Abstract

Advancements in material science have led to the development of new composites and biomaterials. Spider silk and human collagen are examples of animal-derived polymers for which sourcing has been challenging. Interest in strong, sustainable products derived from these biopolymers and increasing demand in bio-based solutions are driving forces for investments in non-animal-based production processes namely for use in biomedical applications. An outline of the current landscape of microbial-based bioprocesses is a useful tool to guide further development of novel biomaterials based on these proteins. While bioproduction can deliver a sustainable source for human collagen and for spider silk, it has been challenging to obtain the desired products via microbial-based bio-industrial processes. Optimization through improvements in upstream processes and better adapted large-scale downstream process steps, including replacing chromatography steps with freeze drying and autoclaving for endotoxin removal (silk) and filtration (collagen) has enabled large-scale production and recent capacity expansion of manufacturing, aiming to deliver hundreds of tonnes of product per year. This article reviews the considerable advances that were made in microbial processes for production of human collagen and spider-silk based biomaterials in the past 30 years in translating the laboratory results into scalable processes. Main challenges for successful large-scale implementation—such as recombinant silk durability and the continuous need to improve process economics—and main opportunities such as demand growth of recombinant spider silk and human collagen are outlined.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Silk and collagen are two protein biopolymers of animal origin with wide applications in industry and in medicine. Silk, a protein produced by insects, spiders, and molluscs, is used as a textile fibre (mainly, silk from the silk moth Bombyx mori, and also other “native” silk types) and has applications in the electronic, aeronautical, cosmetics and medical industries [1]. As a biomaterial, silk presents excellent mechanical properties, such as the combination of tensile strength with extensibility, biodegradability and compatibility with technical applications. Spider silk in particular has very interesting properties such as its tensile strength, comparable to steel. Driven by its remarkable properties of fibre strength, flexibility and stretchability compared to silk-worm silk, there has been increased interest and research in spider silk use in bioengineering, automobile manufacturing, advanced composite construction materials and its continued use in various medical applications. (extensively reviewed in [1, 2]).

Collagen is the most abundant protein in animals and the main component in leather. Animal-derived collagen is used in the food industry, as well as its denatured form gelatine which, traditionally, derives from connective tissue as a by-product of meat rendering. In the food industry, gelatine is used to form gels, gums, emulsifiers and as a polyelectrolyte to aid flocculation. Animal-derived collagen and gelatine are also widely used in the pharmaceutical industry, e.g., as a binder in tablets and manufacture of capsules for supplements and pharmaceuticals and in the cosmetic and nutraceutical industries [3, 4]. Animal-derived collagen and collagen derivatives are also used as scaffolds and sponges in regenerative medicine (see for example [3]), although there are challenges connected with their use, such as the risk of adverse immune reactions [5]. Human collagen has multiple medical applications, but one of the limitations is sourcing.

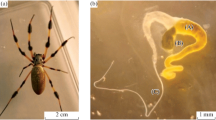

Figure 1 depicts the various silk and collagen related products used in industry. As mentioned, sourcing is a challenge for human collagen and also for spider silk: due to their cannibalistic behaviour it has not been possible to domesticate spiders (see for example [6]).

As more applications are developed for spider silk [2], and the medical need for human or “human-like” collagen continues, research becomes constrained for lack of raw material, resulting in increased interest in alternatives such as recombinant solutions. A trend to avoid animal-derived products is contributing to this interest as well.

There are common challenges for recombinant production of this type of fibre forming protein biopolymers, such as the length and repetitive nature of the native polymers, which has been difficult to replicate in recombinant systems and poses specific challenges in microbial systems, as well as aspects of biosynthesis and “post-production” modifications, important for the sought qualities of the end product [4]. A range of solutions has been developed to deal with these challenges.

At the molecular level, both proteins include long stretches of internally repetitive amino acid sequences and both are modular in nature, their highly repetitive consensus amino acid sequences containing specific structural motifs. The different combination of these conserved motifs directly affects the mechanical properties of the fibres [7].

This review focusses on and tracks the progress in microbial-based production of recombinant collagen (mainly human collagen) and of spider silk, over the past three decades, and points to the breath of strategies deployed to reach the current status in industrial scale bioproduction for these two biopolymers of animal origin with widespread interest for use in medical applications as well as large volume industries (as illustrated in Fig. 1). Various other technology platforms have been tested, including expression of recombinant spider silk elements in transgenic animals, Bombyx mori (Kraig Biocraft Laboratories, cited in [1]) and in transgenic goats (Nexia Biotechnologies, cited in [8]) and expression of recombinant collagen in transgenic B. mori [3] and in transgenic plants (reviewed in [4]). These have recently been reviewed and while they will be referred to in the discussion for the purposes of contextualizing current development, they are not the main theme of this review.

1.1 Natural sources of spider silk and collagen

Currently, many biomaterials in use have animal sources, which are inherently variable and therefore challenging to standardise. In general, standardisation is important for product reliability in particular in industries like the pharmaceutical and biomedical industries (see for example Food and Drug Administration (FDA) and European Medicines Agency (EMA) regulations). For biomedical applications, animal-derived materials carry further process requirements related to e.g. ensuring elimination of potential infectious agents (these can also be found in the FDA and EMA regulations and guidelines for use of animal derived materials for manufacturing of medical products). This context provides an incentive for the search for recombinant production schemes for some of these animal-sourced products. Recombinant products can offer advantages such as improved standardisation and versatility in molecule design. Microbial-based production can be more environmentally balanced and more sustainable than current production processes for these materials. The potential for using recombinant versions of these animal-derived products as raw materials in industries requiring large volumes and/or high consistency motivates the investment in developing production alternatives.

An understanding of how collagen and silk biosynthesis takes place in their natural producing organisms can reveal how nature has solved some of the process challenges in “bioproduction” and serve as inspiration for design of bioprocessing operating units. While, as mentioned, there are similarities between the two proteins at the molecular level, and both proteins form fibres, the natural processes leading to the mature fibres of each polymer is very characteristic and needs to be translated in different process approaches. For example, while in vivo dragline spidroins, are stored in highly concentrated solutions (dope) by specialized organs and mechanisms in the spiders [9, 10], collagen molecules require extensive biochemical modifications in order to form the elemental triple helices characteristic of this class of protein, which is further assembled in supramolecular tissue formats [11]. A brief description about the natural biosynthesis processes for each spider silk and collagen follows.

1.1.1 Spider silk

Spiders make various silks (i.e., different proteins) with a variety of mechanical properties (see for example review by [1]). The research focus has been on the spider dragline silk, produced by spiders in a pair of major ampullate glands.

Figure 2 (reproduced from [10]) provides a schematic representation of the spider major ampullate gland, where its three distinct portions—the tail, the sac and the duct—can be distinguished. The cells in the proximal part of the sac produce spidroins (spider silk proteins) and the duct epithelium, with diameter narrowing from about 100 μm to < 10 μm at the spigot, is covered in its complete length with a cuticle. This part of the major ampullate gland is important in formation of the silk fibres, though the exact mechanisms involved in fibre spinning are still being discussed [9, 10].

(Adapted from [10])

Macroscopic aspect of a major ampullate gland with Duct, Funnel, Sac and Tail identified

1.1.2 Human collagen

Unlike spider silks, collagen molecule are not produced in specialized organs, instead, many types of cells in a tissue produce collagen and secrete it to the extracellular space where, in the case of fibrillar collagens, the molecules are assembled in fibrils [11]. Initial fibril events are thought to occur at the cell-surface. Various types of collagen seem to be involved in forming fibres. It is important to recall that collagens are the most abundant components of the extracellular cell matrices in animal tissues. Apart from the characteristic triple chain, their structure and composition vary amongst tissues, with 28 different types of human collagen having so far been characterised [11].

1.2 Structure of the natural proteins

As mentioned above, the spider silk proteins and fibrillar collagens both present very long (more than 1000 amino acid residues) amino-acid sequences, with three distinct regions: a non-repetitive N terminal domain, a long repetitive, modular domain, and a non-repetitive C-terminal domain (broadly reviewed, more recently in for example [1, 3, 4, 9, 11]).

1.2.1 Silk and fibrillar collagen: protein structure

In spider silk molecules, globular N and C terminal domains flank the internal repetitive domains which are very rich in the amino acid residues Glycine and Alanine, which stretches of polyalanine interrupted by Glycine-rich repeats [9].

Major ampullate gland spidroin, the most studied spider silk, is formed by two proteins, MaSp1 and MaSp2, which seem to be translated from evolutionarily related genes [12].

Most microbial bioproduction processes focus on production of the linear portion of MaSp1, where gene design has been conditioned by the limitations of the microbial hosts in producing long and repetitive sequences, as will be seen further in this review. Thus, sequence modules that confer desired properties to the end material have been identified and used as tandem repeats, to design “spider silk inspired” synthetic genes (for example [13]). One team refers to the manipulation of the amino acid composition as a strategy to influence the mechanical properties of the recombinant silk [14] and recently, it was shown that the multicomponent nature of dragline silk, which includes MaSp1 and MaSp2, is key in order to achieve its mechanical properties [15]. This type of information can be of interest for the development of novel engineered materials.

Engineering solutions that are adapted to the fermentation and downstream processes had to be developed. Hence, while it has not always been possible to mimic the native production process, a deeper understanding of what parameters influence silk fibre formation has contributed to the developments in recombinant spidroin production.

The hallmark of collagens is its characteristic triple helix. These triple tight helical domains have varying lengths of tri-amino acid repeats Glycine-X–Y, where Y and X are any amino acid, and frequently hydroxyproline and proline, respectively [11]. Figure 3, adapted from [11], depicts the basic collagen molecule, with its N’ and C’-terminal domains, flanking the long highly repetitive region, and presents the current understanding of the intracellular processing of collagen molecules and the formation of the triple helix, with export of the procollagen molecule, which is further processed to collagen extracellularly. In their native setting, all fibrillar collagens are initially synthesized intracellularly as precursor molecules that contain large amino- and carboxy-terminal propeptides and are targeted to the rough endoplasmic reticulum (RER), where post-translational modifications take place, leading to the assembly of procollagen molecules (reviewed by [16]). In the lumen of the RER, particular lysine and proline residues within the collagen propeptides are hydroxylated by lysyl and prolyl hydroxylase enzymes to promote the stability of the triple helices following formation, resulting in a mechanically stable fibril [17]. The exact mechanism that controls the stabilization of the triple helix has been the focus of much research. The current consensus suggests that increased stabilization is partly due to increased interchain hydrogen bonds through hydration networks and electrostatic interactions between lysine residues. Following lysyl and prolyl hydroxylation and O-linked glycosylation, α-chains associate to form procollagen and triple helix trimerization is initiated by the association of the C-propeptide domains (see [11] for a detailed description). Procollagen is packaged in the Golgi apparatus for export into the extracellular matrix. Following or during secretion of procollagen, proteolytic processing of the large NH2- and COOH-propeptide domains leads to the production of mature collagen molecules that then self-assemble into fibrils of diameters between 0.5 and 3 μm [18]. Enzymatic removal of the propeptide domains is carried out by collagen type-specific matrix metalloproteinases (MMPs), as well as by furin-like proprotein convertases [19]. If the C-propeptide remains attached, procollagen solubility in the extracellular space remains high, which inhibits premature fibril assembly; on the other hand, the persistence of the N-propeptide influences fibril shape and diameter, without affecting fibril formation. To form mature collagen fibres, further modifications are made during the assembly of collagen fibril aggregates. In the final step of collagen biosynthesis, covalent crosslinks are introduced into the supramolecular assembly to provide stability and enhanced mechanical properties.

(This figure is reprinted with permission from [11], Nature Reviews Molecular Cell Biology)

Collagen structure and formation. The standard collagen molecule has amino-(N) and carboxy-(C) terminal propeptide sequences, which flank a central domain of Gly-X–Y repeats where X and Y are frequently proline and hydroxyproline (1). Three α-chains (the figure shows an example of heterotrimer, which is representative of type I collagen) are intracellularly assembled into a triple helix after initiation of this process by the C-terminal domain (2). Procollagen is secreted into the extracellular space (3) and converted into collagen by cleavage of the N- and C-propeptides via metalloproteinases (4)

The characteristic collagen triple helix is formed by three protein monomers named “α chains”. The molecule can be a homotrimer where the α chains are all similar, or a heterotrimer, where one (usually) or all the α chains are different from each other. The most abundant human collagen is type I collagen, a heterotrimer where the triple helix is formed with two similar and one distinct alpha chains [11]. Collagen type I is most abundant in the extracellular matrix (ECM) of skin, muscle, tendon (about 80–90%) and, together with collagen types II and III (both homotrimers) [4], has been the target of most of the efforts to obtain a recombinant product. Other collagens, although present in lower amounts, have important regulatory roles in for example fibril formation, as mentioned [11].

Interactions between the various collagens, as well as among collagens, proteoglycans and crosslinking enzymes result in a broad range of tissue-, stage- and age-differences in both fibril composition and structure, adapted to specific biochemical, structural and biomechanical roles. Further understanding the structure–function relationships and the roles of the various forms of collagen can guide engineering of future recombinant collagen-based products for the various applications sought.

2 Microbial production of recombinant silk and collagen

In the following sections, the main processes used in the production of recombinant silk and collagen by microbial fermentation are presented in a systematic and non-extensive fashion. Production methods at lab-scale and process steps already being employed at industrial scale are reviewed in chronological fashion. The host organisms are separately mentioned, with some considerations about advantages and disadvantages of each type of host, in terms of the relevant properties of the final product, such as mechanical properties and process yield. Table 1 summarizes the main sources of carbon used (C-source), and what expression inducer was used. While laboratory-based processes tend to use more expensive ingredients, such as Isopropyl β-d-1-thiogalactopyranoside (IPTG), for industrial production it is important if possible, to replace them with cheaper alternatives.

Common process stages comprise gene cloning, protein expression (Upstream process—USP) and protein purification (downstream process—DSP). The published literature shows that all three stages were extensively researched and that viable industrial processes combine many incremental improvements in all stages: many groups worked on optimizing the design of the genes and engineering the host organism, others have performed research into optimizing growth and gene induction conditions, and a large volume of work went into developing scalable economic DSP. Industry research teams have made strong contributions to finding solutions for large-scale production of these biopolymers, in addition to the pioneering and consistent work of academic research teams. Amongst the most academic teams most active in these fields, the Kaplan team at Tufts and the Hedhammar team in Sweden developed bioprocesses to produce a variety of polymers with silk-mimicking properties including fibre formation and went on to test the recombinant products in a range of settings, and the Myllyharju team in Finland who developed the first human recombinant collagen bioproduction processes, as will be seen throughout this review.

2.1 Recombinant silk

The first stage in developing the bioprocess starts with identification of the natural deoxynucleic acid (DNA) sequence of interest, design and production of synthetic silk genes for the protein expression in the producing organism. Further host engineering, such as increase of the pool of specific transfer ribonucleic acids (tRNAs), or introduction of enzymes needed for processing the recombinant gene construct may also be performed. This section describes each of the process steps at its best, to highlight the main challenges that were overcome over the years of optimization, before diving into the detail of the earlier efforts for optimization.

For industrial bioproduction, Escherichia coli is one of the most widely used organisms due to economically viable cell growth, high cell density, ease of manipulation and often it is also used for proof of concept at laboratory scale [20, 21]. E. coli has also been used for recombinant spider silk production. In general, the engineered bacterial cells containing the synthetic genes are cultured in fed-batch mode bioreactors and the produced silk proteins are extracted after high-density fermentation. A chromatography-free DSP comprising cell lysis by urea and thiourea, acetic acid and ammonium sulphate precipitation and subsequent resolubilization and freeze drying has been developed, with subsequent storage of the purified silk in a lyophilized state, and extrusion for the desired formation of silk fibres [22].

2.1.1 Small-scale production

Since the late twentieth century, many research teams have tried, with relative success, to establish and optimize production methods capable of delivering the large quantities of recombinant spider-silk proteins that would be needed for industrial applications. Table 2 summarizes the evolution of the improvements made to the three process stages over the last three decades, highlighting the improvements sought in each of the steps, if applicable.

Fahnestock and Irwin [23] designed synthetic genes to encode expression of analogues of two dragline silk proteins, Masp1 and 2, in E. coli. Using LB medium, induced with IPTG and clarified with centrifugation, with DSP steps including ion-exchange chromatography followed by methanol precipitation, the process resulted in a titre of 300 mg/L (mass of protein per volume of culture) and a purity greater than 90% [23]. However, in order for the process to be developed for the scales needed in commercialization, both USP and DSP yields would need to be optimized.

Several years later, Xia et al. [22] optimized the DSP, replacing the chromatography step with purification by dialysis and freeze drying. Furthermore, this group engineered the expression host to elevate the glycyl tRNA-pool, a strategy that proved to be beneficial for the synthesis of high molecular weight products with an improved yield of 1.2 g/L and purity of, approximately, 90%, using glucose as carbon source [22].

Recombinant technology often makes use of small protein tags, used as affinity tags, to simplify DSP. Genes designed for bioproduction of silk included such tags. Dams-Kozlowska et al. [24] focused on assessing the cytotoxicity of recombinant spider-silk proteins by expressing it in E. coli without the additional N-terminal His-Tag/Thrombin/S-Tag/enterokinase purification sequence, since presence of the tag might also influence the mechanical properties of the final product. This approach yielded 100–200 mg/L of protein, using propionic acid purification followed by the application of an anion exchange resin to recover the silk proteins. Contamination by the pyrogenic agent lipopolysaccharide (LPS), an endotoxin, due to use of E. coli as the expression host was observed, despite its concentration being reduced two to three times with the ion exchange resin, bringing an additional challenge to the feasibility of large-scale processing [24]. In this publication, the authors did not work on increasing the fermentation yield per se, rather focused on studying the cellular toxicity of the purified recombinant product in potential future biomedical applications.

More recently, remarkable high-yield production of dragline silk proteins with elevated expression levels of major ampullate spidroin 2 (MaSp2), responsible for the elastic properties of silk, was obtained in E. coli by a combination of downshifting the induction temperature from 30 to 16 °C in a fed-batch bioreactor, using a tRNAGly overexpression plasmid in order to address the very high Glycine (Gly) content of the silk proteins, and using glucose as the carbon source [25]. By applying this strategy, the USP silk yield reached approximately 3.6 g/L, the highest yield reported to date with bacterial recombinant spider silk production and an improvement on previous findings showing potential for the development of a commercially viable biomanufacturing process [25]. Working on one aspect of product quality for medical applications, Decker et al. [26] found that the treatment of a lab-scale batch of bacterially-derived spider silk proteins in the dope stage by triple autoclaving leads to endotoxin levels lower than 0.25 EU/mL, which corresponds to the FDA limit, without compromising its mechanical properties when compared to alternative methods such as dry heating or ion-exchange chromatography [26].

Despite the major contributions and improvements in lab-scale production of recombinant spider silk, two important issues with the bacterial production, to date, still stand: the discrepancy in the codon usage of the host organism relative to that of the spiders and the repetitiveness of the genetic structure of spidroins [27], which results in much smaller recombinant products using bacteria and in incomplete expression of silk genes [28].

Various research teams attempted to seek alternative host organisms, with Pichia pastoris posing as the most promising option due to (a) its ability, as a eukaryotic organism, to perform post-translational modifications to the silk proteins, thus avoiding the need for engineering of the production host and (b) simpler DSP, due to the absence of endotoxins [29]. Additionally, it has been shown that a yeast methanol-inducible promoter, alcohol oxidase 1 (AOX1), is responsible for the organism’s capacity in metabolizing methanol as a carbon and energy source. This promoter was used for the construction of a production vector, together with a secretion signal and the histidine dehydrogenase (HIS4) selectable marker gene [30, 31], enabling the full-length expression of the heterologous recombinant silk, which had not been the case with E. coli [32, 33].

As a complement to their prokaryotic approach, Fahnestock and Bedzyk [34] were able to produce higher levels of high-molecular-weight proteins by testing also P. pastoris as the host organism and using a glycerol/methanol fermentation medium. The protein yield was 663 mg/L, which is more than twofold the yield obtained with E. coli by the same team, and product length was as expected from the gene construct. However, some problems were found in the purification process due to intracellular aggregation of the silk proteins [28, 34]. In 2008, using fed-batch in minimal basal salts medium, Werten et al. [13] efficiently produced in P. pastoris a 28 kDa silk-like protein consisting of 48 repeating (GA)3GE octapeptides, with self-assembling behavior and pH-responsive properties at acidic pH due to the presence of glutamate residues. Purification by isoelectric precipitation and subsequent ethanol precipitation to remove the remaining host proteins lead to a process yield of, approximately, 3 g/L. Additionally, an amphiphilic variant of the silk protein with 56 octapeptides was produced by the same group, with an associated yield of, approximately, 1 g/L after purification with formic acid [13]. No comparison was made to previous works in terms of the recombinant product size, though. The synthesis of [(GA)3GX]n variants has proved to be useful for biomedical applications as a self-assembling module in several block copolymers to form, for instance, the coating of surgical implants [35].

Jansson et al. [36] investigated the use of P. pastoris for production of a 32 kDa recombinant spider silk fusion protein with the Z domain of Protein A, Z-4RepCT, which had already been intracellularly produced in E. coli and could bind antibodies via the Z-domain [37]. This team had been studying ways of adding functionalization to the recombinant silk, for further biological applications, by introducing known binding domains from other proteins. The protein construct tested in P. pastoris consisted of four consecutive poly-Ala/Gly-rich repeats and the non-repetitive C-terminal (CT) domain, from the Euprosthenops australis spidroin, and was produced in methanol-induced shake flask cultures [36]. Addition of a CT domain had not been included in any previous study. Even though the purification of secreted Z-4RepCT yielded a partially degraded protein, due to glycosylation of the CT domain and proteolytic cleavage of a position in the C-terminal domain of Z-4RepCT by proteases in the culture supernatant, Z-4RepCT purified from the intracellular fraction was shown to retain self-assembling properties after enzymatic deglycosylation [36]. Self-assembling is an inherent property of natural silk proteins which enables the formation of a fibril-like material inside the spider’s spinning gland, and it is therefore an interesting property to retain in recombinant spidroin-inspired products.

In spiders, it has been suggested that the cuticle lining the duct has a role in dehydrating the forming silk fibre. However, discussions are still ongoing as to the exact mechanisms responsible for spider silk fibre formation. There has been evidence that changes in the chemical environment of the silk are partly responsible for initiation of the fibre forming process [10]. Other teams contended that shear forces convert the protein from random coil and alpha helical domains predominant in the “storage” (dope) step to a predominantly beta-sheet formed fibre [38]. In native production of spider silk, small amounts of silk are stored inside the animal in liquid phase, as dope, and processed upon extrusion [39]. In the current industrial processes, recombinant silk is first purified as a powder and it is later processed to form, for example, fibres, or other formats adapted to further use [40, 41]. Under in vitro conditions, self-assembling has been promoted via treatment step in ethanol by [13], as described above, and also by artificial spinning through a microspinneret by [42], which could enhance the development of downstream processing spinning technology for large-scale fibre production.

Besides recent contributions with P. pastoris, Sidoruk et al. [43] achieved optimal protein expression with a system based on engineered strains of the S. cerevisiae yeast. The two-stage USP included yeast growth on a medium consisting of yeast extract, peptone and sucrose, followed by a pH–stat phase between pH 6 and 7 via 12% ammonium solution and 20% phosphoric acid and subsequent growth in a 68–72 h’ fermentation. It was found that, after optimizing concentrations of yeast extract and peptone and replenishment schedule, the yield of produced spidroin-like protein increased by, approximately, 60% when compared to the non-optimized value of 2.6 g product/kg of biomass. No other publications using S. cerevisiae were found prior to this, perhaps related to the lack of tightly-regulated promoters in this yeast [44]. It has also been demonstrated that a P. pastoris-secreted protein is mannosylated to a lesser extent than that of a S. cerevisiae—the terminal α1,3-mannose linkages, which are present in S. cerevisiae glycoproteins, have been shown to be immunogenic [45]. Furthermore, the enzyme invertase is secreted by P. pastoris with must faster kinetics than when using S. cerevisiae secretion signal, which could affect the glycosylation pattern of the synthesized protein, suggesting that P. pastoris may be a more adequate host for spider silk production [46].

2.1.2 Large-scale production

Large-scale production of recombinant silk started in the early twenty-first century being developed by a Canadian company named Nexia Biotechnologies, who mainly focused on manufacturing recombinant proteins for use in biomedical and military products such as artificial tendon ligaments and bullet-proof vests. Nexia had rights to patents covering spider silk genes and proteins. Scientists of both Nexia and U.S. Army laboratories reported, in 2002, the synthesis of silk proteins by transfection of the spider silk gene from Nephila clavipes into bovine and caprine mammary cells, that had mechanical properties similar to those of spider silk [8]. In Nexia’s process, West African dwarf goats were used to generate sexually active transgenic goats that produced milk containing the spider silk, which was centrifuged for fats and cream removal at the initiation of DSP. Subsequently, salts were added for protein precipitation and the silk protein was then dissolved from the pellet in an aqueous solution and turned into a silk concentrate. Finally, the wet silk went through an extruder to produce a continuous strand of a high strength, high toughness fibre material trade-named Biosteel™ [47] which presented several advantages—including an optimized spinning process for a wide range of applications—when compared to bacterial and yeast-derived recombinant spider silk produced to that date. With its transgenic goat technology, Nexia Biotechnologies tried to provide increasing quantities of Biosteel™ for product development and commercialization through a collaboration agreement with Acordis Speciality Fibres Ltd for a fibre spinning process [48]. However, the company failed to produce recombinant silk at an industrial scale and went bankrupt in 2009, leaving the transgenic spider silk goats research to a Utah State University laboratory.

Nowadays, commercial Biosteel is produced by a company named AMSilk, a leading industrial supplier of silk biopolymers produced via bacterial fermentation with E. coli, founded in 2008, by a spin-off of the Technische Universität München. In this process, based on findings from the laboratory of Bayreuth University biomaterials Professor Thomas Scheibel [49], glucose syrup is fed to genetically modified E. coli bacteria cells for bioproduction in bioreactors of more than 50 m3 capacity [50]. Thereafter, the product is subjected to spray-drying from which 100% pure silk is obtained in the form of a white powder and dissolved in aqueous solution. Finally, the liquid is pushed through a spinneret to create the filaments that form the base of the Biosteel fibre. AMSilk’s product was used to make a biodegradable running shoe, developed in collaboration with the sports equipment company Adidas, and a spider-silk based composite material for the aerospace industry, produced in a partnership with Airbus [51]. Since 2015, AMSilk has a collaboration with Natura Cosméticos, the largest cosmetics manufacturer in South America, using biomimicry for applications in hair treatment containing the recombinant spider silk, which culminated, in 2018, with the QLICAR award for best technology innovation of the year [52]. In April of 2019, Givaudan, a large Swiss manufacturer of flavours, fragrances and cosmetic ingredients, as part of its 2020 strategy to expand the Active Beauty business of the company, reached a deal to acquire the cosmetics business of AMSilk. The terms of the deal have not been disclosed [53].

A similar fermentation process for production of recombinant spidroins via E. coli has also been developed by Spiber Inc., a Japanese biomaterials company established in 2007 which is engaged in the research of protein-based materials for applications in medical equipment, clothing and automobiles. After several years focusing on process industrialization, the company announced, in 2013, the production of the spider silk-like fibre via bacteria-based fermentation of sugar in a bench-scale facility with further plans for scaling up. In this process, once fermentation is completed, the protein is separated from the microorganisms and dried into a protein powder which is dissolved in a dope for further extrusion from a nozzle, from which the silk fibre is obtained [41]. In the same year, an automotive parts manufacturer in Japan collaborated with Spiber Inc. to build a plant capable of producing 100 kg/month of Spiber Inc. recombinant spider silk-based fibre. The production was expected to increase to 10 tons/year in 2015, though it has not been possible to confirm if this scale was obtained [54]. Commercial production of Brewed Protein™, which refers to bio-based spider silk produced by the company, is set to start in 2021 in Rayong, Thailand, using molasses provided by the local sugarcane producers in Thailand as the carbon source. The new large production plant has a planned maximum capacity of several hundred tonnes per year—100 times larger than the current plant capacity in Japan—and is expected to be the world’s largest structural protein fermentation facility, with initial plans to wholly export the protein to Japan for fiberization [55,56,57]. In addition, Spiber Inc. has recently secured $240 M investment for its affiliated company Spiber America LLC. to collaborate with the Archer-Daniels Linseed Company, a provider of agriculture-derived fermentation products, to alter a local biorefinery in Clinton, Iowa, which will be designed to produce about 10 times as much Brewed Protein™ as the Rayong facility in Thailand [58]. Spiber Inc. is currently collaborating with sports apparel maker The North Face to produce the first mass-manufactured Brewed Protein™ jacket via E. coli engineered silk [59].

Spiber Technologies AB, a Stockholm-based biomaterials company founded in 2008, focuses on developing technologies for the production of recombinant spider silk proteins Spiber® and SolvNT® for biomedical and life sciences applications [60]. In its production process, a portion of the spidroin protein gene is cloned into E. coli. Protein expression occurs in Luria–Bertani (LB) medium supplemented with kanamycin, using glycerol as the carbon source and IPTG as the expression inducer [61]. In order to obtain a product with low endotoxin content, after production, the bacterial cells undergo a washing step with CaCl2 and ethylenediaminetetraacetic acid (EDTA), followed by passage of the protein solution through an adsorbent column [62]. Silk fibres are then formed by pumping the protein solution through a glass capillary [63]. With two rounds of funding in 2012 and 2013, the company aimed to further improve its final product mechanical properties by optimizing the spinning apparatus and modifying the recombinant protein in order to increase the binding strength between molecules in the fibres [64, 65]. At the Testa Center, in Sweden, the company is currently studying the possibility of scaling up the current recombinant silk production process by optimizing the protein purification step and collaborating with the company BioLamina on developing products for biomedical applications [66].

Significant progress has also been made with the use of P. pastoris as the host organism for spider silk large-scale production by Bolt Threads, a Californian biotechnology start-up that focuses on synthesis and commercialization of its engineered silk—Microsilk™—for applications in the textiles industry [67]. Its production, launched in 2017, uses corn-derived dextrose as carbon source, leading to production of ethanol, which triggers the promoter driving transcription of the spider-silk genes [68]. After processing, the obtained protein powder goes through a dissolution-extrusion phase, similar to the AMSilk and Spiber processes. A spinline device is used to spin the final product into spools [69]. In 2017, the company announced a new partnership with fashion designer Stella McCartney, known for its role in promoting sustainability in fashion, for the production of a dress made with Microsilk™, in efforts to maximize the brand’s goals on combining innovation with sustainability [70].

In summary, the small-scale production of recombinant spider silk was firstly attempted using E. coli. Limitations such as incomplete expression of the recombinant protein and inability to produce long, highly repetitive polymers led to later testing in yeasts such as P. pastoris and S. cerevisiae, with the goal of attaining higher product yields with lower production costs. For recombinant production, replicating the impressive range of mechanical properties of natural dragline silk has been a challenge, Genes and process design has at times privileged properties such as self-assembly of the repetitive regions of the spider silk gene, which was found to be important for fibre formation in the natural setting. Other approaches have focused on developing a gene design and process steps that permit the formation of long and strong fibres. In the current industrial processes, recombinant silk is first purified as a powder and it is later processed from a “dope”, to form, for example, fibres, or other forms adapted to further use [40, 41]. Nowadays, both P. pastoris and E. coli are used for commercial large-scale production of recombinant spider silk-like polymers, with the manufacturers announcing new partnerships for the incorporation of spider silk in a range of industry applications and expanding their production capacity. While detailed information about the current industrial processes is scarce, a process summary could be as follows: design focusing on expression of long tandem repeats of the main gene region of the spider silk, utilize understanding of the correlation amino-acid composition/mechanical properties to design products adapted to the intended use, production of a pure, low in endotoxin dope and development of spinning processes to form fibres adequate to the goals of the various application industries.

2.2 Recombinant collagen

Given the broad use and interest in obtaining new sources of collagen, diverse strategies for recombinant production were tested, including production in microorganisms, which is the focus of this review, as well as use of mammalian cells, which naturally may produce collagen, or the use of plants as producing organisms. The very low yields obtained in mammalian production and the relative expense of these types of production systems were factors that hampered further development of these systems (reviewed by [4]). Nevertheless, in 2020, Jellatech, an American-based business-to-business biotechnology startup, announced the launch of an animal-free, cell-culture (mostly mammalian fibroblasts) based gelatine and collagen production lines, to further decrease the dependency on meat industry by-products and to deliver better quality gelatine and collagen in a more sustainable manner [71]. Efforts to develop plant-made recombinant human collagen (type I) started in the early twenty-first century and had relative success in producing small amounts of human recombinant forms of collagen in tobacco and in corn seeds (reviewed in [4]). One team has successfully produced bioactive post-translationally modified, heterotrimeric, human recombinant Type-I collagen in transgenic tobacco plants [72]. A company, PlantColl, has licensed the technology and is commercializing the product for use in cosmetics and in regenerative medicine. PlantColl is currently working on improving and scaling up the DSP.

In the following paragraphs, we describe the recent advances in microbial bioproduction of recombinant collagen in laboratory scale and then review the information published on large-scale production. Synthetic biology has recently emerged as an alternative strategy for collagen production that can circumvent current issues related to animal sourced collagen. Animal sources may carry prions, such as bovine spongiform encephalopathy (BSE) or potentially cause allergic reactions if used in medical settings, therefore making them clinically undesirable [5, 73].

The main improvement strategies used, over the past 30 years for the successive process steps are summarized in Table 3. First, is the design and integration in the producing host of the synthetic genes coding for collagen. Similar to silk, the collagen molecules have a highly repetitive core motif, and distinct C- and N-terminal regions. Unlike silk, however, collagen requires extensive post-translational modifications in order for the protein to form a stable fibre, resulting in the need to engineer the hosts with genes for the enzymes needed for processing the molecule to maturity, as described before. A further consideration is the fact that, currently, the fermentation results in intracellular accumulation of collagen, while in collagen is secreted from producing cells in the natural process. The current most developed DSP involves performing collagen extraction at low temperatures to minimize protein denaturation. Cell lysis by physical disruption is performed, and further purification steps include affinity chromatography [3] to obtain pure collagen. In some cases, processes were developed to produce gelatine rather than collagen. Gelatine, as we have described, can be obtained via partial hydrolysis of collagen, is formed with shorter molecules, its thermal stability and other physical properties are different from those of collagen and has multiple applications in industry as well as indicated in Fig. 1 and reviewed in [5].

2.2.1 Small-scale production

As mentioned, E. coli is one of the most widely used production hosts and has also been used as the host organism for recombinant collagen production. Given the complexity of the collagen molecules, in particular the post-translational modifications needed to stabilize the triple helices in the fibre, host engineering strategies needed to include steps to address those aspects. As in the previous section about recombinant spider silk production, the following paragraphs will describe first the most advanced outcomes from process development and optimization, before a more detailed chronological review of the various strategies followed by the research teams.

Du and collaborators [24] produced recombinant collagen-like proteins with a C-terminal 27-residue-long foldon sequence derived from the native T4 phage fibritin to stabilize the triple helix, with an additional His tag, using Terrific Broth (TB) at 37 °C and IPTG as the protein expression inducer. No accumulation of product in inclusion bodies was observed. The protein was purified by immobilized nickel chelate affinity chromatography with a yield of, approximately, 90 mg/L of culture. The group showed that the in vitro cell biocompatibility of these collagen-like proteins was better than that of native animal collagen, suggesting its potential as a medical biomaterial [24]. Thermal induction between 34 and 39 °C has proven to be critical to ensure steady presence of plasmid-harbouring cells at a lower temperature and to maximize protein expression at a higher temperature [75]. Guo et al. [76] applied these findings to recombinant E. coli BL21 producing human-like homotrimeric type II collagen in fed-batch cultivation. The team performed process optimization via metabolic-flux analysis (MFA) to investigate the mechanisms of protein production and of cell growth. The human-like collagen produced seems to form stable triple helices in absence of amino acid hydroxylation. However, these aspects were not discussed by the authors in this article, as they focus on fermentation yield optimization. In the study, three carbon/nitrogen molar ratios were employed, in both the preloading and feeding media. Fed-batch cultivations were carried out in a 12.8 L fermenter containing 6 L of initial medium, using glucose as the carbon source and, as indicated above, introducing step changes in temperature during the fermentation to induce protein expression, thus eliminating the need for a costly expression inducer such as IPTG. They achieved fermentation yields in the g/L scale. After fermentation, samples were centrifuged, washed with distilled water and dried in a 105 °C oven. The optimal carbon/nitrogen molar ratio for batch and feeding media were found to be, respectively, 2.36:1 and 5.12:1, resulting in a product yield of up to 10.8 g/L [76]. As far as we could understand, this team is continuing to scale-up and optimize production of this human-like recombinant collagen type II, for applications in regenerative medicine, although this work does not seem to have been published.

In an effort to overcome the lack of endogenous post-translational modifications in E. coli, which leads to an absence of hydroxyproline in prokaryotic collagen and, therefore, an unstable molecule, Rutschmann et al. [77] attempted to use bacterially active prolyl and lysyl hydroxylase enzymes from mimivirus to produce recombinant hydroxylated homotrimeric type III human collagen in E. coli. Protein expression in E. coli BL21 cells was induced by IPTG, and DSP included cell lysis and centrifugation. After protein purification by affinity chromatography, up to 90 mg/L culture of hydroxylated collagen was obtained with a proportion of prolyl and lysyl hydroxylation reaching 25% and 26%, respectively (for reference, in native human collagen, 42–54% of prolines are hydroxylated, see for example [4]). Circular dichroism revealed that hydroxylation increased the thermal stability of the recombinant collagen, as expected [77]. Peng et al. [78] developed a scalable procedure using acid precipitation of E. coli host proteins, followed by proteolysis to produce > 95% pure bacterial collagens with no need for chromatographic steps, which are expensive to implement at very large scale and thus considered unsuitable for production at industrial scale. In that work, constructs based on three different bacterial collagen-like sequences from S. pyogenes, Methylobacterium and S. usitatus were generated and expressed in E.coli, with glucose as the carbon source and IPTG for protein expression induction. After cell recovery via centrifugation and removal of impurities by acid precipitation, the obtained supernatant was treated via proteolysis. Fractions containing the triple helical collagen were concentrated and freeze-dried, yielding 19 g/L of dried product [78]. This method can be adapted for large-scale commercial processes and is applicable to other recombinant bacterial collagens. However, to date, we have not found publications describing such work.

Besides E. coli, the use of yeast such as P. pastoris and S. cerevisiae as hosts for expression of recombinant collagen has been investigated, as these eukaryotic organisms might potentially allow the production of larger quantities of fully hydroxylated recombinant human collagen when compared to prokaryotic hosts. In yeast, human prolyl hydroxylases were co-expressed with human collagen, since the organism lacks native prolyl hydroxylases (reviewed in [3]). Vuorela et al. [79] produced stable triple helical homotrimeric type III collagen with near native hydroxylation percentages in P. pastoris, reporting expression levels of, approximately, 15 mg/L, with absence of lysine hydroxylation. Fully active recombinant human prolyl 4-hydroxylase tetramer requires the presence of collagen polypeptide chains and leads to high-level production of recombinant collagen [79]. In an attempt to improve protein production yield in P. pastoris, the same team developed an expression system for the production of type I procollagen homo and heterotrimers and types II and III procollagens, which were expressed in 2 L bioreactors with a constant O2 supply system and subsequently purified by pepsin digestion and gel filtration, reaching a maximum expression level of 0.6 g/L. Here, a pepsin treatment is applied in order to convert procollagen into collagen, by cleavage in locations where the α-chains are not interacting to form a stable triple-helical structure, and to digest most of the other proteins present in the process. In addition, the same research group investigated heterotrimeric type I recombinant collagen production by co-expressing both subunits of prolyl 4-hydroxylase with the polypeptide chains proα1 and proα2 of collagen, which represented the most complex system for recombinant human collagen production described up until that date. Fermentation in a 2 L bench-top fermenter with glycerol as the carbon source yielded up to 0.5 g/L of recombinant collagen, similar to previously obtained expression levels, reinforcing previous findings in terms of achieving high-level production of recombinant collagen and suggesting further optimization of recombinant collagen production [80, 81]. Pakkanen et al. [82] engineered P. pastoris to express prolyl 4-hydroxylase in order to successfully produce hydroxylated triple-helical recombinant human collagen types I and III. Cell culture took place in shake flasks, in an initial buffered glycerol medium. Expression was performed in a feeding buffered minimal methanol medium for expression induction. Even though procollagen type I chains formed no homotrimers with stable triple helices, high production levels of stable heterotrimeric type I and homotrimeric type III recombinant collagen were obtained [92]. Ruottinen et al. [83] focused on controlling gene expression with the AOX1 (alcohol oxidase) promoter in P. pastoris, induced in the presence of methanol, to optimize stable human type II recombinant collagen production. In this study, application of on-line pO2 monitoring demonstrated that manual pulse feeding of methanol results in low expression levels of AOXI controlled genes due to long starvation phases after methanol exhaustion. A wireless feeding unit which allows the use of computer-controlled continuous feeding profiles was introduced, with pO2 and pH levels controlled by a SENBIT® transmitter. A tenfold increase in yield of stable recombinant human collagen II was obtained, when compared to the pulse method [83]. Taking a different approach, Ma et al. [84] attempted to optimize the parameters of fermentation media for production of collagen in P. pastoris. Initially, Plackett–Burman design was employed to identify the six significant process variables on cell yield: concentrations of yeast extract, peptone, methanol, yeast nitrogen base (YNB), ammonia sulphate and biotin. Three variables (concentrations of yeast extract, methanol and ammonia sulphate) were then identified to have critical impact on the production of collagen, upon employment of a Box–Behnken design by response surface methodology (RSM), and the optimum levels of 1.19% yeast extract, 1.18% peptone and 0.77% glycerol for the cell growth medium were found. Centrifugation and cell resuspension were used to induce protein expression. After 84 h of cultivation, an average production of 5.02 g/L was attained, suggesting the usefulness of statistical analysis for optimization of industrial processes [84]. Recently, Gellermann et al. [85] cloned and produced a non-hydroxylated gelatine mimetic protein based on the helical region of the α chain of human type I collagen, under control of the AOX1 promoter. Protein production took place in a 30 L bioreactor for 80 h, using glycerol as the carbon source and methanol as expression inducer, after which the supernatant was harvested by centrifugation. A polishing step was performed by passing the target protein through an anion exchange membrane, after dissolving it in tris–HCl, and a final yield of 3.4 g/L was obtained. The authors went on to demonstrate the potential of this collagen as scaffolds in cell culture, showing that it facilitates cell attachment and colonization of the substrate [85, 86].

Working with S. cerevisiae, Vaughan and collaborators [87] produced a recombinant hydroxylated fragment of homotrimeric type III human collagen by co-expressing a collagen gene fragment with the two subunit genes for human prolyl-4-hydroxylase. It consisted of 255 residues of the helical domain and the C-propeptide domains. Although the fragment was smaller than triple-helical domains found in interstitial collagens, high hydroxylation levels were obtained, indicating potential to make hydroxylated triple-helix-containing products for medical applications [87]. Toman and collaborators [88] firstly reported a multigene approach in Saccharomyces resulting in the assembly and non-native post-translational modification of type I human procollagen. In this work, four gene constructs—two for coding the polypeptide chains and two additional genes coding for the prolyl hydroxylase subunits—were required to generate a functional and thermally stable heterotrimeric triple helix. Optimization of the medium composition yielded procollagen expression levels of 3 to 4 μg/mg of total protein, with a key requirement for glutamate being identified as a medium supplement to obtain maximum production levels [88]. Chan [89] described a novel recombinant type III human collagen production strategy by designing oligonucleotides favouring correct hybridizations, during de novo gene assembly, for gene synthesis. In this work, mismatched hybridizations were removed by designing a computationally optimized algorithm which favours the organism preferences for codon usage. Engineered S. cerevisiae were cultured using glucose or galactose as the carbon source, with a subsequent purification step comprising cell lysis, pepsin digestion of collagen propeptides and elution via linear NaCl gradient. A final yield of 5.1 μg/mg of total protein was obtained with little optimization of the production levels, suggesting that the amount of collagen could increase with fermentation medium studies. However, proline hydroxylation levels of, approximately, 0.5% were lower than reported in previous studies, creating room for further improvement of hydroxylation by redesigning the gene engineering steps [89]. To the best of our knowledge, scaling up work of this process has not been published.

2.2.2 Large-scale production

Scaling-up of recombinant collagen microbial production processes has seen unprecedented growth in the last 5 years. Up to recently, all industrial-scale collagen for medical or pharmaceutical applications was animal-derived due to unsuccessful efforts to produce functional collagen-like molecules in either prokaryote or eukaryote cells. Geltor, an American start-up established in 2015, specializes in the use of microbial hosts for the production of animal-free gelatine [90]. The company is currently working with Gelita, a large provider of animal origin collagen products for nutrition, in the design, production and commercialization of recombinant animal collagen via fermentation process for direct application in the dietary supplement industry and has filed patents providing methods of producing non-natural collagen. US 2019/0153068 A1, for instance, provides a production method comprising E. coli cultivation under temperatures between 20 and 39 °C, for 30 to 40 h with neutral pH. For DSP, centrifugation and cell lysis is performed to release the recombinant proteins in the supernatant and a histidine tag purification step through a nickel column is mentioned [91]. Recent rounds of funding between 2018 and 2020 enabled the production of the first synthetic leather from recombinant jellyfish-like collagen and, with global demand of collagen expected to grow by 25%, the company scaled up 100 times its fermentation-based technology platform over 2019 [92].

Modern Meadow, a New Jersey-based corporation, develops biofabricated materials. The company began with an R&D initiative to develop a sustainable alternative to leather for textile applications [93]. One of its technology platforms relies on yeast to produce collagen molecules. Genetic modification by insertion of a kgtP (alpha-ketoglutarate permease) gene enables an ascorbate synthesis pathway to catalyze the protein hydroxylation [94]. In 2021, the company announced the formation of BioFabbrica LLC, a joint venture with Italian textile and materials company Limonta, to accelerate market-ready coating technology that can deliver high performance and unique functionality with improved sustainability [95].

In 2020, Evonik—a Germany-based leader in specialty chemicals manufacture—announced the implementation of an industrial biotechnology process for production of recombinant human-like collagen for pharmaceutical, medical, cell culture and tissue engineering applications. The company has communicated a total fermentation capacity of more than 4000 m3 to process over 25 products to the market, including highly pure and soluble collagen which avoids batch-to-batch variability, potential transmission of pathogens and other issues related with animal-sourced collagen [96]. In addition, a pilot plant for up- and downstream processing in Slovakia includes a continuous sterilization line with separator, nanofiltration and ultrafiltration units for protein purification.

In conclusion, recombinant collagen production using microorganisms was firstly attempted and studied in the industrial yeasts P. pastoris and S. cerevisiae by Myllyharju et al. with work published between 1997 and 2008 [79,80,81,82]. A bacterial pathway was also developed in E. coli and, in 2014 a improved purification step which yielded 19 g/L of > 95% pure dried protein was obtained [78]. However, these teams did not publish any research into scaling up these processes. Concerning large-scale production, several companies such as Geltor, Modern Meadow and Evonik have recently announced new partnerships and products in order to expand the markets where currently animal-derived collagen is used. Evonik has indicated developments within medical use of bacterial-derived collagen. The aim of producing human recombinant firbillar types of collagen at a scale adequate for medical applications has not been reached with microbial systems, even if microorganisms such as P. pastoris have been extensively studied. Other producing systems have meanwhile developed and the most advanced in producing fully hydroxylated recombinant human collagen type I has so far been the tobacco plant production systems [72].

3 SWOT matrix—spider silk and collagen bioproduction

As described in this review, recombinant spider silk production processes have seen major improvements in recent years, with the use of non-harmful solvents such as water in product purification step [69] and removal of endotoxins by an autoclave step [26]. The superior mechanical properties of spider silk [9] and the need for a sustainable production method have been driving continuous research and development efforts in process implementation for textile, medical engineering and automotive applications [97]. However, challenges in obtaining pure and durable recombinant spider silk, with mechanical properties similar to those of native spider silk, via metabolically engineered E. coli or yeast still remain and additional product refinement to reach the desired mechanical properties has been required, yielding a more expensive process. Nonetheless, it is clear that in the past 30 years of joint efforts, yields in expression of major ampullate-like spider silk in E. coli increased from the initial 300 mg/L [23] to 3.6 g/L [13, 25], and recombinant human collagen yields have gone from 15 mg/L in 1996 [79], to current 3–5 g/L [84, 85] in P. pastoris, representing a remarkable outcome for production of the recombinant forms of these complex biomaterials.

Given the interest in using this type of biomaterial, research into non-biological means of production has also been conducted to provide (non-biological) production alternatives. For example, in 2017, Wu et al. [98] drew a silk-like supramolecular fibre from a supramolecular polymer–colloidal hydrogel (SPCH) composed of 98% water and 2% silica and cellulose (wt%). The fibre was produced after a spinning time of 30 s and water evaporation at room temperature and exhibited a range of properties like strength and damping capacity similar to those of spider silk. The fibres are non-toxic and far less energy-intensive to produce than other synthetic polymers such as nylon, which is spun at high temperatures, opening a path for development of a non-biological large-scale production process of hydrogel-based polymers.

Production economics for microbial production of recombinant collagen, in turn, is still unattractive when compared to the animal-based process due to lower yield and inability to achieve production of pure, full-length collagen [4, 99]. However, through use of recombinant technologies, advantages such as absence of reported adverse immunogenic reactions and promising yield increases have continued to drive the efforts to develop a scalable production process, for which some measure of success has been reported. Growth of 25% in collagen demand in 2020 and a move away from animal derived sources has led to an expansion in the animal-free collagen platform, creating new opportunities in the field. In the last years of the twentieth century, the focus of the research efforts was mainly on reproducing human collagens for medical applications, given the challenges with the available sources for the protein. The food and leather industries have been supplied from animal sourced collagen. Over the years, two significant changes related to developing collagen-based products could be observed: one is the growing trend for finding biotech-based alternatives to animal farming, which will potentially reduce animal sources of collagen and gelatine and already had a favourable impact on the development of scaled biotech and microbial-based processes for production of non-human collagen and production of gelatine and leather (e.g. Geltor). The other observed change was in product design strategy applied to collagens for medical applications, in addition to the original aim of making recombinant copies of the natural molecules. In fact, there has been a growing trend to engineer molecules that result in “human-like” collagens that can fulfil the same roles—or some of the roles—of the natural molecules.

To summarize the current status of the progress made in bringing these processes to industrial scales, we used a matrix (Table 4) to outline strengths and weaknesses of recombinant silk and recombinant collagen microbial processes, opportunities and threats—when compared to animal-derived production.

4 Concluding remarks

Over the past 30 years, considerable progress was made in developing viable industrial-scale microbial production schemes for recombinant spider silk and collagen production. Nowadays, both P. pastoris and E. coli are used as the host organism for commercial large-scale production of recombinant spider silk. The optimization of DSP steps such as the use of non-harmful solvents (water) and endotoxin removal by autoclaving have facilitated process implementation for large volume applications such as textile (Spiber/Bolt Threads), cosmetics and even automotive applications (AMSilk). However, partial degradation and limited durability of the recombinant product when compared to natural spider silk have been reported, leading to the need for additional steps needed for product refinement, resulting in a more expensive process. While understanding of how the amino-acid composition and the modular composition of the various spidroins [9, 10] has guided improved and more predictable gene design for production of spider-silk-like products, the process of dope storage and further spinning as seen in the natural organisms, has been challenging to reproduce in the industrial processes, although considerable process is being made [53,54,55,56,57].

Concerning the production of recombinant collagen, shortcomings such as low product yield and inability to generate a product hydroxylated to a similar percentage to native collagen have been identified as major challenges/weaknesses for the microbial processes. Despite these limitations, advantages such as the absence of immunogenic reactions and low batch-to-batch variability have been recorded. A scalable purification process comprising centrifugation and freeze-drying has been developed and large-scale process optimization has been targeted, for example, by the chemical company Evonik in 2020. The segment has clear leaders who manufacture collagen-like proteins from different sources for cosmetic and food applications. This elevates barriers to entry to these markets for other manufacturers and emphasizes the importance of continuing to develop economically viable production processes, to gain competitive advantage. The use of alternative product designs instead of trying to replicate exactly natural collagens is also showing good progress. For medical applications, the main aim is to reproduce the properties of at least some of the many types of human collagen. Use of microbial production for this product seems so far to not be the most adequate for this purpose, considering that a P. pastoris-based process has been available for some years, but does not seem to be deployed in clinical trials medical use, while recombinant human collagen made for example in plants, seems to continue to progress in clinical uses.

Due to high interest in demand for spider silk in industries such as fashion and innovative biomaterials, which require large product volumes, it is expected that companies continue to optimize their production processes (AMSilk) and further extend volumetric productivity (Spiber Inc.).

As it pertains to the recombinant collagen platform, the need for a product that decreases dependency on animal sources should lead to growth in non-animal collagen demand, creating opportunities for implementation at an industrial level.

Initially, processes aimed at closely reproducing the native polymers, and while there have been remarkable successes in attaining such products using, for example, plants as production platforms for recombinant human-collagen, the challenges in doing so in microbial platforms have driven interest in the production of biosynthetic materials, i.e., non-natural products, that reproduce the sought mechanical properties of the native spider silk or native collagens within the constraints of a microbial-based economical large-scale process.

While challenges remain, interest in their potential applications due to their exceptional properties drove significant progress in establishing industrial bioprocesses for recombinant collagens and recombinant spider silk, to the point where today there are industrial projects for both molecules. However, further engineering of the molecules and/or of the host strains will be necessary, to fulfil the promise of industrial production of these fascinating polymers.

Data availability

Not applicable.

References

Holland C, Numata K, Rnjak-Kovacina J, Seib FP. The biomedical use of silk: past, present, future. Adv Health Mater. 2019. https://doi.org/10.1002/adhm.201800465.

Belbéoch C, Lejeune J, Vroman P, Salaün F. Silkworm and spider silk electrospinning: a review. Environ Chem Lett. 2021;19:1737–63. https://doi.org/10.1007/s10311-020-01147-x.

Olsen D, Yang C, Bodo M, Chang R, Leigh S, Baez J, Carmichael D, Perälä M, Hämäläinen ER, Jarvinen M, Polarek J. Recombinant collagen and gelatin for drug delivery. Adv Drug Deliv Rev. 2003;55:1547–67. https://doi.org/10.1016/j.addr.2003.08.008.

Wang T, Lew J, Premkumar J, Poh CL, Naing MW. Production of recombinant collagen: state of the art and challenges. Eng Biol. 2017;1:18–23. https://doi.org/10.1049/enb.2017.0003.

Grobben AH, Steele PJ, Somerville RA, Taylor DM. Inactivation of the bovine-spongiform-encephalopathy (BSE) agent by the acid and alkaline processes used in the manufacture of bone gelatin. Biotechnol Appl Biochem. 2004;39:329–38. https://doi.org/10.1042/BA20030149.

Buskirk RE, Frohlich C, Ross KG. The natural selection of sexual cannibalism. Am Nat. 1984;123:612–25. https://doi.org/10.1086/284227.

Hayashi CY, Shipley NH, Lewis RV. Hypotheses that correlate the sequence, structure and mechanical properties of spider silk proteins. Int J Biol Macromol. 1999;24:271–5. https://doi.org/10.1016/S0141-8130(98)00089-0.

Lazaris A, Arcidiacono S, Huang Y, Zhou JF, Duguay F, Chretien N, Welsh EA, Soares JW, Karatzas CN. Spider silk fibers spun from soluble recombinant silk produced in mammalian cells. Science. 2002;295:472–6. https://doi.org/10.1126/science.1065780.

Scheibel T. Spider silks: recombinant synthesis, assembly, spinning, and engineering of synthetic proteins. Microb Cell Fact. 2004;3:14. https://doi.org/10.1186/1475-2859-3-14.

Andersson M, Johansson J, Rising A. Silk spinning in silkworms and spiders. Int J Mol Sci. 2016. https://doi.org/10.3390/ijms17081290.

Mouw JK, Ou G, Weaver VM. Extracellular matrix assembly: a multiscale deconstruction. Nat Rev Mol Cell Biol. 2014;15:771–85. https://doi.org/10.1038/nrm3902.

Prosdocimi F, Bittencourt D, da Silva FR, Kirst M, Motta PC, Rech EL. Spinning gland transcriptomics from two main clades of spiders (Order: Araneae)—insights on their molecular, anatomical and behavioral evolution. PLoS ONE. 2011. https://doi.org/10.1371/journal.pone.0021634.

Werten MW, Moers AP, Vong T, Zuilhof H, van Hest JC, de Wolf FA. Biosynthesis of an amphiphilic silk-like polymer. Biomacromolecules. 2008;9:1705–11. https://doi.org/10.1021/bm701111z.

Morita K, Nakamura H, Modified fibroin, Pub No. WO 2017188434 A1. 2017. https://patents.google.com/patent/WO2017188434A1/en.

Kono N, Nakamura H, Mori M, Yoshida Y, Ohtoshi R, Malay AD, Moran DP, Tomita M, Numata K, Arakawa K. Multicomponent nature underlies the extraordinary mechanical properties of spider dragline silk. Proc Natl Acad Sci. 2021. https://doi.org/10.1073/pnas.2107065118.

Fertala A. Three decades of research on recombinant collagens: reinventing the wheel or developing new biomedical products? Bioengineering. 2020;7:155. https://doi.org/10.3390/bioengineering7040155.

Fertala A, Sieron AL, Ganguly A, Li SW, Ala-Kokko L, Anumula KR, Prockop DJ. Synthesis of recombinant human procollagen II in a stably transfected tumour cell line (HT1080). Biochem J. 1994;298:31–7. https://doi.org/10.1042/bj2980031.

Kyle S, Aggeli A, Ingham E, McPherson MJ. Production of self-assembling biomaterials for tissue engineering. Trends Biotechnol. 2009;27:423–33. https://doi.org/10.1016/j.tibtech.2009.04.002.

Amar S, Smith L, Fields GB. Matrix metalloproteinase collagenolysis in health and disease. Biochim Biophys Acta Mol Cell Res. 1864;2017:1940–51. https://doi.org/10.1016/j.bbamcr.2017.04.015.

Choi JH, Keum KC, Lee SY. Production of recombinant proteins by high cell density culture of Escherichia coli. Chem Eng Sci. 2006;61:876–85. https://doi.org/10.1016/j.ces.2005.03.031.

Sezonov G, Joseleau-Petit D, D’Ari R. Escherichia coli physiology in Luria–Bertani broth. J Bacteriol. 2007;189:8746–9. https://doi.org/10.1128/JB.01368-07.

Xia XX, Qian ZG, Ki CS, Park YH, Kaplan DL, Lee SY. Native-sized recombinant spider silk protein produced in metabolically engineered Escherichia coli results in a strong fiber. Proc Natl Acad Sci. 2010;107:14059–63. https://doi.org/10.1073/pnas.1003366107.

Fahnestock SR, Irwin SL. Synthetic spider dragline silk proteins and their production in Escherichia coli. Appl Microbiol Biotechnol. 1996;47:23–32. https://doi.org/10.1007/s002530050883.

Dams-Kozlowska H, Majer A, Tomasiewicz P, Lozinska J, Kaplan DL, Mackiewicz A. Purification and cytotoxicity of tag-free bioengineered spider silk proteins. J Biomed Mater Res A. 2013;101:456–64. https://doi.org/10.1002/jbm.a.34353.

Yang YX, Qian ZG, Zhong JJ, Xia XX. Hyper-production of large proteins of spider dragline silk MaSp2 by Escherichia coli via synthetic biology approach. Proc Biochem. 2016;51:484–90. https://doi.org/10.1016/j.procbio.2016.01.006.

Decker RE, Harris TI, Memmott DR, Peterson CJ, Lewis RV, Jones JA. Method for the destruction of endotoxin in synthetic spider silk proteins. Sci Rep. 2018. https://doi.org/10.1038/s41598-018-29719-6.

Salehi S, Koeck K, Scheibel T. Spider silk for tissue engineering applications. Molecules. 2020. https://doi.org/10.3390/molecules25030737.

Vendrely C, Scheibel T. Biotechnological production of spider-silk proteins enables new applications. Macromol Biosci. 2007;7:401–9. https://doi.org/10.1002/mabi.200600255.

Purkarthofer T, Dib I, Trummer-Gödl E, What about Pichia? Achievements in protein manufacture. 2017. https://www.validogen.com/unlock-pichia-technology.

Zepeda AB, Pessoa A Jr, Farías JG. Carbon metabolism influenced for promoters and temperature used in the heterologous protein production using Pichia pastoris yeast. Braz J Microbiol. 2018;49:119–27. https://doi.org/10.1016/j.bjm.2018.03.010.

Srivastava N. Chapter 43—Production of food-processing enzymes from recombinant microorganisms. In: Enzymes in food biotechnology. London: Academic Press; 2019. p. 739–67. https://doi.org/10.1016/B978-0-12-813280-7.00043-8.

Ramey A. Optimizing production methods for artificial silk proteins through bioreactor and purification studies of recombinant proteins expressed from Pichia pastoris. Clemson University, All Theses; 2006. https://tigerprints.clemson.edu/all_theses/46.

Tschopp JF, Brust PF, Cregg JM, Stillman CA, Gingeras TR. Expression of the lacZ gene from two methanol-regulated promoters in Pichia pastoris. Nucleic Acids Res. 1987;15:3859–76. https://doi.org/10.1093/nar/15.9.3859.

Fahnestock SR, Bedzyk LA. Production of synthetic spider dragline silk protein in Pichia pastoris. Appl Microbiol Biotechnol. 1997;47:33–9. https://doi.org/10.1007/s002530050884.

Werten MW, Eggink G, Stuart MA, de Wolf FA. Production of protein-based polymers in Pichia pastoris. Biotechnol Adv. 2019;37:642–66. https://doi.org/10.1016/j.biotechadv.2019.03.012.

Jansson R, Lau CH, Ishida T, Ramström M, Sandgren M, Hedhammar M. Functionalized silk assembled from a recombinant spider silk fusion protein (Z-4RepCT) produced in the methylotrophic yeast Pichia pastoris. Biotechnol J. 2016;11:687–99. https://doi.org/10.1002/biot.201500412.

Jansson R, Thatikonda N, Lindberg D, Rising A, Johansson J, Nygren PA, Hedhammar M. Recombinant spider silk genetically functionalized with affinity domains. Biomacromolecules. 2014;15:1696–706. https://doi.org/10.1021/bm500114e.

Breslauer DN, Lee LP, Muller SJ. Simulation of flow in the silk gland. Biomacromolecules. 2009;10:49–57. https://doi.org/10.1021/bm800752x.

Knight DP, Vollrath F. Liquid crystals and flow elongation in a spider’s silk production line. Proc R Soc Lond B. 1999;266:519–23. https://doi.org/10.1098/rspb.1999.0667.

Feldman A. Spider silk in airplanes? Germany’s AMSilk inks deal with airbus to develop a new high-performance material. 2018. https://www.forbes.com/sites/amyfeldman/2018/09/08/spider-silk-in-airplanes-germanys-amsilk-inks-deal-with-airbus-to-develop-a-new-high-performance-material/?sh=246523d73520.

Hahn J. Spiber creates first commercially available jacket from emulated spider silk for The North Face. 2019. https://www.dezeen.com/2019/10/24/spiber-moon-parka-spider-silkthe-north-face-japan/.

Sokolova OS, Bogush VG, Davydova LI, Polevova SV, Antonov SA, Neretina TV, Klinov DV, Debabov VG, Kirpichnikov MP. The formation of a quaternary structure by recombinant analogs of spider silk proteins. Mol Biol. 2010;44:150–7. https://doi.org/10.1134/S0026893310010188.