Abstract

Aloe vera, a medicinal herb, is used in health care and cosmetics due to its biological activity. Its gel contains acemannan, which has high water content, biocompatibility, biodegradability, and customizable properties. Acemannan hydrogels can absorb and retain up to 99% of their weight, enabling supercooling and longer periods. There are literature reports on cellulose-based, chitosan-based, alginate-based, and starch-based hydrogels, but very limited studies on acemannan-based hydrogels, especially for supercooling applications. Hence, understanding AvP’s supercooling properties is crucial for developing reliable supercooling devices. The potential of hydrogels based on AvP for supercooling applications is examined in this review. The study reports on the idea of supercooling, how important it is in different fields, and how current techniques are limited. The review focuses on the characteristics, composition, and hydrogel formation process of AvP. It goes over AvP hydrogels’ capacity for supercooling, and the difficulties and potential paths for enhancing these hydrogels’ functionality and performance are also covered.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The anti-inflammatory, antioxidant, and wound-healing capabilities of Aloe vera (AvP) have been proven to minimize nanoparticle cytotoxicity in supercooling applications. It causes ice crystals to form, which lowers the temperature and increases the volume of liquid that may be supercooled [1]. Because of its thick epidermis wrapped in cuticle, AvP is a perennial plant with turgid green leaves that is employed in cryopreservation, food processing, and energy storage. The parenchyma cells contain AvP gel, a translucent mucilaginous liquid. AvP gel processing has evolved into a worldwide business. It is utilized in the production of health beverages, milk, and ice cream sweets [2]. However, because of their laxative impact and absence of active mucilaginous polysaccharides or acemannan, gel juices are not widely consumed. To increase gel quality and maintain bioactive chemical entities, a simple yet effective processing approach is required. The active ingredient in AvP is a source of contention, with numerous reasons for its healing qualities claimed, including synergistic action and high-water content [3]. Researchers suggest tannic acid and polysaccharide components for wound healing, but polysaccharides can exhibit pharmacological and physiological activities without additional components. Hence, AvP gel has been linked to its medicinal properties, with many researchers citing its pain-relieving properties [4]. High-quality AvP products are difficult to distinguish from adulterated ones. Harvesting, processing, and distribution factors affect their quality. To ensure quality, a certification seal and assess healing capacity by mucopolysaccharide content is necessary. AvP gel is a mucilaginous jelly produced from the parenchyma cells of the AvP plant, so its biological activities are lost when exposed to air [5]. Different processing techniques, such as cold processing or heat treatment, are used to sterilize and stabilize the gel. The optimal outcomes are achieved when leaves are processed immediately after harvesting. The process involves washing the leaves in bactericide, processing to separate the gel matrix, and treating the liquid with activated carbon to remove laxative effects [6]. The stabilized gel can be concentrated or used as a drink formulation. Cold processing involves enzymes to inhibit aerobic organism growth, while heat treatment involves pasteurization at high temperatures. Pasteurization techniques like flash cooling and high-temperature shot time can decrease activity levels, while stabilization can be achieved by adding preservatives and other additives [7].

Research on AvP gel juice found that heat treatment significantly affects polysaccharide stability and barbaloin content, with polysaccharide stability peaking at 70 °C and barbaloin content decreasing [8]. Main components of the AvP is listed in Table 1. Garau et al. [9] investigated the effect of air-drying temperature on the dehydration curves and functional properties of AvP cubes. A diffusion model was proposed and solved, with the maximum functional properties of the aloe gel observed at 40 °C [10]. Femenia et al. [11] conducted a study on the physico-chemical modifications of acemannan, a bioactive polysaccharide from AvP parenchyma, after heat treatment and dehydration at varying temperatures. The changes were significant when dehydration was performed above 60 °C, with significant losses of mannosyl residues. These alterations impact the physiological activities of the AvP plant. AvP leaves can also be processed through traditional hand-filled, whole-leaf, or total-process methods. Traditional hand filleting involves removing the lower 1 inch of the leaf base, tapering point, and short spines, and then introducing the mucilage layer below the green rind [12]. This method is labor-intensive and involves dilution of the fillet's water, which is stored in the fillet cells. The inner gel is extracted from the leaf without disrupting the latex portion, preventing bitterness. Whole leaf processing involves a cold process, allowing the cellulose (skin) and aloin to be removed. The leaf is pulverized, treated with chemicals, and juiced through a press, rind particles removed, and filtering to remove harmful substances [13].

AvP is also processed using traditional and whole leaf methods, with the hand-filled method being labor-intensive and potentially containing anthraquinones and laxatives. A depulping extractor separates the liquid from pulp [14]. The juice is filtered to remove aloe, emodin, leaves, particles, and residue. It is then placed in a holding tank, then cold filtered for final purification and stabilization. According to the International Aloe Science Council [15], the total processing of aloe, which combines conventional hand-filleting and a new proprietary methodology, has superior quality and higher concentrations of total solids, calcium, magnesium, and malic acid. AvP can be used to nucleate supercooling in various liquids, but the optimal conditions depend on the specific liquid being used. The concentration of AvP is crucial, as it increases the supercooling temperature of the liquid. However, too much AvP can inhibit supercooling by increasing the viscosity of the liquid, making it harder for ice crystals to form. Supercooling is a metastable condition where phase change materials (PCMs) are chilled below their melting point temperature while maintaining their liquid phase. This mechanism is critical for sustaining pressure in the laboratory environment without becoming a solid state. Although supercooled liquids need the release of additional energy, stored latent heat refers to the energy absorbed or released during a phase shift. High-purity AvP is essential for supercooling applications, as impurities can act as nucleation sites for ice crystals, reducing the supercooling temperature [16]. The temperature at which the liquid is cooled is also important, as too fast cooling can also cause ice crystals to form. The presence of other substances in the liquid can also affect the supercooling temperature. For example, in water, the optimal conditions are 0.5–1% AvP concentration and cooling to -10 °C or below. In milk, the optimal conditions are a 1–2% AvP concentration and cooling to -5 °C or below [17].

Botanical extracts for business purposes are generally extracted using an organic solvent, such as ethanol or aqueous solution, and then freeze or spray dried. Acemannan, a key component of AvP leaf, is removed through aqueous extraction, but calcium oxalate is dissolved. To lower the pH and precipitate acemannan, which makes smaller pieces with better biological effects, hydrochloric or nitric acid is used. Handling and filleting should be completed within 36 h to prevent gel matrix decomposition [18]. At room temperature, crush and homogenize the aloe gel product using a commercial high-speed tissue crusher. The addition of pectolytic enzymes to AvP gel can improve its biological activity, particularly polysaccharide. Filtration can affect the juice's stability, but it can also cause particle sedimentation. Deaeration prevents ascorbic acid oxidation, improving shelf life of the gel. Flash cooling is also crucial to preserving biological activity [19]. Pasteurization, which involves heating the gel at 65 °C for less than 15 min, remains active and affects taste and biological activity, but can be avoided with HTST (High Temperature Short Time) treatment. Flash cooling, storage, leaf processing, and gel harvesting are essential for preserving the juice’s biological activity, quality, and shelf life. Leaf preparation must be carried out within 36 h of harvesting, and gel accumulation and handling must be done under vacuum to avoid activity loss [20].

2 Polymeric biomaterials based on AVP

AvP is a polymeric biomaterial because it is composed of polysaccharides, which are long sugar chains and have unique properties like biocompatibility, biodegradability, anti-inflammatory, and wound-healing properties [21]. Polymers, derived from biological sources, are crucial in prosthetic devices, surgical systems, and biosensors, with ongoing research enhancing their stability and performance in vivo [22]. Research on tissue engineering materials focuses on durable implants and transplants, with increasing interest in polymeric systems for cell-polymer interaction [23, 24]. Macromolecular engineering assesses low-cost, custom polymeric structures for vascular devices, soft-tissue replacement and drug delivery focusing on bulk morphology for physical properties like strength, density, and elasticity [25]. The porosity of implant materials allows for easy passage of proteins, nutrients, and oxygen while also removing metabolic wastes. The design of these materials, including fibers, films semipermeable membranes, nanoparticles, biocomposites and hydrogels as shown in Fig. 1, is crucial for artificial organs and cell-growth scaffolds. Polymer compositions for applications like sutures and skin substitutes considers shape memory, elasticity, adhesion, durability and tensile strength. Shapeability is crucial for structural applications and nerve regeneration. While selection depends on system type, action, and target site [26, 27].

Soft contact lenses require properties such as transparency, durability, sterilizability, hydrophilicity, and water insolubility. Material selection of contact lens depends on physicochemical, interfacial, and biomimetic properties, impact strength, elasticity, and permeability. Bulk properties, including permeability and degradation rate, are crucial for long-term applications [28]. Polymers with controlled degradation rates are ideal for temporary implants, drug-delivery devices and long-term skin substitutes. Acrylics are preferred for structural materials, while hydrophilic synthetic polymers like Poly(vinyl alcohol) PVA are used for nondegradable materials [29]. Long-term applications of polymeric materials shown in Fig. 2 necessitate water-repellent materials for immunoisolation, bioartificial organs, drug delivery, and ocular applications. High water permeability and hydrophilicity determine adhesion, environmental responsiveness, and degradation rate, while considering solubility and swelling ability [30]. Polymers, both natural and synthetic, are macromolecules with a variety of uses in the building, textile, packaging, and medical industries. These are macromolecules created through the joining of monomers, and their characteristics can be modified to suit particular needs. Natural polymers come from natural sources, whereas synthetic polymers are created by humans. While synthetic polymers are more expensive and offer specific functionalities and better performance, natural polymers are more readily available, have more defined structures, are biodegradable, and have higher availability. Natural and synthetic polymers are frequently related to one another; for better qualities, synthetic polymers are modified using natural polymers that serve as inspiration. With continuous research and development efforts to improve performance, sustainability, and functionalities for various applications, both types are always changing. Both natural and synthetic polymers have special qualities and similarities that influence application research. It is essential to comprehend how these properties relate to one another in order to create novel materials and overcome obstacles in the future.

Environmental changes in swelling characteristics of polymeric materials are useful for drug delivery and biomaterials. pH-responsive systems, composed of polyelectrolytes, are used for oral administration and artificial muscle-tissue substitutes [31]. Amphiphilic polymers and polyelectrolyte gels with Poly(N-isopropylacrylamide) LCST monomers combine pH and temperature sensitivity for biomaterials [32, 33]. Hybrid polymer systems, based on copolymers, are useful in tissue engineering and biodegradable implants. Polymer blends, containing synthetic or natural polymers, are attractive biomaterials [34]. Networking in polymer selection involves developing 3D systems for implantable biodegradable scaffolds for tissue replacement or cell transplantation. These systems provide a structural framework, facilitate tissue formation, and protect isolated cells from damage [35]. Ophthalmology uses biomaterials since the mid-nineteenth century for eye diseases, including contact lenses, IOLs, artificial corneas, and implants, and is now used in various clinical applications [36]. Modern ophthalmic implants, particularly contact lenses, IOLs, and artificial corneas, are primarily made of polymers. These high-performance materials offer various properties, including light transmission, resistance to tear-film deposition, tear-film wettability and oxygen permeability. They can be hard or soft, with Poly(methyl methacrylate) PMMA being the first generation [37]. PMMA offers superior optical properties, durability, and tear film resistance. However, its lack of oxygen permeability and eye shape alteration have limited its use. Rigid gas-permeable (RGP) contact lenses were developed in the late 1970s to improve oxygen permeability [38]. Wetting agents in RGP lens formulations include hydrophilic monomers such as methacrylic acid MAA, 2-hydroxyethyl methacrylate HEMA, and N-vinylpyrrolidone (NVP). Soft contact lenses, developed by Otto Wichterle in the 1960s, use hydrogels for water retention but are hydrophobic and uncomfortable [39]. Commercialized siloxane hydrogel contact lenses like Focus Night & Day and PureVision use surface treatments like Fluorocarbon radio-frequency glow-discharge (RFGD) and graft polymerization. These lenses improve oxygen permeability and comfort, unlike polymeric lenses lacking oxygen permeability [40]. Orthopedic biomaterials like PMMA are used in bone tissue engineering, but radicals can cause wear and inflammatory reactions. Antioxidants, crosslinking of ultra-high molecular weight polyethylene (UHMWPE), and PMMA fixative improve wear resistance, but have drawbacks [41]. Reinforcing PMMA with bioactive glass and hydroxyapatite HA, poly(ethylmethacrylate)/n-butylmethacrylate PEMA and n-BMA bone cements with bioactive HA particles improve creep resistance, but still fail at lower cycles [42]. Polymers like polyethylene terephthalate (PET), expanded PTFE (ePTFE), and polyethylene glycol (PUs) are commonly used in cardiovascular applications [43,44,45]. Bioresorbable PUs are being used as elastomeric tissue engineering scaffolds, while PET, a semicrystalline polymer, is used in medical applications for prosthetic vascular grafts and wound dressings. Despite its stability and stiffness, PET grafts face thrombogenicity, necessitating strategies to make them thrombo-resistant [46]. Surgical wounds are closed using adhesives, sutures, tapes, laser tissue welding and staples. The materials used for these wounds are listed in Table 2. Sutures are sterile filaments, natural or synthetic, absorbable or nonabsorbable, with minimal adverse biological response [47].

Nonabsorbable polymers like polypropylene, polyamides, polyesters, and polyether-esters are used in sutures. Polypropylene monofilament sutures are resistant to hydrolytic degradation, while polyamide sutures have a yearly decrease in tensile strength. Fluoropolymers like polytetrafluoroethylene PTFE, Polyvinylidene fluoride- co-hexafluoropropylene PVDF/HFP are used for delicate tissues [48]. PVDF/HFP sutures are used for wound closure in surgeries, while Polybutylene terephthalate PBT and PET are polyester-based nonabsorbable sutures. PET sutures are stable and have long-lasting strength retention, while PBT sutures are less brittle and stiff. Synthetic absorbable sutures are biodegradable, eliminating clinical visits for removal [49]. Sutures, based on degradable polymeric units like polylactic acid, poly-p-dioxanone or polyglycolic acid, are being researched for their potential in wound closure, antimicrobial control, and therapeutics [50]. Extracorporeal artificial organs support failing organ systems like kidney replacement, hemodialysis, and plasma separation, using membrane materials like cellulosic. However, regenerated cellulose has poor hemocompatibility, causing inflammation and immune response. Repairing nerves is complex [51]. Polymers like silicone and expanded polytetrafluoroethylene ePTFE are used for engineering, while electrical charge affects neurite extension and improves nerve regeneration in vivo [52]. The research on nerve regeneration involves the use of natural polymers like, methylcellulose, chitosan, hyaluronic acid, fibrin gels, alginate, collagen, self-assembling peptide scaffolds and keratin. These materials can enhance neurite extension, mimic wound-healing matrix, and align axons. Recent research focuses on bioactive material design with neurotransmitters [53]. Polymers, such as dopamine polymerized with diglycidyl ester and polysialic acid, significantly impact biomedical research and medical practice [54].

3 AVP extraction and processing for its gelation properties

AvP gel's viscosity and elasticity are due to its high-molecular-weight polymer, acemannan [55]. Extracting and processing as shown in Table 3, involves harvesting mature leaves, splitting them open, and using filtration, centrifugation, and spray drying methods to process the extracted gel [56]. A simple home method involves harvesting mature leaves, washing, and revealing gel, scooping, blending, and straining the gel, avoiding green rind bitterness, for use or storage [57]. McConaughy et al. [58] purified galacturonate polysaccharides from the AvP plant and revealed that AvP polysaccharide is a high molecular weight species with a unique composition, including high galacturonic acid content and low methyl ester substitution. As a result, it is appropriate for gel formation in formulations for in situ protein administration. At high salt concentrations, the critical concentration for the shift from dilute to concentrated solution is linked to increasing intermolecular interactions. The capacity of AvP to generate robust gels at low polymer and calcium ion concentrations shows its potential for in situ drug administration. In another study, McConaughy et al. [59] studied the properties of AvP galacturonate hydrogels, focusing on molecular weight, ionic strength, and molar ratio of Ca2+ to COO − functionality. They extracted pectin from AvP low-methoxyl pectin (LM pectin) and conducted dynamic oscillatory rheology, pulsed field gradient and Nuclear magnetic resonance spectroscopy NMR studies to assess in situ gelation for controlled therapeutic delivery. The study found that elastic AvP polysaccharide hydrogel networks can provide elastic modulus values between 20 and 20000 Pa. Khan et al. [60] developed a gel containing carbopol 934 for surgically induced skin wound healing in Wistar rats. The gel was created using AvP leaves and a gelling agent. The gel showed promising results, with 80.14% wound healing up to 14 days, compared to 52.68% in the control group. The gel also showed no inflammation or pus formation.

Gentilini et al. [61] aimed to optimize the extraction, purification, and gel preparation of AvP pectin, a natural source with a high molecular weight and low esterification. Different extraction processes were tested, including the separation of alcohol-insoluble residues (AIRs), microwave pretreatment, and microwave deactivation with sodium citrate as a chelating agent. The resulting pectin had a molecular weight of 118 kDa and a 2.93% esterification degree. The ionotropic gelation produced improved cell adhesion compared to commercial pectin. The results suggest that extracted A. vera pectins have interesting properties for regenerative medicine applications, including mechanically stable gels and high-rhamnose content matrices. Jales et al. [62] developed AvP mucilaginous-based hydrogels for topical use in psoriasis treatment. The hydrogels were prepared using 80% w/w of AvP mucilaginous gel and evaluated for organoleptic, rheological, pH, and glucomannan content. The hydrogel-based hydroxyethylcellulose had glucomannan contents of 6.76 and 4.01 mg/g, respectively, making it ideal for psoriasis treatment. The hydrogel showed no significant difference in keratolytic activity compared to the classic treatment (clobetasol propionate), making it effective in controlling hyperkeratinization. Salama et al. [63] used nanotechnology to create controlled drug delivery devices using AvP extract as a carrier. They created non-toxic, tissue-compatible nanocomposites using chitosan nanoparticles (CSNPs). The composites were applied to cotton and viscose fabrics, preventing bacterial growth. The cytotoxicity of the composite was assessed using a cell viability assay. The results showed that the AvP leaf extract contained bioactive substances that were loaded onto the CSNPs polyload, increasing bioactivity without toxicity. Padmaja et al. [64] used AvP gel as an edible coating to prolong the storage life of tropical and subtropical fruits, particularly Indian jujube. The gel effectively inhibited undesirable changes during storage, extending the shelf life to 45 days under refrigerated conditions. The treatment reduced microbial counts and improved sensory scores for the fruits, resulting in less shrinkage, less fungal infestation, uniform color development, and a visually good appearance. The literature reviewed showed that most studied on AvP gel has been biomedical applications with limited studies based on refrigeration or supercooling applications.

4 Supercooling prospects of AVP: Acemannan

Acemannan, a linear, high-molecular-weight polysaccharide found in AvP gel, has been shown to have various properties, including wound-healing, anti-inflammatory and immunomodulatory effects. It may also have supercooling properties, which involve cooling a liquid below its freezing point without solidifying. This process can be achieved by adding impurities or quickly cooling the liquid [65]. Acemannan also has potential applications in cryopreservation, food processing, and energy storage, as it can supercool water and milk to temperatures as low as − 5 °C. Acemannan, has β-1,4 linkages and a variable degree of acylation. The variability of acemannan depends on the cultivation conditions and species, with a higher β-polysaccharide content in AvP than in arborescens [18]. Acemannan and acetylation content in AvP plants vary based on planting conditions, growth age, and harvest season. Acemannan levels are higher in three-year-old plants and with increasing light intensities. Heating, drying, pasteurization, and dehydration are all steps in the processing process [66]. Table 4 shows the comparison behaviour of AvP and other Materials for supercooling applications.

Pasteurization enhances acemannan yield in 65–85 °C conditions. Extracting acemannan with hot water and ethanol has disadvantages like long extraction times, high temperatures, and polysaccharide degradation. Acemannan, with molecular weights 1000–1600 kDa, extracted through ethanol precipitation often contains water, necessitating further drying and dehydration methods like freeze-drying, spray-drying, refractance window drying, and radiant zone drying [68]. Partial digestion with cellulose improves extraction conditions. [67]. Acemannan is separated and purified using techniques such as anion exchange chromatography, gel permeation chromatography, gradient ethanol precipitation, and gradient ammonium sulfate precipitation [69]. More efficient and environmentally friendly methods like graded precipitation and membrane ultrafiltration are popular while colorimetry, spectroscopy, and chromatography are commonly used [70]. Polysaccharides content of acemannan can be determined using various methods including colorimetric, spectral, and chromatographic techniques. Recent research suggests carbohydrate microarray profiling for extracting cell wall polysaccharides from acemannan [71].

4.1 Polysaccharides as hydrogel

Polysaccharide is a biocompatible and biodegradable natural material with unique properties like hydrophilicity, mechanical stability, and tunable functionality. It can be used to create hydrogels, which can be a porous network structure or nanofibrillar structures [72]. Hydrogels are porous 3D networks constructed of biopolymers or polyelectrolytes that expand when exposed to water or biological fluid. They may be natural or manufactured, and they can be created by physical or chemical means. Natural hydrogels interact with aqueous solvents, causing crosslinkers to expand and attach them through retractive force. Chemical or physical crosslinkers connect these "solid-like fluid" polymers through molecular chains [73]. Glycans, or hydrogenopolysaccharides, are polysaccharide networks with high water retention capacity, renewability, biodegradability, and nontoxicity. They are employed in advanced engineering hydrogels for medication delivery, wound healing, implant/tissue engineering, and other applications [74]. Hydrogels can prevent drug degradation, reduce side effects, and speed up wound healing. Proper humidity, pH, microbial protection and oxygen pressure speed up the healing process. The interface between hydrogels and wound beds provides a biocompatible platform, adequate moisture, and bacteria isolation, making tissue engineering an effective treatment method [75]. These materials have nontoxic, biocompatible, and appropriate mechanical properties. Recent research on cellulose-, chitosan-, alginate-, and starch-based hydrogels, with applications in medical and healthcare, discusses their fabrication and engineering, including tissue engineering and wound healing [76]. When polysaccharides with various hydrophilic groups are inflated with water, they may create hydrogels. Water-soluble cellulose-based hydrogels may be made directly from solutions using hydrogen bonding and hydroxyl groups [77]. Fagiolari et al. [78] fabricated carboxymethyl cellulose for sustainable solar cell applications. Bacterial cellulose synthesized from fermentation displayed a porous nature and higher tensile strength, hydrophilicity, and biocompatibility. Li et al. [79] prepared ultralight, flexible, fire-retardant carbon aerogels using bacterial cellulose pellicle precursor, chitosan-based hydrogels for engineering applications, and solubilization in diluted acidic solution. Tu et al. [80] studied the gelling process of chitosan, which is formed through thermal-induced gelation and rinse stages. The process involved forming a crystal structure and enhancing hydrogen bonds, but requires prefabrication. The report revealed hydrogelation, a process where natural chitosan and transition metal ions crosslink, with superior water content and stimuli-responsive abilities. Hydrogels are used in energy storage, batteries, and supercapacitors for ionic conductivity, electrochemical activity, and flexibility. They can coordinate with cations for higher conductivity [81]. Carboxylated chitosan hydrogel films exhibit high flexibility, electrolyte absorption capacity, and ionic conductivity. They can be used as templates for inorganic frameworks. However, challenges like hazardous solvents and mechanical strength remain. Future research should focus on green chemistry synthesis [82, 83].

4.2 Hydrogel for supercooling applications

Hydrogels are ideal for supercooling due to their high-water content, biocompatibility, biodegradability, and tunable properties, making them suitable for biomedical fields like refrigeration, cryopreservation and drug delivery [84]. Hydrogel properties like nucleation ability, viscosity, and thermal conductivity enable supercooled liquids to be used in various applications. High viscosity lowers ice crystal formation, while thermal conductivity removes heat, preventing ice crystal formation [85]. Supercooled materials are used in thermal systems like air conditioning, absorption refrigeration, and solar heating due to low installation costs and energy savings. They are commonly encapsulated in polyethylene pellets or immersed in wallboard, with nanotechnology advancements enabling new applications [86]. Supercooled materials are used in architectural integration, heat and cold storage units, and solar energy generation systems due to their cost-effectiveness, toxicity, and corrosiveness. They are ideal for seasonal applications and heat storage devices [87]. Blocks can store thermal energy at high temperatures without losing energy, using grid, renewable sources, or direct heating. New solar thermal storage materials, including fatty acid esters and eutectic mixtures, improve performance efficiency in seasonal heat storage systems [88]. Supercooled AvP-based materials offer high energy density, corrosion-free properties, and minimal maintenance for solar thermal systems. They can be integrated into solar combined systems (Heat and power systems, integrated solar systems, solar hybrid systems and multifunctional solar systems) for space heating and cooling, and used in solar water heaters. This technology is promising for domestic hotwater supply and requires less storage volume than traditional systems [89]. AvP's polysaccharides, like acemannan, can hinder ice crystal development, affecting the supercooling temperature of various liquids. However, too much AvP can increase liquid viscosity, making it harder for ice crystals to form. Therefore, the appropriate concentration for supercooling applications varies, with 0.5–1% suitable for water and 1–2% for other liquids [90]. Acemannan, a water-soluble polymer, may be used to construct a polysaccharide-based network skeleton in gel material, which improves mechanical strength and water absorption. Physical or chemical cross-linking techniques are used to create acemannan hydrogel, with physical approaches having poor mechanical characteristics and degradability [91]. It provides greater mechanical strength and stability, although it may result in initiator, cross-linking agent, and unreacted monomer residues. Diverse acemannan preparation procedures result in diverse physical qualities, such as mesoporous or open porous structures [92].

5 Aloe vera applications

Supercooled liquids are not efficient in short-term applications, but they can maintain thermal equilibrium between the supercooled liquid and the surrounding environment [93]. Supercooling is a common phenomenon in the natural world, with water being a vital substance essential for the survival of all living organisms. Researchers have been able to manipulate the crystallization process within their systems, using the advantages of different seasons. Supercooled water has applications in various technological domains, such as thermal energy storage in solar systems and commercial heat pads. Cold climates have been extensively studied, and extensive scholarly literature has thoroughly examined the intricacies of studies pertaining to supercooling in water. Overall, supercooling is a promising approach for long-term applications in various fields. Impurities and external shocks may cause metastable supercooled liquids to create a new phase toward stability. Reliable nucleation is required for the release of latent heat, and the material should have a high activation energy to avoid spontaneous crystallization. Metastable liquids, despite their theoretical understanding, remain a challenge in technical applications due to their uncalculated thermophysical properties [94]. Supercooling is a process where liquids and solids undergo thermal behavior due to poor nucleation and crystal growth. It happens at the melting point and becomes stable at the freezing point. Asides from supercooling, other applications of AvP are listed in Table 5.

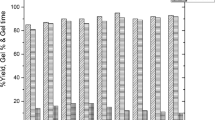

The temperature difference between the melting and freezing points determines the degree of supercooling. To increase effective heat capacity, the interval between melting and freezing temperature ranges is reduced [95,96,97]. Supercooling is complex due to factors like latent heat and density. PCMs undergo supercooling, with inorganic compounds having higher thermal storage density. Paraffin waxes, fatty acids, hydrated salts, and eutectic are examples of common PCMs. However, paraffin waxes have poor heat conductivity and are expensive. Several techniques to increasing thermal conductivity have been investigated [98]. Commercial paraffin waxes offer moderate thermal storage densities but low thermal conductivity. Blend freezing can overcome these constraints. Fatty acids are popular for thermal energy storage due to their high heat storage density and thermal conductivity. However, they face issues like phase segregation, supercooling, corrosiveness, low density, and instability. Supercooling is crucial in salt hydrate applications, and techniques like crystal-forming agents, thickening agents, and heterogeneous nucleation can improve nucleation rate [99,100,101]. A study on eutectic mixtures of fatty acids for low-temperature solar heating found their thermal stability and reliability for four-year energy storage periods. The study suggests further research in this area, as current literature primarily focuses on fatty acids [102]. Hence, applications of AvP- based hydrogels is listed in Table 6.

5.1 Tissue engineering Scaffolds

Tissue engineering uses polymeric biomaterials to overcome donor-receiver compatibility by culturing cells and stem cells on porous polymeric scaffolds. While literature shows promising porous scaffold fabrication, there's a lack of information on cell adhesion, proliferation, and tissue formation [103]. Researchers face challenges in determining surface properties for cell proliferation and differentiation. Growth factors aid in neo-tissue formation hence, tissue engineering requires bioresorbability, but vascularization is limited. Degradable devices can be integrated [104]. Some studies explored the use of degradable polymers for therapeutic devices, but the exact mechanism of degradation is unclear. Artificial biopolymers, composed of pro-metabolites, constitutive repeating units, and pro-excretable chain fragments, are being developed as a potential solution [105]. Artificial biopolymers, such as poly (glycolic acid), are commonly used in clinical applications. However, the number of new systems is limited. Secondary factors like degradation rates within complex macromolecules can affect selectivity, composition, and morphology. The future research focuses on improving biostability and performance and matching the rate of degradation of temporary therapeutic devices with reconstruction machines is crucial [106, 107].

Acemannan, has been found to inhibit colon cancer by increasing cytotoxicity in macrophages. It reduces colonic adenomas and adenocarcinomas in mice by inhibiting NF-κB and cyclin-dependent kinases. Acemannan also shows antiproliferative effects on normal and tumor cells, suggesting potential for immunotherapy. It also has antioxidant and gastrointestinal effects, protects against radiation-induced oxidative stress, and improves cognitive performance [108]. Acemannan, as a natural biomolecule, has been shown to enhance bone formation, promote mineralization of dental pulp cells, and stimulate IL-6 and IL-8 expression. Its biocompatibility with the pulp has been confirmed through computer simulations. Acemannan has been found to increase dental bone density and improve histopathological response in children with reversible pulpitis. These findings suggest that natural polysaccharides could be used as a direct pulping material for human deep deciduous teeth [109].

5.2 Sutures

Medical sutures are crucial surgical threads used to prevent bleeding, hold tissues together, and squeeze blood vessels. However, increasing surgical site infections have led to higher costs, longer hospitalizations, and high mortality. Nanofibers can play a significant role in developing new sutures with excellent performance, anti-inflammatory properties and effective antibacterial, using electrospinning for its high specific surface area and porosity [110]. Studies have examined the physical properties of surgical sutures, focusing on secondary cracking, knotting difficulties, and reduced support strength during postoperative healing [111]. Tobias et al. [112] found that synthetic absorbable suture material, coated with antibacterial and anti-inflammatory drugs like curcumin, gentamicin, and nano-silver, can significantly improve tensile strength and maximum elongation. These sutures show better cell migration and collagen fiber deposition, making them suitable for postoperative wound infection treatment [113]. Electrospinning, a process involving a generator, pumps, spinneret, and collector, is used in various fields like drug-sustained release, sewage treatment, food packaging, wound dressings and sensors. It involves single-fluid, double-fluid, and multi-fluid electrospinning [114]. Double-fluid electrospinning, multi-fluid electrospinning and coaxial electrospinning, in-situ electrospinning are methods used in controlled drug release and medical sutures. Dual-fluid electrospinning uses a double-layer composite structure, while multi-fluid electrospinning improves performance and complex structures. In-situ electrospinning uses medical materials for wound treatment, achieving wound hemostasis through nanofiber depositing on living organs [115].

Absorbable sutures are crucial in medical surgery due to their degradability and ability to absorb easily. Commonly used absorbable suture materials include cellulose, sheep catgut, polycaprolactone (PCL), polylactic acid (PLA), poly-p-dioxanone (PDO), poly (lactic-co-glycolic acid) (PLGA), polyurethane (PU) and polyglycolic acid (PGA) [116]. Catgut, a naturally degradable suture, is used in hemostatic applications due to its ability to degrade naturally. Oxidative regenerated cellulose (ORC) is another hemostatic material, but its clinical application is not fully realized. Researchers have synthesized biodegradable polymers like P3BV-co-HB, P4HB, PCL, and PDO for improved biocompatibility and flexibility. PLA sutures, used in modern surgery, have been combined with carbon nanotubes to control the degradation cycle and increase their strength effective time [117]. Researchers are developing new-feature absorbable smart sutures using PLGA, a synthetically biodegradable polymer. These sutures combine biodegradable materials with electro-optical capabilities, reducing inflammation and bacterial infection, measuring tissue tension, and monitoring function in real time. Combining these materials with natural degradable substances can reduce polymer toxicity and improve the safety of suture lines [118]. Non-absorbable sutures are non-degradable materials that provide long-term tissue support without requiring surgical removal. Synthetic materials like silk thread, nylon, and polyester offer better mechanical properties than natural materials. Silk, a natural suture, has lower tensile strength and can cause infection. Nylon, a synthetic material, is used for non-inflammatory wound closure [119].

PET is a non-absorbable, smooth, and easy-to-use monofilament suture made of polyethylene terephthalate. Its surface is smooth and resistant to tissue reactivity. Nanofibers can be enhanced with functional bioactive substances like silver nanoparticles, triclosan, and nitric oxide to reduce infection and prevent SSI. These nano-silver particles also inhibit fatty acid synthesis and prevent bacteria colonization [120]. Researchers have developed a surgical suture using nitric oxide (NO) and graphene oxide as fillers. PVA/MEG nano-composite fibers show antibacterial properties and low cytotoxicity. Growth factors like VEGF promote intravascular cell migration, making them promising for medical suture applications. They also developed a multifunctionally aligned electrospinning fiber suture and a new type with a "core-sheath" structure [121]. Researchers have developed electrospinning nanofibers using PLGA, polyethylene oxide, and PgP to release cationic growth factors, including heparin, curcumin, Aceclofenac, and chitosan. These nanofibers can enhance suture properties, reduce infections, and provide therapeutic effects for wound healing [122]. Acemannan, an essential immunoenhancer, has been confirmed in both in vitro and in vivo studies to enhance the lymphocyte response to alloantigen. It may be related to the release of IL-1 from ordered nuclear cells under alloantigen protection. Acemannan from AvP activates and regulates immunity, reducing radiation-induced mortality in mice and increasing survival rates. It upregulates cytokines like TNF-α and IL-1, improves hematopoiesis and mitogenic activities, and enhances NO production and IL-1/IL-6 production in macrophages. Acemannan promotes nonspecific immunity, cellular immunity, and humoral immunity in dendritic cells [123]. Polysaccharides are increasingly used as wound dressing materials due to their natural origin, non-immunogenic properties, abundance, affordability, and absorbent properties. These hydrogels promote non-specific immune system activation and have excellent hemostatic and healing effects. Future studies aim to improve hydrogel characteristics for intelligent, customizable hydrogels with biomodulatory effects [124]. Electrical components are being considered for accurate monitoring of wound healing in hydrogels. Polysaccharide-based hydrogel wound dressings are being developed for precision and personalized medicine. Combining therapeutically beneficial substances enhances wound healing efficacy. However, chemical components sometimes restrict cross-linked hydrogels' application and more research is needed to improve stability and address these issues [125]. Future research should focus on clinical data, biosafety assessments, and novel polysaccharides for smart hydrogels. Successful hydrogels with cell attachment in wound healing require more advancements. Batch-to-batch variability affects performance, and environment-friendly synthesis of water-soluble derivatives is crucial. Further research should explore nanoparticles, nanocarriers, cross-linking techniques, multifunctional hydrogels, and derivatization approaches [126].

5.3 Contact lenses

The human eye affects 1.3 billion people worldwide, with most over 50. Eye dysfunctions include refractive errors, cataracts, glaucoma, and diabetic retinopathy. Eye surgery technologies like LASIK have gained popularity, but post-LASIK complications are common. Contact lenses are used by 140 million people worldwide, with the global market predicted to reach over 19 billion by 2024 [127]. AvP-based contact lenses are currently not commercially available because of issues with oxygen permeability, mechanical qualities, biocompatibility, and regulatory barriers. Extended contact with the eye necessitates stringent testing for biocompatibility, whereas mechanical properties demand particular qualities like elasticity and strength. Long-term wear requirements might not be met by oxygen permeability, and thorough safety and efficacy testing would be necessary for regulatory approval procedures. Materials used for contact lenses is listed in Table 7. Nonetheless, Hydrogel and silicone hydrogel lenses were introduced in the 1960s and 1998 respectively. The first eye-like structure was found during the Cambrian explosion 521 million years ago, and visual systems became a survival strategy. Rigid lenses were replaced by polymethyl methacrylate (PMMA) due to corneal respiration limitations and increased risk of ocular complications. Flexible thermoplastics and silicone rubber were proposed but not suitable due to low hydrophilicity. The demand for CLs ranges from corrective vision and therapeutics to cosmetic appearance, with end users requiring factors like wear time, comfort, durability, and stability. Manufacturers also have demands such as material costs, ease of production, and reliability [128]. Materials scientists have developed materials like glass scleral lenses, PMMA, and hydrogel lenses. Hard and soft lenses are available in various types. Hydrogels, based on HEMA, offer greater biocompatibility and oxygen permeability, improving the comfort, oxygen permeability, and wear time of contact lenses. However, the oxygen permeability of HEMA hydrogels was not sufficient for extended CL wear. Silicone-based rigid lenses and hydrogels were developed to improve gas-permeability and comfort. Newer CL materials, such as polyvinyl alcohol (PVA) and polyethylene glycol (PEG), emerged in the 1990s to improve hydrophilicity [129]. Contact lenses (CLs) are increasingly used for cosmetic and corrective vision, as well as for proactive ophthalmic treatments. PVA hydrogels, a hydrophilic and biocompatible material, are being explored for their potential in treating eye conditions like myopia and glaucoma [130, 131].

HA has been used in ophthalmic treatments, lubricating solutions, and contact lens modifications. It has shown stability even after 12 h of wear and is a reusable wetting agent. Commercial success is seen with Bausch&Lomb BiotrueTM solution and Open30 lenses. HA can improve contact lens properties and can be entrapped or chemically bound to the hydrogel. However, its high cost limits its wider application [132]. Polysaccharide addition affects properties like wettability, surface topography, and protein deposition. It can occur before or after polymerization, with pre-polymerization evaluating solubility. Releasable polysaccharides offer benefits like tear film stability and reduced bacterial adhesion. They can be fast-release or slow-release, providing lasting comfort [133]. Polysaccharides, while not the primary material in contact lenses, offer benefits such as improved wearer comfort, protein resistance, and antibacterial properties. They are renewable and environmentally friendly, but their development faces challenges like compatibility with existing lenses and the impact on lens comfort. Accurate quantification of polysaccharide addition is crucial for lens performance improvements, and more specialized methods should be developed for precise control [134]. Polysaccharide derivatives with improved compatibility with lenses could increase their use in contact lens applications. Interpenetrating polymer networks (IPNs) can combine the benefits of both networks. However, polysaccharides may cause adverse changes to lens properties, such as decreased transmittance and modulus. Modifications to lens monomers can mitigate these effects. Further research is needed to strengthen subjective wearer comfort evaluations and ensure lens safety [135]. Nanopatterned HA films can be transferred to contact lenses via water bridges, a potential alternative to hazardous chemicals. Investigating the mechanisms of polysaccharide-added lenses is crucial for optimizing performance. Future research should use computer simulations, visual characterization, and quantification methods. Environmentally triggered release systems can address leakage issues. Polysaccharide-added lenses offer ocular discomfort-relieving options [136]. Polysaccharides can improve lens wear parameters in contact lenses, but the process is complex and depends on factors like incorporation method, lens materials, and polysaccharide type. Personalized lens customization requires rational selection of factors based on wearing requirements. New production procedures, quantitative approaches, mechanistic investigations, and polysaccharide combinations should be investigated in future study [137]. Polysaccharide-added lenses provide renewable and biodegradable alternatives to contact lens removal owing to ocular discomfort. However, wear performance measurement, manufacture, user acceptability, and lens recovery and degradation all impede clinical application [138].

5.4 Drug delivery systems

AvP hydrogels can stay liquid below freezing temperature; hence, they have potential for use in supercooling applications. However, they aren't yet utilised in materials that are sold commercially. Performance is affected by additives, composition, and concentration. Restricted supercooling depth, long-term stability, cost-effectiveness, and scalability are among the challenges. Scientists are investigating optimisation techniques to enhance the performance of these hydrogels. Since AvP-based materials are still being developed for supercooling applications, their special qualities may have an impact on drug delivery. These hydrogels can provide biocompatibility and biodegradability, targeted delivery to specific sites, enhanced stability for drugs susceptible to degradation at higher temperatures, and controlled release for drugs that are temperature-sensitive. AvP is a good choice for drug delivery applications because of its biocompatibility and biodegradability, which minimise adverse effects.

Controlled drug delivery in biomaterials is gaining momentum due to the rise of proteins as potential pharmaceuticals and the ability to sustainably release active proteins from polymer matrices. This has led to the development of protein and peptide therapeutics [139]. Polymeric delivery systems are being developed for localized delivery of molecules like VEGF, which stimulate blood vessel growth. However, delivering these fragile molecules at the right dose remains a challenge. Controlled protein delivery and transiently expressed VEGF gene delivery may yield clinical importance in gene therapy, with most applications involving permanent gene expression modification [140]. Clinical gene therapy trials have been less successful than anticipated, leading to the development of synthetic polymer conjugates. Controlled delivery devices, like implantable contraceptives like Norplant™, are being developed to overcome biological barriers to gene delivery. Langer's work shows implantable devices can control macromolecule release [141]. Langer's approach to drug release in implantable and injectible devices involves solubilizing particles at the surface, allowing deeper drugs to diffuse out. However, adapting this method to clinical products requires controlling release profiles, ensuring drug stability, and producing suitable delivery configurations. Low drug loadings and surface-eroding polymers can be used for controlled release [142]. The choice of polymer is influenced by drug-polymer interactions, especially for protein-based drugs. Surgical implantation is suitable for certain applications, but surgery alone is not ideal. Microspheres are a successful method for converting drug particles into injectable formats. This can be achieved through dissolved drug powder in polymer solution, emulsion, or solvent evaporation [143]. Microsphere delivery has been adapted for lung delivery using theoretical models and experimental verification. Hydrogels, formed in situ through photopolymerization, are being used as smart delivery systems for protein and macromolecule drugs. The efficacy of localized delivery may be affected by drug diffusion distance. The delivery of nucleic acids to single tissues or cell types for long-term sustained expression is the next frontier. Viruses are the most effective vectors for gene transfer, and synthetic polymer conjugates are gaining popularity [144, 145]. Gene delivery vectors, such as polymers, are used in tissue engineering to replace diseased or damaged tissue with genetically engineered cells, overcoming limitations of artificial prosthetic devices [146]. Tissue engineering involves breaking down donor material into individual cells and forming tissue structures using a physical scaffold. This procedure may take place either in vitro or in vivo. In material design and processing, materials science encounters both obstacles and possibilities. Scaffolds must control cell placement and communicate molecular signals. New materials are needed for receptor-mediated interactions [147]. Model polymeric and oligomeric systems are being used to study tissue engineering issues, requiring new polymer processing approaches for complex scaffolds and macroscopic shapes. These techniques must be cost-effective and comply with FDA regulations. Understanding biological processes is essential for creating materials and scaffolds, and novel materials and devices aid in illuminating the complexities of biological reactions [148]. Wound healing involves various factors, including cell types, migration, proliferation, differentiation, clearance, and extracellular matrices. Acemannan, a polysaccharide, has been shown to speed up healing, minimize pain, and promote keratinocyte growth factor-1 and type I collagen synthesis. However, its molecular mechanisms remain unclear [149]. Drug delivery systems (DDSs) face significant limitations in their development due to factors like structural stability, drug properties, and release profiles. The methodology must be optimized for optimal properties, considering factors like target delivery site, hydrogel size, and bioavailability. Predicting drug release is challenging, especially for stimulus-responsive hydrogels, and computational models may not accurately represent findings for medicinal applications [150]. Chelu et al. [151] investigated the use of hydrogels derived from AvP for the treatment of wounds, emphasizing the special qualities and biocompatibility of these materials. The synthesis processes, structural traits, and mechanisms of the therapeutic agents released are covered, along with their beneficial effects on tissue regeneration, wound healing, inflammation reduction, and antimicrobial activity. Their review also covers the difficulties and potential uses of these hydrogels as wound dressings in the future [152].

6 Current trends and future perspectives

The potential of polysaccharide-based hydrogels in tissue engineering, drug delivery, and supercooling is being enhanced for increased functionality, stability, and liquid retention, with possible uses in cryopreservation and temperature-sensitive medication storage. This involves implementing controlled release mechanisms and self-healing properties. In order to improve cell growth and differentiation, researchers are creating biomimetic hydrogels, which imitate the extracellular matrix found in nature. Furthermore, in order to produce functional tissues with sufficient blood vessel networks and applications for personalised medicine, they are investigating vascularization strategies and 3D printing techniques. In recent studies, researchers have used polysaccharide hydrogels to develop drug delivery systems, and targeted delivery systems can also improve the effectiveness of drugs. Because these hydrogels are stimulus-responsive, controlled drug release is possible. In order to treat complicated diseases, they can also be utilised in combination therapies.

Future research on AvP’s supercooling properties should focus on understanding its concentration, purity, and other factors. Improved methods for extracting and processing AvP gel are needed to preserve its properties. Stabilizing AvP gel in supercooled liquids is also crucial. The effect of AvP concentration and purity on the supercooling temperature of different liquids must be examined. Research on the effect of other substances in the liquid on the supercooling temperature and the best methods for extracting and processing AvP gel to preserve its supercooling properties needs to be investigated. Further research on the safety margin for AvPin supercooling applications and the best methods for stabilizing AvP gel in supercooled liquids is needed.

7 Conclusion

Polysaccharides, which are long chains of sugar molecules, are found in AvP, a polymeric biomaterial. These polysaccharides have distinct characteristics that make them valuable for a variety of biological applications. There is, however, a rising interest in employing AvP for sophisticated supercooling applications, such as hydrogel for refrigeration. Acemannan, found in AvP, has properties such as nucleation ability, viscosity, and thermal conductivity that enable liquids to be supercooled to lower temperatures, prevent ice crystal growth, and remove heat from the liquid, ensuring longer supercooling periods. AvP hydrogels have the ability to supercool, which would enable them to stay liquid below freezing temperatures. This has potential uses in biomedical applications, medication delivery, and food preservation. These hydrogels could be used to develop sophisticated biosensors for disease diagnostics or preserve tissues or organs for transplantation because they increase drug efficacy, prolong shelf life, and decrease waste. Hence, AvP may be a promising polymeric biomaterial with a wide range of supercooling applications. Supercooling research using AvP hydrogels is encouraging, but more work is needed to optimise depth, release substances safely, and assess the efficacy and biocompatibility for particular applications—all while acknowledging that the field is still in its infancy.

Data availability

Not applicable.

References

Sánchez M, González-Burgos E, Iglesias I, Gómez-Serranillos MP. Pharmacological update properties of Aloe vera and its major active constituents. Molecules. 2020;25(6):1324.

Hęś M, Dziedzic K, Górecka D, Jędrusek-Golińska A, Gujska E. Aloe vera (L.) Webb.: natural sources of antioxidants–a review. Plant Foods Hum Nutr. 2019;74:255–65.

Maan AA, Ahmed ZFR, Khan MKI, Riaz A, Nazir A. Aloe vera gel, an excellent base material for edible films and coatings. Trends Food Sci Technol. 2021;116:329–41.

Kumar R, Singh AK, Gupta A, Bishayee A, Pandey AK. Therapeutic potential of Aloe vera—a miracle gift of nature. Phytomedicine. 2019;60: 152996.

Nalimu F, Oloro J, Kahwa I, Ogwang PE. Review on the phytochemistry and toxicological profiles of Aloe vera and Aloe ferox Future. J Pharm Sci. 2021;7(1):21.

Danish P, Ali Q, Hafeez MM, Malik A. Antifungal and antibacterial activity of aloe vera plant extract. Biol Clin Sci Res J. 2020;2020(1):1.

Liang J, Cui L, Li J, Guan S, Zhang K, Li J. Aloe vera: a medicinal plant used in skin wound healing. Tissue Eng Part B Rev. 2021;27(5):455–74.

López Z, Salazar Zúñiga MN, Femenia A, Acevedo-Hernández GJ, Godínez Flores JA, Cano ME, Knauth P. Dry but not humid thermal processing of aloe vera gel promotes cytotoxicity on human intestinal cells HT-29. Foods. 2022;11(5):745.

Garau MC, Simal S, Rossello C, Femenia A. Effect of air-drying temperature on physico-chemical properties of dietary fibre and antioxidant capacity of orange (Citrus aurantium v. Canoneta) by-products. Food Chem. 2007;104(3):1014–24.

Sonawane SK, Gokhale JS, Mulla MZ, Kandu VR, Patil S. A comprehensive overview of functional and rheological properties of aloe vera and its application in foods. J Food Sci Technol. 2021;58:1217–26.

Femenia A, Garcı́a-Pascual P, Simal S, Rosselló C. Effects of heat treatment and dehydration on bioactive polysaccharide acemannan and cell wall polymers from Aloe barbadensis Miller. Carbohydr Polym. 2003;51(4):397–405.

Ebrahim AA, Elnesr SS, Abdel-Mageed MAA, Aly MMM. Nutritional significance of aloe vera (Aloe barbadensis Miller) and its beneficial impact on poultry. Worlds Poult Sci J. 2020;76(4):803–14.

Kumar S, Kalita S, Das A, Kumar P, Singh S, Katiyar V, Mukherjee A. Aloe vera: a contemporary overview on scope and prospects in food preservation and packaging. Prog Org Coat. 2022;166: 106799.

Esmaeili Y, Zamindar N, Paidari S, Ibrahim SA, Mohammadi Nafchi A. The synergistic effects of aloe vera gel and modified atmosphere packaging on the quality of strawberry fruit. J Food Process Preserv. 2021;45(12): e16003.

Baldi A, Sommella E, Campiglia P, Daglia M. Aloe gel-base food products: chemical, toxicological, and regulatory aspects. Regul Toxicol Pharmacol. 2021;119: 104818.

Canche-Escamilla G, Colli-Acevedo P, Borges-Argaez R, Quintana-Owen P, May-Crespo JF, Cáceres-Farfan M, Puc JAY, Sansores-Peraza P, Vera-Ku BM. Extraction of phenolic components from an Aloe vera (Aloe barbadensis Miller) crop and their potential as antimicrobials and textile dyes. Sustain Chem Pharm. 2019;14: 100168.

Shakib Z, Shahraki N, Razavi BM, Hosseinzadeh H. Aloe vera as an herbal medicine in the treatment of metabolic syndrome: A review. Phytother Res. 2019;33(10):2649–60.

Liu C, Cui Y, Pi F, Cheng Y, Guo Y, Qian H. Extraction, purification, structural characteristics, biological activities and pharmacological applications of acemannan, a polysaccharide from aloe vera: a review. Molecules. 2019;24(8):1554.

Nicolau-Lapeña I, Colàs-Medà P, Alegre I, Aguiló-Aguayo I, Muranyi P, Viñas I. Aloe vera gel: an update on its use as a functional edible coating to preserve fruits and vegetables. Prog Org Coat. 2021;151: 106007.

Mondal MIH, Saha J, Rahman MA. Functional applications of aloe vera on textiles: A review. J Polym Environ. 2021;29:993–1009.

Griffith LG. Polymeric biomaterials. Acta Mater. 2000;48(1):263–77.

He W, Benson R. Polymeric biomaterials. In: He W, editor. Applied plastics engineering handbook. Norwich: William Andrew Publishing; 2017. p. 145–64.

Angelova N, Hunkeler D. Rationalizing the design of polymeric biomaterials. Trends Biotechnol. 1999;17(10):409–21.

Vert M. Polymeric biomaterials: Strategies of the past vs. strategies of the future. Progr Polym Sci. 2007;32(8–9):755–61.

Teo AJ, Mishra A, Park I, Kim YJ, Park WT, Yoon YJ. Polymeric biomaterials for medical implants and devices. ACS Biomater Sci Eng. 2016;2(4):454–72.

Dumitriu S, Popa VI. Polymeric biomaterials, vol. 2. Boca Raton: CRC Press; 2013.

Becker ML, Burdick JA. Introduction: polymeric biomaterials. Chem Rev. 2021;121(18):10789–91.

Kohane DS, Langer R. Polymeric biomaterials in tissue engineering. Pediatr Res. 2008;63(5):487–91.

Kumar A, Sood A, Han SS. Poly (vinyl alcohol)-alginate as potential matrix for various applications: A focused review. Carbohyd Polym. 2022;277: 118881.

Shtilʹman, M.I., 2003. Polymeric biomaterials (Vol. 15). VSP.

Shan D, Gerhard E, Zhang C, Tierney JW, Xie D, Liu Z, Yang J. Polymeric biomaterials for biophotonic applications. Bioactive materials. 2018;3(4):434–45.

Miao S, Wang P, Su Z, Zhang S. Vegetable-oil-based polymers as future polymeric biomaterials. Acta Biomater. 2014;10(4):1692–704.

Tanzi, M.C. and Farè, S. eds., 2017. Characterization of polymeric biomaterials. Woodhead Publishing.

Kohn J, Welsh WJ, Knight D. A new approach to the rationale discovery of polymeric biomaterials. Biomaterials. 2007;28(29):4171–7.

Merrett K, Cornelius RM, McClung WG, Unsworth LD, Sheardown H. Surface analysis methods for characterizing polymeric biomaterials. J Biomater Sci Polym Ed. 2002;13(6):593–621.

Mir M, Ali MN, Barakullah A, Gulzar A, Arshad M, Fatima S, Asad M. Synthetic polymeric biomaterials for wound healing: a review. Prog Biomater. 2018;7:1–21.

Ratner BD, Castner DG, editors. Surface modification of polymeric biomaterials (p. 206). New York: Plenum Press; 1997.

Grinstaff, M.W., 2002. Biodendrimers: new polymeric biomaterials for tissue engineering. Chemistry–A European Journal, 8(13), pp.2838–2846.

Baldwin AD, Kiick KL. Polysaccharide-modified synthetic polymeric biomaterials. Peptide Science: Original Research on Biomolecules. 2010;94(1):128–40.

Rogero SO, Malmonge SM, Lugão AB, Ikeda TI, Miyamaru L, Cruz ÁS. Biocompatibility study of polymeric biomaterials. Artif Organs. 2003;27(5):424–7.

Ngo, B.K.D. and Grunlan, M.A., 2017. Protein resistant polymeric biomaterials.

Kalirajan C, Dukle A, Nathanael AJ, Oh TH, Manivasagam G. A critical review on polymeric biomaterials for biomedical applications. Polymers. 2021;13(17):3015.

Wang YX, Robertson JL, Spillman WB, Claus RO. Effects of the chemical structure and the surface properties of polymeric biomaterials on their biocompatibility. Pharm Res. 2004;21:1362–73.

Vladkova, T.G., 2010. Surface engineered polymeric biomaterials with improved biocontact properties. International Journal of polymer science, 2010.

Mann JL, Anthony CY, Agmon G, Appel EA. Supramolecular polymeric biomaterials Biomaterials science. 2018;6(1):10–37.

Pugliese, R., Beltrami, B., Regondi, S. and Lunetta, C., 2021. Polymeric biomaterials for 3D printing in medicine: An overview. Annals of 3D Printed Medicine, 2, p.100011.

Boni R, Ali A, Shavandi A, Clarkson AN. Current and novel polymeric biomaterials for neural tissue engineering. J Biomed Sci. 2018;25:1–21.

Michanetzis GPA, Katsala N, Missirlis YF. Comparison of haemocompatibility improvement of four polymeric biomaterials by two heparinization techniques. Biomaterials. 2003;24(4):677–88.

Madhumanchi, S., Srichana, T. and Domb, A.J., 2021. Polymeric biomaterials. Biomedical materials, pp.49–100.

Ding J, Zhang J, Li J, Li D, Xiao C, Xiao H, Yang H, Zhuang X, Chen X. Electrospun polymer biomaterials. Prog Polym Sci. 2019;90:1–34.

Deshayes S, Kasko AM. Polymeric biomaterials with engineered degradation. J Polym Sci, Part A: Polym Chem. 2013;51(17):3531–66.

Krishna OD, Kiick KL. Protein-and peptide-modified synthetic polymeric biomaterials. Peptide Science: Original Research on Biomolecules. 2010;94(1):32–48.

Sun W, Liu W, Wu Z, Chen H. Chemical surface modification of polymeric biomaterials for biomedical applications. Macromol Rapid Commun. 2020;41(8):1900430.

Hukins DWL, Mahomed A, Kukureka SN. Accelerated aging for testing polymeric biomaterials and medical devices. Med Eng Phys. 2008;30(10):1270–4.

Ramachandra CT, Rao PS. Processing of Aloe vera leaf gel: a review. Am J Agric Biol Sci. 2008;3(2):502–10.

Ray A, Gupta SD. A panoptic study of antioxidant potential of foliar gel at different harvesting regimens of Aloe vera L. Ind Crops Prod. 2013;51:130–7.

Cristiano, G., Murillo-Amador, B. and De Lucia, B., 2016. Propagation techniques and agronomic requirements for the cultivation of Barbados aloe (Aloe vera (L.) Burm. F.)—a review. Frontiers in plant science, 7, p.1410.

McConaughy SD, Stroud PA, Boudreaux B, Hester RD, McCormick CL. Structural characterization and solution properties of a galacturonate polysaccharide derived from Aloe vera capable of in situ gelation. Biomacromol. 2008;9(2):472–80.

McConaughy SD, Kirkland SE, Treat NJ, Stroud PA, McCormick CL. Tailoring the network properties of Ca2+ crosslinked Aloe vera polysaccharide hydrogels for in situ release of therapeutic agents. Biomacromol. 2008;9(11):3277–87.

Khan AW, Kotta S, Ansari SH, Sharma RK, Kumar A, Ali J. Formulation development, optimization and evaluation of aloe vera gel for wound healing. Pharmacogn Mag. 2013;9(Suppl 1):S6.

Gentilini, R., Bozzini, S., Munarin, F., Petrini, P., Visai, L. and Tanzi, M.C., 2014. Pectins from Aloe Vera: Extraction and production of gels for regenerative medicine. Journal of Applied Polymer Science, 131(2).

Jales ST, Barbosa RDM, de Albuquerque AC, Duarte LH, da Silva GR, Meirelles LM, da Silva TM, Alves AF, Viseras C, Raffin FN, Moura TFDL. Development and Characterization of Aloe vera Mucilaginous-Based Hydrogels for Psoriasis Treatment. Journal of Composites Science. 2022;6(8):231.

Salama RM, Osman H, Ibrahim HM. Preparation of biocompatible chitosan nanoparticles loaded with Aloe vera extract for use as a novel drug delivery mechanism to improve the antibacterial characteristics of cellulose-based fabrics. Egypt J Chem. 2022;65(3):589–604.

Padmaja N, Bosco SJD. Preservation of jujube fruits by edible Aloe vera gel coating to maintain quality and safety. Indian Journal of Scientific Research and Technology. 2014;2(3):79–88.

Sierra-García, G.D., Castro-Ríos, R., González-Horta, A., Lara-Arias, J. and Chávez-Montes, A., 2014. Acemannan, an extracted polysaccharide from Aloe vera: a literature review. Natural product communications, 9(8), p.1934578X1400900836.

Sadgrove NJ, Simmonds MS. Pharmacodynamics of Aloe vera and acemannan in therapeutic applications for skin, digestion, and immunomodulation. Phytother Res. 2021;35(12):6572–84.

Bai Y, Niu Y, Qin S, Ma G. A new biomaterial derived from Aloe vera—Acemannan from basic studies to clinical application. Pharmaceutics. 2023;15(7):1913.

Kumar S, Tiku AB. Immunomodulatory potential of acemannan (polysaccharide from Aloe vera) against radiation induced mortality in Swiss albino mice. Food Hydrocolloids. 2016;27(1):72–86.

Im SA, Park CS, Lee CK. Immunoaugmenting activity of acemannan, the polysaccharides isolated from aloe vera gel. Korean Journal of Pharmacognosy. 2016;47(2):103–9.

Wynn RL. Aloe vera gel: Update for dentistry. Gen Dent. 2005;53(1):6–9.

Ni, Y., Turner, D., Yates, K.Á. and Tizard, I., 2004. Isolation and characterization of structural components of Aloe vera L. leaf pulp. International immunopharmacology, 4(14), pp.1745–1755.

Li Z, Lin Z. Recent advances in polysaccharide-based hydrogels for synthesis and applications. Aggregate. 2021;2(2): e21.

Manzoor A, Dar AH, Pandey VK, Shams R, Khan S, Panesar PS, Kennedy JF, Fayaz U, Khan SA. Recent insights into polysaccharide-based hydrogels and their potential applications in food sector: A review. Int J Biol Macromol. 2022;213:987–1006.

Zhu T, Mao J, Cheng Y, Liu H, Lv L, Ge M, Li S, Huang J, Chen Z, Li H, Yang L. Recent progress of polysaccharide-based hydrogel interfaces for wound healing and tissue engineering. Adv Mater Interfaces. 2019;6(17):1900761.

Hu H, Xu FJ. Rational design and latest advances of polysaccharide-based hydrogels for wound healing. Biomaterials science. 2020;8(8):2084–101.

Pooresmaeil, M. and Namazi, H., 2020. Application of polysaccharide-based hydrogels for water treatments. In Hydrogels based on natural polymers (pp. 411–455). Elsevier.

Liu K, Chen YY, Zha XQ, Li QM, Pan LH, Luo JP. Research progress on polysaccharide/protein hydrogels: Preparation method, functional property and application as delivery systems for bioactive ingredients. Food Res Int. 2021;147: 110542.

Fagiolari L, Bonomo M, Cognetti A, Meligrana G, Gerbaldi C, Barolo C, Bella F. Photoanodes for aqueous solar cells: exploring additives and formulations starting from a commercial TiO2 paste. Chemsuschem. 2020;13(24):6562–73.

Li C, Ding YW, Hu BC, Wu ZY, Gao HL, Liang HW, Chen JF, Yu SH. Temperature-invariant superelastic and fatigue resistant carbon nanofiber aerogels. Adv Mater. 2020;32(2):1904331.

Tu, H., Li, X., Liu, Y., Luo, L., Duan, B. and Zhang, R., 2022. Recent progress in regenerated cellulose-based fibers from alkali/urea system via spinning process. Carbohydrate Polymers, p.119942.

Abazari M, Akbari T, Hasani M, Sharifikolouei E, Raoufi M, Foroumadi A, Sharifzadeh M, Firoozpour L, Khoobi M. Polysaccharide-based hydrogels containing herbal extracts for wound healing applications. Carbohyd Polym. 2022;294: 119808.

Qi X, Wei W, Shen J, Dong W. Salecan polysaccharide-based hydrogels and their applications: a review. Journal of Materials Chemistry B. 2019;7(16):2577–87.

Rial-Hermida MI, Rey-Rico A, Blanco-Fernandez B, Carballo-Pedrares N, Byrne EM, Mano JF. Recent progress on polysaccharide-based hydrogels for controlled delivery of therapeutic biomolecules. ACS Biomater Sci Eng. 2021;7(9):4102–27.

Timofejeva A, D’Este M, Loca D. Calcium phosphate/polyvinyl alcohol composite hydrogels: A review on the freeze-thawing synthesis approach and applications in regenerative medicine. Eur Polymer J. 2017;95:547–65.

Song M, Wang L, Shao F, Xie H, Xu H, Yu W. Thermally induced flexible phase change hydrogels for solar thermal storage and human thermal management. Chem Eng J. 2023;464: 142682.

Wang C, Wiener CG, Sepulveda-Medina PI, Ye C, Simmons DS, Li R, Fukuto M, Weiss RA, Vogt BD. Antifreeze hydrogels from amphiphilic statistical copolymers. Chem Mater. 2018;31(1):135–45.

Xu Y, Rong Q, Zhao T, Liu M. Anti-freezing multiphase gel materials: bioinspired design strategies and applications. Giant. 2020;2: 100014.

Wei J, Li R, Li L, Wang W, Chen T. Touch-Responsive Hydrogel for Biomimetic Flytrap-Like Soft Actuator. Nano-Micro Letters. 2022;14(1):182.

Purohit BK, Sistla VS. LAPONITE® based hydrogel for cold thermal energy storage application. Bull Mater Sci. 2021;44(2):110.

Grenier J, Duval H, Barou F, Lv P, David B, Letourneur D. Mechanisms of pore formation in hydrogel scaffolds textured by freeze-drying. Acta Biomater. 2019;94:195–203.

Zhao, Y., Chen, Y., Song, X., Li, Y., Zhang, L., Meng, Y., Zhang, X., Qiu, X. and Huang, J., 2023. Starfish‐Inspired Cut‐Resistant Hydrogel with Self‐Growing Armor: Where Softness Meets Toughness. Advanced Functional Materials, p.2304439.

Sepulveda-Medina PI, Wang C, Li R, Fukuto M, Weiss RA, Vogt BD. Kinetically controlled morphology in copolymer-based hydrogels crosslinked by crystalline nanodomains determines efficacy of ice inhibition. Molecular Systems Design & Engineering. 2020;5(3):645–55.

Murphy DM, Koop T. Review of the vapour pressures of ice and supercooled water for atmospheric applications. Quarterly Journal of the Royal Meteorological Society: A journal of the atmospheric sciences, applied meteorology and physical oceanography. 2005;131(608):1539–65.

Safari A, Saidur R, Sulaiman FA, Xu Y, Dong J. A review on supercooling of Phase Change Materials in thermal energy storage systems. Renew Sustain Energy Rev. 2017;70:905–19.

Beaupere N, Soupremanien U, Zalewski L. Nucleation triggering methods in supercooled phase change materials (PCM), a review. Thermochim Acta. 2018;670:184–201.

Lin, H., Xu, Y., Guan, W., Zhao, S., Li, X., Zhang, C., Blecker, C. and Liu, J., 2023. The importance of supercooled stability for food during supercooling preservation: a review of mechanisms, influencing factors, and control methods. Critical Reviews in Food Science and Nutrition, pp.1–15.

Jebasingh BE, Arasu AV. A detailed review on heat transfer rate, supercooling, thermal stability and reliability of nanoparticle dispersed organic phase change material for low-temperature applications. Materials Today Energy. 2020;16: 100408.

Kang T, You Y, Jun S. Supercooling preservation technology in food and biological samples: A review focused on electric and magnetic field applications. Food science and biotechnology. 2020;29:303–21.

Shamseddine I, Pennec F, Biwole P, Fardoun F. Supercooling of phase change materials: A review. Renew Sustain Energy Rev. 2022;158: 112172.

Ediger MD. Spatially heterogeneous dynamics in supercooled liquids. Annu Rev Phys Chem. 2000;51(1):99–128.

Banerjee R, Maheswarappa NB. Superchilling of muscle foods: Potential alternative for chilling and freezing. Crit Rev Food Sci Nutr. 2019;59(8):1256–63.

Zahir MH, Mohamed SA, Saidur R, Al-Sulaiman FA. Supercooling of phase-change materials and the techniques used to mitigate the phenomenon. Appl Energy. 2019;240:793–817.

Tchobanian A, Van Oosterwyck H, Fardim P. Polysaccharides for tissue engineering: Current landscape and future prospects. Carbohyd Polym. 2019;205:601–25.

Dinoro J, Maher M, Talebian S, Jafarkhani M, Mehrali M, Orive G, Foroughi J, Lord MS, Dolatshahi-Pirouz A. Sulfated polysaccharide-based scaffolds for orthopaedic tissue engineering. Biomaterials. 2019;214: 119214.

Sivakumar PM, Yetisgin AA, Sahin SB, Demir E, Cetinel S. Bone tissue engineering: Anionic polysaccharides as promising scaffolds. Carbohyd Polym. 2022;283: 119142.

Nosrati H, Khodaei M, Alizadeh Z, Banitalebi-Dehkordi M. Cationic, anionic and neutral polysaccharides for skin tissue engineering and wound healing applications. Int J Biol Macromol. 2021;192:298–322.

Lakshmanan Y, Wong FSY, Zuo B, So KF, Bui BV, Chan HHL. Posttreatment intervention with Lycium barbarum polysaccharides is neuroprotective in a rat model of chronic ocular hypertension. Invest Ophthalmol Vis Sci. 2019;60(14):4606–18.

Nayak, A.K., Ahmed, S.A., Tabish, M. and Hasnain, M.S., 2019. Natural polysaccharides in tissue engineering applications. In Natural polysaccharides in drug delivery and biomedical applications (pp. 531–548). Academic Press.

Yang Q, Peng J, Xiao H, Xu X, Qian Z. Polysaccharide hydrogels: Functionalization, construction and served as scaffold for tissue engineering. Carbohyd Polym. 2022;278: 118952.

Wang S, Zhao Q, Li J, Du X. Morphing-to-Adhesion polysaccharide hydrogel for adaptive biointerfaces. ACS Appl Mater Interfaces. 2022;14(37):42420–9.

Arora S, Singh D, Rajput A, Bhatia A, Kumar A, Kaur H, Sharma P, Kaur P, Singh S, Attri S, Buttar HS. Plant-based polysaccharides and their health functions. Functional Foods in Health and Disease. 2021;11(4):179–200.

Tobias KM, Kidd CE, Mulon PY, Zhu X. Tensile properties of synthetic, absorbable monofilament suture materials before and after incubation in phosphate-buffered saline. Vet Surg. 2020;49(3):550–60.

Peng X, Liu G, Zhu L, Yu K, Qian K, Zhan X. In vitro and in vivo study of novel antimicrobial gellan–polylysine polyion complex fibers as suture materials. Carbohyd Res. 2020;496: 108115.

Moszynski R, Burchardt B, Sajdak S, Moszynska M, Englert-Golon M, Olbromski P. Using a Modified Polysaccharide as a Hemostatic Agent Results in Less Reduction of the Ovarian Reserve after Laparoscopic Surgery of Ovarian Tumors—Prospective Study. Medicina. 2022;59(1):14.

Hormozi, B., 2023. Plant polysaccharides for orthopedic drug delivery. In Plant Polysaccharides as Pharmaceutical Excipients (pp. 513–532). Elsevier.

Thodikayil, A.T., Sarkar, C. and Saha, S., 2023. Carbohydrate-Based Biodegradable Polymers for Biomedical Applications. In Biodegradable Polymers and Their Emerging Applications (pp. 69–88). Singapore: Springer Nature Singapore.