero-carbon construction of new buildings/communities also requires an entire process and complete grasp of the focus of work. The process is started from the three aspects of demand-side reduction, high-efficiency conversion chain, and zero-carbon supply side. As shown in Fig. 14, in addition to the above-mentioned supply side zero-carbon and full utilization of renewable energy work, it is also necessary to reduce demand to a near-zero carbon standard, achieve low energy, low dissipation, and low entropy increase in the operation of building communities, and reduce energy demand to near zero on the basis of meeting building functional activities (enclosure structure, airtightness, underground heat transfer, solar radiation, etc.).

The total energy consumption equals the energy consumption of specific functional activities (scope 2) + energy consumption of transportation related to the airport (Scope 3). In this study, the energy consumption of airports with the same volume and throughput was measured. With power storage, as part of absorbing external photovoltaic and wind power generation, the energy consumption fully reflects the flexibility of the building + system and achieves 100% absorption of grid renewable power through the balance of supply and demand.

5 Discussion & conclusion

5.1 Discussion

From public buildings to communities and finally cities: a comprehensive understanding and in-depth implementation of the dual carbon goals.

Based on the actual work results of specific projects, the KAYA model of the public building department provides a reference, uniform, and benchmark index system for different types and sizes of buildings/communities for decarbonization work. The decarbonization actions taken with buildings and communities have the opportunity to spill over to the town and city scale from the bottom up. According to Fig. 15, the decarbonization actions from buildings/communities to towns/cities should start from the following “2 + 2 + 3” work, which is the specific work of each of the three categories illustration in the figure below. The first ‘2’ means the work from supply side and demand side. The second ‘2’ means the work with technological innovation and market mechanism. And the ‘3’ means the work with life style, carbon sink and international cooperation. Focusing on urban decarbonization, this process should start from the energy consumption side, urban and rural construction and high-quality energy-saving development, reducing consumption and carbon, and building cities with flexible, decentralized, and coordinated zero-carbon operations and continuous update systems. This action should take advantage of the important window period of the 14th Five-Year Plan period and form an efficient management mechanism and implementation steps for carbon-neutral construction.

5.2 Conclusion

At present, China’s building operations still emit more than 2 billion tons of carbon dioxide each year, and building construction also indirectly causes the emission of 1.6 to 1.8 billion tons of carbon dioxide each year due to the production of steel and building materials. To achieve the dual-carbon goals on schedule or even ahead of schedule, the building sector currently needs to provide a clear development path. The top-down decarbonization work in the building sector focuses more on the macro-level economic and livelihood impacts, while the bottom-up work starts with the building’s energy bill and utilizes data, which is more helpful than the top-down approach. If the focus is on the main building structure and the technology itself, a decarbonization action plan with clearer boundaries, more feasible measures, and more credible results can be realized.

This paper introduces the decomposable white box KAYA model for different scales and different types of buildings and proposes a concrete and implementable action plan, through the implementation of demand reduction, energy efficiency improvement, and zero-carbon open source in five clear steps; three tasks are required to achieve the desired goal of decarbonization of buildings/communities/cities. Further, take the implementation cases of zero carbon reconstruction of existing buildings/communities and zero carbon construction of new buildings/communities as examples. The former is based on the actual test data to save energy at a high level, fully electrify and upgrade the zero-carbon operation power energy system dominated by new energy. Gradually build a zero-carbon power system that fully absorbs renewable power from power grids and buildings and has zero carbon emission factor for its own electricity use. The latter is based on the simulation results, starting from the three aspects of demand side reduction, transformation chain efficiency and supply side zero carbon, combined with the system design method driven by the zero-carbon goal. These implementation cases also preliminarily verified the feasibility and operability of the model. Decarbonization in the building sector is not an isolated activity. It requires the entire industry to move towards the dual-carbon goal to promote the completion of the zero-carbon transformation of the entire society. The current decarbonization work in the building sector provides a good prerequisite and starting point for future technological innovations and social progress. To investigate the decarbonization of the building sector from a new development perspective, we must first take action on the decarbonization of more buildings.

6 Nomenclature

\(\varvec{C}\) | Total carbon emissions of the public building sector | \(\varvec{P}\) | Population |

\({\varvec{C}}_{\varvec{e}\varvec{n}\varvec{e}\varvec{r}\varvec{g}\varvec{y}}\) | Carbon emissions from the energy consumption side | \(\varvec{G}\) | Regional GDP |

\({\varvec{C}}_{\varvec{m}\varvec{a}\varvec{t}\varvec{e}\varvec{r}\varvec{i}\varvec{a}\varvec{l}}\) | Carbon emissions from the material consumption side | \(\varvec{E}\) | Energy consumption |

\({\varvec{E}}_{\varvec{i}}\) | i-th energy consumption | \({\varvec{C}\varvec{O}}_{2}\) | Carbon emission coefficient |

\({\varvec{\alpha }}_{\varvec{i}}\) | Carbon emission coefficient of the i-th energy | \(\varvec{S}\) | Built-up area |

\({\varvec{M}}_{\varvec{j}}\) | Consumption of type j-th materials | \({\varvec{U}}_{\varvec{i}}\) | Class i energy consumption |

\({\varvec{\beta }}_{\varvec{j}}\) | Carbon emission coefficient of the j-th material | \({\varvec{\gamma }}_{\varvec{i}}\) | Carbon emission coefficient of class i energy |

\({\varvec{\mu }}_{\varvec{j}}\) | Recycling coefficient of the j-th material | \(\varvec{n}\) | Type of energy |

\(\varvec{E}\varvec{E}\varvec{R}\) | Energy efficiency ratio of air conditioning system | \(\varvec{W}\varvec{T}\varvec{F}\) | Energy efficiency ratio of transmission system |

Availability of data and materials

The qualitative data analyzed for the current report are available from the corresponding author on reasonable request.

Abbreviations

- C:

-

Total carbon emissions of the public building sector

- Cenergy :

-

Carbon emissions from the energy consumption side

- Cmaterial :

-

Carbon emissions from the material consumption side

- Ei :

-

i-th energy consumption

- αi :

-

Carbon emission coefficient of the i-th energy

- Mj :

-

Consumption of type j-th materials

- βj :

-

Carbon emission coefficient of the j-th material

- µj :

-

Recycling coefficient of the j-th material

- EER:

-

Energy efficiency ratio of air conditioning system

- P:

-

Population

- G:

-

Regional GDP

- E:

-

Energy consumption

- CO2 :

-

Carbon emission coefficient

- S:

-

Built-up area

- Ui :

-

Class i energy consumption

- γi :

-

Carbon emission coefficient of class i energy

- n:

-

Type of energy

- WTF:

-

Energy efficiency ratio of transmission system

References

Department of Energy Statistics, National Bureau of Statistics (2019) : China Statistics Press. 2020:457

China Building Energy Consumption Annual Report (2020): 2020. J BEE, 2021,49(02):1–6

Li HM, Tong JJ (2021) Regional differences in carbon emissions from China’s building sector and carbon neutralization path. Environ Prot 49(17):23–29

Yang J, Wang J, Zhang ZY (2012) Inter-provincial discrepancy and abatement target achievement in carbon emissions: A study on carbon Lorenz curve. Acta Sci Circumst 32(8):2016–2023

Wang Q, Jiang R (2019) Is China’s economic growth decoupled from carbon emissions? J Clean Prod 225:1194–1208

Wang Q, Wang S (2022) Carbon emission and economic output of China’s marine fishery–a decoupling efforts analysis. Mar Policy 135:104831

Hu S (2017) Research on the path of building energy conservation in China from the perspective of ecological civilization. Tsinghua University, Beijing

Peng C (2014) Research on the path of building energy conservation in China based on total amount control. Tsinghua University, Beijing

Yang X (2009) Research on building energy efficiency in China based on energy consumption data. Tsinghua University, Beijing

Zhou N, Khanna N, Feng W et al (2018) Scenarios of energy efficiency and C02 emissions reduction potential in the buildings sector in China to year 2050. Nature Energy. 3:978–984

Shi J, Chen W, Yin X (2016) Modelling building’s decarbonization with application of China TIMES model. Applied Energy. 162:1303–1312

Tan X, Lai H, Gu B et al (2018) Carbon emission and abatement potential outlook in China’s building sector through 2050. Energy Policy. 118:429–439

Yang T, Pan Y, Yang Y et al (2017) CO2 emissions in China’s building sector through 2050: A scenario analysis based on a bottom-up model. Energy. 128:208–223

Liu JL, Xiang QX, Wang K et al (2019) Mid- to long-term low carbon development pathways of China’s building sector. Resour Sci 41(3):509–520

Sun W, Yu ZJ, Liao CP et al (2016) Analysis of Carbon Emission Peak in Guangzhou[J]. Adv New Renew Energy 4(3):246–252

Zhou LN (2015) Low-carbon Development Scenario Analysis in Shandong Province Based on LEAP. Shandong University of Finance and Economics, Shandong

Yang X, Fu L, Ding D et al (2015) Issues on Regional CO2 Emission Peak Measurement: Taking Beijing as an Example. China Popul Resour Environ 25(10):39–44

Kavgic M, Mavrogianni A, Mumovic D et al (2010) A review of bottom-up building stock models for energy consumption in the residential sector. Build Environ 45(7):1683–1697

Pan YQ, Liang YM, Zhu MY (2021) Review of building carbon emission calculation models in context of carbon neutrality, vol 51. HV&AC. pp 37–48 (7)

Feng B (2015) Research on the calculation and analysis of CO2 Emission and Energy Environmental Efficiency of Construction Industry. Tianjin University, Tianjin

Wang CJ, Wang F, Zhang HO (2016) The process of energy-related carbon emissions and influencing mechanism research in Xinjiang. Acta Ecol Sin 36(8):2151–2163

Funding

Open access funding provided by Shanghai Jiao Tong University. This research was funded by the National Natural Science Foundation of China, grant number 51,521,005 and Energy Foundation.

Author information

Authors and Affiliations

Contributions

PC: Data Curation, Visualization, Writing-Review & Editing, WQ: Conceptualization, Methodology, Formal analysis, Writing–original draft. WW: Data Curation, Visualization, Writing–original draft. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

All authors have seen the manuscript and approved to submit to the journal.

Consent for publication

Not applicable.

Competing interests

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Peng, C., Wei, Q. & Wei, W. Decarbonization path of China’s public building sector from bottom to top. Carb Neutrality 1, 39 (2022). https://doi.org/10.1007/s43979-022-00036-2

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s43979-022-00036-2