Abstract

Due to the large amount of greenhouse gas (GHG) emissions and the high dependence on fossil energy, the aviation industry has attracted a lot of attention for emission reduction and sustainable development. Biomass is a green and sustainable renewable resource, and its chemical conversion to produce bio-jet fuel is considered to be an effective way to replace fossil jet fuel and achieve emission reduction. In this study, the cradle-to-grave life cycle analysis is conducted for three bio-jet fuel conversion pathways, including biomass aqueous phase reforming (APR), hydrogenated esters and fatty acids (HEFA), and hydrothermal liquefaction (HTL). Compared with fossil jet fuels, the three bio-jet fuels have a great advantage on global warming potential (GWP), contributing 29.2, 43.6 and 51.2 g CO2-eq/MJ respectively. In general, as a relatively new bio-jet fuel conversion technology, the technology of aqueous phase reforming has minimal environmental impact. If the barriers of raw material availability and economy could be broken down, bio-jet fuel will have great development potential in replacing fossil jet fuel and realizing sustainable development.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

With the exhaustion of fossil energy and the increasingly serious environmental problems, it is urgent to find renewable and clean energy to replace traditional fossil energy. Fossil fuels are still the world’s main source of energy, which will inevitably lead to more consumption of non-renewable resources and greenhouse gas (GHG) emissions. In 2020, the Chinese government proposed at the United Nations General Assembly that China would enhance its nationally determined contribution, adopt more effective policies and measures, strive for the peak of CO2 emissions before 2030, and strive for carbon neutrality before 2060. This is China’s first long-term climate target, to limit CO2 and other GHG emissions to zero within 40 years. Biomass is a green, sustainable and abundant renewable resource. It could be utilized through direct combustion, thermochemical conversion and biochemical conversion. Jet fuel is an important fuel for air traffic, which is mainly composed of chain n-alkanes and isomeric alkanes (C8-C16) and its production mainly depends on fossil energy. In recent years, the research on obtaining high quality liquid fuel from biomass has gradually attracted the attention of researchers. Compared with fossil fuels, the raw materials of bio-jet fuel are renewable biomass resources, which could reduce the pressure of fossil energy and promote sustainable development. Whether the development and utilization of bio-jet fuel could effectively replace fossil jet fuel and reduce GHG emissions has gradually attracted the attention of researchers.

Life cycle assessment (LCA) is a powerful tool to assess the environmental performance of products, processes and production systems [8], and has been used by many researchers to assess environmental impact of bio-jet fuel.

LCA studies related to bio-jet fuel could be divided into two categories. The first type of paper reviews or compares various bio-jet fuel paths. Yilmaz et al. [32] conducted a literature review on bio-jet fuel, assessed its potential for commercial application, and summarized potential GHG emissions from various jet fuel production routes. The results showed that the development of bio-jet fuel based on renewable energy would support social and economic development. In addition, with the improvement of the characteristics of bio-jet fuel and the reduction of production cost, it would have a good development prospect in the future. Staples et al. [21] evaluated the availability of raw materials, possible output, life cycle emissions and capital investment needed to achieve emission reduction of bio-jet fuel, and analyzed the possibility of using bio-jet fuel to replace fossil jet fuel to reduce GHG emissions from multiple perspectives. The results showed that the application of bio-jet fuel could contribute up to 68.1% of GHG emissions reductions by 2050, but this requires strong policy and capital support. O’Connell et al. [18] evaluated the GHG emissions potential and energy input of bio-oil hydrogenation and Fischer-Tropsch technology (FT), and found that different production methods of bio-jet fuel may have a significant impact on GHG emissions, and bio-jet fuel may also lead to higher emissions than fossil jet fuel. In addition, different raw materials could also lead to different GHG emissions and energy inputs. Kolosz et al. [13] summarized and explored the application of life cycle assessment in alternative jet fuel assessment and reviewed several studies. It is found that the use of biomass as raw material for the preparation of bio-jet fuel has a good prospect, and HEFA technology and FT technology have relatively large emission reduction potential. Jong et al. [11] studied and compared GHG emissions performance of various jet fuel conversion methods from well-to-wake, and discussed the impact of different product allocation methods. Compared with fossil-based jet fuel, bio-jet fuel has certain environmental advantages. Among them, the path of Fischer-Tropsch process (FT) has the highest emission value, and the path of alcohol-to-jet fuel (ATJ) has the lowest value. The supply of hydrogen is the main contributor to the total emissions. In addition, the product distribution method may have a significant impact on the results. Budsberg et al. [2] investigated the environmental impact of the conversion paths of bio-jet fuel from poplar biomass and found that the GWP of lignin gasification and natural gas steam reforming are 32–73 and 60–66 g CO2-eq/MJ respectively. The development of bio-jet fuel could reduce GWP and fossil energy use. Neuling et al. [17] evaluated the environmental and economic impacts of four bio-jet fuel production paths. They found that the alcohol-to-jet path (ATJ) could achieve the lowest emissions, and GHG emissions were closely related to biomass cultivation and production. Staples et al. [22] studied GHG emissions of renewable jet fuel prepared by different fermentation pathways, and analyzed different technical path parameters and conversion efficiency. They found that the carbon footprint of jet fuel showed a wide range, ranging from − 27 to 117.5 g CO2-eq/MJ.

The second type of paper mainly focuses on the assessment of a specific type of bio-jet fuel production. For example, Vásquez et al. [27] evaluated the application of HEFA technology in Brazil, and found that the production of bio-jet fuel with palm or soybean as raw materials could achieve GHG emissions reduction compared with fossil jet fuel, while the overall emission could be further reduced when renewable hydrogen was used in the production process. Fortier et al. [7] evaluated the GWP of bio-jet fuel produced by biomass thermal liquefaction technology, and evaluated the uncertainty and sensitivity of the system. The study found that compared with fossil fuels, this path could reduce the emission value by about 55.4%, and the system optimization could reduce the emission value by about 76.0%. Li et al. [14] conducted a comprehensive economic, resource and environmental assessment on the path of FT technical pathto produce bio-jet fuel. The study found that the bio-jet fuel based on FT path had better environmental performance than fossil jet fuel, but had higher production cost. Among them, the consumption of electricity and biomass were the sensitive factors that affected the comprehensive performance of bio-jet fuel.

Many literatures have carried out horizontal comparative studies on a variety of bio-jet fuels, or conducted in-depth analysis on a single type of bio-jet fuels. However, there are relatively few comparative studies on bio-jet fuel under current industrial conditions in China, and few analyses on the technical path of aqueous phase reforming. Moreover, the GWP of bio-jet fuel under different evaluation conditions may differ. Therefore, in view of the characteristics of biomass resources in China and the maturity of jet fuel technology, the three paths of aqueous phase reforming (APR), hydrogenated esters and fatty acids (HEFA) and hydrothermal liquefaction (HTL) are selected as evaluation objects. China is rich in cellulosic biomass resources, both APR and HTL paths use cellulosic biomass as raw materials, which have the characteristics of relatively mild production conditions. HEFA path uses oil crops or waste oil as raw materials and is the most mature jet fuel production path at present. The study assumes that all three jet fuel production paths are carried out in China. Based on the current industrial conditions in China, the environmental impact of Bio-jet fuel is assessed with a unified method and system boundary.

2 Methods and system boundary

2.1 Life cycle assessment framework

The application of LCA follows ISO14040 series standard formulated by international organization for standardization [6], there are usually four steps to assess environmental impact.

-

1)

Definition of objectives and scope, which explain the reasons for conducting the study and serve as the starting point and foothold on which the subsequent evaluation depends.

-

2)

Life cycle inventory analysis, which includes the input and output of each step of the production process, is a quantitative analysis of the material flow and energy flow in and out of the whole production system.

-

3)

In the impact assessment stage, the data compiled in the previous stage will be used for environmental impact assessment with the help of the impact assessment methods, and the data will be converted into specific impact indicators for comparative evaluation.

-

4)

Results interpretation stage. Analyze the results, form conclusions, explain limitations and put forward suggestions according to the research and data obtained in the previous stages, so as to achieve the research objectives.

ReCiPe Midpoint method is used in the LCA calculation of this study [10] to evaluate the environmental impact of three bio-jet fuel conversion paths. Midpoint method focuses on a single environmental issue, such as global warming potential, water eutrophication, fossil resource consumption, etc., with a total of 18 single environmental indicators. This study focuses on the indicator of global warming potential (GWP).

2.2 System boundary

The system boundary of the evaluation includes the farming and collection of biomass, pretreatment and conversion through various conversion paths to produce bio-jet fuel, and subsequent combustion for use. System boundary does not include plant construction and assembly material consumption. In addition, according to the carbon neutral hypothesis, the CO2 emission from the combustion of bio-jet fuel is assumed to be zero [3, 11]. The production of 1 MJ of bio-jet fuel is taken as the functional unit (Fig. 1).

2.3 Methods to deal with co-products

For a multi-product system, the distribution method of by-products may have a significant impact on the results [20, 23]. Environmental impact could be allocated to different products based on economy, energy, or quality. In addition, substitution method can also be used to award an emission credit in calculation according to the output of by-products and the environmental impact value of substitute products. This approach may result in negative emissions when the emissions of the substitution products exceed the total emissions produced by the system. According to economic allocation, emissions are allocated according to the economic value of products, but they will be affected by price fluctuations and may have greater uncertainty. The methods of mass and energy distribution based on the properties of by-products is relatively unaffected by uncertainty and generally applicable. However, there may be massless by-products in the system, such as heat, electricity, etc., in which case the method of mass distribution is not applicable. In this study, the emissions are allocated according to energy distribution.

3 LCI datasource

OpenLCA developed by Greendelta is an open source LCA computing tool, which has a good user interaction interface and comprehensive functional modules, and has been recognized and used by many researchers. It is also the tool chosen for this study. Ecoinvent is one of the databases with the most comprehensive data, the most widely used, and the most covering software. Data in the database are mainly derived from statistical data and technical literature, and it has units and aggregated data sets covering many countries in the world [19, 25]. The background data of this study are based on the data of Ecoinvent v3.7. The LCI data and technical path parameters collected in the study are based on process data disclosed by researchers in recent years, and the conversion process is assumed to take place in China. Therefore, the first choice for background data to be used is the data located in China. Global average data or average data excluding Europe will only be used if no data for China exists.

3.1 Aqueous phase reforming (APR)

The path of lignocellulosic aqueous phase reforming is mainly referred to the study of Guangzhou Institute of Energy Research, Chinese Academy of Sciences [15, 16, 33], and LCI data are collected from the model for calculation. The reaction system mainly consists of four main modules: 1. Furfural (FF) production and concentration; 2. hydrolysis to produce levulinic acid (LA); 3. condensation; 4. hydrogenation upgrade. The technical path assumes that corn straw is used as raw material and the overall process of bio-jet fuel production through aqueous-phase reforming is shown in the figure below (Fig. 2).

The reaction temperature of FF production is 175 °C, the reaction pressure is 0.9 MPa, and the mass ratio of biomass to sulfuric acid is 2.5. The hemicellulose in the raw material is catalyzed by acid to degrade FF, and then saturated steam is used to extract the FF in time, which can avoid the self-polymerization of furfural and the copolymerization reaction with xylose. After steam stripping, furfural is condensed and the recovery can reach about 95%. The FF solution is then further concentrated. The reaction process of furfural production can obtain part of steam stripping residual (SSR). About 9 times the mass of sulfuric acid solution is added to the separated SSR and the reaction is carried out at 180 °C. The cellulose in the residue is converted to LA by acid catalysis. Based on the initial cellulose content of raw materials, the design of LA yield is 34.4%. After that, the hydrolysis residue is filtered and separated. Lime is added to the hydrolysate to remove impurities such as colloid and lignin, and the PH is then adjusted to neutral. The hydrolysis residue and LA solution are obtained by filtration and separation, and then the LA solution is concentrated. Furfural and levulinic acid obtained in the first two steps are condensed in an intermittent reaction kettle at 50 °C and atmospheric pressure. Under the catalysis of alkaline catalyst, long chain oxygen-containing condensation products (C15 and C10) are formed. After that, sulfuric acid solution is added to precipitate oxygen-containing products, and the precursor is separated. The last step is the hydrogenation upgrading stage of the product, which is mainly divided into two steps. Firstly, low temperature hydrogenation is carried out in methanol solution under the condition of 150 °C and 4 MPa with the help of Ru/C catalyst, and the existing carbon-oxygen double bond and carbon-carbon double bond are saturated. Subsequently, hydrotreating is carried out at 280 °C and 4 MPa at high temperature, in which oxygen atoms are removed in the form of carbon dioxide, carbon monoxide or water. And at the same time, long chain hydrocarbons are cleaved to form crude oil. The product is then further deoxidized at 300 °C and 4 MPa, and the yield of bio-jet fuel is about 51.0 wt%. About 18.9 wt% of n-alkanes, 60.1 wt% of isomerized alkanes, 15.6 wt% of cycloalkanes, 3.8 wt% of aromatic hydrocarbons and 1.6 wt% of oxygen-containing compounds are contained in bio-jet fuel, including 84.7 wt% of C, 15.0 wt% of H and 0.2 wt% of O.

In addition, the residues and tail gas in the production process are considered to be burned to produce steam required by the reaction process, and the generated wastewater is purified to realize recycling. The overall mass yield of bio-jet fuel based on aqueous phase reforming is about 10.0%, and the calorific value of jet fuel is about 43.6 MJ/kg. After energy allocation, the process data is evenly distributed to 1 MJ of jet fuel production. The data for this technical path is listed in Table 1.

3.2 Hydrogenated esters and fatty acids (HEFA)

The technical path of HEFA refers to the study of Vásquez et al. [27]. Oily biomass can be used to prepare bio-jet fuel by means of removing functional group, cracking or aromatization. The process of producing bio-jet fuel through HEFA is usually divided into two steps: firstly, unsaturated fatty acids and triglycerides are converted to saturated fatty acids through catalytic hydrogenation, and then the saturated fatty acids are converted to straight alkane of C15-C18 through hydrotreating and decarboxylation. The overall process of producing bio-jet fuel from soybeans is shown in Fig. 3.

There are four main stages for soybean to be transformed into bio-jet fuel: soybean farming and collection, oil extraction, soybean oil refining and hydrotreating. The stage of oil extraction mainly adopts mechanical process, the input of this stage includes water, steam, energy and so on. The collected soybean oil is extracted by solvent, and the extraction rate is about 19.2% of the raw material. The extracted soybean oil is then refined to produce refined oil. Soybean oil consists mainly of diesel molecules with long carbon chains, which are fed into a hydrogenation reactor together with hydrogen to react with hydrogen to remove oxygen, saturate the double bond, and crack the propane main chain of triglycerides under the catalysis of catalyst. The products of the reaction are water, carbon dioxide, and a series of alkanes. The products are cooled by steam and then enter the isomerization unit. The isomerized products are cooled by cooling water and then separated in the separation tower, producing paraffin gas, carbon dioxide and so on. The products are separated into bio-jet fuel, diesel, gasoline and other fuels, and the waste water is treated in the treatment unit. The overall mass yield of jet fuel is about 9.3% and the calorific value is about 42.8 MJ/kg. After energy allocation, the LCI data of HEFA are listed in Table 2.

3.3 Biomass hydrothermal liquefaction (HTL)

HTL process is based on the study of Tews et al. [24]. The path mainly uses water as the medium and converts forest residue into bio-jet fuel under the reaction conditions of 250–550 °C and 5–25 MPa pressure. The overall process of HTL is shown in Fig. 4.

The hydrothermal liquefaction process mainly includes the following stages: raw material collection, pretreatment, liquefaction and hydrotreatment. Since forest residues are usually treated as wastes, the collection stage of raw materials does not consider the farming and growth stage of plants, and only includes the collection and transportation of materials [24]. In the raw material pretreatment stage, forest residue is ground into fine particles and injected directly into hot water without drying and softening to obtain a slurry with a solid content of about 8%. After that, the slurry is further preheated and pressurized, and sent to the reactor running at 20.3 MPa and 335 °C for reaction. The slurry reacts to produce crude oil, water phase and gas phase products, and then depressurizes and separates. Most of the organic matter exists in crude oil and water phase. The separated crude oil then reacts hydrotreated with catalysts until the oxygen content falls below 1%. In this process, the oil is preheated and sent to the hydrogenation system for reaction, which is almost completely converted into hydrocarbons at about 400 °C, and the products are mainly composed of C4-C17. The treated products are further separated after the removal of lighter components. The product contains gasoline, diesel and heavy oil, and it is assumed that the diesel could be split in 25% bio-jet fuel and 75% diesel [11]. The overall mass yield of jet fuel is about 2.7% and the calorific value of jet fuel is about 42.8 MJ/kg. After energy allocation, the LCI inputs for HTL are listed in Table 3.

4 Results and discussion

4.1 Results of global warming potential

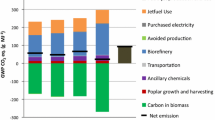

This study focuses on the indicator of GWP, compares and evaluates the above three bio-jet fuel conversion technical paths, performs uncertainty and sensitivity analysis on this basis. In addition to bio-jet fuel, the products of the three technical paths also include other hydrocarbon fuels, which are typical multi-product systems. Therefore, in the process of emissions allocation, emissions are allocated to each MJ of bio-jet fuel based on the calorific value of the different fuels. And the results obtained are shown in Fig. 5.

Emissions of GHG will lead to an increase in the concentration of GHG in the atmosphere, which will enhance radiation intensity and lead to an increase in global average temperature, which will ultimately affect human health and ecosystems. GWP mainly comes from CO2, followed by CH4 and N2O emissions. Due to the differences in crude oil quality and processing methods, the GWP range of fossil jet fuel production is large. For example, the range reported by relevant regulatory agencies is 80.7–109.3 g CO2-eq/MJ in the United States [23] and 80.4–105.7 g CO2-eq/MJ in the European Union [5]. In the process of literature review, there is no baseline emission value of fossil jet fuel for China. Therefore, the average emission baseline value of 83.8 g CO2-eq/MJ issued by EU Renewable Energy Directive [5] is used as the baseline GWP of fossil jet fuel for this study.

Among the conversion pathways evaluated, APR had the lowest GWP (29.2 g CO2-eq/MJ), followed by HEFA (43.6 g CO2-eq/MJ), and HTL has the highest value (51.2 g CO2-eq/MJ). However, compared with the fossil fuel baseline, GWP of the three bio-jet fuel technical paths are significantly reduced by 65.2%, 48.0% and 38.9%, respectively, demonstrating the good environmental impact of bio-jet fuel.

In order to study the influence of different factors on GWP in the life cycle process, the emission structures of three technical paths are analyzed and has been shown in Figs. 6 and 7. For APR, the contribution of biomass farming and collection process is not large, which is about 15.2%. The contribution of conversion stage is about 84.8%. The input and use of electric power in the production process contributes 55.8% of the GWP, while the hydrogen consumption contributes about 9.6%. The consumption of other chemicals, such as methanol, catalyst and sodium hydroxide, contributes about 19.5% of the total GWP. If it is distinguished according to different stages of the conversion process, the FF and LA production process is the most influential one, mainly because of the usage of sulfuric acid and electricity. While the condensation stage is the links with the least impact, acounting for about 7.7% of total GWP. For the HTL process, the consumption in the biomass farming and collection stage is very small, contributing only about 0.8%. Since forest residue is a kind of waste, only consumption in the collection stage is considered. Almost all GWP come from the conversion stage, of which the input of electric power contributes about 27.6%, and the consumption of hydrogen contributes about 3.6%. The use of a large amount of water in the liquefaction process contributes less, but leads to the treatment process of a large amount of wastewater contributes the largest emission value, accounting for about 67.3% of the total GWP. In addition, there are some catalyst and chemical consumption emissions, but they account for a small proportion. The GWP of the HEFA path is between the other two paths. The soybean farming and collection process contributes about 25.8% of the total emissions, and the consumption of a large amount of steam in the conversion process results in a high GWP, contributing about 56.6%. The input of electric power contributed about 12.7% of the total value. In addition, the hydrogen consumption in the hydrotreating stage contributes about 3.9%, and other parts, such as sodium hydroxide and diesel consumption, contribute less. Compared with APR and HEFA paths, HTL path has a relatively simple transformation process, but contributes a relatively high GWP. There are two main reasons for this: 1. A relatively low conversion efficiency; 2. High wastewater discharge in the reaction process, but that is not effectively recovered and utilized in the system.

In general, the three technical paths could reduce GHG emissions, and the APR path is the most environmentally friendly one. HTL path requires a large amount of water to be put into use, which leads to the discharge of subsequent wastewater treatment, and has a great impact. It is an effective way to promote the improvement of technology and reduce the amount of water used in the raw material treatment stage. In the future, if commercial application is promoted, advanced wastewater treatment technology could also be integrated in the plant to promote emission reduction in the production process. For APR and HEFA paths, GWP mainly comes from the consumption in the process of jet fuel conversion. From the technical point of view of bio-jet fuel production, improving the conversion efficiency of jet fuel and realizing the reduction of materials and energy consumption is an important link of emission reduction. From the perspective of background energy production, reducing emissions from the industrial production of electricity and steam is also an effective means. In addition, the cultivation and collection of biomass resource also restricts the further reduction of GWP to a certain extent. When selecting the site of future bio-jet fuel plant, the local biomass resources should be fully investigated, and the site with large amount of available raw materials and short transportation distance should be selected as far as possible.

4.2 Uncertainty and sensitivity analysis

4.2.1 Uncertainty analysis

There might be some uncertain data in the calculation, which may lead to differences in the results. The study uses pedigree matrices to assess the quality of the data used. And the uncertainties of the results are investigated by means of 10,000 times Monte Carlo simulations. Regarding the reliability of LCI data sources, the data of APR and HEFA paths come from published research papers, and the data of HTL paths come from research reports of research institutions. For the completeness of the data, the representative data from all sites relevant for the market are not fully considered, and therefore there are some uncertainties. For temporal correlation of data, the time of data disclosure of APR and HEFA paths is close to the study time, and the release time of HTL path is 2014, which may lead to increased uncertainty. In terms of geographical correlation, the data of APR comes from the research in China, while the data of HEFA and HTL come from abroad. This study assumes that jet fuel production technologies in China and abroad are similar, and data from China are used as much as possible for material, energy and other background data input. As for further technological correlation, the data of the three paths are basically obtained through simulation and investigation, and the uncertainty is relatively small.

The results of Monte Carlo simulation are shown in Fig. 8, where the upper and lower bounds in the bar chart are 95% confidence intervals of this indicator. Among them, the uncertainty range of the baseline value of fossil jet fuel comes from the reference value of literature [5, 23]. For the three technical paths, the uncertainty range of HEFA is − 4.3% to 4.8%, the uncertainty range of APR is − 5.0% to 6.5%, and that of HTL is the largest among the three paths, which is − 17.6% to 24.0%.

Assuming that the uncertainty of the three paths is considered, the GWP of bio-jet fuel still has a significant advantage over the fossil baseline. Considering the maximum value of the HTL path, the GWP is still reduced by approximately 21.0%. It could be considered that the use of bio-jet fuel instead of fossil jet fuel could effectively help the aviation industry to achieve emission reduction targets.

4.2.2 Sensitivity analysis on conversion yield

For sensitivity analysis, this study first evaluates the impact of conversion yield on bio-jet fuel life cycle emissions. Since the bio-jet fuel production system is a multi-product system, there are some by-products besides bio-jet fuel, the study uses the mass yield range of jet fuel to measure the change of the overall conversion yield of the production system. The mass yields in the previous study are regarded as the baseline values, and the yields under pessimistic and optimistic estimates of the three technical paths are considered. The yields of HTL and HEFA paths are based on the research in the existing literatures. For APR path, a mass yield range of ±15% is considered because there are few studies on the path. The mass yields of bio-jet fuel are listed in Table 4, and the results are listed in Table 5.

The results show that the GWP of the three technical paths are highly sensitive to the change of conversion yield. When considering the optimistic scenario, the GWP of APR, HEFA and HTL decrease by 13.0%, 12.3% and 6.9%, respectively, and the GWP of APR path is reduced to 25.4 g CO2-eq/MJ. When considering the pessimistic scenario, the GWP of the three paths increase by 17.6%, 5.7% and 22.7%, respectively, and the GWP of HTL path reaches the highest 62.8 g CO2-eq/MJ. Overall, the conversion yiled of bio-jet fuel is an important factor influencing the GWP, and the improvement of efficiency could effectively help reduce the environmental impact, while the specific emission reduction value is closely related to the baseline value.

4.2.3 Sensitivity analysis on power input

China’s current power generation is still dominated by coal-fired power, and the high emission of coal-fired power generation directly leads to the high average GWP of China’s grid mix. Compared with coal-fired power, renewable power such as wind power, solar PV power and hydropower, has a lower GWP. In the context of carbon neutrality, the government is also actively promoting the development of renewable power [4, 28]. Electric power is a sensitive parameter for bio-jet fuel, so we investigate and analyze the sensitivity of power input to three bio-jet fuel production paths.

Four scenarios assumed are as follows: 1. China’s grid mix (power input in LCI); 2. wind power; 3. solar PV power; 4. hydropower. The data of the power input are obtained from data for China in Ecoinvent database. And the results are shown in Table 6.

According to the results obtained, HTL path have the highest sensitivity to power input. When the power from grid mix is replaced by the hydropower with a lower emission, the GWP decreases to 30.9 g CO2-eq/MJ, reducing the GWP by about 39.6%. Power input has the least influence on HEFA path as shown above, because the GWP contribution of power is relatively small in the total GWP. When solar PV power is used, the impact is minimal, with GWP reduced by only about 14.2%. For APR path, wind power, solar PV power and hydropower input can reduce GWP by 35.6%, 34.6% and 36.0% respectively.

It could be seen from the results that the use of green energy power can further reduce the greenhouse gas emissions of bio-jet fuel, and further expand the advantage of bio-jet fuel over fossil jet fuel. Although the GWP caused by hydropower, wind power and solar PV power are different (GWP calculated are 4.0, 30.5 and 36.2 g CO2-eq/MJ, respectively), there is no significant difference in GWP reduction between the three types of power. This also suggests that if the production of bio-jet fuel could be applied on a large scale in the future, the government and enterprise could also fully consider the distribution of local green energy, to realize the application of different green power in bio-jet fuel production according to local conditions, which could further reduce greenhouse gas emissions and contributes to the sustainable development of society and aviation industry.

4.2.4 Sensitivity analysis on hydrogen input

The three jet fuel paths all involve the hydrogenation stage, and the hydrogen input is also one of the sensitive indicators that many researchers focus on [11, 12, 21]. At present, large-scale industrialized hydrogen production still relies on fossil energy, mainly including petroleum processing, methanol cracking and natural gas reforming, etc. And the main sources of renewable hydrogen production are water electrolysis and biomass conversion. The water electrolysis technology is developing rapidly, and hydrogen produced by water electrolysis is considered to be used in the production of bio-jet fuel.

In the baseline scenario, the technical path of natural gas reforming is adopted. And the path of water electrolysis with wind power input is adoped in alternative scenario. In addition, the LCI data of hydrogen production from water electrolysis are referred to the study of Valente et al. and Wulf et al. [26, 31]. And the results are listed in Table 7.

According to the results, it could be found that hydrogen input has the greatest influence on the APR path, and the GWP decreases by 5.2% to 27.7 g CO2-eq/MJ. For HEFA and HTL paths, the change of hydrogen input contributes about 2.3% and 2.0% of the GWP decreases. The GWP decreased to 42.6 and 50.2 g CO2-eq/MJ, respectively, and the results are not significant. At present, the path of natural gas reforming is relatively mature, while the path of water electrolysis still has room for improvement. The current efficiency of water electrolysis is still relatively low, and it has the highest cost among several hydrogen production methods. From the perspective of GHG emission reduction, the use of hydrogen produced by water electrolysis could reduce GHG emission in jet fuel production, but the effect is not significant. If the water electrolysis technology is further upgraded in the future and the cost is reduced, it will be a good choice for using in bio-jet fuel production process [30]. Under the current industrial conditions, the entry points of GHG emission reduction in bio-jet fuel production and utilization should pay more attention to the factors such as production efficiency or electric power source, and the source of hydrogen is not the main factor.

4.3 Summary

In view of the above results, the comparison of different features of the three technical paths has been sorted out and listed in Table 8. Among them, the minimum selling price for different technical paths are collected from the study of Wei et al. [30].

At present, APR and HTL paths are still in the demonstration stage, and have not yet achieved large-scale commercial application. HEFA path is relatively mature, and there are some commercial application scenarios. The APR path has the highest calorific value and mass yield of jet fuel, while the HTL path has the lowest mass yield of jet fuel, which is mainly due to the low selectivity of the production system for jet fuel. In addition, the APR path has the lowest GWP, which could be considered as the path with the greatest GHG emission reduction potential among the three paths. The GWP of the HEFA and HTL paths are relatively high, but still have an advantage over the fossil baseline. From an economic point of view, the APR path has the highest cost while the HEFA path has the lowest cost. However, the costs of bio-jet fuels are still higher than that of fossil jet fuel. In summary, the production and application of bio-jet fuel could help achieve sustainable development of the aviation industry. Among them, the APR path has the advantage in a number of indicators and has the greatest potential, but the cost needs to be further reduced.

5 Conclusion

This study compares the environmental impact of three different cradle-to-grave conversion pathways, in which the global warming potential (GWP) is calculated and analyzed based on an energy distribution approach. As an indicator of greenhouse effect, GWP is considered as an important indicator to measure the environmental performance of fossil and bio-based fuels in many studies. The results show that APR, HEFA and HTL could contribute 29.2, 43.6 and 51.2 g CO2-eq/MJ GWP respectively, and could reduce 65.1%, 48.0% and 38.9% g CO2-eq/MJ emissions compared to fossil jet fuel, which reflects a better environmental impact. For bio-jet fuel, GWP is highly sensitive to the conversion yield, and the specific emission reduction value depends on the baseline value. In addition, the high emission of power generation process caused by China’s power structure directly increases the GWP, and the use of cleaner power could effectively reduce the GWP of bio-jet fuel. HTL has the highest sensitivity to power input, while HEFA has the lowest sensitivity. Moreover, APR path has the highest sensitivity to the application of green hydrogen, with a reduction benefit of about 5.2%. However, the impacts of hydrogen input on HTL and HEFA paths are not significant. In general, the production and utilization of bio-jet fuel under the three technical paths could reduce GHG emissions. And the APR path is the most environmentally friendly one. In addition, the use of green energy and green chemicals may also could help realizing the huge environmental potential of bio-jet fuel in the future.

From the perspective of aviation industry demand, the conversion of biomass to jet fuel is a valuable technology, which could help achieving greenhouse gas emission reduction and saving fossil energy. However, the development of bio-jet fuel is still restricted by factors such as economy and availability of raw materials. The government could devote itself to providing policy support, encouraging technological improvement, selecting fuel conversion paths based on regional characteristics, and promoting the commercial application of bio-jet fuel.

Availability of data and materials

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

Abbreviations

- GWP:

-

Global warming potential

- GHG:

-

Greenhouse gas

- APR:

-

Aqueous phase reforming

- HEFA:

-

Hydrogenated esters and fatty acids

- HTL:

-

Hydrothermal liquefaction

- FT:

-

Fischer-Tropsch

- ATJ:

-

Alcohol-to-jet

- LCA:

-

Life cycle assessment

- LCI:

-

Life cycle inventory

- FF:

-

Furfural

- LA:

-

Levulinic acid

References

Beal CM, Cuellar AD, Wagner TJ (2021) Sustainability assessment of alternative jet fuel for the U.S. Department of Defense. Biomass Bioenergy 144:105881

Budsberg E, Crawford JT, Morgan H, Chin WS, Bura R, Gustafson R (2016) Hydrocarbon bio-jet fuel from bioconversion of poplar biomass: life cycle assessment. Biotechnology for Biofuels 9:170

Cherubini F, Bird ND, Cowie A, Jungmeier G, Schlamadinger B, Woess-Gallasch S (2009) Energy- and greenhouse gas-based LCA of biofuel and bioenergy systems: key issues, ranges and recommendations. Resour Conserv Recycl 53:434–447

Ding N, Liu J, Yang J, Yang D (2017) Comparative life cycle assessment of regional electricity supplies in China. Resour Conserv Recycl 119:47–59

European Commission (2015) Study on actual GHG data for diesel, petrol, kerosene and natural gas. European Commission, Brussels

Finkbeiner M, Inaba A, Tan R, Christiansen K, Klüppel H-J (2006) The new international standards for life cycle assessment: ISO 14040 and ISO 14044. Int J Life Cycle Assess 11:80–85

Fortier M-OP, Roberts GW, Stagg-Williams SM, Sturm BSM (2014) Life cycle assessment of bio-jet fuel from hydrothermal liquefaction of microalgae. Appl Energy 122:73–82

Heijungs R, Guineév JB (2012) Life cycle assessment handbook: a guide for environmentally sustainable products

Huang E, Zhang X, Rodriguez L, Khanna M, Sierk de Jong KC, Ting YY, Lin T (2019) Multi-objective optimization for sustainable renewable jet fuel production: a case study of corn Stover based supply chain system in Midwestern U.S. Renew Sust Energ Rev 115:109403

Huijbregts MAJ, Steinmann ZJN, Elshout PMF, Stam G, Verones F, Vieira M, Zijp M, Hollander A, van Zelm R (2017) ReCiPe2016: a harmonised life cycle impact assessment method at midpoint and endpoint level. Int J Life Cycle Assess 22:138–147

de Jong S, Antonissen K, Hoefnagels R, Lonza L, Wang M, Faaij A, Junginger M (2017) Life-cycle analysis of greenhouse gas emissions from renewable jet fuel production. Biotechnol Biofuels 10:64

de Jong S, Hoefnagels R, Faaij A, Slade R, Mawhood R, Junginger M (2015) The feasibility of short-term production strategies for renewable jet fuels – a comprehensive techno-economic comparison. Biofuels Bioprod Biorefin 9:778–800

Kolosz BW, Luo Y, Xu B, Maroto-Valer MM, Andresen JM (2020) Life cycle environmental analysis of ‘drop in’ alternative aviation fuels: a review. Sustainable Energy Fuels 4:3229–3263

Li M, Zhao W, Yue X, Zhao Y, Yang K, Tao W, Xiao J (2019) Comprehensive Life Cycle Evaluation of Jet Fuel from Biomass Gasification and Fischer–Tropsch Synthesis Based on Environmental and Economic Performances. Ind Eng Chem Res 58:19179–19188

Li Y, Chen L, Zhang X, Zhang Q, Wang T, Qiu S, Tan J, Li K, Ma L (2017) Process and techno-economic analysis of bio-jet fuel-range hydrocarbon production from Lignocellulosic biomass via aqueous phase deconstruction and catalytic conversion. Energy Procedia 105:675–680

Li Y, Zhao C, Chen L, Zhang X, Zhang Q, Wang T, Qiu S, Tan J, Li K, Wang C, Ma L (2018) Production of bio-jet fuel from corncob by hydrothermal decomposition and catalytic hydrogenation: lab analysis of process and techno-economics of a pilot-scale facility. Appl Energy 227:128–136

Neuling U, Kaltschmitt M (2018) Techno-economic and environmental analysis of aviation biofuels. Fuel Process Technol 171:54–69

O’Connell A, Kousoulidou M, Lonza L, Weindorf W (2019) Considerations on GHG emissions and energy balances of promising aviation biofuel pathways. Renew Sust Energ Rev 101:504–515

Pascual-González J, Guillén-Gosálbez G, Mateo-Sanz JM, Jiménez-Esteller L (2016) Statistical analysis of the ecoinvent database to uncover relationships between life cycle impact assessment metrics. J Clean Prod 112:359–368

Shonnard DR, Williams L, Kalnes TN (2010) Camelina-derived jet fuel and diesel: sustainable advanced biofuels. Environ Prog Sustain Energy 29:382–392

Staples MD, Malina R, Suresh P, Hileman JI, Barrett SRH (2018) Aviation CO2 emissions reductions from the use of alternative jet fuels. Energy Policy 114:342–354

Staples MD, Malina R, Olcay H, Pearlson MN, Hileman JI, Boies A, Barrett SRH (2014) Lifecycle greenhouse gas footprint and minimum selling price of renewable diesel and jet fuel from fermentation and advanced fermentation production technologies. Energy Environ Sci 7:1545–1554

Stratton RW, Wong HM, Hileman JI (2011) Quantifying variability in life cycle greenhouse gas inventories of alternative middle distillate transportation fuels. Environ Sci Technol 45:4637–4644

Tews IJ, Zhu Y, Drennan CV, Elliott D, Snowden-Swan LJ, Onarheim K (2014) Biomass direct liquefaction options: technoeconomic and life cycle assessment. Pacific Northwest National Laboratory, Richland

Treyer K, Bauer C (2016) Life cycle inventories of electricity generation and power supply in version 3 of the ecoinvent database—part II: electricity markets. Int J Life Cycle Assess 21:1255–1268

Valente A, Iribarren D, Candelaresi D, Spazzafumo G, Dufour J (2020) Using harmonised life-cycle indicators to explore the role of hydrogen in the environmental performance of fuel cell electric vehicles. Int J Hydrog Energy 45:25758–25765

Vásquez MC, Martínez A, Castillo EF, Silva EE (2019) Holistic approach for sustainability enhancing of hydrotreated aviation biofuels, through life cycle assessment: a Brazilian case study. J Clean Prod 237:117796

Wang L, Wang Y, Huibin D, Zuo J, Li RYM, Zhou Z, Bi F, Garvlehn MSP (2019) A comparative life-cycle assessment of hydro-, nuclear and wind power: a China study. Appl Energy 249:37–45

Wang WC, Tao L (2016) Bio-jet fuel conversion technologies. Renew Sust Energ Rev 53:801–822

Wei H, Liu W, Chen X, Yang Q, Li J, Chen H (2019) Renewable bio-jet fuel production for aviation: a review. Fuel 254:115599

Wulf C, Kaltschmitt M (2018) Hydrogen supply chains for mobility—environmental and economic assessment. Sustainability 10:1699

Yilmaz N, Atmanli A (2017) Sustainable alternative fuels in aviation. Energy 140:1378–1386

Zhang Q, Xiao J, Hao J, Qijing W, Song G (2022) Energy and exergy analyses of bio-jet fuel production from full components in lignocellulosic biomass via aqueous-phase conversion. Appl Therm Eng 201:117723

Acknowledgements

This work was supported by the National Key R&D Program of China (2018YFB1501500).

Funding

This work was supported by the National Key R&D Program of China (2018YFB1501500).

Author information

Authors and Affiliations

Contributions

Conceptualization: Xiaonan Zhu. Methodology: Xiaonan Zhu. Formal analysis and investigation: Xiaonan Zhu. Writing original draft preparation: Xiaonan Zhu. Writing review and editing: Jun Xiao, Chenguang Wang, Lingjun Zhu, Shurong Wang. Funding acquisition: Shurong Wang. Supervision: Shurong Wang. The author(s) read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

Shurong Wang is an editorial board member for Carbon Neutrality and was not involved in the editorial review, or the decision to publish this article. All authors declare that there are no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Zhu, X., Xiao, J., Wang, C. et al. Global warming potential analysis of bio-jet fuel based on life cycle assessment. Carb Neutrality 1, 25 (2022). https://doi.org/10.1007/s43979-022-00026-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s43979-022-00026-4