Abstract

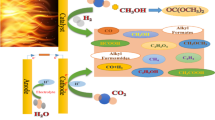

The unprecedented increase of atmospheric CO2 concentration and the associated climate change calls for the urgent implementation of CO2 mitigation approaches. Among the various proposed measures, CO2 capture from several industrial point sources or directly from air and its subsequent hydrogenation via renewable H2 towards value-added products formation has gained particular attention. Specifically, the production of CO or CH4 is of great importance for the eventual generation of liquid fuels or synthetic natural gas, respectively. Herein, an overview of the state-of-the-art noble and non-noble metal-based catalysts employed for the thermocatalytic CO2 hydrogenation towards CO (reverse water–gas shift reaction, rWGS) or CH4 (Sabatier reaction) is elaborated. A brief description of fundamental considerations is initially provided for each reaction, involving thermodynamic, mechanistic and kinetics considerations. Then, the recent catalytic studies on rWGS and Sabatier reactions over both noble metal and non-noble metal catalysts (e.g., metal oxides, carbides, metal organic frameworks) are discussed from the perspective of structure–property relationships. Lastly, the most important conclusions arising from the comparative analysis of the most promising catalysts are summarized and are complemented with proposed outlooks associated with future directions towards the rational design of highly active and selective catalytic materials for each process.

Highlights

-

Recent advances on the catalytic CO2 hydrogenation to CO or CH4

-

Comprehensive overview and comparison of state-of-the-art catalytic systems

-

Thermodynamic, mechanistic and kinetics considerations

-

Rational design of cost-efficient and highly active CO2 hydrogenation catalysts

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

It is largely acknowledged that the valorization of the ever-increasing emissions of CO2 is a necessity to avoid the catastrophic climate change consequences on our planet and society. Specifically, the latest report of the Intergovernmental Panel on Climate Change (IPCC), a United Nations entity, elaborately confirms the human-induced global warming over the last century and presents very ominous projections regarding the state of the climate over the next decades [1]. To this end, and given the relatively large time frame required for the decarbonization of anthropogenic activities on a global scale, the scheme of the capture and utilization of carbon in the form of emitted CO2, the so-called Carbon Capture and Utilization, CCU, has attracted significant research interest lately. Whereas several processes have been proposed for an effective and sustainable CCU technology, the exploitation of the intermittently generated renewable energy (i.e., solar or wind energy) as a source for hydrogen production via water electrolysis and its combination with a CO2 capture unit (preferably from an industrial point source such as cement production or power plants) can potentially produce value-added chemicals in a manner that not only decreases the carbon footprint of the parent carbon sources, but also curtails the excess renewable energy, effectively storing it in a stable chemical carrier [2,3,4,5].

Herein, an overview of the advances in the catalytic materials employed for heterogeneous thermocatalytic CO2 hydrogenation is provided instead. Given the significance of the scheme of CO2 hydrogenation, this reaction has attracted immense research interest and there exists a plethora of relevant lab-scale studies and review papers addressing the optimization of catalytic materials. Besides, elucidation of the underlying micro-scale phenomena is a prerequisite with the eventual scope of process scaling-up.

However, the catalyst is nothing but a small part in an integrated CO2 hydrogenation process and catalyst optimization is not by itself sufficient for the development and implementation of flexible and efficient processes on an industrial scale. With this in mind, several chemical engineering aspects must be taken into consideration, such as reaction engineering and reactor design, process modelling, integration, intensification, optimization and lastly even feasibility and life cycle assessments and supply chain modeling. As with any catalytically-driven process, the integration of catalyst development and engineering approaches is essential for the understanding of the dynamic character of the involved reaction or system of reactions as well [6]. In other words, the operation and control of a real CO2 hydrogenation process may very well be influenced by the behavior of the catalyst, thereby modifying the overall reaction pathway. For this reason, it is crucial that, prior to implementation, a detailed assessment and elucidation of possible mechanisms should be conducted. Insights regarding real-scale catalytic behavior enable process engineers to minimize the effect of kinetic limitations of elementary reaction steps, eventually leading to an optimized process (Fig. 1).

General approaches for multi-scale modeling of catalytic reaction processes in terms of relevant space and time frames. Adapted from [6]

As of yet, the most prominent category of the examined CO2 hydrogenation catalysts in the scientific literature involves composite materials based on both noble and non-noble transition metals supported on different oxides. In general, these materials are largely characterized by properties that enhance the overall catalytic activity, selectivity and thermal stability, such as high CO2 and H2 adsorption affinity, reducibility, basicity, electronic properties, resistance to sintering or poisoning and synergy between the active phases and the supports in multi-component catalytic systems.

In particular, metal oxides have shown high activity in CO2 adsorption and activation on the basis of oxygen defects and surface acidity/basicity [7]. In conjunction with these parameters, the modification of specific properties, such as structure, metal particle size, loading and dispersion, the formation of active centers at the metal-support interface can exert a profound influence on the local surface chemistry and metal-support interactions, thus leading to the fabrication of catalytic materials of increased activity and endurance with direct implications on selectivity/stability [8, 9].

In light of the above, in the present work a general overview of the state-of-the-art catalysts in CO2 hydrogenation for CO and CH4 production is given, as these are the main routes of interest in the scope of implementing the hydrogenation at low or even ambient pressure conditions. Firstly, and in order to better contextualize the necessity of the two main schemes examined in this review, a description of the fundamentals as well as the thermodynamic considerations of each involved reaction is presented at the start of each section. Subsequently, since practically all mentioned catalysts involve the presence of a metallic phase, in each category a further subdivision is made based on the type of metal, that is: i) noble metal-based and ii) non-noble metal-based catalysts. Categorization on the basis of the supporting material is not attempted, as the various supports are essentially included in the above analyses. Finally, a brief overview of the various proposed reaction mechanisms regarding the studied products of CO2 hydrogenation is made in an attempt to provide the full picture regarding the trends in the thermocatalytic route for CO2 hydrogenation. Moreover, a thorough comparison under similar reaction conditions is carried out to reveal the most promising catalysts for the two reaction schemes (Sabatier and rWGS reactions), providing the rationale and main principles for the design of cost-efficient and highly active catalysts for CO or CH4 production via CO2 hydrogenation.

2 CO2 hydrogenation to CO

2.1 Fundamentals and thermodynamics

The reduction of carbon dioxide to carbon monoxide through the rWGS reaction (Eq. 1) is of paramount importance, taking into account that CO is a building block for the production of various useful chemicals such as methanol or other long-chain hydrocarbons via the well-established Fischer–Tropsch (F-T) synthesis from syngas (a mixture of COx/H2) [10]. Besides, a single-step process for the production of methanol, dimethyl ether (DME) or hydrocarbons directly from CO2 hydrogenation has not yet been commercialized, predominantly due to the inherently higher stability of carbon dioxide as opposed to the highly active carbon monoxide. However, once CO2 is activated, any subsequent reactions will be energetically favorable and practically proceed to a larger extent, owing to the higher reactivity of the CO molecule. Thus, undesired CO2 in the syngas mixture can be removed by its conversion to CO, rendering the rWGS reaction an intermediate in situ or ex situ process in many CO2 conversion schemes. Therefore, a fundamental understanding of the rWGS reaction is of key importance towards the design of active and highly selective catalysts for syngas production [6].

Although syngas is conventionally produced from fossil fuels and biomass, the growing demand for environmentally friendly fuels and chemical commodities reinforces the significance of designing highly efficient rWGS processes in conjunction with CO2 valorization schemes. Furthermore, rWGS reactors can be advantageously implemented with the current infrastructure in any heavy carbon industry (e.g., cement, steel making, refineries) [11]. Indeed, this process is more feasible compared to the alternative CO2-to-CO technologies and provides additional versatility, by the variable products that may be obtained from the subsequent CO conversion. Every reaction pathway involving syngas, mainly from hydrocarbons partial oxidation, steam or autothermal reforming will produce a gas with a specific H2/CO ratio, which also depends on the feedstock employed. Commonly, syngas composition is modified by adjusting this ratio via the WGS/rWGS reaction or a downstream separation step. Although other oxygenated compounds like DME and alcohols might be produced, COx methanation reactions (Eqs. 2–3) represent the main side reactions that may affect product distribution even under atmospheric pressure. Also, the stoichiometric H2:CO2 ratio is unity (see Eq. 1), the lowest of all the other relevant CO2 hydrogenation processes. This is evidently a benefit of the specific process, especially considering the bottleneck associated with the high cost of RES-produced H2. However, given its endothermicity, this reaction is practically limited in temperatures below 600 °C (Fig. 2a), whereas complete suppression of methane formation occurs only after 700 °C (Fig. 2b), as revealed by the thermodynamic analysis carried out at the stoichiometric ratio of H2:CO2 = 1. Furthermore, given that during rWGS the number of gaseous moles remains unchanged, the effect of pressure is expected to be practically nonexistent, rendering this process operational even at atmospheric pressure.

As mentioned earlier, the production of CO from CO2 proceeds according to Eq. 1. However, several parallel and side reactions practically occur under real CO2 hydrogenation conditions, most notably the exothermic Boudouard reaction (or CO disproportionation), CO and CO2 methanation (Eqs. 2–4);

The above reaction system very often occurs in real applications, thus resulting in mixtures of H2O, CO, CO2, H2 and C, although the formation of solid carbon is demonstrated less frequently. Also, the forward water–gas shift reaction (WGS) takes place to a certain extent under relevant applications, which may limit CO2 and H2 conversion by instead producing them via the forward route, especially below 400 °C.

In general, however, the rWGS reaction showed higher efficiency compared to other CO-producing processes when CO2 is derived from a flue gas stream [12]. Therefore, a major incentive for improving rWGS catalytic activity in the low-temperature regime is the reduction of heat requirements, since this process is designed as intermediate to the eventual F-T synthesis. According to a comprehensive thermodynamic analysis that was conducted using ASPEN Plus by the Gibbs free energy minimization method, it can be seen from Fig. 2c, at temperatures lower than 500 °C, COx methanation reactions are dominant, and significant CO production is expected only at above 600 °C. Moreover, although a higher H2 concentration in the feed favors CO yield (Fig. 2d), this can also lead to enhanced COx methanation activity, along with inducing additional costs for the provision of the excess amount of hydrogen. The most challenging issues regarding the development of efficient rWGS catalysts are associated with low temperature activity/selectivity, metal sintering and carbon deposition. Therefore, an appropriate catalyst is needed in order to address these issues and achieve high activity and selectivity at the medium-to-low temperature regime [13,14,15].

In the sections below mechanistic and reaction kinetics considerations of rWGS reaction are provided on the basis of the recent theoretical and experimental advances in the field.

2.2 Mechanistic and kinetic considerations

2.2.1 Proposed mechanisms

The inherent reaction mechanism for the production of CO from heterogeneous thermocatalytic CO2 hydrogenation has not yet been fully understood. Also, it must be stated that the rWGS does not necessarily proceed via a specific mechanism, but rather than a distinct pathway that is almost completely dependent on the solid catalytic material used. In general, though, given the great amount of literature works for the forward reaction (WGS), valuable mechanistic information can be obtained, especially by combining in situ and/or operando studies with computational methods [16]. As of yet, it is considered that there are two main pathways for the reverse route, essentially referring to the direct participation or not of H2 in the activation of CO2, i.e. the redox and the associative/dissociative mechanism [15, 17,18,19], whose elementary steps are summarized in Scheme 1 and are briefly described below. The symbol “*” denotes adsorption sites or surface adsorbed species and “(g)” refers to gaseous species. In any case, the interested reader can find detailed information and a literature overview of mechanistic studies of the reverse water gas-shift reaction in recent literature reviews [12, 17, 20, 21].

Elementary reactions for the main proposed mechanisms for rWGS. Adapted from [22]

Redox mechanism: In the redox mechanism, as the name suggests, the reaction is carried out via a reduction/oxidation cycle on the catalyst surface. Specifically, gaseous CO2 is firstly activated by its adsorption on an electron donor entity, most typically a metal or an oxygen vacancy in a reducible metal oxide, and subsequently reacts for the formation of intermediate carbonyl species (either metal-bound or support-bound) that are eventually desorbed as gas-phase CO. The participation of H2 lies in the reduction of the oxidized sites by removing oxygen ad-atoms and forming water molecules, leading to their regeneration for another CO2 activation cycle and so on.

Associative/dissociative mechanism: Within the associative mechanism (also referred to as dissociative route), surface-bound CO2 activated species (denoted as *CO2) react with H ad-atoms derived from H2 dissociation (*H) for the formation of intermediate species that eventually decompose to CO and H2O. The main associative reaction path is the one involving the formation of active formate species (*HCOOH), although other routes are proposed, such as formyl and carboxyl. Most commonly, bidentate formate species are produced through the reaction of *CO2 with *H, preferably via the adsorption of O atoms to a metal surface, which then decompose into *HCO and *O and subsequently into *CO and *H. For the carboxyl route, *CO is selectively produced and is eventually desorbed through activation of the C–O bond, followed by H-assisted formation of COOH*.

In principle, the primary active site in a metal-based catalytic material is the metal surface and in unsupported catalysts the metal phase must be able to dissociatively adsorb both CO2 and H2. As for most CO2 activation reactions, CO2 dissociation is considered the rate determining step (rds) due to the thermodynamic stability of the CO2 molecule and the observed dissociative adsorption heat over the metal phase that practically determines the reaction rate [23]. In this regard, in a theoretical study by Nolen et al. [24] on CO2 transformation reactions over close-packed surfaces of transition metal catalysts (Ni, Co, Rh, Ru, Pd, Pt), it was found that the first step of CO2 activation is enabled from a kinetic and thermodynamic point of view on most transition metal surfaces. CO2 is activated through direct dissociation over oxophilic transition metals, such as Ni, Co, Rh, Ru, whereas in less oxophilic transition metals, such as Pd and Pt, the contribution of hydrogen is required. As illustrated in Fig. 3, the selectivity in CO, CH4 and methanol is dependent of the different steps, i.e., CO desorption, C–O dissociation and hydrogenation. Methane formation requires two C-O bond dissociation steps, while the formation of methanol or CO requires only one. CO is the C1 product that is kinetically preferred on all transition metal surfaces (Ni, Co, Rh, Ru, Pd, Pt) [24]. According to the results, the conversion of CO2 progresses through the formation of CO* and the hydrogenation to C1 products (adsorbed species are denoted as *). The formation of CO/CH4 is favored over Ni, Co, Rh, Ru surfaces, while the Pd and Pt surfaces favor the formation of CO/CH3OH. The CH4/CH3OH selectivities are driven by the metal's C-O dissociative ability, whereas CO selectivity by the competition between CO* desorption and surface hydrogenation [24].

CO2 hydrogenation routes on transition-metal surfaces including C-O bond cleavage (–O), C–OH bond cleavage (–OH), and hydrogenation (+ H) to either the carbon or an oxygen atom. Reproduced with permission from [24]

In this point, it should be mentioned that the catalytic conversion of CO2 is strongly associated with the adsorption and dissociation processes of gaseous molecules on transition metal surfaces. Therefore, as shown in Fig. 4, there is a consistency between the changes in the adsorption energy trend and the charge transfer amount from the transition metal surfaces to CO2 [25].

Change trends of adsorption energy and Bader charge of CO2 on different low index transition metal surfaces. Reproduced with permission from [25]

Nevertheless, under reaction conditions, the above reaction pathways may very well occur simultaneously and the dominant intrinsic mechanism depends mainly on the catalytic system and to a lesser extent on reaction conditions such as H2 concentration [22]. This is evident in the great variabilities of the prevailing pathway with the catalyst composition, structural, or electronic properties demonstrated in experimental works, whereas the results from computational studies also show a dependence on the system modelling, i.e., whether extended surfaces or finite clusters are used or whether the consideration of model (well-defined) or non-model surface studies are made [26]. In any case, high CO selectivity values and methane formation suppression can be attained by adjusting catalytic features that enhance a specific reaction mechanism, such as metal size, shape and crystal facets exposure, acid/basic properties, metal-support interactions, among others [15]. The latter can be achieved under a rational design approach of multifunctional composites through the use of advanced synthesis and promotional routes, as recently reviewed in relevant articles [27,28,29] and further discussed below on the framework of state-of-the-art catalytic systems of rWGS reaction.

2.2.2 Reaction kinetics

The elucidation of reaction kinetics is of critical importance in the scheme of process implementation, particularly for catalyst and reactor design, as well as for process simulation. All these can provide valuable insight into the performance of a process at various conditions stemming from changes in configuration and operating conditions, especially in a process involving rWGS and RES-produced H2. Essentially, all reactions that may take place during CO2 hydrogenation (Eqs. 5, 6) are driven by vapor equilibrium, so the equilibrium constant Kc,rWGS, is typically defined by Eq. 5, depending on the partial pressures of reactants and products. Also, the standard free energy difference of the reaction, ΔG, can be derived by Eq. 6;

Thus, as is the case for all chemical reactions, the rWGS reaction is in theory thermodynamically favorable only at the temperature regime for which the value of ΔG is negative. As can be seen from Fig. 2a, this occurs at values higher than ca. 800 °C. This essentially necessitates the use of a catalyst that will render the reaction more favorable kinetically at lower reaction temperatures.

Given its inherent reversibility, the rWGS reaction proceeds through a similar mechanism as reported for the forward WGS reaction, thus most of the kinetic studies are based on the widely employed Cu-based catalyst. Indicatively, CO2 dissociation was identified as the rate determining step for Cu(110), ascribed to the nearly identical activation energies for rWGS and CO2 dissociation [30, 31]. From these studies it was concluded that under over-excess hydrogen conditions, (i.e., H2:CO2 > 10), the reaction order is around 1 for CO2 and 0 for H2, at a range between 2 and 10 the reaction rate diminished due to the formation of the less active Cu entities and for H2:CO2 ratios lower than 2 the rate is limited by the dissociative CO2 adsorption. For commercial CuO/ZnO/AI2O3 a similar behavior was disclosed [32], however, though the rate was also independent of the H2 partial pressure at high and low hydrogen coverages, a dependence of the rate on both reactant partial pressures was seen for intermediate H2:CO2 feed ratio values. The kinetics of rWGS was also studied on Cu nanoparticles supported on SiO2 [33], where it was disclosed that the reaction mainly proceeds through the formation of formate species.

Elsewhere, the effect of CO2 and H2 reaction orders towards product distribution was studied for a variety of catalysts, and it was found that CO2 methanation was largely suppressed and CO generation was instead favored on Fe/Al2O3, MoS2 and WS2, with higher values for partial reaction orders for CO2 than for H2 [34]. Validation of experimental results and kinetics expression using the Langmuir–Hinshelwood-Hougen-Watson (LHHW) model was performed for Cu/ZrO2 and Ga2O3/Cu/ZrO2 [35]. The authors postulated that the reaction rate is almost independent of the total pressure and that based on CO2 dissociation being the rate determining step, a kinetic model was derived accordingly. Also, a kinetics evaluation based on both reaction mechanisms was attempted for Pt/TiO2 and Pt/Al2O3 [36]. Whereas the initial reaction rate assuming both reaction mechanisms was consistent with experimental data under low and high hydrogen coverages, only the surface redox mechanism model was experimentally consistent under intermediate hydrogen coverages.

2.3 Catalysts for rWGS reaction

2.3.1 Noble metal (NM)-based catalysts

Insights from theoretical and experimental studies have showcased that one of the most important criteria in the design of metal/metal oxide rWGS catalysts is the electronic properties of the metallic d-orbital holes and the difference between the dissociation barrier of metal-bound carbonyl and the desorption energy and dissociation barrier of metal carbonyl species [37]. Noble metals are associated with partially filled d-orbitals that generally are a favorable electronic configuration for the adsorption of gaseous reactants and intermediate active species formation onto the catalyst surface, thereby improving the catalytic activity. Also, the dispersion and chemical state of noble metal nanoparticles is crucial for the adsorption behavior of the reactants and the subsequent conversion of reaction intermediates [38]. Thus, they are considered promising catalysts for the rWGS reaction, together with characteristics such as corrosion resistance and strong affinity for H2 dissociation [39]. Research on the noble metal catalysts for rWGS mainly focuses on Pt, Pd and Au-based catalysts, which are generally the most active for the forward reaction. In general, the main product of CO2 hydrogenation over Rh-, Ru-, Co- and Ni-based catalysts is CH4, while Pd-, Pt-, Au-, Fe- and Cu-based catalysts are mostly selective towards CO generation [40], as thoroughly discussed below.

2.3.1.1 Pt-based catalysts

Platinum has been widely studied as a rWGS catalyst and it was found that it largely suppresses CO2 methanation [41]. However, the activity and selectivity of Pt-based catalysts were strongly influenced by the nature of the oxide support. For example, CO yield over Pt/γ-Al2O3 is higher than Pt/CeO2 at similar Pt loadings and CO2 conversion values [42]. Elsewhere [43], a study on mono- and bimetallic Pt catalysts supported on different oxides showed that catalytic activity and selectivity were notably dependent on the support nature. Additionally, the replacement of titania with ZrO2 as support led to intensification of the metal-support interaction, which weakened the C-O and O-bonds of the intermediate species at the Pt/Co-oxide interphase and thus high selectivity toward CO was observed [44]. On a Pt/SiO2 catalyst, oxygen vacancy formation was hindered and CO2 could be weakly adsorbed at the metal-oxide interface; in contrast, the presence of oxygen vacancies due to the presence of reducible TiO2, led to superior CO2 adsorption affinity [45]. The favorable interaction of Pt with titania was also observed in the study by Kim et al. [46], in which it was found that the increased electron donation properties of Pt0 in contact with Ti3+ sites causes strong metal-support interactions and generates new active Pt-Ov-Ti3+ sites for CO formation (Ov denotes oxygen vacancies) (Fig. 5).

Reaction mechanism of CO production from CO2 hydrogenation over Pt/TiO2. Reproduced with permission from [46]

Elsewhere, the effect of CeO2 addition to Pt/TiO2 showed that ceria affected the lattice and pore structure through substitution with TiO2 and optimized the catalyst activity [47]. Notably, CO selectivity is improved even further upon promotion. Huang and co-workers [48, 49] studied the effect of adding K to supported Pt-based catalysts and they showed that even though Pt is able to catalyze both rWGS and CO2 methanation, the addition of potassium highly increases CO yield, ascribed to the strong interaction between Pt nanoparticles and KOx species that weakens the adsorption energy of Pt-bound carbonyl, thus inhibiting its further hydrogenation to methane.

Furthermore, Na promotion favored the CO selectivity of Pt/m-ZrO2 catalyst, as evidenced by Seuser et al. [50], who demonstrated that the presence of sodium resulted in the suppression of on-top platinum sites, consequently dispersing the Pt0 ensembles that contribute to methanation. Another study examined the promotion of a Pt-based catalyst with other transition metals such as Ni and Co [51]. The formation of bimetallic catalysts enhanced the electronic properties of platinum and in turn CO selectivity compared to monometallic Pt. The same trend was observed by Wang et al. [52] who suggested that Fe addition on a Pt catalyst can not only act as a promoter by regulating the surface sites of the catalyst, but also functions as active site for the formation of intermediate species. Expanding further on catalytic synergy, a series of bimetallic Pt-Re/SiO2 catalysts showcased the promotional effect of Re, which favored the adsorption and activation of CO2, while the presence of Pt helped H2 activation, eventually leading to enhanced rWGS activity [53]. Furthermore, Pt addition to α-MoC catalysts resulted to a synergistic effect that enhanced the catalytic activity, where α-MoC can effectively break the C=O bond of carbon dioxide and mitigate the strong *CO adsorption properties while Pt facilitated H2 activation and CO formation occurred on the α-MoC sites [54].

2.3.1.2 Pd-based catalysts

Pd-based catalysts have been also investigated, despite their tendency to be also selective to CH4 [55, 56], since both the Sabatier reaction and the rWGS follow the same initial mechanistic steps and involve similar intermediates. Nevertheless, Qian et al. [57] designed a series of Pd nanoparticles supported on two-dimensional silicon hydride nanosheets, which demonstrated a great synergetic effect between the two components. More specifically, even though Pd nanoparticles exhibit low catalytic activity, SiH nanosheets were able to immobilize Pd nanoparticles, thus leading to a higher surface area and dispersion of the metal, favoring CO selectivity. Wang et al. [58, 59] investigated the effect of Pd loading on Al2O3 and they noted that CO2 is adsorbed on the hydroxyl groups of the alumina surface to form formate species, while H2 is dissociatively adsorbed on the Pd nanoparticles. The difference in CO selectivity between catalysts with high and low Pd loading is determined by the concentration of active sites and their CO adsorption/desorption affinity. In accordance with the aforementioned results, Kwak et al. [60] studied the effect of support on a series of Pd/Al2O3 and Pd/MWCNT catalysts, highlighting the distinctive function of alumina not only as support but also as an active participant in the catalytic configuration due to its ability to effectively activate CO2. The ability to tune Pd tendency to favor CO selectivity was also shown on a Pd/Ga2O3 catalyst by a study combining modulation-excitation spectroscopy with phase sensitive detection [61]. Contrary to alumina, Ga2O3 was reduced by H2 to form Ga-H entities through the spillover effect. In addition, the effect of Pd particle size was explored by Lebarbier et al. [62] on a Pd/ZnO catalyst, who demonstrated higher CO selectivity with a decrease of the particle size, highlighting the structure sensitivity of that system.

2.3.1.3 Au-based catalysts

Given the low CO adsorption energy of gold, Au-based catalysts are also employed as active materials for the rWGS reaction [17]. In particular, gold nanoparticles encapsulated in the metal organic framework UiO-67 selectively produce CO [63] and Au supported on CeO2 was found to be active for both methanol synthesis and rWGS reactions [64]. In another study, it was shown that Au/TiO2 exhibited a higher reaction rate than Au/Al2O3, since titania actively participates in the reaction. More specifically, the presence of oxygen vacancies in the support combined with the enhanced electron mobility of Ti provided enough active sites for CO2 activation while the presence of Au was crucial for the activation of gas-phase H2 and its subsequent spillover [65]. Also, promotion via alkali addition enhances rWGS reaction activity, stemming from the stabilization of Au particles due to the “Metal-O(OH)-Alkali” interphase and leading to increased CO desorption [6]. Moreover, promoting Au/SiO2 catalysts with MoOx led to the creation of under-coordinated Au/MoOx interfacial sites that were highly active for the rWGS reaction even at 300 °C [66]. Similarly, gold nanoparticles (2.2 nm) supported on TiO2 prepared via deposition–precipitation attained high CO yield (50%) at low temperatures (400 °C), ascribed to the synergistic interaction between Au and TiO2 [67].

2.3.1.4 Other noble metal-based catalysts

Several other noble metals have been separately explored as active phases for rWGS reaction, as promoters or even as bimetallic entities. As is the case of Pd, Ru and Rh are also known to strongly adsorb CO species, which is the main reason for their high CO2 methanation activity. However, very small (or atomically dispersed) Ru particles have been shown to favor the production of CO rather than CH4, with the selectivity being very sensitive to Ru particle size [68,69,70]. Also, a small amount of Ru (0.5 wt.% Ru) enhanced the activity of a Cu/ZnO/Al2O3 catalyst owing to the electronic interactions of Ru with Cu over this bimetallic catalyst [71]. Panaritis et al. [72] studied the reaction of CO2 hydrogenation over Ru-Fe bimetallic nanoparticles supported on samarium-doped ceria. It was shown that the addition of a low amount of Ru equal to less than 1 wt.% to Fe led to high stability and CO yield at high temperatures without deactivation. Similar results have been demonstrated for Rh-based catalysts [73, 74], as recently reviewed in Ref. [75]. Although supported rhodium nanoparticles are widely studied for methane production, Wang et al. [76] demonstrated that by selecting molecular sieve crystals as supports and consequently encapsulating Rh nanoparticles, the catalytic selectivity can be adjusted to steer the reaction products towards CO rather than methane. More specifically, their study indicated that core–shell enveloped rhodium nanoparticles at pure Silica (Rh@S-1) showed the highest CO selectivity indicating a strong association among the nanoporosity and CO selectivity, suggesting that S-1 enables the decrease of further hydrogen migration and promotes the rapid CO desorption to prevent excessive hydrogenation. Furthermore, Büchel et al. [53] explored K promotion on a Rh/K/Al2O3 catalyst, and concluded that the catalyst demonstrated minimal CO interaction, suggesting that CO is not retained but is released prior to its reduction to elemental carbon. Iridium was also used as an active phase with variable Ir oxidation states [77], in which partially oxidized Ir species attained complete CO2 conversion to CO, whereas Ir0 favored the formation of CH4. Additionally, while In2O3-supported catalysts are known to inhibit CO yield, a study on bimetallic In-Pd/SiO2 catalysts demonstrated 100% CO selectivity, attributed to weaker CO adsorption on the bimetallic system, suppressing CO2 methanation [78].

Single-atom catalysts (SAC) are a relatively recent promising category for catalytic materials in order to achieve high productivity and investigate the atomic-level reaction mechanism. In recent years, some SACs based on noble metals have been studied for the rWGS reaction. Notably, the product distribution was observed to be largely different from the respective nanoparticle-based catalysts, as shown in indicative works [60, 69, 70, 73, 79,80,81]. However, one of the major issues regarding their use for the rWGS reaction is their largely low thermal stability, which eventually leads to agglomeration at the elevated temperatures required for the rWGS reaction.

2.3.2 Non-noble metal-based catalysts

Despite the higher reaction rates that can be exhibited by noble metal catalysts, their high price and limited availability certainly hinder their implementation at larger scales. In this regard, significant efforts have been put forward on the design of cost-effective and equally active/selective catalysts based on earth abundant transition metals (TMs) as very promising alternatives [15, 39, 82]. Among others, the most used TMs employed for the rWGS reaction are Cu and Fe, either as monometallic phases or promoted entities, whereas the other two active 3d-TMs, Co and Ni, are known to preferentially generate hydrocarbons and methane under CO2/H2 mixtures, respectively [6]. Preliminarily, in a study examining various metals (Ni, Cu, Ag, Rh, Ru, Pt, Pd and Au) supported on ZrO2 [83] demonstrated that Ni and Ru were selective towards CH4. The catalysts based on the remaining metals produced a mixture of CH4, and CO. Similarly, in another study examining M-CeO2 catalysts (M: Ni, Cu, Co, Fe, Mn), Ni and Co showed the highest CO2 conversion values, accompanied by high methane selectivity. On the other hand, Cu, Fe and Mn were practically completely selective towards carbon monoxide production [84]. Apart from the typical metal-based catalysts, transition metal carbides (TMCs) and metal organic frameworks (MOFs) have recently gained particular attention as alternative materials with improved catalytic performance. In the sections below, the most commonly employed non-noble metal catalysts for the rWGS reaction are separately elaborated.

2.3.2.1 Cu-based catalysts

Copper is the most studied active metallic phase for the specific reaction, since it has been proven as active metal for the forward WGS reaction and is largely known for its high CO selectivity [85]. Ternary catalysts of Cu/ZnO supported on Al2O3 are among the widely explored copper-based catalysts for low-temperature rWGS at ambient pressure [32, 71, 86]. An inverse-type Cr2O3/Cu catalyst was designed by Shen et al. [87], which was found to be more active than noble metal catalysts for the rWGS reaction. A Cu-Al spinel catalyst showed very good activity and negligible deactivation after a 40-h stability test [88] and Cu/Al2O3 was efficient in the high-temperature rWGS reaction [37]. Elsewhere, the high activity of a Cu/CeO2 hollow sphere catalyst was attributed to the high oxygen vacancy density, whereas inferior performance was attained by other Cu/CeO2 catalysts characterized by a lower density of vacancies [89, 90]. In a similar manner, the key role of preparation procedure and the synergy between Cu nanoparticles and oxygen vacancies contained in the CeO2 support has been well documented [90,91,92].

However, the major disadvantage of Cu-based catalysts is the low thermal stability of copper which leads to rapid deactivation, especially at high temperatures, as well as re-oxidation above ca. 600 °C. Therefore, most of the Cu-based catalysts are accompanied by an appropriate promoter, predominantly Fe and K. Chen et al. [93] demonstrated that the addition of Fe to Cu/SiO2 and Cu/Al2O3 inhibits Cu sintering and improves stability even above 600 °C. Elsewhere, the addition of high-density Fe oxide clusters proved to be effective textural promoters that enhanced the stability in the high-temperature regime [94]. Also, in another study, Cu3Zr and CuZr3 clusters were suggested as good candidates for CO2 activation and dissociation through the use of DFT calculations, as small barrier heights were observed for these clusters [95]. The CuFe synergy was further explored by Navarro et al. [96], who demonstrated that bimetallic CuFe2O4 spinels favor CO production, due to their abundance on oxygen vacancies, facilitated by the positioning of Fe3+ ions in the tetrahedral sites. Moreover, other alkali metals like K, Na or Cs have been used as promoters, facilitating the CO2 adsorption. Indicatively, potassium increased the surface dispersion of Cu and created new adsorption sites, which led to higher CO2 conversion values compared to K-free Cu/SiO2 catalysts [97]. However, an optimum K loading of 1.9 wt.% was shown, since the addition of higher amounts of potassium significantly suppressed the catalytic performance due to the K-induced coverage of Cu active sites. A similar behavior has been observed for Cs-doped Fe-Cu/Al2O3 catalysts [98]. Cesium addition exerted a strong promoting effect especially at medium temperatures (400–500 °C), evidenced by the higher CO2 conversion values in comparison to the un-promoted catalyst. More importantly, a 50-h stability test demonstrated that the composite catalyst Cs-Fe-Cu/Al2O3 exhibited exceptional long-term behavior, since no coke formation was detected. Also, in our previous work [99] we demonstrated that the addition of Cs into a Cu/CeO2 system is inhibitory towards CO2 conversion, although the alkali promoter effectively favors CO selectivity (Fig. 6) via increased basicity and stabilization of partially reduced copper species.

Effect of Cs loading and surface basicity on CO selectivity over Cs-doped Cu/CeO2 catalysts. Reproduced with permission from [99]

2.3.2.2 Fe-based catalysts

Being the cheapest transition metal, iron can be a potential replacement of noble metals in the reaction of rWGS, along with its sufficient thermal stability. Although there are only a few examples of iron-based rWGS catalysts reported so far due to the fact that the literature on Fe-based catalysts is dominated by its utilization as a Fischer–Tropsch catalyst, the performance of some recently reported catalysts for CO2 hydrogenation to CO was remarkable in terms of both activity and stability [100]. Fishman et al. [101] investigated the catalytic activity of ultrathin FexOy nanomaterials in the rWGS reaction and demonstrated that the nanowire catalyst was highly active and selective towards CO at all temperatures examined.

However, iron is mostly used as a promoter in bimetallic catalytic systems, rather than being the standalone active metallic phase for the rWGS reaction. Indicatively, a bimetallic Fe-Mo catalyst has shown increased stability and complete CO selectivity due to the small particle size with higher Fe dispersion from the formation of a Fe2(MoO4)3 phase [102]. Loiland et al. [103] demonstrated that the addition of potassium to Fe/Al2O3 led to a three-fold increase in the reaction rate. At temperatures above 600 °C, activity of Cu or Ru can be increased by the addition of Fe, owing to their improved thermal stability and oxygen mobility [72, 93, 98]. Also, the bimetallic promoting effect was demonstrated in the study of Yang et al. [104], in which an improved catalytic activity was shown for Fe–Ni/CeO2-Al2O3 and Fe-Cu/CeO2-Al2O3 in comparison to Fe/CeO2-Al2O3, especially at temperatures lower than 600 °C. It was suggested from XPS analysis that Ni and Cu incorporation into the Fe-based sample induced relatively strong interactions between these metals and Fe, in part due to the slight decrease in Fe electron density. The double promotion with Fe and K also improved CO selectivity in carbon-templated BaFe-hexaluminate catalysts [105], whereas a Fe-Ru bimetallic composite could effectively diminish CH4 formation and offer increased stability with the addition of very small amounts of sulfur species [106]. Addition of Fe to Ni was also shown to lead to the formation of Ni-FeOx interfaces, which selectively catalyze CO formation thus suppressing methane formation (Fig. 7), since the strength of the metal-carbonyl interaction was decreased, a fact that facilitated the desorption of CO [107].

Effect of Ni and Fe content on conversions of CO2 (a) and H2 (b), yields of CH4 (c) and CO (d), selectivity of CH4 (e) and CO (f) over zirconia-based catalysts in the reaction of CO2 hydrogenation. Reproduced with permission from [107]

2.3.3 Transition metal carbide catalysts (TMCs)

While copper is predominantly used as the non-noble metal phase for the rWGS reaction, other non-noble metal-based structures have attracted scientific attention as catalytic materials and their performance in CO2 conversion was recently reviewed [108]. Specifically, transition metal carbide catalysts (TMCs) are often referred to as “low-cost precious metals” or “Pt-like” materials [109], due to the combination of more reasonable price with similar catalytic behavior to that of noble metals [110].

The most commonly used metal carbide is molybdenum carbide, Mo2C, due to its excellent ability towards both H2 dissociation and C-O bond cleavage [111]. It was also shown that Mo2C was more active and highly selective to CO compared to other carbides [112]. Elsewhere, it was shown that the CO yield was higher for Mo2C compared to PtCo/CeO2 and PdNi/CeO2 [113]. Additionally, various studies reported enhanced CO2 activation specifically by β-Mo2C, onto which CO2 is bounded in a bent configuration, which facilitates the cleavage of the C-O bond. Subsequently, the dissociated CO desorbs to produce gas-phase CO, while O interacts with Mo2C and forms oxy-carbide moieties (Mo2C-O), which are re-reduced by dissociated hydrogen ad-atoms [113]. More importantly, the combination of various transition metals, such as Co [113] and Cu [114, 115] with Mo2C, can lead to synergistic interactions, resulting in enhanced catalytic activity and stability. In view of above aspects, it has been shown that copper supported on β-Mo2C offered high CO yield values and reaction rates compared to commercial Cu/ZnO/Al2O3 [115]. More importantly, thermal stability was enhanced because of the homogeneous Cu dispersion achieved over the Mo2C support which prevented particle sintering, in comparison with the observed Cu agglomeration on the commercial Zn-Al support.

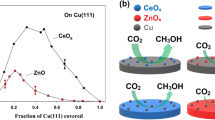

As for other carbide catalysts, Rodriguez et al. [116] reported on the deposition of small particles of Au, Cu, and Ni on TiC, where it was revealed that the metal coverage on the carbide surface exerted a strong influence on the catalytic activity, i.e., it was significantly higher for smaller metal coverages. Moreover, a vanadium carbide (VC) catalyst with high carbon vacancies demonstrated high conversion and selectivity [117]. The addition of alkali promoters to TMCs strengthens CO2 adsorption and increases selectivity towards CO. Specifically, K-WC/γ-Al2O3 exhibited high CO yield values compared to un-promoted samples [118]. Also, Na and K could act as structural promoters for WC that alter the local geometry and crystallographic orientation of the active sites, affecting their availability for reactant adsorption and activation [119].

2.4 Metal organic frameworks (MOFs) catalysts

Apart from the typical metal/metal oxide and metal carbide catalytic systems, catalysts based on a metal organic framework (MOF) have been attracting more and more interest as alternative materials with improved catalytic performance. These complex compounds constitute a novel class of highly porous crystalline materials built from organic linkers and metal cluster-based secondary building units. Owing to their structural diversity, compositional tunability, and high porosity, MOFs have provided a versatile platform to design solid catalysts with uniform active sites for many reactions such as the CO2 hydrogenation to CO [120]. This rather complex but advanced architecture may potentially result in both remarkable catalytic activity and CO selectivity and the concept of inserting metallic nanoparticles into microporous MOFs will possibly revolutionize future industrial applications.

Specifically, in the recent report by Li et al. [121], CO2 hydrogenation was explored over various transition metal catalysts (M/ZIF-8-C; M: Ni, Fe, Co and Cu) supported on zeolitic imidazolate framework-derived carbon support enriched with pyridinic N sites. The main advantage of using these materials was their dual functionality, since the metal/metal carbide phase facilitates H2 dissociation and pyridinic N is active for CO2 adsorption. On a series of hierarchical FeNiZn-MIL-88B-on-MOF-5 with different morphologies, the octapod catalyst showed both high CO2 conversion and CO selectivity, mainly attributed to the structural superiority of the catalyst, as depicted in Fig. 8 [122]. Elsewhere, the microporous nature of the MOF known as UiO-66 assisted the adsorption of Pt nanoparticles, which in turn enhanced the interaction between Pt and MOF, favoring the formation of isolated and well-dispersed Pt active sites and eventually producing CO [123]. In a similar manner, various multifunctional compositions, such as core–shell Pt/Au@Pd@1Co@MOF [124], Au@Pd@MOF-74 [125], Pt–Pd@UiO-67 nanocages [126], HZSM-5@ZrO2–In2O3@UiO-66 [127] exhibited high rWGS activity and selectivity, ascribed mainly to their advanced nano-architecture in conjunction to the key role of active metal entities. For instance, Fang et al. [127] developed an HZSM-5@ZrO2–In2O3 core–shell catalyst by decomposing the In(NO3)3/HZSM-5@UIO-66 precursor. Their enhanced performance was attributed to the In-Zr interface and the increased number of oxygen vacancies which improved CO2 adsorption, while the special pore structure of UIO-66 enabled HZSM-5@ZrO2–In2O3 offered more active sites.

CO2 conversion (a) and CO selectivity (b) as a function of temperature for different FeNiZn MOFs morphologies (flowers, octapods and cubes) and FeNiZnOx. Reproduced with permission from [122]

In light of the catalytic evaluation studies presented above, a comparison of the most active and selective materials for the rWGS reaction is summarized in Table 1. The comparison is carried out among representative materials based on both noble and non-noble metals under ambient pressure and at reaction conditions that are mostly comparable in terms of the H2/CO2 ratio and weight hourly space velocity (WHSV). More specifically, according to the reaction thermodynamics [128], CO2 conversion is enhanced under elevated H2:CO2 values, while CO selectivity remains unaffected. Consequently and to showcase the affinity towards CO generation instead of the competing reaction of CO2 methanation, Table 1 involves a list of the most active rWGS catalysts at H2:CO2 = 4 and relatively low reaction temperature. This will allow the reader to acquire an understanding about the most promising materials for rWGS reaction, formulating the research rationale and design principles for highly active and selective catalysts.

Collectively, the evaluation of state-of-the-art catalysts in the rWGS process reveals distinct behaviors between noble and non-noble metal-based catalysts. Noble metal catalysts, typically supported on metal oxides like alumina, zirconia, ceria or titania, achieve equilibrium values of CO2 conversion even at lower temperatures. This can be attributed to the synergistic effect between the support and metal, which influences key activity descriptors, such as metal dispersion and basicity. Among the various supports, reducible metal oxides, such as CeO2, exhibit advanced catalytic performance for the rWGS reaction. Several studies demonstrate that the significant improvement of the performance registered for those supports is associated to their direct contribution to the reaction, either through the creation of oxygen vacancies that favor CO2 activation or their strong interaction (of either electronic or geometric nature) with the active metal phase which finally determines chemisorption and catalytic properties. Nevertheless, it was proved that the catalyst's deactivation due to coke deposition was mainly attributed on the support rather than the metal, namely ceria, since its participation to the reaction led to its gradual coverage by the deposited carbon [129]. To address this phenomenon, a combination of two different oxides, such as ceria and zirconia, has proven to enhance catalyst’s stability [134]. Moreover, a significant improvement, in terms of activity and stability, can be obtained through the use of bimetallic phases or alkali promoters, which could be used to fine-tune the local surface chemistry and metal-support or metal–metal interactions towards a pronounced rWGS performance [50, 98, 104, 131].

On the other hand, the scarcity and increased market price of noble metals have directed the focus on non-noble metal catalysts, which even though present lower resistance to deactivation, they are more feasible for scale up applications. Transition metals, particularly Cu, have gathered significant attention, though their tendency to sinter at high temperatures can be a drawback, underscoring the need for thermally stable supports, such as ceria. In this regard, Cu/CeO2 systems are widely explored due to their affordability and the strong metal-support interactions between those counterparts. Notably, different ceria synthesis protocols significantly affect the rWGS performance, through mainly the modifications induced on the structural/textural properties and metal-support interactions [27,28,29, 90, 91, 132, 135].

Moreover, bimetallic catalysts can notably modify the catalytic behavior from single-metal systems by leveraging the synergistic effects between different metals. For instance, doping Ru or In with transition metals like Cu or Ni redirects their tendency to produce methane towards CO formation [71, 132, 134, 136]. In the context of NiFe and FeCu systems, metal addition has shown to be pivotal; Fe addition in FeCu systems not only enhances copper stability due to its high melting point, but also introduces more active sites to the reaction [98]. Similarly, NiFe catalysts demonstrate different behavior from their monometallic counterparts, mainly due to the Ni-FeOx interaction which also improves the catalytic stability and performance.

Apart from metal doping, alkali doping has also been beneficial in promoting catalytic behavior, due to alkali metals inherent characteristics. More specifically, alkali metals tend to enhance electrostatic interactions, increasing the dipole–dipole interaction during CO2 activation, thus favoring catalytic activity. Furthermore, alkali doping can promote the dispersion of active sites [98], however small amounts are required in order not to block them [50]. As mentioned, metal dispersion and more specifically metal particle size are also highly influential to products' selectivity. Even though many different parameters of the preparation procedure affect metal dispersion, metal-support interactions or their combinations, it has been highlighted that particle sizes in the range of 1–20 nm favor CO selectivity [135, 137]. In view of these aspects, non-precious metal catalysts, such as Cs-promoted Fe-Cu/Al2O3 or nanostructured Cu/CeO2 systems, exhibit excellent CO2 hydrogenation performance towards CO production (ca. 40–50% CO yield at 400–500 °C, Table 1), approaching or even surpassing the corresponding performance of noble metals (Table 1).

Figure 9 provides a more thorough comparison among the most active catalysts included in Table 1, in terms of CO formation rate (rCO, μmol g−1 s−1) at 400 °C. In accordance to aforementioned aspects, it is evident that the appropriate catalyst formulation comprising of cost-effective and earth-abundant non-noble metals can lead to highly active and selective catalysts for rWGS.

Relative comparison of the most active catalysts for the rWGS reaction. Reaction conditions and corresponding references are provided in Table 1

In addition to the intrinsic catalytic attributes, reaction conditions also impact product selectivity. This effect is not solely due to thermodynamic constraints, as previously mentioned in relation to temperature, pressure, and reactant ratios, but also because of macroscopic limitations, such as space velocity and mass/heat transport. More specifically, it was highlighted that lower contact time facilitates CH4 formation, especially at the temperature window where methanation competes with the rWGS [98]. Consequently, a meticulous selection of both the operating conditions as well as the metal composition of the catalyst is crucial. The ability to fine-tune these catalysts allows for steering product selectivity towards more beneficial yields while maintaining CO2 conversion values close to equilibrium for extended periods. Additionally, ensuring the stability of the catalysts under these conditions is essential to sustain their performance and economic viability over long-term operation.

3 CO2 hydrogenation to CH4

3.1 Fundamentals and thermodynamics

The hydrogenation of carbon dioxide into methane or CO2 methanation is known as Sabatier reaction, since its discovery by the French chemist Paul Sabatier at the beginning of the twentieth century (Eq. 7). The Sabatier reaction is an eight-electron chemical process that requires the input of a large energy amount in order to overcome the difference in the Gibbs formation energy between the reactant CO2 and product CH4 (− 395 and − 51 kJ/mol, respectively).

In general, CO2 methanation is regarded as the equivalent of two processes, the endothermic reverse water–gas shift reaction (Eq. 1) and the highly exothermic methanation of CO (Eq. 2). In other words, methane is more often than not produced by the intermediate step of CO formation, albeit the reaction mechanism is still not fully elucidated and is catalyst-dependent to a certain extent. Also, considering Le Chatelier’s principle for chemical equilibrium, the reaction of CO2 methanation is thermodynamically favored at high pressures and low temperatures, due to its mole-reducing and exothermic nature, respectively. Nonetheless, a low reaction temperature inevitably hinders the reaction kinetics and thus the use of an appropriate catalyst is practically a prerequisite. At the same time, COx hydrogenation reactions are very exothermic, therefore the maximum conversion of carbon oxides is expected to decrease when operating at higher reaction temperatures.

The effluent composition can be influenced by several factors, mainly the reaction parameters (temperature, pressure, H2:CO:CO2 ratio) and reactor configuration [138]. Additionally, the employed catalyst influences the reaction kinetics, conversion and product distribution [139]. Also, at the reactor outlet, besides methane, the gas mixture includes typically unconverted CO2 and H2, large amounts of H2O, and CO formed by rWGS. A typical operation window for the industrial production of methane from CO2 hydrogenation is 250–500 °C and 10–50 bar [139, 140] and can proceed in a single or multiple reactors in series [141].

As stated above, CO2 methanation is associated with a reduction in gaseous moles, thus an increase in the inlet pressure is expected to shift the equilibrium towards products and increase the yield of CH4 due to molar contraction, thereby increasing methane yield. This is clearly evidenced by the thermodynamic analysis carried out and reflected in the plots of the Gibbs free energy of the reaction at variable pressures (Fig. 10a). Interestingly, the highly negative ΔG values at lower temperatures can theoretically lead to complete CO2 conversion at T < 250 °C, regardless of the reaction pressure (Fig. 10b) whereas the formation of CO is negligible at T < 550 °C, as can be seen in the equilibrium composition plots (dry basis) in Fig. 10c. Although higher (C2+) hydrocarbons can be also theoretically produced as carbonaceous by-products, the associated yields are practically negligible, especially when operating under low to moderate reaction pressures (< 15 bar). Also, the beneficial effect of H2 excess in the feed towards increased CO2-to-CH4 conversion is evidenced in Fig. 10d, considering that the stoichiometric ratio of hydrogen and carbon dioxide according to Eq. 7 is equal to H2:CO2 = 4. Nonetheless, at the operation window where CO2 methanation is thermodynamically favored, significant kinetic limitations exist and thus the design of a highly active catalyst at low reaction temperature is of key importance to attain overall cost-effectiveness from a process engineering perspective. Also, given the intermittent nature of RES-derived H2 in a real-scale process, it is imperative that an appropriate catalyst can also function satisfactorily under variable H2 feed concentrations, providing adequate stability and conversion/selectivity performance with minimum changes in the quality of the final product.

3.2 Mechanistic and kinetic considerations

3.2.1 Proposed mechanisms

Although methanation of carbon dioxide is a relatively old reaction and much effort has been devoted to mechanistic studies, as of yet no definitive answer with regards to the underlying mechanism exists in the literature. As is the case for the rWGS reaction, the reaction mechanism of Sabatier reaction is largely dependent on the employed catalytic system, as well as operating conditions. In this sense, two types of mechanisms have been proposed for the reaction of CO2 methanation. Briefly, the first mechanism is named “associative mechanism” and states that gaseous CO2 is adsorbed associatively and along with the adsorbed hydrogen ad-atoms form oxygenate intermediate species which are eventually hydrogenated to produce gas-phase CH4. The other mechanism, known as “dissociative mechanism” involves firstly the activation of the CO2 molecule via its dissociative adsorption to carbonyl and oxygen surface species, which is followed by the carbonyl hydrogenation to CH4. A vast number of studies is now available regarding the examination of the CO2 methanation mechanism, available in various review papers where detailed information can be found for the interested reader [19, 142, 143], whereas a comparison of the reaction mechanism and kinetics over the more widely used Ni and Ru-based catalysts is presented in [144]. However, since detailed mechanistic analysis of the reaction is beyond the scope of the present review, only the general steps of each proposed mechanism are shown herein (Scheme 2).

Elementary reactions for the main proposed mechanisms for CO2 methanation, adapted from [19]

A number of techniques have been used to confirm the associative or dissociative pathway for CO2 methanation, mostly over nickel-based catalysts. These methods mostly refer to adsorption/desorption analyses of surface species formed upon CO2 adsorption in the absence of H2 and vice versa or with both reactants in the feed, transient response analysis (SSITKA) or in-situ diffuse reflectance infrared Fourier transform spectroscopy (DRIFTS) experiments [142]. In most cases where the CO-dissociation pathway is proposed, the formation of other surface species (essentially carbonates or formates) is negligible or not detectable. This does not disregard their formation, as more specifically designed mechanistic studies may detect all surface intermediates under variable conditions, as was recently reviewed in the comprehensive work by Feng et al. [16]. However, formates formation cannot be unequivocally excluded as a general rule and at the same time their presence does not necessitate their role as intermediate species, but rather that they are merely spectator species.

In the formate pathway, formates are the main intermediate species without the involvement of adsorbed carbonyl. According to this mechanism, CO2 is linearly adsorbed as mono- or bi- dentate carbonates or bicarbonates, which then react with dissociated H ad-atoms on the metal to form hydrogenated carbonates. These hydrogenated carbonate species in turn react with H(ad) to form monodentate formates, which eventually transform to formaldehyde-like and/or methoxy species, before being desorbed as CH4. It is also possible that formate formation does not necessitate the occurrence of the reaction, but rather these species are merely spectator species.

3.2.2 Reaction kinetics

Both empirical and mechanistic kinetic models have been developed by conducting experiments under differential conditions over a wide range of temperatures and reactant concentrations. The mathematical form of the kinetic rate expressions is typically determined from the derivation of Langmuir–Hinshelwood/Eiley-Rideal models, based on the reaction mechanism. The derived rate equation is ultimately fitted to the experimental rate data. An overview of the recently reported kinetic expressions can be found in Refs. [12, 19], while in the comprehensive review by Jalama [142] detailed information on kinetic studies categorized with regards to the variation of reaction parameters can be found. Considering the reaction of CO2 methanation on Ru-based catalysts, predominantly power-law empirical equations are available [145, 146], although a mechanistic model is reported in [147]. The overview of kinetic models on Ru-based catalysts by Falbo et al. [145] indicated that CO2 methanation rate is more dependent on the partial pressure of hydrogen rather than carbon dioxide, with values for reaction orders in the range of 0.3–2.5 and 0–1, respectively. Recently, Erdőhelyi reviewed the kinetic data for a variety of Rh-based catalysts employed in CO2 methanation [75].

As for nickel-based catalysts, in the seminal work by Weatherbee and Bartholomew [148], one of the most comprehensive kinetic studies for methanation of CO2 over Ni/SiO2 was proposed. It was revealed that the reaction rate is very sensitive to reactant’s concentration at low partial pressures, whereas reaction rates approach zero at high pressures. Another important study modeled the process through the simultaneous reactions of CO methanation, CH4 steam reforming and water gas-shift reaction [149]. Although the model was developed and validated specifically for steam reforming on Ni-based catalysts, it has also been used to kinetically evaluate CO2 methanation by Schlereth and Hinrichsen [150]. Moreover, a mechanistic kinetic expression for Ni/Al2O3 catalyst based on the Langmuir–Hinshelwood-Hougen-Watson approach has been proposed in [151]. Through the CO-intermediate mechanism, the proposed elementary reactions are the ones shown in Scheme 2, assuming the dissociation of CO* surface species to C* and O* to be the rds. A recent study by Miguel et al. [152] also described the reaction mechanism and kinetics over Ni-based catalysts, with the mechanism assuming H2 and CO2 dissociation followed by hydrogenation of adsorbed CO to formyl species and considering hydroxyls as the most abundant species, exhibiting a good fit to the experimental data. In the work by Ibraeva et al. [153], the CO2 methanation kinetics was studied over a NKM-4A nickel-containing catalyst. The kinetic equation was derived involving a formate intermediate without preliminary dissociation of gas-phase CO2 to CO* and O* (reaction pathway in the third column in Scheme 2) and assuming that the reaction between adsorbed CO2 and hydrogen ad-atoms is the rate-determining step. The reaction mechanism involving the formation of formate intermediate was also proposed, in which the formation of hydrogen carbonate is assumed to be the rate-determining step (reaction pathway in the last column in Scheme 2) [154].

In this point, it ought to be mentioned once more that the reaction mechanism of CO2 methanation reaction is strongly dependent on the employed catalytic system. Therefore, the intrinsic properties of the catalytic materials can have a profound influence on the reaction pathway and consequently, on the catalytic activity and selectivity. In particular, catalytic properties such as particle size and shape, metal dispersion, amount of oxygen vacancies and basic sites can significantly affect the metal-support interface and local geometry of metal particles, thus affecting the adsorption and dissociation of gaseous CO2 and H2 towards the formation of specific key intermediates through a specific reaction route. In the following section, the state-of-the-art catalytic materials for the CO2 methanation reaction and the parameters affecting their intrinsic properties and consequently their catalytic performance are thoroughly described.

3.3 Catalysts for CO2 methanation

3.3.1 Noble metal (NM)-based catalysts

For the reaction of CO2 methanation all metals of groups 8–10 exhibit significant performance when employed as active phases. Among them, the best activity is generally reported for catalysts based on Ru and Rh, mostly supported on metal oxides with high surface areas such as SiO2, TiO2, Al2O3 and CeO2. Other active methanation metallic phases include Pt and Pd, whereas most of the remaining group 8–10 metals are generally less active for methane formation and are mostly selective to CO, as discussed above. Contrary to the order for CO2 conversion in the methanation reaction, CH4 selectivity is largely reported to follow the order: Pd > Pt > Ir > Rh > Ru [19, 155, 156]. Indeed, CH4 selectivity depends on different parameters aside from the employed active phase, such as the reaction conditions and mass/heat transfer phenomena. Indicatively, the methanation performance over typical noble metal-based catalysts of variable weight loadings (0.1–5.0 wt.%) and crystallite sizes (1.3–13.6 nm) supported on titania showed that the catalytic activity and methane selectivity were dependent on the noble metal, structural properties and reaction conditions. Rh/TiO2 catalyst attained the highest activity values, being more than three times higher than the corresponding performance of Pd/TiO2 [157].

Taking also into consideration that noble metal-based methanation systems are active even with a low metal loading (even less than 1 wt.%), a cost-effective operation can be implemented. Regarding the resistance to deactivation, noble metal-based catalysts are characterized by higher thermal stability over a wider temperature range and are more tolerant than nickel to sulfur poisoning, carbon deposition or carbides formation [158, 159]. However, the above are general rules that are valid mostly for monometallic systems, whereas the performance of a multi-component catalyst in the reaction of CO2 methanation is not solely determined by the active metal phase, but is a combination of various descriptors, the most prominent of which are the nature of the supporting material, promotion effects, bimetallic effects, metal-support interactions, metal particle size, as well as operating conditions such as the reactant ratio or the presence of impurities in the feed of a real process [143, 160, 161]. Notably, traces of H2S have been shown to promote CO2 methanation on Ru, Rh, and Pd supported on TiO2 and CeO2, since when the support is exposed to H2S new active sites are formed in the metal-support interface and the catalyst becomes more active. However, in the cases of supported catalysts on ZrO2 and MgO or under higher H2S content the reaction rate is substantially suppressed, [162]. Thus, fundamental studies for the development of low-content, highly active and selective noble metal-based catalysts are of key importance and actually significant progress has been made over the last decade with respect to assessing these parameters, as elaborated below for the most widely employed active noble metals.

3.3.1.1 Ru-based catalysts

Ruthenium is possibly the most active and selective catalyst for COx methanation reactions, even at low loadings and at low reaction temperature (< 300 °C). Indeed, Ru-based catalysts can attain a methane yield of 99% at atmospheric pressure, being particular active in a temperature range where the reaction thermodynamics is particularly favorable (Fig. 9). Fully reduced metallic Ru is known for its high affinity towards H2 dissociation, which subsequently reacts with adsorbed CO2 on the catalyst surface. Nevertheless, CO2 conversion and CH4 yield over Ru-based catalysts are largely dependent on metal loading, particle size and dispersion, the nature of the support material and metal-support interactions [143]. Notably, the recovery of the initial methanation activity of Ru-based catalysts after accumulation of surface carbonaceous species was demonstrated in various early works employing high-temperature treatment under hydrogen atmosphere [163,164,165].

The influence of the support on Ru-based catalysts was studied using various oxides, including both reducible (CeO2, ZrO2 and TiO2) and non-reducible (Al2O3, SiO2) carriers. Among them, Ru/TiO2 catalyst has been regarded as the most effective and selective [166]. Particularly, the effect of TiO2 crystalline phases (i.e., rutile and anatase titania) on the structure and performance of Ru nanoparticles was explored [167]. In this work, rutile-TiO2 exhibited better Ru dispersion and lower Ru aggregation due to Strong Metal Support Interaction (SMSI) effects via the Ru–O-Ti bond and in turn superior methanation activity and thermal stability in comparison with anatase-TiO2. The structure–activity correlation over Ru/r-TiO2 was corroborated in a follow-up study by varying the pretreatment temperature [168]. It was found that the activity was dependent on the extent of Ru encapsulation by TiOx layers and the amount of surface OH– species on TiOx. Recently, an advanced support consisting of porous hexagonal boron nitride (pBN) material has been employed for the preparation of a catalyst with a very low Ru loading (0.58 wt.%) [169]. By utilizing Density Functional Theory (DFT) simulations, it was claimed that atomic-scale size and low oxidation state of Ru species supported on pBN contributed to a significant enhancement of the methane production rate and a remarkable stability even after 110 h on stream.

In a similar manner, Ru nanoparticles deposited on nanocrystal titania exposing (001) and (101) facets were investigated for CO2 methanation. Ru nanoparticles supported on TiO2 (001) exhibited improved CO2 conversion rate and methanation reactivity, as well as considerable durability in comparison to the TiO2 (101) nanocrystal with the same Ru loading (2.5 wt.% Ru). The dispersion of Ru species and the synergism between Ru and TiO2 were found to be significantly affected by the exposed facets, thus influencing their capability for CO2 activation and determining the CO2 methanation activity [170]. The high catalytic activity of Ru nanoparticles deposited on TiO2 (001) facets, namely 80% CO2 conversion and 100% CH4 selectivity at 350 °C, originates from the nature of (001) facets with high surface energy and oxygen vacancy concentration that could provide more active sites for the CO2activation [170].

Also, the impregnation of Ru with variable loadings on Al2O3 was found to affect the catalytic activity in [171], since although increasing Ru loading from 1 to 5 wt.% did not alter dispersion and particle size, higher contents increased the surface basicity and thus provided enhanced CO2 adsorption capacity, concomitantly increasing CO2 conversion, at the optimum loading of 4 wt.% Ru (Fig. 11). In a separate study over Ru/Al2O3 catalysts with variable Ru loadings, product distribution was highly affected by Ru content [172]. In particular, CO formation was favored over Ru monolayers in the catalyst with 1 wt.% Ru loading, while CH4 formation was favored over nanoclusters being predominant in the catalysts with higher Ru loading. Based on DFT calculations, the authors claimed that the dissociation energy barrier for H2COOH* (the rate-determining step) for the 3D nanoclusters was lower than that for the monolayers. The dependence of product selectivity on Ru loading and particle size in the range of 0.1–5 wt.% was also shown in another work [69], where 3D metal clusters preferably formed on Ru/Al2O3 catalysts with Ru loadings equal and higher than 1 wt.%, resulted in higher CH4 selectivity.

Effect of Ru loading on Ru/Al2O3 catalysts for the reaction of CO2 methanation. Adapted with permission from [171]

A series of Ru catalysts supported on CrOx-modified Al2O3 with various amounts of Cr were prepared through a step impregnation method and used for CO2 methanation, with RuO2/7%CrOx/Al2O3 exhibiting elevated CO2 methanation activity compared to Ru/Al2O3 at low temperatures. The formation of a solid solution structure inhibited the crystallization of RuO2 and the aggregation of Ru during reduction, thus resulting in decreased Ru nanoparticle sizes and enhanced metal-support interactions in the reduced catalysts [173]. The effect of Ru loading (1–5 wt.%) on CeO2 supports has been also studied, with the optimum Ru loading being 2.5 wt.% [174]. Sakpal and Lefferts [175] investigated the CO2 methanation performance over ruthenium catalysts of identical Ru particle size supported on ceria of various shapes (rods, cubes, octahedra) in order to gain insight into the effect of ceria morphology on the catalytic activity. Ru addition promotes the reducibility and increases the oxygen vacancy concentration in comparison to bare ceria, with the rod-shaped catalyst (Ru/CeO2/r) demonstrating abundant oxygen vacancies as compared to cubic and octahedral Ru/Ceria catalysts, thus leading to the optimum CO2 methanation activity (79.3% CO2 conversion and 100% CH4 selectivity at 325 °C). The highest catalytic activity is observed in the catalyst that generates oxygen vacancies most easily, indicating that CO2 activation on oxygen vacancies is the rate determining step. Figure 12 depicts the activity trend at 225 °C, which is well correlated with the vacancy concentration trend obtained from Raman and XPS results, in terms of the I598/I462 and OV/OL ratios, respectively [175].

Correlation between the activity (at 225 °C) and oxygen vacancy concentration of catalysts. Reproduced with permission from [175]

In addition, the size of ruthenium nanoparticles was also found to notably influence CH4 selectivity. In a recent work by Aitbekova et al. [70], it was found that Ru nanoparticles with a size of 2.6 nm pretreated in H2 at 230 °C favored CH4 formation. In contrast, single-site RuOx pretreated subsequently at 230 °C in O2 and H2 both revealed increased CO selectivity (> 90%). This prominent change in the reaction pathway was ascribed to the re-dispersion of Ru nanoparticles into atomically dispersed RuOx species during oxidative pretreatment. These Ru single-site species were associated with weaker CO* adsorption than Ru nanoparticles, thus leading to easier CO desorption in the gas phase. The relationship between the activity in CO2 methanation and variabilities in the Ru particle size including single atoms, nanoclusters (ca. 1 nm) and larger nanoparticles (approximately 4 nm) was systematically investigated over Ru/CeO2 [176], where Ru nanoclusters and large Ru nanoparticles exhibited weaker SMSIs than single Ru atoms, thus facilitating the activation of Ru-CO species, as depicted in Fig. 13. Conversely, single Ru atoms and Ru nanoclusters were not so active towards hydrogen spillover compared to large Ru nanoparticles, thus enhancing water desorption (Fig. 13). The balance between these two factors as well as the optimal activity (TOF of 7.41 × 10−3 s−1 at 190 °C) were achieved by CeO2-supported Ru nanoclusters. In another study, Abe et al. [177] investigated the relationship between the CO2 methanation activity and the mean Ru particle size on TiO2-supported samples. A significant reduction in the onset temperature and concomitantly a significant increase in the methanation activity were observed upon decreasing the particle diameter from 6 to 2.5 nm, whereas both descriptors remained almost constant for a Ru size higher than 6 nm.

Competitive SMSI and H-Spillover effect on the Competing CO Activation and Surface Dehydration for CeO2-Supported Single Ru Atoms, Ru Nanoclusters, and Large Ru Nanoparticles. Reproduced with permission from [176]