Abstract

The Nb2CTx prepared by hydrothermal-assisted in-situ HF generation etching was investigated in terms of its gas sensor performance. The Nb2CTx was obtained by mixing Nb2AlC with pure water, hydrochloric acid, and fluoride (LiF or NH4F) and then hydrothermally treated at 180 °C for 24 h. This in-situ HF generation etching by hydrothermal treatment was more efficient and safer in the synthesis of the Nb2CTx than the direct HF etching. The Nb2CTx etched with LiF had relatively wide interlayer spacing because the hydration radius of Li+ was larger than that of NH4+. The results also suggest that Nb2O5 is formed during the synthesis process. These results suggest that interlayer spacing, surface termination, and secondary phases formation can be controlled by the etchant, and that hydrothermal treatment extended the applicability of insoluble etchants. The Nb2CTx synthesized with LiF was evaluated as a gas sensor at room temperature in air in the presence of designated concentrations of 6 different gases, which exhibited good sensitivity and repeatability and fast recovery time, except for NH3. Hydrothermal-assisted etching contributed to providing sufficient interlayer spacing for the gas response without an exfoliation process.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Extensive attentions have been paid to the development of wearable gas sensor for volatile organic compounds (VOCs) at early stage VOCs above acceptable levels are harmful to human health and the exhaled breath and skin gases of patients with certain diseases contain high concentrations of certain VOCs, e.g. the concentration of acetone in the exhaled breath of diabetics is about 4 times higher than that of healthy individuals [1, 2].

Physical–chemical performance of materials greatly changed with their phase composition, particle size, microstructure, surface chemical status etc., leading to a variety of applications [3,4,5]. Metal oxide semiconductors (MOS) have been applied to gas sensors [6]. For example, in n-type semiconductors, in which free electrons are carriers, the electrical resistance decreases with an electron-donating gas such as acetone adsorbed on the surface, while it increases with electron-withdrawing gases such as NO2 adsorbed.

The performance of gas sensors is defined by several factors: temperature and atmosphere, response sensitivity, selectivity, detection limit, and response-recovery time. The MOSs gas sensors have issues in terms of operating temperature and atmosphere and gas selectivity. In the case of a normal metal oxide semiconductor gas sensing system, the operation usually requires around 300 °C and the response decreases with humidity [7]. Recently, MXene, which is expressed as Mn+1X nTx (n = 1–4), where M is early transition metal, X is the C/N group element, T is the functional group such as –OH, –F, has been found to be promising materials to work as a gas sensor satisfied with the required performances. The MXene exhibits metal/semiconductor-like behavior, with a significant change in band gap depending on the surface functional group (termination) [8], which is obtained by etching the A site of the MAX phase, which is expressed as Mn+1AX n (n = 1–4), where A is the main III/IV group element. The diversity of MAX phases can design the resulting MXene with a variety of compositions and structures such as (TixNb1-x)2CTx [9], Ti2NTx [10], Ti3C2Tx [11], Ti4N3Tx [12], Mo1.33CTx [13]. Numerous theoretical calculations and experiments have indicated that the MXene exhibit excellent physical and chemical properties, leading to its application to various fields: catalytic materials [14], energy storage materials [15] and gas sensor [16].

The MXene gas sensors outperforms conventional MOS gas sensors in terms of room temperature operation and selectivity [17, 18], while their electrical resistance variation does not correlate with electron-donating or electron-withdrawing gases [19,20,21]. The electrical resistance of MXene varies both positively and negatively depending on the M site element [22], surface termination [23], and thickness of film [20]. Despite these interesting gas sensing behavior, MXenes gas sensors are mostly utilized as composites [24, 25], and few studies have focused on the basic gas sensor behavior of MXene. Current experimental reports of MXene gas sensors are limited to a few types, such as Ti3C2Tx [21, 23, 26, 27], V4C3Tx [28], V2CTx [22, 29], Mo2CTx [20, 30]. In addition, the detailed mechanism on the MXenes gas sensing is still ambiguous due to their insufficient fundamental data. Therefore, the research should focus on the analysis of the roles of elements, surface termination and interlayer distances of the MXene to elucidate the gas sensing mechanism.

The surface termination and interlayer distances are mainly determined by etching methods. Since HF is not enough strong to break the M-A bonds, it may be difficult to obtain MXene from MAX phase with strong M-A by etching with HF [11]. Although HF has been commonly used as etchant, HF itself is very dangerous and the HF etching lacks variation in surface termination. In recent years, various etching techniques have been developed by use of in-situ HF generation [31], electrochemical etching [32], molten salts [33], alkalis [34] and deep eutectic solvents [35]. The in-situ HF generation method is generally accepted as relatively simple and safe, with a wide variety of surface functional group variations which could contribute to MXene diversity. In this method, HF is produced in-situ by mixing, dissolving, and reacting HCl with fluorides such as NaF, KF, LiF and NH4F. The hydrothermal-assisted etching method is safe for exposure of HF thanks to its sealed environment and reduced etching time significantly because of increased reaction rate and solubility of reagents, e.g. LiF which is low solubility at room temperature [36,37,38].

A M2CTx is expected to have a larger specific surface area than M3C2Tx or M4C3Tx due to its fewer atomic layers [39]. The Nb2CTx should be a good candidate for the high-performance wearable gas sensors operated at room temperature because it is biocompatible [40, 41]. Nb2CTx has potential as a gas sensor, however the accumulation of experimental studies is lacking. In addition, in the development of previous MXene gas sensors, exfoliation was necessary during the synthesis process to obtain a gas response [27].

In this study, we investigated the gas response of unexfoliated multilayer Nb2CTx as a gas sensor by using hydrothermal-assisted etching to achieve a wide interlayer distance. Nb2AlC was hydrothermally etched by LiF, and NH4F to obtain the Nb2CTx, which were characterized in terms of structure and morphology to compare with those prepared by HF etching. Gas sensor properties of Nb2CTx synthesized with LiF were also investigated for 6 gases.

2 Experimental procedures

2.1 Materials

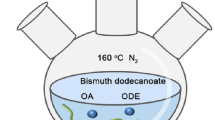

Nb2CTx MXenes were prepared by etching off Al from Nb2AlC. The Nb2AlC (98%, 400 mesh) was purchased from Jilin 11 Technology Co., Ltd, China). The Nb2AlC powders were then etched with 3 different fluorine solutions such as NH4F + HCl (ammonium fluoride with hydrochloric acid), LiF + HCl (lithium fluoride with hydrochloric acid), and HF (hydrofluoric acid). The NH4F + HCl and LiF + HCl solutions consisted of 30 mL H2O, 10 mL HCl (35–37 wt.%, Wako Pure Chemical Industries, Ltd., Japan), and 2 g NH4F (≥ 97. wt.%, Kanto Chemical Co., INC., Japan) or 3 g LiF (≥ 99.0 wt%, Wako Pure Chemical Industries, Ltd., Japan). Then 2 g Nb2AlC powders were added into the solutions, sealed in Teflon-lined stainless autoclave, and kept in an rotary oven at 180 °C for 24 h. The HF etching solution is 30 mL HF (46–48 wt.%, Wako Pure Chemical Industries, Ltd., Japan). 2 g Nb2AlC was slowly added to the HF etching solution and kept at 35 °C for 72 h. The etched mixture was then washed with 6 M HCl and deionised water and centrifuged several times until the pH value ≥ 6. Finally, the mixture was washed with ethanol and the precipitate was vacuum-dried overnight at 60 °C to obtain multilayer Nb2CTx.

The samples made with LiF + HCl, NH4F + HCl and HF were named LiF-Nb2CTx, NH4F-Nb2CTx and HF-Nb2CTx respectively.

2.2 Characterization

The compositions of samples were characterized by X-ray diffractometer (XRD, Bruker D2 Phaser, USA) with Cu Kα radiation, λ = 0.15418 nm. The morphology and microstructure were investigated using a field emission scanning electron microscope (FE-SEM, JSM-7800F, JEOL Ltd., Japan) equipped with an energy-dispersive spectrometer (EDS). Crystal phase defined by using high-resolution transmission electron microscopy (HRTEM, EM-002B, TOPCON CORPORATION, Japan). X-ray photoelectron spectroscopy (XPS, PHI5600, ULVAC-PHI Inc., Japan) measurements were performed using a focused monochromate Al Kα monochromatic (200 W) at 20 eV X-ray source. Samples are mounted with double-sided tape and binding energies are based on the C 1 s peak at 284.8 eV on an irregular carbon surface to correct for shifts due to charge effects.

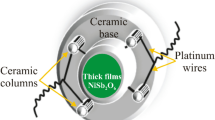

2.3 Fabrication of gas-sensing device and analysis

10 mg of the MXene sample was added into 200 µL ethanol, and then dispersed through the ultrasonic wave. The comb-shaped electrode sheet was placed on a heated magnetic stirrer with the temperature set to 70 ℃, and 15 μl of the slurry was dropped onto the comb-shaped electrode using a pipette. Drop 15 μl at a time until all the slurry is transferred to the electrode, and after the slurry dropped electrode was dried overnight in a 60 °C drying oven, it was fixed in the chamber for the gas sensing instrument.

The evaluation of gas sensing properties of the samples was collected using a data acquisition unit (Agilent 34970A) with the two points probe method. The target gas analytes, including H2, H2S, NH3, ethanol, toluene and acetone with a concentration of 0.1–50 ppm, were carried out to a sensor device to measure sensor responsivity and selectivity. The target gas in each concentration in the N2 base gas is mixed with air gas and flowed at a total flow rate of 200 ml/min. The flow rate of the target gas in 200 ml/min corresponds to the concentration. The injection time of analytes was 10 min, with intervals of 10 min to reintroduce the air atmosphere. The gas sensing response ΔR was defined as the ratio of the sensor electrical resistance in air, immediately before the flow of the target gas at each concentration (Ra) to the sensor electrical resistance in the analyzed gas (Rg) as follow;

The gas sensing response repeatability Rr was defined as follow;

where the initial electrical resistance is ΔRi, and the electrical resistance at cycle is ΔRn. The recovery time (trec) of the sensor has been defined as the time needed to the sensor to recover 90% of its baseline electrical resistance.

3 Results and discussions

3.1 Synthesis of Nb 2 CT x

From the XRD patterns of Nb2AlC, LiF–Nb2CTx, NH4F–Nb2CTx, and HF-Nb2CTx (Fig. 1), most of peaks for the Nb2AlC were disappeared or significantly weakened after the etching process. In addition, the peaks characteristic of 2-dimensional MXenes are highlighted at low angle (< 10°), indicating successful synthesis of Nb2CTx by the following reactions [37, 42]:

The 2θ values at the low angle (002) peak of the samples etched with LiF, NH4F, and HF were 7.05°, 7.72°, and 8.61°, respectively. The (002) peak shifts to lower angle and tends to broaden, corresponding to an increase of d-spacing and a decline of the thickness of Mxene layer stacks, respectively [43]. Compared to the HF etching for 72 h, hydrothermal-assisted in-situ HF etching could efficiently synthesize MXene with large interlayer space and well delamination even in a short time of 24 h. The peak for LiF-Nb2CTx appeared at the lowest position indicating that it has wider interlayer space than NH4F-Nb2CTx, which linked to the fact that the hydration radius of Li+ is larger than that of NH4+ [44, 45]. The NH4F generally makes a wider interlayer space at room temperature because of low solubility of LiF, while the hydrothermal treatment successively led to the efficient etching even by use of LiCl. AlF3 was identified around 25° as an impurity [36] on NH4F-Nb2CTx. This secondary phase was reported to precipitate depending on the ionic strength in solution [46].

The SEM images of Nb2AlC and Nb2CTx multilayer powder provides the dense layered solid of Nb2AlC and the typical accordion-like structure of Nb2CTx multilayer (Fig. 2). In addition, TEM images of Nb2CTx indicates typical hexagonal structure [47] and interlayer spaces (Fig. S1), as Nb2CTx is the basal plane of Nb2AlC and thus inherits the hexagonal structure and atomic positions.

EDS analysis was carried out to compare the effects of the etchant on surface conditions and the presence of impurities. The elemental mapping (Fig. 3) and elemental analysis (Table 1) of LiF-Nb2CTx and NH4F-Nb2CTx indicate the concentration of elements on the surface varies greatly depending on the etchant. The concentration of Cl was similar in both compounds, but the ratio of O, Al and F was relatively low in LiF-Nb2CTx. The high concentration of O in NH4F-Nb2CTx could imply the formation of many−O/−OH groups on the surface as a result of hydrolysis based on reaction (6), presence of residual adsorbed H2O, or the presence of Nb-oxide by the oxidizing Nb2CTx at high temperature during synthesis. The use of NH4F can be etched for a shorter time than that of LiF [48] even at relatively low temperatures thanks to its relatively high solubility. The longer exposure to the hydrothermal environment in the etched state may proceed the surface oxidation. The formation of AlF3 as an impurity was found in the high amount of Al and F.

The XPS analysis of LiF-Nb2CTx gives peaks in the Nb 3 days, C 1 s, and O 1 s regions of Nb2CTx, which were fitted with the corresponding components [39, 49, 50], indicating that the surface of Nb2CTx is occupied by Nb, O, C, and F elements (Fig. 4). The high-resolution Nb 3d spectrum shows the presence of Nb5+ is attributed to the oxidation of Nb to Nb2O5 [51]. The Nb2O5 occurs on the Nb2CTx surface, and Nb2O5 is generated from the slow surface oxidation in air or in a hydrothermal environment. The MXene has extremely low oxidation resistance even at room temperature, thus resulting in this localized oxidation state. Similar surface conditions were observed for Nb2CTx synthesized by hydrothermal-assisted etching [37]. The Gaussian fitting of XPS spectra is assigned to C-O, C-C, and C-Nb for C1s and to Nb-C-(OH)x, Nb-C-Ox and Nb-O for O1s, respectively.

In Nb3d region of XPS spectrum of NH4F-Nb2CTx, the residual adsorbed H2O was detected (Fig. 5). The surface of NH4F-Nb2CTx may be exposed to oxidizing species as H2O [52] for a longer period of time because it starts etching earlier (at lower temperatures) than LiF-Nb2CTx. However, no particle and diffraction peak of Nb2O5 were observed in the SEM images and the XRD pattern of Nb2CTx, respectively, suggesting that Nb2O5 is decorated on the pristine Nb2CTx in the form of ultra-small clusters or ultra-thin films [53]. The results of XPS analysis is good agreement with those of the elemental mapping analysis.

3.2 Gas sensing performance

Wide interlayer spacing provides contact between the MXene surface and the gas. The single-layer MXene show a sensing performance, while the multi-layer MXene did not show sensing performance [27]. In this study, the gas sensing performance of LiF-Nb2CTx with the widest interlayer was evaluated at room temperature in air in the presence of the target gases (Figs. S2, S3S4).

As shown in Fig. 6a, the electrical resistance increased when H2 gas flowed, and the gas sensing response ΔR was obtained by Eq. (1). The response values after 10 min exposure to the target gases to LiF-Nb2CTx were positive for all gases (Fig. 6b–d) and increases with increasing gas concentration. Blocking carrier transport due to gas adsorption increases the electrical resistance of the Nb2CTx. Among gases investigated in this study, H2 could be detected at the lowest concentration (0.5 ppm). The LiF-Nb2CTx showed highest response to NH3 compared to ethanol, toluene and acetone at the same concentrations exposure (10 ppm) (Fig. 6c). DFT calculation of T3C2Tx implies NH3 is the most favorable adsorbed gas [54]. In Fig. 6d shows the response at 50 ppm. On addition of 50 ppm gases, LiF-Nb2CTx responded to toluene and acetone, while less response to ethanol was observed (Fig. 6d). When the same concentrations of gases were added 4 times, the response with a difference from the initial response is less than 15% was observed except for NH3, indicating is available for a gas sensor with reasonable repeatability (Fig. 6e). Regarding gas sensing, the full and rapid recovery may not be achieved due to the high adsorption energy between MXenes and NH3 generated from chemical adsorption [27, 54]. The recovery time in the case of NH3 was not estimated due to baseline drift probably generated from gas adsorption (Fig. S5).

Gas sensing performance of Nb2CTx: (a) H2 gas sensing performance, the change in gas response with time elapsed during gas flow (0.5 ppm) and after stopping gas flow, (b–d) The changes in gas response value after 10 min gas exposure to the specified concentrations, and (e) repeatability of changes in gas sensing response after 10 min gas exposure at the maximum concentration of each gas (Fig. S4)

As for the recovery time is required need for the sensor to recover 90% of the baseline resistance (Fig. 6a). The average recovery times for 4 cycles at the maximum gas concentration used in this study were 21 s, 28 s, 35 s, and 27 s for H2, H2S, toluene, and acetone, respectively. In the case of ethanol, the response did not recover after 10 min. Fast response recovery is physisorption rather than chemisorption, suggesting that electrical conduction was significantly influenced by physisorption. The fast recovery time is sufficient for practical use.

Although the Nb2CTx is reported to exhibit the metallic-like behavior [55], the electrical resistance values obtained in this study was relatively high (Fig. 6(a) and Fig. S2), which is ascribed to the presence of Nb2O5 on the surface, as shown by XPS. In other studies, V2CTx/V2O5 exhibited higher electrical resistance than pristine V2CTx [56] because the presence of oxides could increase electrical resistance. Therefore, the material in this study can be regarded as an Nb2CTx/Nb2O5. The Nb2O5 is an n-type semiconductor [57] with a work function of 4.0 eV [58, 59]. The surface termination controls the work function of MXene. The work function of Nb2CTx, where all surface are covered by -OH group, is 2.5 eV, and increases as the ratio of surface substituted by the other functional groups increases [52, 60]. The presence of in-situ grown Nb2O5 nanoparticles on the Nb2CTx surface allows electrons to move from the conduction band of Nb2CTx to n-type Nb2O5, resulting in the formation of Schottky barriers and depletion layers at their interfaces. The presence of the depletion layer and Schottky barrier prevents charge carrier transfer in Nb2CTx and increases the electrical resistance of the LiF-Nb2CTx itself.

The response types of electrical resistance MXene gas sensors reported in this, and previous studies are summarized in Table S1. Blocking out-of-plane electron transport generated from [56, 61]. In addition, gas adsorption also decreases the number of carriers from gas adsorption and increases the electrical resistance [21]. Thin Mo2CTx devices prepared by spin-coating showed a negative response to the gas, while thicker devices prepared by dropping showed a positive response [20]. Similarly reported for Ti3C2Tx, the electrical resistance of the sensor to gas increases significantly with increasing thickness [27]. Recently, the devices prepared by dropping 0.05 mg Nb2CTx/Nb2O5 onto an electrode showed a negative response [62]. In contrast, the Nb2CTx/Nb2O5 utilized in this study was 10 mg drops, which is inferred to have a thicker powder layer than reported earlier. The results indicating that positive/negative response change of MXene could depend on contact between MXene and electrode. Large amounts of primary charge carriers reduce the ability to modify sensitive conduction pathways due to gas adsorption. The thickness of the MXene on the electrode may influence the positive/negative response, suggesting that a thin layer of MXene on the electrode should be selected to obtain dynamic positive /negative response changes by gas adsorption. The influence of surface termination on gas selectivity needs to be approached from both experimental and theoretical perspectives, with the tuning of Mxene thickness in the experimental condition.

4 Conclusions

The Nb2CTx with a trace amount of Nb2O5 was successfully synthesised using a hydrothermally assisted in-situ HF generation etching method by mixing HCL with LiF and NH4F in a shorter time than conventional HF etching. The combination of hydrothermal treatment and the etchants could control the interlayer, surface termination, oxides and other impurities. The LiF-Nb2CTx with the largest interlayer spacing showed a positive response to the 6 gases used in this study. The showing gas response without an exfoliation process suggests that hydrothermal contributes to a sufficient wide interlayer spacing for gas response. The Nb2CTx exhibited good gas sensing performance with good sensitivity and repeatability and fast recovery time, although the issue still remained for a decreased response at the repeated use for NH3 due to chemical interactions.

Data availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

Reyes-Reyes A, Horsten RC, Urbach HP, Bhattacharya N. Study of the exhaled acetone in type 1 diabetes using quantum cascade laser spectroscopy. Anal Chem. 2015;87:507–12. https://doi.org/10.1021/ac504235e.

Hermawan A, Amrillah T, Riapanitra A, Ong WJ, Yin S. Prospects and challenges of MXenes as emerging sensing materials for flexible and wearable breath-based biomarker diagnosis. Adv Healthc Mater. 2021;10:2100970. https://doi.org/10.1002/adhm.202100970.

Cao J, Hasegawa T, Asakura Y, Sun P, Yang S, Li B, Cao W, Yin S. Synthesis and color tuning of titanium oxide inorganic pigment by phase control and mixed-anion co-doping. Adv Powder Technol. 2022;33:103576. https://doi.org/10.1016/j.apt.2022.103576.

Yin S, Hasegawa T. Morphology control of transition metal oxides by liquid-phase process and their material development. KONA Powder Part J. 2023;40:94–108. https://doi.org/10.1435/kona.2023015.

Wang Z, Wang F, Hermawan A, Zhu J, Yin S. Surface engineering of Ti3C2Tx MXene by oxygen plasma irradiation as room temperature ethanol sensor. Funct Mater Lett. 2022;15:1. https://doi.org/10.1142/S1793604722510079.

Kim HJ, Lee JH. Highly sensitive and selective gas sensors using p-type oxide semiconductors: overview. Sens Actuators B Chem. 2014;192:607–27. https://doi.org/10.1016/j.snb.2013.11.005.

Dey A. Semiconductor metal oxide gas sensors: a review. Mater Sci Eng B Solid State Mater Adv Technol. 2018;29:206–17. https://doi.org/10.1016/j.mseb.2017.12.036.

Zhang Y, Xia W, Wu Y, Zhang P. Prediction of MXene based 2D tunable band gap semiconductors: GW quasiparticle calculations. Nanoscale. 2019;11:3993–4000. https://doi.org/10.1039/c9nr01160a.

Han M, Maleski K, Shuck CE, Yang Y, Glazar JT, Foucher AC, Hantanasirisakul K, Sarycheva A, Frey NC, May SJ, Shenoy VB, Stach EA, Gogotsi Y. Tailoring electronic and optical properties of MXenes through forming solid solutions. J Am Chem Soc. 2020;142:19110–8. https://doi.org/10.1021/jacs.0c07395.

Soundiraraju B, George BK. Two-dimensional titanium nitride (Ti2N) MXene: synthesis, characterization, and potential application as surface-enhanced raman scattering substrate. ACS Nano. 2017;11:8892–900. https://doi.org/10.1021/acsnano.7b03129.

Ghidiu M, Lukatskaya MR, Zhao MQ, Gogotsi Y, Barsoum MW. Conductive two-dimensional titanium carbide “clay” with high volumetric capacitance. Nature. 2015;516:78–81. https://doi.org/10.1038/nature13970.

Urbankowski P, Anasori B, Makaryan T, Er D, Kota S, Walsh PL, Zhao M, Shenoy VB, Barsoum MW, Gogotsi Y. Synthesis of two-dimensional titanium nitride Ti4N3 (MXene). Nanoscale. 2016;8:11385–91. https://doi.org/10.1039/c6nr02253g.

Tao Q, Dahlqvist M, Lu J, Kota S, Meshkian R, Halim J, Palisaitis J, Hultman L, Barsoum MW, Persson POÅ, Rosen J. Two-dimensional Mo1.33C MXene with divacancy ordering prepared from parent 3D laminate with in-plane chemical ordering. Nat Commun. 2017. https://doi.org/10.1038/ncomms14949.

Zhang J, Zhao Y, Guo X, Chen C, Dong CL, Liu RS, Han CP, Li Y, Gogotsi Y, Wang G. Single platinum atoms immobilized on an MXene as an efficient catalyst for the hydrogen evolution reaction. Nat Catal. 2018;1:985–92. https://doi.org/10.1038/s41929-018-0195-1.

Lukatskaya MR, Kota S, Lin Z, Zhao MQ, Shpigel N, Levi MD, Halim J, Taberna PL, Barsoum MW, Simon P, Gogotsi Y. Ultra-high-rate pseudocapacitive energy storage in two-dimensional transition metal carbides. Nat Energy. 2017. https://doi.org/10.1038/nenergy.2017.105.

Mehdi Aghaei S, Aasi A, Panchapakesan B. Experimental and theoretical advances in MXene-based gas sensors. ACS Omega. 2021;6:2450–61. https://doi.org/10.1021/acsomega.0c05766.

Yu XF, Li YC, Cheng JB, Liu ZB, Li QZ, Li WZ, Yang X, Xiao B. Monolayer Ti2CO2: a promising candidate for NH3 sensor or capturer with high sensitivity and selectivity. ACS Appl Mater Interfaces. 2015;7:13707–13. https://doi.org/10.1021/acsami.5b03737.

Yang D, Fan X, Zhao D, An Y, Hu Y, Luo Z. Sc2CO2 and Mn-doped Sc2CO2 as gas sensor materials to NO and CO: a first-principles study. Physica E Low Dimens Syst Nanostruct. 2019;111:84–90. https://doi.org/10.1016/j.physe.2019.02.019.

Yao L, Tian X, Cui X, Zhao R, Xiao M, Wang B, Xiao X, Wang Y. Two-dimensional Ti3C2Tx MXene/SnO nanocomposites: towards enhanced response and selective ammonia vapor sensor at room temperature. Sens Actuators B Chem. 2022. https://doi.org/10.1016/j.snb.2022.131501.

Choi J, Chacon B, Park H, Hantanasirisakul K, Kim T, Shevchuk K, Lee J, Kang H, Cho SY, Kim J, Gogotsi Y, Kim SJ, Jung HT. N-p-conductor transition of gas sensing behaviors in Mo2CTx MXene. ACS Sens. 2022;7:2225–34. https://doi.org/10.1021/acssensors.2c00658.

Kim SJ, Koh HJ, Ren CE, Kwon O, Maleski K, Cho SY, Anasori B, Kim CK, Choi YK, Kim J, Gogotsi Y, Jung HT. Metallic Ti3C2Tx MXene gas sensors with ultrahigh signal-to-noise ratio. ACS Nano. 2018;12:986–93. https://doi.org/10.1021/acsnano.7b07460.

Wu M, An Y, Yang R, Tao Z, Xia Q, Hu Q, Li M, Chen K, Zhang Z, Huang Q, Ma SH, Zhou A. V2CTxand Ti3C2Tx MXenes nanosheets for gas sensing. ACS Appl Nano Mater. 2021;4:6257–68. https://doi.org/10.1021/acsanm.1c01059.

Yang Z, Liu A, Wang C, Liu F, He J, Li S, Wang J, You R, Yan X, Sun P, Duan Y, Lu G. Improvement of gas and humidity sensing properties of organ-like MXene by alkaline treatment. ACS Sens. 2019;4:1261–9. https://doi.org/10.1021/acssensors.9b00127.

Hermawan A, Zhang B, Taufik A, Asakura Y, Hasegawa T, Zhu J, Shi P, Yin S. CuO nanoparticles/Ti3C2Tx MXene hybrid nanocomposites for detection of toluene gas. ACS Appl Nano Mater. 2020;3:4755–66. https://doi.org/10.1021/acsanm.0c00749.

Wang Z, Wang F, Hermawan A, Asakura Y, Hasegawa T, Kumagai H, Kato H, Kakihana M, Zhu J, Yin S. SnO-SnO2 modified two-dimensional MXene Ti3C2Tx for acetone gas sensor working at room temperature. J Mater Sci Technol. 2021;73:128–38. https://doi.org/10.1016/j.jmst.2020.07.040.

Lee E, Vahidmohammadi A, Prorok BC, Yoon YS, Beidaghi M, Kim DJ. Room temperature gas sensing of two-dimensional titanium carbide (MXene). ACS Appl Mater Interfaces. 2017;9:37184–90. https://doi.org/10.1021/acsami.7b11055.

Wu M, He M, Hu Q, Wu Q, Sun G, Xie L, Zhang Z, Zhu Z, Zhou A. Ti3C2 MXene-based sensors with high selectivity for NH3 detection at room temperature. ACS Sens. 2019;4:2763–70. https://doi.org/10.1021/acssensors.9b01308.

Zhao WN, Yun N, Dai ZH, Li YF. A high-performance trace level acetone sensor using an indispensable V4C3T: X MXene. RSC Adv. 2020;10:1261–70. https://doi.org/10.1039/c9ra09069j.

Lee E, Vahidmohammadi A, Yoon YS, Beidaghi M, Kim DJ. Two-dimensional vanadium carbide MXene for gas sensors with ultrahigh sensitivity toward nonpolar gases. ACS Sens. 2019;4:1603–11. https://doi.org/10.1021/acssensors.9b00303.

Thomas T, Ramos Ramón JA, Agarwal V, Méndez AÁ, Martinez JAA, Kumar Y, Sanal KC. Highly stable, fast responsive Mo2CTx MXene sensors for room temperature carbon dioxide detection. Microporous Mater. 2022. https://doi.org/10.1016/j.micromeso.2022.111872.

Zhang T, Pan L, Tang H, Du F, Guo Y, Qiu T, Yang J. Synthesis of two-dimensional Ti3C2Tx MXene using HCl+LiF etchant: enhanced exfoliation and delamination. J Alloys Compd. 2017;695:818–26. https://doi.org/10.1016/j.jallcom.2016.10.127.

Yang S, Zhang P, Wang F, Ricciardulli AG, Lohe MR, Blom PWM, Feng X. Fluoride-free synthesis of two-dimensional titanium carbide (MXene) using A binary aqueous system. Angew Chem. 2018;130:15717–21. https://doi.org/10.1002/ange.201809662.

Liu L, Orbay M, Luo S, Duluard S, Shao H, Harmel J, Rozier P, Taberna PL, Simon P. Exfoliation and delamination of Ti3C2Tx MXene prepared via molten salt etching route. ACS Nano. 2022;16:111–8. https://doi.org/10.1021/acsnano.1c08498.

Li T, Yao L, Liu Q, Gu J, Luo R, Li J, Yan X, Wang W, Liu P, Chen B, Zhang W, Abbas W, Naz R, Zhang D. Fluorine-free synthesis of high-purity Ti3C2Tx (T = OH, O) via Alkali treatment. Angew Chem. 2018;130:6223–7. https://doi.org/10.1002/ange.201800887.

Wu J, Wang Y, Zhang Y, Meng H, Xu Y, Han Y, Wang Z, Dong Y, Zhang X. Highly safe and ionothermal synthesis of Ti3C2 MXene with expanded interlayer spacing for enhanced lithium storage. J Energy Chem. 2020;47:203–9. https://doi.org/10.1016/j.jechem.2019.11.029.

Peng C, Wei P, Chen X, Zhang Y, Zhu F, Cao Y, Wang H, Yu H, Peng F. A hydrothermal etching route to synthesis of 2D MXene (Ti3C2, Nb2C): enhanced exfoliation and improved adsorption performance. Ceram Int. 2018;44:18886–93. https://doi.org/10.1016/j.ceramint.2018.07.124.

Wang L, Zhang H, Wang B, Shen C, Zhang C, Hu Q, Zhou A, Liu B. Synthesis and electrochemical performance of Ti3C2Tx with hydrothermal process. Electron Mater Lett. 2016;12:702–10. https://doi.org/10.1007/s13391-016-6088-z.

Guo Y, Liu D, Huang B, Wang L, Xia Q, Zhou A. Effects of surface compositions and interlayer distance on electrochemical performance of Mo2CTx MXene as anode of Li-ion batteries. J Phys Chem Solids. 2023;176:111238. https://doi.org/10.1016/j.jpcs.2023.111238.

Naguib M, Halim J, Lu J, Cook KM, Hultman L, Gogotsi Y, Barsoum MW. New two-dimensional niobium and vanadium carbides as promising materials for li-ion batteries. J Am Chem Soc. 2013;135:15966–9. https://doi.org/10.1021/ja405735d.

Xiang H, Lin H, Yu L, Chen Y. Hypoxia-irrelevant photonic thermodynamic cancer nanomedicine. ACS Nano. 2019;13:2223–35. https://doi.org/10.1021/acsnano.8b08910.

Song M, Pang SY, Guo F, Wong MC, Hao J. Fluoride-free 2D niobium carbide MXenes as stable and biocompatible nanoplatforms for electrochemical biosensors with ultrahigh sensitivity. Adv Sci. 2020;7:2001546. https://doi.org/10.1002/advs.202001546.

Zhang C, Ma Y, Zhang X, Abdolhosseinzadeh S, Sheng H, Lan W, Pakdel A, Heier J, Nüesch F. Two-dimensional transition metal carbides and nitrides (MXenes): synthesis, properties, and electrochemical energy storage applications. Energy Environ. 2020;3:29–55. https://doi.org/10.1002/eem2.12058.

Liu F, Zhou A, Chen J, Jia J, Zhou W, Wang L, Hu Q. Preparation of Ti3C2 and Ti2C MXenes by fluoride salts etching and methane adsorptive properties. Appl Surf Sci. 2017;416:781–9. https://doi.org/10.1016/j.apsusc.2017.04.239.

Volkov AG, Paula S, Deamer DW. Two mechanisms of permeation of small neutral molecules and hydrated ions across phospholipid bilayers. Bioelectrochem Bioenergetics. 1997. https://doi.org/10.1016/S0302-4598(96)05097-0.

Kiriukhin MY, Collins KD. Dynamic hydration numbers for biologically important ions. Biophys Chem. 2002. https://doi.org/10.1016/S0301-4622(02)00153-9.

Cockreham CB, Zhang X, Li H, Hammond-Pereira E, Sun J, Saunders SR, Wang Y, Xu H, Wu D. Inhibition of AlF3·3H2O impurity formation in Ti3C2Tx MXene synthesis under a unique CoFx/HCl etching environment. ACS Appl Energy Mater. 2019;2:8145–52. https://doi.org/10.1021/acsaem.9b01618.

Du L, Duan H, Xia Q, Jiang C, Yan Y, Wu S. Hybrid charge-storage route to Nb2CTx MXene as anode for sodium-ion batteries. Chem Select. 2020;5:1186–92. https://doi.org/10.1002/slct.201903888.

Guo Y, Jin S, Wang L, He P, Hu Q, Fan LZ, Zhou A. Synthesis of two-dimensional carbide Mo2CTx MXene by hydrothermal etching with fluorides and its thermal stability. Ceram Int. 2020;46:19550–6. https://doi.org/10.1016/j.ceramint.2020.05.008.

Li Z, Cui Y, Wu Z, Milligan C, Zhou L, Mitchell G, Xu B, Shi E, Miller JT, Ribeiro FH, Wu Y. Reactive metal-support interactions at moderate temperature in two-dimensional niobium-carbide-supported platinum catalysts. Nat Catal. 2018;1:349–55. https://doi.org/10.1038/s41929-018-0067-8.

Halim J, Cook KM, Naguib M, Eklund P, Gogotsi Y, Rosen J, Barsoum MW. X-ray photoelectron spectroscopy of select multi-layered transition metal carbides (MXenes). Appl Surf Sci. 2016;362:406–17. https://doi.org/10.1016/j.apsusc.2015.11.089.

Cai P, He Q, Wang L, Liu X, Yin J, Liu Y, Huang Y, Huang Z. Two-dimensional Nb-based M4C3Tx MXenes and their sodium storage performances. Ceram Int. 2019;45:5761–7. https://doi.org/10.1016/j.ceramint.2018.12.042.

Peng C, Xie X, Xu W, Zhou T, Wei P, Jia J, Zhang K, Cao Y, Wang H, Peng F, Yang R, Yan X, Pan H, Yu H. Engineering highly active Ag/Nb2O5@Nb2CTx (MXene) photocatalysts via steering charge kinetics strategy. Chem Eng J. 2021. https://doi.org/10.1016/j.cej.2021.128766.

Su T, Peng R, Hood ZD, Naguib M, Ivanov IN, Keum JK, Qin Z, Guo Z, Wu Z. One-step synthesis of Nb2O5/C/Nb2C (MXene) composites and their use as photocatalysts for hydrogen evolution. Chemsuschem. 2018;11:688–99. https://doi.org/10.1002/cssc.201702317.

Khakbaz P, Moshayedi M, Hajian S, Soleimani M, Narakathu BB, Bazuin BJ, Pourfath M, Atashbar MZ. Titanium carbide MXene as NH3 sensor: realistic first-principles study. J Phys Chem C. 2019;123:29794–803. https://doi.org/10.1021/acs.jpcc.9b09823.

Gao G, O’Mullane AP, Du A. 2D MXenes: a new family of promising catalysts for the hydrogen evolution reaction. ACS Catal. 2017;7:494–500. https://doi.org/10.1021/acscatal.6b02754.

Majhi SM, Ali A, Greish YE, El-Maghraby HF, Mahmoud ST. V2CTx MXene-based hybrid sensor with high selectivity and ppb-level detection for acetone at room temperature. Sci Rep. 2023;13:3114. https://doi.org/10.1038/s41598-023-30002-6.

Yan J, Wu G, Guan N, Li L. Nb2O5/TiO2 heterojunctions: synthesis strategy and photocatalytic activity. Appl Catal B. 2014;152–153:280–8. https://doi.org/10.1016/j.apcatb.2014.01.049.

Jia J, O’Brien PG, He L, Qiao Q, Fei T, Reyes LM, Burrow TE, Dong Y, Liao K, Varela M, Pennycook SJ, Hmadeh M, Helmy AS, Kherani NP, Perovic DD, Ozin GA. Visible and near-infrared photothermal catalyzed hydrogenation of gaseous CO2 over nanostructured Pd@Nb2O5. Adv Sci. 2016. https://doi.org/10.1002/advs.201600189.

Mähne H, Berger L, Martin D, Klemm V, Slesazeck S, Jakschik S, Rafaja D, Mikolajick T. Filamentary resistive switching in amorphous and polycrystalline Nb2O5 thin films. Solid State Electron. 2012;72:73–7. https://doi.org/10.1016/j.sse.2012.01.005.

Liu Y, Xiao H, Goddard WA. Schottky-barrier-free contacts with two-dimensional semiconductors by surface-engineered MXenes. J Am Chem Soc. 2016;138:15853–6. https://doi.org/10.1021/jacs.6b10834.

Koh HJ, Kim SJ, Maleski K, Cho SY, Kim YJ, Ahn CW, Gogotsi Y, Jung HT. Enhanced selectivity of MXene gas sensors through metal ion intercalation. in situ X-ray diffraction study. ACS Sens. 2019;4:1365–72. https://doi.org/10.1021/acssensors.9b00310.

Zhou T, Zhang P, Yu Z, Tao M, Zhou D, Yang B, Zhang T. Light-driven, ultra-sensitive and multifunctional ammonia wireless sensing system by plasmonic-functionalized Nb2CTx MXenes towards smart agriculture. Nano Energy. 2023. https://doi.org/10.1016/j.nanoen.2023.108216.

Acknowledgements

This research was partly supported by the Japan Society funded the present work for the Promotion of Science (JSPS) Grant-in-Aid for Scientific Research (Nos. 20H00297), Iketani Science and Technology Foundation (0351132-A), and by the Dynamic Alliance for Open Innovations Bridging Human, Environment and Materials, the Cooperative Research Program of “Network Joint Research Centre for Materials and Devices.”

Funding

Iketani Science and Technology Foundation, 0351132-A,0351132-A, Dynamic Alliance for Open Innovations Bridging Human,Environment and Materials, the Cooperative Research Program of “Network Joint Research Centre for Materials and Devices.”, Japan Society for the Promotion of Science, 20H00297, 20H00297

Author information

Authors and Affiliations

Contributions

AO, TH and SY conceptualized and designed the study, while MY managed sample preparation and the collection of experimental data. AO authored the primary manuscript text and produced all figures and tables. All authors participated in editing and proofreading the manuscript. AO, TH, TU, SHC, TS, and SY oversaw project management and secured funding. All Authors read and approved the final manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests associated with this manuscript.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Okawa, A., Yang, M., Hasegawa, T. et al. Gas sensing performance of Nb2CTx synthesized by hydrothermal assisted in-situ HF generation etching method. Discov Mater 3, 12 (2023). https://doi.org/10.1007/s43939-023-00048-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s43939-023-00048-4