Abstract

Global warming and increasing environmental pollution have become global concerns that, coupled with the scarcity of traditional forms of energy, have motivated the implementation of more sustainable production systems, such as biorefineries. This is because biorefineries are capable of integrating technologies and processes in a single facility, generating biofuels, value-added chemicals, and energy. Thus, the aim of the study was to investigate the bioproducts and emergent technologies surrounding the processing of corn into bioethanol and refined oil. A bibliometric analysis he was carried out in order to construct and evaluate prospective scenarios related to corn biorefineries. An analysis of the proposed layouts highlighted flexibility in the production process, given that one raw material could be transformed into various bioproducts. Thus, the results presented provide a bibliographic foundation for future studies on integrating residues-processes-products in corn processing. The reason for this is that the technological routes presented could be considered incremental innovations to develop a biorefinery, which takes place gradually, given that highly integrated biorefineries are highly complex.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

More than 80% of the global demand for energy is met by fossil fuels, which pose a serious threat to the environment and society, due to climate change. Fossil fuels also present sustainable and economic problems, given the prediction that by 2050 they will have run out. It is therefore imperative that a change is made to the energy matrix towards one that is led by sources of efficient and renewable energy [1, 2].

The diversification of the energy matrix has been a global priority, driving the development and utilization of various types of biofuels as alternatives to fossil fuels. Biofuels, including bioethanol, biodiesel, and biogas, offer significant advantages in terms of reducing greenhouse gas emissions and decreasing reliance on non-renewable resources. However, there are challenges associated with large-scale biofuel production, like for example technical issues such as biomass-to-fuel conversion efficiency and economic considerations like competitiveness against conventional fuels. Nonetheless current research highlights technological innovations, such as advances in metabolic engineering of microorganisms to enhance bioethanol productivity, and economic approaches, including tax incentives and sustainability policies, as promising solutions to overcome these challenges and promote a sustainable transition to renewable energy sources [3, 4].

Among the biofuels, bioethanol is used most intensively on a global scale, with production projections at 132 billion liters by 2030, of which 60% is expected to be produced from corn [5, 6].

Corn is an energetic and versatile cereal, representing the second most abundant annual crop globally, with significant potential for conversion into biofuels and bioproducts. However, the primary challenge is related to the complexity of the corn’s lignocellulosic matrix, composed of cellulose, hemicellulose, and lignin. Cellulose and hemicellulose need to be broken down into simple sugars before being fermented into bioethanol, while lignin exhibits resistance to degradation. This necessitates sophisticated pre-treatment processes to destructure the corn’s cell wall, making sugars more accessible for fermentation. Additionally, the efficiency of enzymes used in the saccharification process is crucial, requiring advances in to optimize the conversion of biomass into fermentable sugars. In economic terms, production scale is also a challenge, as costs associated with implementing advanced technologies and the logistics of harvest and transportation can be substantial. Thus, is required to overcome these challenges by seeking more effective pre-treatment methods, efficient enzymes, and innovative strategies, particularly in integrated systems such as biorefineries [7,8,9].

Biorefineries therefore play an important role in the research, development and innovation agenda and fall into the United Nation’s Sustainable Development Goals (SDG), the efforts of which are focused on the universal production of accessible, reliable and clean energy [10, 11]. From an environmental standpoint, these facilities contribute to greenhouse gas emission reduction by harnessing renewable biomass for the production of biofuels and bioproducts. Additionally, biorafineries promote the comprehensive utilization of biomass, minimizing waste and fostering sustainable agricultural practices. Economically, these facilities drive the bioeconomy, creating employment opportunities and stimulating the development of innovative technologies, like the advanced pretreatment, enzyme engineering to enhance efficiency in sugar conversion and the utilization of genetically modified microorganisms in fermentation processes, adoption of cogeneration systems, production of value-added bioproducts, and the monitoring and control based on Internet of Things (IoT) technologies. Thus, by diversifying the energy matrix, biorafineries also enhance energy security, reducing dependence on non-renewable sources and, by integrating efficiency, sustainable resource utilization, and economic advantages, biorafineries emerge as essential pillars for a more sustainable and energy-secure future [12].

However, to reach the SDGs, new basic research concepts such as planning tools and scenario modeling are required in order to identify future opportunities, anticipating technological advancement and driving decision-making and new innovation strategies [13].

Scientometric analysis has been increasingly used to achieve this goal. This type of analysis is guided by quantifying scientific progress based on bibliometric studies which use graphic presentation to establish connections between authors and define lines of research in diverse fields of study. Thus, it is possible to map how biofuels become integrated with other bioprocesses and predict chains with a wide product portfolio that optimise the use of resources in order to minimize production costs [14].

Therefore, the intention is to create and evaluate prospective scenarios for corn-based biorefineries, by integrating emerging technologies involved in the processing of inputs generated in corn processing in bioethanol and refined oil production. Bibliometric analysis and reference mapping represent the methods employed.

2 Research methodology

2.1 Research structure

Corn processing using the wet milling process, in bioethanol and refined oil, was organized via an integrated flowchart, in order to identify the inputs generated throughout the production chain and how the processes connect, thus establishing the main keywords of the study.

The bibliometric study was carried out using software R [15] and an analysis of social networks. Thus, for every input identified in the previous step, all papers collected up until July 2021 were compiled in the data base Scopus. Denominative variations in terminology were considered in order to carry out broad searches and cover a wider range of data.

Bibliographic coupling networks were then created, in which the papers were the nodes and vertices were the references. In these networks, the bibliographic references that were not part of the vertices presented, were excluded. Therefore, the connection with a paper was only maintained if the edge was connected to another paper in the same network. This was followed by the extraction of the giant components, in order to eliminate the publications that did not present citations from other papers [16].

Each giant component identified was fractioned into groups, based on the similarities of the connections or the citations between the papers, using the Louvain algorithm to maximize the modularity score. As in the definition given by [17], modularity was used to compare the quality of the partitions obtained during the separation of the networks using fast unfolding.

To analyze the content of the groups of publications in each partition, the characteristic terms of each group were extracted using natural language processing in addition to analyzing the keywords of the paper. Thus, using the frequency of the term \(({tf})\) which indicates the importance of the term within the specific document and the inverse frequency of the document \(({idf})\) which is one way to measure the overall importance of the term, the common words were identified [18, 19]. The weight of tf-idf of a certain term \({i}\) in a document \({j}\) \(({p}_{i,j})\) was defined by:

In which \(({{tf}_{i,j}})\) is the number of times the term appears \({i}\) in a document \({j}\); \(({{df}_{i}})\) is the number of documents that contain the term \({i}\) and \(({N})\) is the number of documents.

Thus, the most important papers were those with the highest number of citations of the paper within the network and according to the topological position of the papers within the group. Thus, the relevance of each paper was determined, including the point to which the vertex \({i}\) was connected to other vertices in the same group (parameter \({{z}_{i}}\)) and the degree in which the connections of a vertex \({i}\) were distributed into different groups (participation coefficient \({{P}_{i}}\)).

Therefore, while \({{z}_{i}}\) measured how “well-connected” the node was to other nodes in the group, \({{P}_{i}}\) measured how “well-distributed” the node connections were between the different groups [20]. According to this approach, \({{z}_{i}}\) and \({{P}_{i}}\) were defined as:

In which \(({{K}_{i}})\) represents the number of connections of the vertex \({i}\) with other vertices in the same group; \(({\bar{K}}_{si})\) is the average of \({K}\) in all the vertices \({i}\) in the group \({s}\), \((\sigma {{Ks}_{i}})\) is the standard deviation obtained for \({\bar{K}}_{si}\); \(({{K}_{is}})\) is the number of connections of a vertex \({i}\) in other vertices of a group \({s}\) and \(({{k}_{i}})\) is the total degree of vertices \(i\), i.e., the number of angles of this vertex.

Based on Eqs. 2 and 3, the papers were classified according to Guimerà and Amaral [20]; the most relevant and characteristic papers of each group were considered hub nodes (z ≥ 2,5) and the least relevant and characteristic of each group, albeit with a large number of citations, were considered non-hub nodes (z < 2,5).

The resultant algorithm from the list of characteristic terms of the groups, of the most relevant papers according to the hub and non-hub classification and the number of citations, as well as average age of the publication of the documents, made it possible to obtain data and consequently the categorization of the groups according to the main themes, acting as a bibliographic foundation to identify the main bioproducts obtained and the emergent technologies employed.

2.2 Layouts for the corn biorefinery

The references associated to each of the bioproducts considered as the main contributors in corn-based biorefining were mapped. In this step, the papers ranked most important were systematically analyzed in order to determine the stages involved in processing the inputs under investigation. The most promising technologies were also selected to build two scenarios for corn biorefineries, considering technology integration and future perspectives.

3 Results and discussion

3.1 Research structure

In the defined production chain, the starch was converted into bioethanol by fermentation and the corn germ was used to produce refined oil (Fig. 1). Eleven inputs were generated, which, together with the terms “corn” and “maize” referring to the raw material, were considered as keywords in the study.

As shown in Tables 1 and 13,751 papers, quantitatively distributed, were obtained. Generally speaking, China, the US, India and Brazil published the most papers on the inputs researched. Interest from these countries in the corn production chain could be a reflection of their effective participation as the largest global producers of corn.

Despite the conversion of corn into refined oil being well-established, the diffusion of knowledge surrounding the inputs generated in this process was lower. The same was true for their respective destinations, compared to the results obtained for the rest of the proposed production chain. This signalizes an increase in the maturity of the potential associated technologies and consequently a lack of research interest in these areas.

3.1.1 Husks

Husks were the input most researched by the scientific community. Of the 6042 papers retrieved, 5304 were selected and categorized into ten groups. Group one (G1) obtained 1676 papers, with an average age of 2015.3. The main theme of this group was the different methods of production of biochar. The hub paper, thus most relevant in this group, was [21], with 1532 network citations.

In group 2 (G2), 1090 papers were obtained with an average age of 2014.7 and the main theme surrounding the production methods of biogas and the conversion of lignin into high value products. The hub papers were [22] with 515 network citations, [23] with 271, [24] with 207, [25] with 183 and [26] with 176.

With 978 papers and an average age of 2007.4 the main theme of Group 3 (G3) was animal supplementation and cultivation methods, which were not included in the objective of the present study.

Group 4 (G4), with 681 papers and an average age of 2016.0, focused on sustainability and the emissions of pollutants provoked by the burning of agricultural residues. The central theme of this group was the production of biofuels as an alternative to this problem. The hub papers in topological position were [27] with 149 network citations, [28] with 86 and [29] with 73. However, due to the number of citations, the non-hub papers by [30] and [31] were also considered, with 350 and 252 citations, respectively.

Group 5 (G5) obtained 440 papers, with an average age of 2013.2. Several central themes appeared related to the production of biogas, green composites and crop-livestock-forestry integration technologies. The hub papers were [32] with 253 citations, [33] with 190, [34] with 105 and [35] with 50. The non-hub papers were also selected, as follows: [36] with 177 citations, [37] with 172 and [38] with 130.

In Group 6 (G6), 184 papers with an average age of 2011.8 were retrieved. The main subject theme focused on the effects of corn husks on soil fertility and the pelletizing of different groups. Song et al. [39] and Sun et al. [40] were the most relevant hub papers, with 45 and 12 citations, respectively. Mani et al. [41], despite not being classified as a hub paper, was analyzed since it received 490 citations.

The central theme of Group 7 (G7), which contained 112 papers and an average age of 2010.5, was the use of corn husks as a substrate for the production of mushrooms and enzymes. The hub papers included [42] with 72 citations, [43] with 24 and [44] with 13. Regarding the non-hub papers, [45] with 194 citations, [46] with 153 and [47] with 106 stood out.

Regarding Group 8 (G8), 83 papers were obtained with an average age of 2016.3. The main theme in this group was the emission of pollutants provoked by the burning of husks and other grain residues. In this group, [48,49,50] were considered hub papers, with 215, 130 and 86 citations, respectively.

Group 9 (G9) retrieved 39 papers with an average age of 2006.7 and group 10 (G10) retrieved 21 papers with an average age of 2016.0. Neither of these groups classified papers as hub and therefore it was not possible to determine the main theme of G9.

However, for G10, a thematic axis highly linked to porous carbons was identified. The non-hub papers in G10 were [51] with 138 citations, [52] with 128 and [53] with 84.

The evolution of the publications is presented in Fig. 2. Group G1 studies the production of biochar, primarily after 2014. Growth in this group is related to the importance that this bioproduct has gained in recent years to reduce soil acidity on a large scale as well as acting as a potential adsorbent, which has been studied in recent years to remove toxic metal ions from aqueous solutions [54].

Groups G2 and G4 represent a recent and growing area of knowledge surrounding environmental policy incentives for the development of biofuels. While the focus of G2 is on the production of biogas and the conversion of lignin and of G4 the study of different types of biofuels, both these areas of study are related to the challenge of accessing lignocellulosic biomass structures. It is also worth highlighting that in G4 the studies tend to use levulinic acid in the production chain of solvents, pesticides, polymers, polyesters, fuel additives and pharmaceutical products, thus highlighting the need to minimize the costs of its production [55, 56].

The average age of group G5 is in line with the area of study of green composites given that this field of study presents the largest number of publications in the last decade. These composites are a result of the combination of bioplastics and natural fibers that in recent years have emerged as promising alternatives to conventional composites [37]. The growth in G5 was also influenced by the overlapping with other papers that analyzed the other central themes in this group.

Despite the largest concentration of publications in G7 occurring in recent years, this group did not present growth or regression. However, this area of knowledge has been primarily explored in theoretical studies, but still presents challenges related to the development of production techniques with large scale potential.

Group G8, despite not representing a potential technology, is significant since its content goes hand in hand with the increasing interest in solving the environmental problem associated with the burning of biomass, increasingly evident in the last decade. Efforts to minimize the impacts have risen recently with the knowledge that this residual biomass can be used as a potential raw material in biorefineries.

Finally, the growth in G10 is related to efforts in the last decades to develop more powerful pseudocapacitors, which have greater capacitance than electric double layer capacitors.

3.1.2 Corncob

Corncob was the second most researched input. Of the 2907 papers retrieved, 1989 were categorized into ten groups. Group G1 obtained 400 papers with an average age of 2006.7 and a central theme related to the different methods of pre-treatment of lignocellulosic biomass. The hub papers included [57] with 216 citations, [58] with 97 and [59] with 75. Chundawat et al. [60] with 285 citations was considered non-hub.

Group G2 retrieved 321 papers with an average age of 2012.3. The production of adsorbents and their use in the treatment of wastewater was the central theme. The hub papers were [61] with 249 citations, [62] with 97, [63] with 169 and [64] with 131. Kadirvelu et al. [65] with 529 citations and Schipper et al. [66] with 356 were considered non-hub papers.

In group G3, 288 papers were selected with an average age of 2011.0 and a central theme surrounding second-generation bioethanol, agglomerates and enzymes. The hub papers were [67] with 134 citations, [68] with 133 and [69] with 84. Qu et al. [70] and Demirbas et al. [71] were considered non-hub papers, albeit with 191 and 60 citations, respectively.

The central themes of G4, G5, G6, G7, G8, G9 and G10 also appeared in the studies related to husks, were inconclusive or irrelevant to the scope of the study. They referred to growing and harvest techniques for corn, the effects of insecticides on corn plantations and the use of corncob as a component in animal supplements. The total number of papers was 980 and the average age was between 1989.5 and 2007.5.

The analysis of the growth in the publications in G1, G2 and G3, showed G2 to be the most promising, while G1 and G3 reached a peak in publications around 2010, highlighting a strong connection between the subject areas (Fig. 3).

Group G1, in which the studies are based on the pre-treatment of lignocellulosic biomass, presents growth, particularly in the last five years. This highlights the current interest in improving the processes employing cellulose, which at the beginning of 2010 were extensively studied in order to improve the efficiency of such processes that use corncob as a raw-material to obtain acids, bioethanol, xylooligosaccharides and non-conventional sugars. Thus, according to the papers ranked, the use of hydrothermal pretreatments that use high water temperatures and pressures and seems to be a promising route for building biorefineries, has been increasingly employed in recent years.

Group G3 primarily studies the production of second-generation bioethanol and, despite its growth being lower than expected, given the potential of lignocellulosic biomass to obtain bioethanol via fermentation processes, it is worth remembering that in this group, the primary focus was on agglomerates and enzymes, which influenced the data on this technology. However, the decrease in the volume of publications after 2010 may be due to agricultural, industrial and technological barriers faced by the sector, making it economically inadvisable [72].

Finally, the growth in G2 in recent years could be attributed to the promising treatment of wastewater using adsorbents produced primarily with corncob. It is worth highlighting that the more recent studies also included the production of biochar, while the older publications were limited to the production of activated carbon. This is in line with the finding that pyrolysis is a newer technology and that the production of biochar presents a promising scenario in biorefinery complexes, in terms of generating different products and high yields.

3.1.3 Steepwater

Of the 1657 papers retrieved, 1233 were chosen by the algorithm and categorized into ten groups. Group G1 obtained 253 papers with an average age of 2012.1 and focused on the use of steepwater as a source of nutrients to produce lactic acid, succinic acid, malic acid, glucose oxidase and 1,3-Propanediol. The hub papers were [73] with 115 citations, [74] with 80, [75] with 62, [76] with 47 and [77] with 35 citations. The non-hub papers from [78] with 46 citations and [79] with 12 were also considered.

No central theme was identified in Group G2 which had 169 papers and an average age of 2010.1. This group studied both the use of corn steep liquor as a substrate to produce biodiesel and enzymes, and animal supplementation.

Group G3 with 155 papers and an average age of 2012.4 looked at different processes to obtain chemical and biochemical products from corn inputs. However, steepwater was not the focus of these studies, since other corn residues such as corncob and husks are used.

Group G4 with 124 papers and an average age of 2010.8 analyzed the use of corn steep liquor as a nitrogen supplement in the production of carotenoids and enzymes. The hub papers comprised [80] with 150 citations, [81] with 61, [82] with 58, [83] with 37 and [84] with 17 citations.

Group G5, with 113 papers and an average age of 1995.3, analyzed the use of steepwater as a source of nitrogen in the production of biopolymer polydroybutyrate, with [85] standing out as the hub paper with 178 citations.

Group G6 with 102 papers and an average age of 2014.8 showed the greatest connection between the papers, the central theme of which was the production of biosurfactants using corn steep liquor as a low-cost alternative. The most important and hub papers were [86] with 104 citations, [87] with 76 and [88] with 68.

In group G7, also with 102 papers and an average age of 2008.1, the hub papers focused on the production of enzymes, as seen in [89] with 68 citations, [90] with 51 citations and with 32. The non-hub papers were represented by [91] with 406 citations.

Group G8 with 97 papers and an average age of 2007.0, evaluated the production of erythromycin, a macrolide antibiotic used in the treatment of acute and chronic inflations. The hub papers in this group were [92] with 78 citations and [93] with 74.

With 82 papers and an average age of 2005.2, G9 obtained two hub papers that referred to the use of steep liquor in bioremediation [94] with 148 citations and [95] with 14.

Group G10, with 36 papers and an average age of 2009.6, focused on the optimization of the production process of bacterial cellulose and its applications in a range of industrial sectors. El Saied et al. [96] was the only paper considered hub, with 85 citations. Nguyen et al. [97] and Nguyen et al. [98] with 163 and 91 citations, respectively, were considered non-hub.

The increase in publications in each of the groups related to the input steepwater can be seen in Fig. 4. The publications associated with the content in G1 have grown significantly since the 2000s. This is largely a reflection of the studies that analyze the use of corn steep liquor as a low-cost source of nutrients in the production of lactic acid, succinic acid and malic acid. The high cost of yeast extract, despite the increase in concentrated lactic acid in a number of nitrogen sources, corresponds to around 30% of the total cost of production.

G1 also contains publications on the production of 1,3-Propanediol, one of the most researched value-added products, the demand of which has increased due to its role as a monomer in the synthesis of polytrimethylene terephthalate [99].

Although no significant growth was seen in G4, it is worth mentioning due to the increasing demand for carotenoids in the food, pharmaceutical and cosmetic industries, as important liposoluble pigments found in orange, yellow and red foods.

Regarding G5, interest in this field appears to be stagnated, given that since 1990 polyhydroxybutyrates have been commercialized successfully for shampoo bottles, and despite existing research on substituting the biotechnological process with fermentation at a lower cost, the technology necessary for its production is already taking place on an industrial scale [100].

The same is true of G8, since the technology necessary to produce erythromycin is already well-established. The production of biosurfactants studied in G6, despite promising, has not increased enough to make it economically competitive in relation to synthetic surfactants, therefore the focus of the investigations was on reducing the costs of the raw-material and the process [86].

Growth in G10 was noted by the academic community in terms of the optimization of the process to obtain bacterial cellulose from cheaper sources of carbon and nitrogen, given the extensive demand for films that can potentially be used for antimicrobial packaging.

3.1.4 Corn gluten fed (CGF) and corn gluten meal (CGM)

Of the 1376 papers retrieved for the inputs CGF and CGM, 1161 were categorized into seven groups. However, six (G1, G2, G3, G4, G5 and G7) were linked to the digestibility of nutrients and the effects of incorporating fibers and proteins present in these inputs in the diets of different animals. These themes did not fall into the scope of this study, for example, the swine nutrition, fish nutrition, dairy cattle and sheep nutrition, young ruminant nutrition and animal nutrition with corn gluten.

Thus, G6 with 85 papers and an average age of 2011.1, was the only group with a central area of study relevant to the scope of the research. The hub papers in this group looked at the production of antioxidant and antihypertensive peptides and were represented by [101] with 119 citations, [102] with 95 and [103] with 54. The non-hub papers with the most citations in the network focused on the production of medicines, biodegradable plastics and cell growth, as well as the production of thermoplastic resins and corn protein membranes. Anderson and Lamsal [104] with 131 citations and [105] with 128 stood out.

Figure 5 presents the growth in publications in each group categorized for CGF and CGM. Given the medical and pharmaceutical importance, the main theme in G6 has gained increasing attention in recent years.

However, the number of publications related to the subject was still low compared to the other groups, since the use of CGF and CGM in feed supplements is an older and widely employed practice.

3.1.5 Starch, wax and germ meal

A study of the papers on starch generated inconsistent information that made it impossible to analyze the content of the groups or identify conversion technologies. This is because the papers considered most relevant were related to another input, namely starch from corn fiber, the primary low value subproduct from wet/dry milling established largely from the fiber and the pericarp of the corn grain [106].

As observed with the starch, inconsistencies were also identified in the network built for the input “wax”. The publications established connections with insecticides, genetic mutations in the corn, beeswax and waxy corn, which did not correlate with the objective of the study.

The retrieval of papers for germ meal was not as low as for the inputs clarifying clay and soap. However, the analysis of the content and identification of promising technologies was inconclusive for the subjects that focused on mineral and organic fertilizers, the characterization of toxins present in the germ meal and how they affect feed supplementation.

3.1.6 Vinasse

Of the 166 papers retrieved for the input vinasse, 100 were categorized into four groups. Group G1 with 31 papers and an average age of 2013.5 had a central theme associated to the anaerobic digestion process and the use of bioreactors in the treatment of thin vinasse. The only paper classified as hub was [107], with 124 citations. The other papers that stood out in the group in terms of the number of citations were [108] with 60 citations and [109] with 50.

Group G2, with 26 papers and an average age of 2006.0, analyzed the problem of incrustation in evaporators use in the concentration of vinasse to produce distiller’s dried grains with solubles or syrup. The hub papers included [110] with 30 citations, [111] with 30, [112] with 29 and [113] with 25.

Group G3 obtained 23 papers and had an average age of 2015.1. The central theme of this group was the production of corn bioethanol, primarily surrounding the optimization of fermentation and identifying the by-products. The hub papers were [114] with 419 citations, [115] with 299, [116] with 75 citations and [117] with 26. The non-hub papers, albeit with many citations, analyzed the recuperation of fibers and proteins from corn vinasse prior to centrifugation, represented by [118] with 48 citations and [119] with 14.

Group G4 obtained 20 papers with an average age of 2010.5. The main focus of this group was the study of biomolecules present in the residuary currents of the bioethanol production chain. Hayman et al. [120] with 56 citations was the only paper classified as hub and the most cited.

Thus, considering the low number of papers retrieved, the data used to analyze growth were based solely on the average age of the groups. The majority of publications were produced in the last two decades, with an average age of between 2010 and 2015. The subject areas of these publications are directly related to the need to optimize the use of the residues from bioethanol production, such as vinasse [119].

Thus, G1 is the only group that stands out, since the growth in publications is related to increasing the production of liquid fuel in the corn bioethanol industry, by acquiring energy in the form of biogas. Therefore, the production of biogas could lead to a reduction in the consumption of natural gas in a bioethanol plant by up to 43%, which represents a saving of US$ 17 million in an industry with a productive capacity of 360 million liters of bioethanol per year [118].

3.1.7 Deodorized distillate

For this input it was not possible to separate the giant component due to the small number of papers retrieved in the network. However, some of the most cited papers focus on the production of biodiesel and the retrieval of tocopherols which can be used in the pharmaceutical, cosmetic, food and feed industries. Ergonul and Koseoglu [121] with 27 citations and [122] with 12, stood out. Interest in deodorized distillate has therefore grown, primarily in the 2010 and 2020 s when more than 50% of all the publications were retrieved in the network since 1948.

3.2 Layouts of corn biorefineries

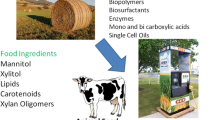

The bioproducts identified by the present study and considered the main contributors for corn-based biorefining are listed in Table 2.

Thus, biochar, bioethanol, biogas, biodiesel, green composites, succinic acid, porous carbon, biosurfactants, antioxidants and tocopherols were chosen in terms of the future prospects and the likelihood to present process integration in the construction of biorefinery scenarios.

Biochar production technologies involve the thermal degradation of biomass in a closed system with limited oxygen supply, known as pyrolysis, in which bio-oil, biochar and non-condensable gasses are generated [123].

Thus, the processes to obtain these bioproducts are classified according to the pyrolysis temperature, the amount of time the material resides in the reactor and the temperature ramp. Thus, generally speaking they are considered as slow pyrolysis processes, in which thermal conversion takes places at low and medium temperatures in the absence of oxygen, fast pyrolysis processes, in which the biomass is heated up quickly, resulting in a larger proportion of bio-oil and a lower proportion of biochar, and gasification, which corresponds to pyrolysis at high temperatures and results in biochar as a biproduct [124].

The stages that make up the production of bioethanol include pre-treatment, hydrolysis, fermentation and distillation. Technically speaking, one of the crucial points of this chain is the pre-treatment of biomass. Thus, of the pre-treatment technologies investigated, vapor explosion stood out, since it is the most widely used, and the hydrothermal treatments or thermal hydrolysis, since the advantages include the dispensability of additional chemical products to the biomass, the inexistence of problems related to corrosion of the reactor and the formation of fewer resultant undesirable products [125, 126].

Theoretically the production of biogas is simple and consists of the fermentation of the organic matter via a process of anaerobic digestion, which results in the release of methane and carbon dioxide. The stages that make up the production of biogas using husks and cob include drying, milling, pre-treatment followed by digestion, which comprises four main stages: hydrolysis, acidogenesis, acetogenesis and methanogenesis. In terms of the pre-treatment, the biological treatment proposed by Zhong et al. [25] and the alkaline pre-treatment proposed by Khatri et al. [35] are highlighted.

The production of biodiesel was identified via the deodorized distillate that, due to its high content of free fatty acids, can be converted into biodiesel via esterification, often using homogenous catalyzers.

The production of green composites from corn husks can be carried out using twin-screw extrusion, followed by injection molding. Thus, the employment of underused agricultural products that contain cellulose fibers is an important way to add value to corn biorefineries, while also helping to maintain the balance of carbon dioxide [37].

Of the technologies investigated, succinic acid was chosen because of its flexible chemical structure and high efficiency in fermentation. As shown in Xi et al. [76], succinic acid obtained from Actinobacillus succinogenes can also be produced using carbon sources of agricultural origin, including materials rich in xylose.

The obtainment of porous carbons in the studies mapped is centered on the chemical activation of biochar with a solution of KOH. In the papers ranked, the lignocellulosic biomass is utilized in its entirety to produce biochar via fast pyrolysis and after submitted to the activation step to form the hierarchically structured porous materials.

However, in Guo et al. [51], just a fraction of the lignin from the enzymatic hydrolysis in the fermentation process of butanol from corn husks was used to produce hydrochar and after porous carbon. This indicates integration between the biofuel production chain and the concept of biorefineries.

The biosurfactants are produced biologically using bacteria, yeast and fungus. The major challenge related to their large scale production is the high cost associated with the low productivity, when compared to synthetic surfactants. The study by Silva et al. [127] looks at the use of Pseudomona cepacia and steepwater, with waste frying canola oil, as a medium for fermentation, using centrifugation to extract the final product.

Antioxidants in Zhuang et al. [101] were attained via hydrolysis with alkaline proteases and flavourzyme. The stages of production include alkaline hydrolysis of the input, followed by centrifugation and purification.

Molecular distillation is an industrial method to retrieve tocopherols from deodorized distillate. It does however pose problems in terms of the capacity limit of the unit and low selectivity of separation and energetic efficiency. Thus, other techniques have been developed, such as the extraction of solvent, extraction of supercritical fluid, chemical treatment, adsorption and ion exchange, thus highlighting the continuous diffusion of knowledge in this field of research [128, 129].

Considering the findings, the first layout represented a biorefinery system for energy production, where the biomass was primarily used to produce biofuels and the inputs were utilized to obtain value-added bioproducts (Fig. 6).

The biorefinery proposed was made up of three main platforms (C-5 and C-6 sugars and oil) and nine bioproducts, with corn as the raw-material. Moreover, the scenarios proposed did not necessarily represent a complete integration of mass and/or energy. The aim was to drive integration possibilities between the raw material, bioproducts and operations, in order to connect, in the most effective way possible, the steps that make up each stage of processing.

In this integration, the lignocellulosic biomass was fractioned into hemicellulose (sugar polymers with five carbons), cellulose (glucose polymers with six carbons) and lignin (phenol polymers). To do so, the corn husks and corncob underwent a pre-treatment of vapor explosion (SE), where the hemicellulose-rich element was extracted (C5). The rest of the material (cellulignin) underwent enzymatic hydrolysis, the objective of which was to obtain fermentable sugars (C6) and lignin. The resultant lignin was used to produce porous carbon from biochar produced via pyrolysis and activated with potassium hydroxide, while the fractions of C-5 and C-6 sugars were fermented to obtain succinic acid and bioethanol, respectively.

The SE pre-treatment was chosen due to yields and since it is commonly used. Thermal hydrolysis is however a more sustainable alternative and considering future perspectives, can substitute this step in the proposed chain.

Steepwater was used as the nitrogen source in the production of succinic acid and as a fermentation medium to produce biosurfactants. While the residues rich in fiber and protein (CGF and CGM) were employed to produce antioxidant peptides via alkaline hydrolysis.

On the oil platform, as well as obtaining refined oil, biodiesel was produced by esterification and tocopherols by extraction, both using deodorized distillate. The vinasse produced in the bioethanol chain was converted, via anaerobic digestion, into biogas that can be used as a source of carbon dioxide to produce succinic acid. Finally, the use of biogas to supply CO2 to the succinic acid chain made it possible to remove the separation and cleaning steps. These steps are necessary to obtain pure methane, which can be compressed after the fermentation process.

In this context, different scenarios can be constructed with different levels of complexity, aiming for maximum integration between the raw-materials, technologies and bioproducts. The second layout, however, despite the focus of production staying on biofuels, aimed to use the lignocellulosic biomass to its fullest potential (Fig. 7).

The main difference between the two scenarios was the conversion of corn husks, via fast pyrolysis, into bio-oil, biochar or to produce green composites. In addition, the obtainment of carbon dioxide from platform C6 was proposed as well as the compression of methane-rich gas from the fermentation of succinic acid, represented, respectively, by the blue and red dotted lines.

It is worth highlighting that in Guo et al. [51], as a foundation for the proposal to convert the lignin chain, the authors proposed the activation of hydrochar obtained via hydrothermal carbonization (HTC), which differs from pyrolysis, primarily since it takes place in liquid. Given the integration in the proposed chain, the pyrolysis was presented as an option that must be investigated, since this same operation could be used to convert biochar and bio-oil, as presented in the second layout.

By substituting the production of biosurfactants, it would be possible to obtain bacterial cellulose, the synthesis of which takes places via the inoculation of the microorganism in a culture medium rich in phosphorous, nitrogen, carbon, oligoelements and others. As in the production of biosurfactants, the use of fermentation mediums modified with corn steep liquor represents a cheaper and more effective alternative.

In this situation, as seen in Albuquerque et al. [130], membranes of bacterial cellulose can be produced via komagataeibacter hansenii in a fermentation medium containing glucose and corn steep liquor and then incorporated with polyhydroxybutyrat, activated with essential clove oil to produce the biodegradable antimicrobial film, which can be used in perishable food industries.

In addition, since biosurfactants can be produced using residual oil, a chain was proposed for the refining process (continuous green line), referring to corn oil soap as a inexpensive source of substrate in the fermentation of biological surfactants. This could therefore represent one more route to integration in the proposed chain to increase the viability of the process.

According to Oliveira [131], integrated systems like those presented, have, in addition to processes that are joined together, a high degree of commercial technological and organizational complexity. This can only be achieved when maximum use is made of the pre-existent structure in the previous biorefinery, resulting in a larger number of bioproducts, but without increasing the number of processes. Thus, the modifications in biorefinery systems must be guided by innovations that better incorporate the pre-existing products and processes.

4 Conclusions

The citation networks for each of the listed inputs indicated a higher concentration of publications related to wet grinding and the bioethanol chain. This scenario reveals lines of research predominantly led by the USA, the world’s largest bioethanol producer. Conversely, residues from corn refining attract less scientific interest, reflecting the technological maturity of this chain.

Regarding the overall landscape of scientific production, the academic community’s interest in straw stands out, driven by the challenge of addressing the global environmental issue associated with the substantial waste generated post-corn harvest. Geographically, China leads this research field, as straw is traditionally burned by farmers in this country as a convenient means of biomass disposal after harvest, resulting in elevated levels of environmental pollution. In this context, many authors presented the concept of biorefinery as an alternative to minimize environmental impacts. The majority of promising bioproducts for corn biorefining fall into categories such as biofuels, green composites, adsorbents, acids, and biopolymers.

Regarding the identification of emerging topics, the analysis of group evolution allowed for the assessment of technology maturity, facilitating the correlation of technologies with the current context and observation of research trends. In a technological prospecting context, this translates to risk reduction in investments, increased technology competitiveness, improved process control, and, most importantly, guidance for the development of more focused and robust research and development strategies.

The technology prospecting analysis enabled the cataloging of potential bioproducts, including Biochar, Bioethanol, Biogas, Biodiesel, Green composites, Levulinic acid, Porous carbon, Malic, lactic, and succinic acids, 1,3-Propanediol, Biosurfactants, Carotenoids, Bacterial cellulose, Peptides bioactives, and Tocopherols. Among these, some were selected, and two layouts were devised.

An intrinsic characteristic of the proposed layouts worth highlighting is production flexibility, facilitated by processing a single raw material into various products, allowing for estimation of the products to be produced. For instance, straw can be utilized to produce bioethanol, while corn cobs can be employed for the production of biochar, bio-oil, and green composites, or any combination of these options. Regarding the proposal’s integration, using C5 sugar to produce succinic acid was observed as a prominent route, enabling the obtainment of pure methane, thereby adding value through the incorporation of another product, without the need for a substantial increase in operations or raw material acquisition.

It can be concluded that the results presented represent a biographical foundation for future studies on the integration of inputs-processes-bioproducts using corn. The reason for this is that the technological routes presented can be seen as incremental innovations to develop a biorefinery, which takes place gradually, since highly integrated biorefineries are also highly complex. Thus, despite additional research still required surrounding these scenarios, they represent a major contribution to the academic community by including many lines of emergent research, identified through an effective, consolidated method.

Data availability

The authors declare that the data supporting the findings of this study are available within the paper and the references. However, the code availability can be requested from the corresponding author.

References

Xiong M, Huang J, He X, Zhou Z, Qu X, Faisal S, Abomohra A. Evaluation of bio-oil/biodiesel production from co-pyrolysis of corn straw and natural hair: a new insight towards energy recovery and waste biorefinery. Fuel. 2023. https://doi.org/10.1016/j.fuel.2022.125710.

Kusmiyati K, Hadiyanto H, Fudholi A. Treatment updates of microalgae biomass for bioethanol production: a comparative study. J Clean Prod. 2022. https://doi.org/10.1016/j.jclepro.2022.135236.

Liu Y, Cruz-Morales P, Zargar A, Belcher MS, Pang B, Englund E, Dan Q, Yin K, Keasling JD. Biofuels for a sustainable future. Cell Press. 2021. https://doi.org/10.1016/j.cell.2021.01.052.

Wang Y, Wu JJ. Thermochemical conversion of biomass: potential future prospects. Renew Sustain Energy Rev. 2023. https://doi.org/10.1016/j.rser.2023.113754.

OECD/FAO. Agricultural outlook 2021–2030. Paris: OECD Publishing; 2021. https://doi.org/10.1787/19428846-en.

Avanthi A, Banerjee R. A strategic laccase mediated lignin degradation of lignocellulosic feedstocks for ethanol production. Ind Crops Prod. 2016. https://doi.org/10.1016/j.indcrop.2016.08.009.

Aghaei S, Alavijeh MK, Shafie M, Karimi K. A comprehensive review on bioethanol production from corn stover: worldwide potential, environmental importance, and perspectives. Biomass Bioenergy. 2022. https://doi.org/10.1016/j.biombioe.2022.106447.

Althuri A, Mohan SV. Emerging innovations for sustainable production of bioethanol and other mercantile products from circular economy perspective. Bioresour Technol. 2022. https://doi.org/10.1016/j.biortech.2022.128013.

Momenitabar M, Ebrahimi ZD, Ghasemi P. Designing a sustainable bioethanol supply chain network: a combination of machine 923 learning and meta-heuristic algorithms. Ind Crop Prod. 2022. https://doi.org/10.1016/j.indcrop.2022.115848.

Aragonés MM, Domínguez CG, Ondrejíčková P, Torralvo FA. Bioenergy production side-streams availability assessment as decision making driver for sustainable valorisation technologies development. Case study: bioethanol and biodiesel industries. Energy Rep. 2022. https://doi.org/10.1016/j.egyr.2022.05.030.

Griggs D, Stafford-Smith M, Gaffney O, Rockström J, Öhman MC, Shyamsundar P, Steffen W, Glaser G, Kanie N, Noble I. Sustainable development goals for people and planet. Nature. 2013. https://doi.org/10.1038/495305a.

Solarte-Toro JC, Ortiz-Sanchez M, Alzate CAC. Sustainability analysis of biorefineries based on country socio-economic and environmental context: a step-by-step way for the integral analysis of biomass upgrading processes. Renew Energy. 2023. https://doi.org/10.1016/j.renene.2023.02.065.

Bleischwitz R, Spataru C, VanDeveer SD, Obersteiner M, van der Voet E, Johnson C, Andrews-Speed P, Boersma T, Hoff H, Van Vuuren DP. Resource nexus perspectives towards the United Nations sustainable development goals. Nat Sustain. 2018. https://doi.org/10.1038/s41893-018-0173-2.

Santoyo-Castelazo E, Santoyo E, Zurita-Garcia L, Luengas DAC, Solano-Olivares K. Life cycle assessment of bioethanol production from sugarcane bagasse using a gasification conversion process:bibliometric analysis, systematic literature review and a case study. Appl Therm Eng. 2023. https://doi.org/10.1016/j.applthermaleng.2022.119414.

Core Team R. R: a language and environment for statistical computing. 2018. https://www.R-project.org/. Accessed 10 Dec 2022.

Bollobás B. Random graphs. Cambridge: Cambridge University Press; 2001.

Blondel VD, Guillaume JL, Lambiotte R, Lefebvre E. Fast unfolding of communities in large networks. J Stat Mech Theory Exp. 2008. https://doi.org/10.1088/1742-5468/2008/10/P10008.

Shibata N, Kajikawa Y, Takeda Y, Sakata I, Matsushima K. Detecting emerging research fronts in regenerative medicine by the citation network analysis of scientific publications. Technol Forecast Soc Change. 2011. https://doi.org/10.1016/j.techfore.2010.07.006.

Robertson S. Understanding inverse document frequency: on theoretical arguments for IDF. J Doc. 2004. https://doi.org/10.1108/00220410410560582.

Guimerà R, Amaral LAN. Functional cartography of complex metabolic networks. Nature. 2005. https://doi.org/10.1038/nature03288.

Yuan J-H, Xu R-K, Zhang H. The forms of alkalis in the biochar produced from crop residues at different temperatures. Bioresour Technol. 2010. https://doi.org/10.1016/j.biortech.2010.11.018.

Buranov AU, Mazza G. Lignin in straw of herbaceous crops. Ind Crops Prod. 2008. https://doi.org/10.1016/j.indcrop.2008.03.008.

Kristensen JB, Börjesson J, Bruun MH, Tjerneld F, Jørgensen H. Use of surface active additives in enzymatic hydrolysis of wheat straw lignocellulose. Enzyme Microb Technol. 2007. https://doi.org/10.1016/j.enzmictec.2006.07.014.

Brown D, Shi J, Li Y. Comparison of solid-state to liquid anaerobic digestion of lignocellulosic feedstocks for biogas production. Bioresour Technol. 2012. https://doi.org/10.1016/j.biortech.2012.08.051.

Zhong W, Zhang Z, Luo Y, Sun S, Qiao W, Xiao M. Effect of biological pretreatments in enhancing corn straw biogas production. Bioresour Technol. 2011. https://doi.org/10.1016/j.biortech.2011.09.077.

Liew LN, Shi J, Li Y. Methane production from solid-state anaerobic digestion of lignocellulosic biomass. Biomass Bioenergy. 2012. https://doi.org/10.1016/j.biombioe.2012.09.014.

Gai C, Dong Y. Experimental study on non-woody biomass gasification in a downdraft gasifier. Int J Hydrog Energy. 2012. https://doi.org/10.1016/j.ijhydene.2011.12.031.

Hamelin L, Naroznova I, Wenzel H. Environmental consequences of different carbon alternatives for increased manure-based biogas. Appl Energy. 2014. https://doi.org/10.1016/j.apenergy.2013.09.033.

Rokni E, Ren X, Panahi A, Levendis YA. Emissions of SO2, NOx, CO2, and HCl from co-firing of coals with raw and torrefied biomass fuels. Fuel. 2018. https://doi.org/10.1016/j.fuel.2017.09.049.

Li C, Hu Y, Zhang F, Chen J, Ma Z, Ye X, Yang X, Wang L, Tang X, Zhang R, Mu M, Wang G, Kan H, Wang X, Mellouki A. Multi-pollutant emissions from the burning of major agricultural residues in China and the related health-economic effects. Atmos Chem Phys. 2017. https://doi.org/10.5194/acp-17-4957-2017.

Cherubini F, Ulgiati S. Crop residues as raw materials for biorefinery systems—a LCA case study. Appl Energy. 2010. https://doi.org/10.1016/j.apenergy.2009.08.024.

Triolo JM, Sommer SG, Møller H, Weisbjerg MR, Jiang XY. A new algorithm to characterize biodegradability of biomass during anaerobic digestion: influence of lignin concentration on methane production potential. Bioresour Technol. 2011. https://doi.org/10.1016/j.biortech.2011.07.026.

Dinuccio E, Balsari P, Gioelli F, Menardo S. Evaluation of the biogas productivity potential of some Italian agro-industrial biomasses. Bioresour Technol. 2010. https://doi.org/10.1016/j.biortech.2009.12.113.

Menardo S, Airoldi G, Balsari P. The effect of particle size and thermal pretreatment on the methane yield of four agricultural by-products. Bioresour Technol. 2012. https://doi.org/10.1016/j.biortech.2011.10.061.

Khatri S, Wu S, Kizito S, Zhang W, Li J, Dong R. Synergistic effect of alkaline pretreatment and Fe dosing on batch anaerobic digestion of maize straw. Appl Energy. 2015. https://doi.org/10.1016/j.apenergy.2015.08.045.

Stahl T, Heyn J, Thiele H, Huther J, Failing K, Georgii S, Brunn H. Carryover of perfluorooctanoic acid (PFOA) and perfluorooctane sulfonate (PFOS) from soil to plants. Arch Environ Contam Toxicol. 2008. https://doi.org/10.1007/s00244-008-9272-9.

Nyambo C, Mohanty AK, Misra M. Polylactide-based renewable green composites from agricultural residues and their hybrids. Biomacromolecules. 2010. https://doi.org/10.1021/bm1003114.

Govaerts B, Sayre KD, Lichter K, Dendooven L, Deckers J. Influence of permanent raised bed planting and residue management on physical and chemical soil quality in rain fed maize/wheat systems. Plant Soil. 2007. https://doi.org/10.1007/s11104-006-9172-6.

Song X, Liu M, Ju X, Gao B, Su F, Chen X, Rees RM. Nitrous oxide emissions increase exponentially when optimum nitrogen fertilizer rates are exceeded in the North China Plain. Environ Sci Technol. 2018. https://doi.org/10.1021/acs.est.8b03931.

Sun L, Wu Z, Ma Y, Liu Y, Xiong Z. Ammonia volatilization and atmospheric N deposition following straw and urea application from a rice-wheat rotation in southeastern China. Atmos Environ. 2018. https://doi.org/10.1016/j.atmosenv.2018.02.050.

Mani S, Tabil LG, Sokhansanj S. Effects of compressive force, particle size and moisture content on mechanical properties of biomass pellets from grasses. Biomass Bioenergy. 2006. https://doi.org/10.1016/j.biombioe.2005.01.004.

Zervakis G, Philippoussis A, Ioannidou S, Diamantopoulou P. Mycelium growth kinetics and optimal temperature conditions for the cultivation of edible mushroom species on lignocellulosic substrates. Folia Microbiol. 2001. https://doi.org/10.1007/BF02818539.

Piotrowska-Cyplik AC, Chrzanowski L, Cyplik P, Dach J, Olejnik A, Staninska J, Czarny J, Lewicki A, Marecik R, Powierska-Czarny J. Composting of oiled bleaching earth: fatty acids degradation, phytotoxicity and mutagenicity changes. Int Biodeterior Biodegrad. 2011. https://doi.org/10.1016/j.ibiod.2012.12.007.

Jeznabadi EK, Jafarpour M, Eghbalsaied S. King oyster mushroom production using various sources of agricultural wastes in Iran. Int J Recycl Org Waste Agric. 2016. https://doi.org/10.1007/s40093-015-0113-3.

Wang D, Sun XS. Low density particleboard from wheat straw and corn pith. Ind Crops Prod. 2002. https://doi.org/10.1016/S0926-6690(01)00094-2.

Scudamore KA, Livesey CT. Occurrence and significance of mycotoxins in forage crops and silage: a review. J Sci Food Agric. 1998. https://doi.org/10.1002/(sici)1097-0010(199805)77:1%3c1::aid-jsfa9%3e3.0.co;2-4.

Kapich AN, Prior BA, Botha A, Galkin S, Lundell T, Hatakka A. Effect of lignocellulose-containing substrates on production of ligninolytic peroxidases in submerged cultures of phanerochaete chrysosporium ME-446. Enzyme Microb Technol. 2004. https://doi.org/10.1016/j.enzmictec.2003.10.004.

Zhang H, Ye X, Cheng T, Chen J, Yang X, Wang L, Zhang R. A laboratory study of agricultural crop residue combustion in China: emission factors and emission inventory. Atmos Environ. 2008. https://doi.org/10.1016/j.atmosenv.2008.08.015.

Sun J, Peng H, Chen J, Wang X, Wei M, Li W, Yang L, Zhang Q, Wang W, Mellouki A. An estimation of CO2 emission via agricultural crop residue open field burning in China from 1996 to 2013. J Clean Prod. 2016. https://doi.org/10.1016/j.jclepro.2015.09.112.

Sun J, Shen Z, Ca J, Zhang L, Wu T, Zhang Q, Yin X, Huang Y, Huang RJ, Iu S, Han Y, Xu H, Zheng C, Liu P. Particulate matters emitted from maize straw burning for winter heating in rural areas in Guanzhong Plain, China: current emission and future reduction. Atmos Res. 2017. https://doi.org/10.1016/j.atmosres.2016.10.006.

Guo N, Li M, Sun X, Wang F. Enzymatic hydrolysis lignin derived hierarchical porous carbon for supercapacitors in ionic liquids with high power and energy densities. Green Chem. 2017. https://doi.org/10.1039/C7GC00506G.

Qiu Z, Wang Y, Bi X, Zhou T, Zhou J, Zhao J, Miao Z, Yic W, Fuc P, Zhuo S. Biochar-based carbons with hierarchical micro-meso-macro porosity for high rate and long cycle life supercapacitors. J Power Sources. 2018. https://doi.org/10.1016/j.jpowsour.2017.11.077.

Ren Q, Zhao C, Wu X, Liang C, Chen X, Shen J, Tang G, Wang Z. Effect of mineral matter on the formation of NOx precursors during biomass pyrolysis. J Anal Appl Pyrolysis. 2009. https://doi.org/10.1016/j.jaap.2008.08.006.

Shi C, Jing CY, Xiao J, Wang X, Yao Y, Jia Y. Solvent extraction of lithium from aqueous solution using non-fluorinated functionalized ionic liquids as extraction agents. Sep Purif Technol. 2017. https://doi.org/10.1016/j.seppur.2016.08.034.

Patel AD, Ruiz JCS, Dumesic JA, Anex RP. Techno-economic analysis of 5-nonanone production from levulinic acid. J Chem Eng. 2010. https://doi.org/10.1016/j.cej.2010.03.034.

Manzer LE. Catalytic synthesis of α-methylene-γ-valerolactone: a biomass-derived acrylic monomer. Appl Catal. 2004. https://doi.org/10.1016/j.apcata.2004.05.048.

Garrote G, Domínguez H, Parajó JC. Autohydrolysis of corncob: study of nonisothermal operation for xylooligosaccharide production. J Food Eng. 2002. https://doi.org/10.1016/S0260-8774(01)00108-X.

Latif F, Rajoka MI. Production of ethanol and xylitol from corn cobs by yeasts. Bioresour Technol. 2000. https://doi.org/10.1016/s0960-8524(00)00134-6.

Gomes J, Purkarthofer H, Hayn M, Kapplmiiller J, Sinner M, Steiner W. Production of a high level of cellulase-free xylanase by the thermophilic fungus Thermomyces lanuginosus in laboratory and pilot scales using lignocellulosic materials. Appl Microbiol Biotechnol. 1993. https://doi.org/10.1007/bf00164453.

Chundawat SPS, Venkatesh B, Dale BE. Effect of particle size based separation of milled corn stover on AFEX pretreatment and enzymatic digestibility. Biotechnol Bioeng. 2007. https://doi.org/10.1002/bit.21132.

Hale SE, Alling V, Martinsen V, Mulder J, Breedveild GD, Cornelissen G. The sorption and desorption of phosphate-P, ammonium-N and nitrate-N in cacao shell and corn cob biochars. Chemosphere. 2013. https://doi.org/10.1016/j.chemosphere.2012.12.057.

Tsai WT, Chang CY, Wang SY, Chang CF, Chien SF, Sun HF. Cleaner production of carbon adsorbents by utilizing agricultural waste corn cob. Resour Conserv Recycl. 2001. https://doi.org/10.1016/S0921-3449(00)00093-8.

Guo YAN, Ma Y, Zhan Z, Li B, Dingkuhn M, Luquet D, Reffye P. Parameter optimization and field validation of the functional–structural model GREENLAB for maize. Ann Bot. 2006. https://doi.org/10.1093/aob/mcj033.

Cao Q, Xie KC, Lv YK, Bao WR. Process effects on activated carbon with large specific surface area from corn cob. Bioresour Technol. 2006. https://doi.org/10.1016/j.biortech.2005.02.026.

Kadirvelu K, Kavipriya M, Karthika C, Radhika M, Vennilamani N, Pattabhi S. Utilization of various agricultural wastes for activated carbon preparation and application for the removal of dyes and metal ions from aqueous solutions. Bioresour Technol. 2003. https://doi.org/10.1016/s0960-8524(02)00201-8.

Schipper LA, Robertson WD, Gold AJ, Jaynes DB, Cameron SC. Denitrifying bioreactors—an approach for reducing nitrate loads to receiving waters. Ecol Eng. 2010. https://doi.org/10.1016/j.ecoleng.2010.04.008.

Kim S, Jiménez-gonzález C, Dale BE. Enzymes for pharmaceutical applications—a cradle-to-gate life cycle assessment. Int J Life Cycle Assess. 2009. https://doi.org/10.1007/s11367-009-0081-9.

Hoskinson RL, Karlen DL, Birrenll SJ, Radtke CW, Wilhelm WW. Engineering, nutrient removal, and feedstock conversion evaluations of four corn stover harvest scenarios. Biomass Bioenergy. 2007. https://doi.org/10.1016/j.biombioe.2006.07.006.

Shinners KJ, Binversie BN, Muck RE, Weimer PJ. Comparisonof wet and dry corn stover harvest and storage. Biomass Bioenergy. 2007. https://doi.org/10.1016/j.biombioe.2006.04.007.

Qu T, Guo W, Shen L, Xiao J, Zhao K. Experimental study of biomass pyrolysis based on three major components: hemicellulose, cellulose, and lignin. Ind Eng Chem Res. 2011. https://doi.org/10.1021/ie1025453.

Demirbas A. Producing and using bioethanol as an automotive fuel. Energy Sources. 2007. https://doi.org/10.1080/15567240600705466.

Lorenzi BR, Andrade THN. O Etanol De Segunda Geração no Brasil: Políticas E redes sociotécnicas. Rev bras Ci Soc. 2021. https://doi.org/10.1590/3410014/2019.

Oh H, Wee YJ, Yun JS, Han SH, Jung S, Ryu HW. Lactic acid production from agricultural resources as cheap raw materials. Bioresour Technol. 2005. https://doi.org/10.1016/j.biortech.2004.11.020.

Yu L, Lei T, Ren X, Pei X, Feng Y. Response surface optimization of l-(+)-lactic acid production using corn steep liquor as an alternative nitrogen source by Lactobacillus rhamnosus CGMCC 1466. Biochem Eng J. 2008. https://doi.org/10.1016/j.bej.2007.11.008.

Kona RP, Qureshi N, Pai JS. Production of glucose oxidase using aspergillus Niger and corn steep liquor. Bioresour Technol. 2001. https://doi.org/10.1016/s0960-8524(01)00014-1.

Xi YL, Chen KQ, Dai WY, Ma JF, Zhang M, Jiang M, Wei P, Ouyang PK. Succinic acid production by Actinobacillus succinogenes NJ113 using corn steep liquor powder as nitrogen source. Bioresour Technol. 2013. https://doi.org/10.1016/j.biortech.2013.03.107.

Khan I, Nazir K, Wang ZP, Liu GL, Chi ZM. Calcium malate overproduction by Penicillium viticola 152 using the medium containing corn steep liquor. Appl Microbiol Biotechnol. 2013. https://doi.org/10.1007/s00253-013-5326-7.

Wischral D, Zhang J, Cheng C, Lin M, De Souza LM, Pessoa FL, Pereira N Jr, Yang ST. Production of 1, 3-propanediol by Clostridium beijerinckii DSM 791 from crude glycerol and corn steep liquor: process optimization and metabolic engineering. Bioresour Technol. 2016. https://doi.org/10.1016/j.biortech.2016.04.020.

Ju JH, Wang D, Heo SY, Kim MS, Seo JW, Kim YM, Kim DH, Kang SA, Kim CH, Oh BR. Enhancement of 1, 3-propanediol production from industrial by-product by Lactobacillus reuteri CH53. Microb Cell Factories. 2020. https://doi.org/10.1186/s12934-019-1275-x.

Mazutti M, Bender JP, Treichel H, Luccio MD. Optimization of inulinase production by solid-state fermentation using sugarcane bagasse as substrate. Enzyme Microb Technol. 2006. https://doi.org/10.1016/j.enzmictec.2005.09.008.

Wei W, Zheng Z, Liu Y, Zhu S. Optimizing the culture conditions for higher inulinase production by Kluyveromyces sp. Y-85 and scaling-up fermentation. J Ferment Bioeng. 1998. https://doi.org/10.1016/S0922-338X(99)89011-4.

Valduga E, Ribeiro AHR, Cence K, Colet R, Tiggemann L, Zeni J, Toniazzo G. Carotenoids production from a newly isolated Sporidiobolus pararoseus strain using agroindustrial substrates. Biocatal Agric Biotechnol. 2014. https://doi.org/10.1016/j.bcab.2013.10.001.

Valduga E, Valério A, Treichel H, Di Luccio M, Furigo Júnior A. Study of the bio-production of carotenoids by Sporidiobolus salmonicolor (CBS 2636) using pre-treated agro-industrial substrates. J Chem Technol Biotechnol. 2008. https://doi.org/10.1002/jctb.1940.

Colet R, Di Luccio M, Valduga E. Fed-batch production of carotenoids by Sporidiobolus salmonicolor (CBS 2636): kinetic and stoichiometric parameters. Eur Food Res Technol. 2015. https://doi.org/10.1007/s00217-014-2318-5.

Gouda MK, Swellam AE, Omar SH. Production of PHB by a Bacillus megaterium strain using sugarcane molasses and corn steep liquor as sole carbon and nitrogen sources. Microbiol Res. 2001. https://doi.org/10.1078/0944-5013-00104.

Sobrinho HBS, Rufino RD, Luna JM, Salgueiro AA, Campostakaki GM, Leite LFC, Sarubbo LA. Utilization of two agroindustrial byproducts for the production of a surfactant by Candida sphaerica UCP0995. Process Biochem. 2008. https://doi.org/10.1016/j.procbio.2008.04.013.

Santos DKF, Rufino RD, Luna JM, Santos VA, Salgueiro AA, Sarubbo LA. Synthesis and evaluation of biosurfactant produced by Candida lipolytica using animal fat and corn steep liquor. J Pet Sci Eng. 2013. https://doi.org/10.1016/j.petrol.2013.03.028.

Silva NMPR, Rufino RD, Luna JM, Santos VA, Sarubbo LA. Screening of Pseudomonas species for biosurfactant production using low-cost substrates. Biocatal Agric Biotechnol. 2014. https://doi.org/10.1016/j.bcab.2013.09.005.

Furlan SA, Schneider ALS, Merkle R, Carvalho MF, Jonas R. Formulation of a lactose-free, low-cost culture medium for the production of β-d-galactosidase by Kluyveromyces marxianus. Biotechnol Lett. 2000. https://doi.org/10.1023/A:1005629127532.

Vicentim MP, Ferraz A. Enzyme production and chemical alterations of Eucalyptus grandis wood during biodegradation by Ceriporiopsis subvermispora in cultures supplemented with Mn2+, corn steep liquor and glucose. Enzyme Microb Technol. 2007. https://doi.org/10.1016/j.enzmictec.2006.05.021.

Reddy LVA, Wee YJ, Yun JS, Ryu HW. Optimization of alkaline protease production by batch culture of Bacillus sp. RKY3 through Plackett–Burman and response surface methodological approaches. Bioresour Technol. 2008. https://doi.org/10.1016/j.biortech.2007.05.006.

Zou X, Hang HF, Chu J, Zhuang YP, Zhang SL. Oxygen uptake rate optimization with nitrogen regulation for erythromycin production and scale-up from 50 L to 372 m3 scale. Bioresour Technol. 2009. https://doi.org/10.1016/j.biortech.2008.09.017.

El-Enshasy HA, Mohamed NA, Farid MA, El-Diwany AI. Improvement of erythromycin production by Saccharopolyspora erythraea in molasses based medium through cultivation medium optimization. Bioresour Technol. 2008. https://doi.org/10.1016/j.biortech.2007.08.050.

Sarwar G, Corsi R, Allen D, Weschler C. The significance of secondary organic aerosol formation and growth in buildings: experimental and computational evidence. Atmos Environ. 2003. https://doi.org/10.1016/S1352-2310(02)01013-0.

Adebusoye SA, Ilori MO, Obayori OS, Oyetibo GO, Akindele KA, Amund OO. Efficiency of cassava steep liquor for bioremediation of diesel oilcontaminated tropical agricultural soil. Environmentalist. 2010. https://doi.org/10.1007/s10669-009-9239-z.

El-Saied H, El-Diwany AI, Basta AH, Atwa NA, El-Ghwas DE. Production and characterization of economical bacterial cellulose. BioResources. 2008. https://doi.org/10.15376/BIORES.3.4.1196-1217.

Nguyen VT, Gidley MJ, Dykes GA. Potential of a nisin-containing bacterial cellulose film to inhibit Listeria monocytogenes on processed meats. Food Microbiol. 2008. https://doi.org/10.1016/j.fm.2008.01.004.

Nguyen VT, Flanagan B, Gidley MJ, Dykes GA. Characterization of cellulose production by a gluconaceto bacterxylinus strain from Kombucha. Curr Microbiol. 2008. https://doi.org/10.1007/s00284-008-9228-3.

Wang XL, Zhou JJ, Shen JT, Zheng YF, Sun YQ, Xiu ZL. Sequential fed-batch fermentation of 1, 3-propanediol from glycerol by Clostridium butyricum DL07. Appl Microbiol Biotechnol. 2020. https://doi.org/10.1007/s00253-020-10931-2.

Lee SY, Chang HN. Effect of complex nitrogen source on the synthesis and accumulation of poly (3-hydroxybutyric acid) by recombinant Escherichia coli in flask and fed-batch cultures. J Environ Polym Degrad. 1994. https://doi.org/10.1007/BF02067442.

Zhuang H, Tang N, Yuan Y. Purification and identification of antioxidant peptides from corn gluten meal. J Funct Foods. 2013. https://doi.org/10.1016/j.jff.2013.08.013.

Li XX, Han LJ, Chen LJ. In vitro antioxidant activity of protein hydrolysates prepared from corn gluten meal. J Sci Food Agric. 2008. https://doi.org/10.1002/jsfa.3264.

Lin F, Chen L, Zhang Z, Wang J, Cai M, Li Y. Pilot-scale production of low molecular weight peptides from corn wet milling byproducts and the antihypertensive effects in vivo and in vitro. Food Chem. 2011. https://doi.org/10.1016/j.foodchem.2010.06.099.

Anderson TJ, Lamsal BP. Zein extraction from corn, corn products, and coproducts and modifications for various applications: a review. Cereal Chem. 2011. https://doi.org/10.1094/CCHEM-06-10-0091.

Di Gioia L, Guilbert S. Corn protein-based thermoplastic resins: effect of some polar and amphiphilic plasticizers. J Agric Food Chem. 1999. https://doi.org/10.1021/jf980976j.

Yadav MP, Johnston DB, Hotchkiss AT Jr, Hicks KB. Corn fiber gum: a potential gum arabic replacer for beverage flavor emulsification. Food Hydrocoll. 2007. https://doi.org/10.1016/j.foodhyd.2006.07.009.

Agler MT, Garcia ML, Lee ES, Schlicher M, Argenent LT. Thermophilic anaerobic digestion to increase the net energy balance of corn grain ethanol. Environ Sci Technol. 2008. https://doi.org/10.1021/es800671a.

Dereli RK, Grelot A, Heffernan B, Van Der Zee FP, Van Lier JB. Implications of changes in solids retention time on long term evolution of sludge filterability in anaerobic membrane bioreactors treating high strength industrial wastewater. Water Res. 2014. https://doi.org/10.1016/j.watres.2014.03.073.

Andalib M, Elbeshbishy E, Mustafa N, Hafez H, Nakhla G, Zhu J. Performance of an anaerobic fluidized bed bioreactor (AnFBR) for digestion of primary municipal wastewater treatment biosolids and bioethanol thin stillage. Renew Energy. 2014. https://doi.org/10.1016/j.renene.2014.05.039.

Singh V, Panchal CB, Eckhoff SR. Effect of corn oil on thin stillage evaporators. Cereal Chem. 1999. https://doi.org/10.1094/CCHEM.1999.76.6.846.

Arora A, Seth A, Dien BS, Belyea RL, Singh V, Tumbleson ME, Rausch KD. Microfiltration of thin stillage: process simulation and economic analyses. Biomass Bioenergy. 2011. https://doi.org/10.1016/j.biombioe.2010.08.024.

Arora A, Dien BS, Belyea RL, Wang P, Singh V, Tumbleson ME, Rausch KD. Thin stillage fractionation using ultrafiltration: resistance in series model. Bioprocess Biosyst Eng. 2008. https://doi.org/10.1007/s00449-008-0240-6.

Arora A, Dien BS, Belyea RL, Wang P, Singh V, Tumbleson ME, Rausch KD. Heat transfer fouling characteristics of microfiltered thin stillage from the dry grind process. Bioresour Technol. 2010. https://doi.org/10.1016/j.biortech.2010.03.077.

Kim Y, Mosier NS, Hendricson R, Ezeji T, Blaschek H, Dien B, Cotta M, Dale B, Ladisch MR. Composition of corn dry-grind ethanol byproducts: DDGS, wet cake, and thin stillage. Bioresour Technol. 2008. https://doi.org/10.1016/j.biortech.2007.09.028.

Espana-Gamboa E, Mijangos-Cortes J, Barahona-Perez L, Dominguez-Maldonado J, Hernández-Zarate G, Alzate-Gaviria L. Vinasses: characterization and treatments. Waste Manag Res. 2011;29(12):1235–50.

Liu KS, Han J. Changes in mineral concentrations and phosphorus profile during dry-grind processing of corn into ethanol. Bioresour Technol. 2011. https://doi.org/10.1016/j.biortech.2010.10.070.

Luangthongkam P, Fang AL, Noomhormb A, Lamsal B. Addition of cellulolytic enzymes and phytase for improving ethanol fermentation performance and oil recovery in corn dry grind process. Ind Crops Prod. 2015. https://doi.org/10.1016/j.indcrop.2015.09.060.

Reis CER, Rajendran A, Hu B. New technologies in value addition to the thin stillage from corn-to-ethanol process. Rev Environ Sci Biotechnol. 2017. https://doi.org/10.1007/s11157-017-9421-6.

Kim SM, Li S, Pana SC, Ding Y, Sasu R, Van Egmond P, Singh V. A whole stillage sieving process to recover fiber for cellulosic ethanol production. Ind Crops Prod. 2016. https://doi.org/10.1016/j.indcrop.2016.08.012.

Hayman GT, Mannarelli BM, Leathers TD. Production of carotenoids by Phaffia rhodozyma grown on media composed of corn wet-milling co-products. J Ind Microbiol. 1995. https://doi.org/10.1007/BF01569956.

Ergönül PG, Köseoğlu O. Changes in α-, β-, γ-and δ-tocopherol contents of mostly consumed vegetable oils during refining process. CYTA J Food. 2014;12(2):199–202.

Naz S, Kara H, Sherazi STH, Aljabour A, Talpur FN. A green approach for the production of biodiesel from fatty acids of corn deodorizer distillate. RSC Adv. 2014. https://doi.org/10.1039/C4RA08108K.

Sohi SP, Krull E, Capel EL, Bol R. A review of biochar and its use and function in soil. Adv Agron. 2010. https://doi.org/10.1016/S0065-2113(10)05002-9.

Brownsort PA. Biomass pyrolisis processes: review of scope, control and variability. In: United Kingdom Biochar Research Centre; 2009. https://www.biochar.ac.uk/abstract.php?id=16. Accessed 01 Dec 2022.

Rivas B, Moldes AB, Domínguez JM, Parjó JC. Lactic acid production from corn cobs by simultaneous saccharification and fermentation: a mathematical interpretation. Enzyme Microb Technol. 2004. https://doi.org/10.1016/j.enzmictec.2004.01.011.

Li D, Zhu FZ, Li JY, Na P. Preparation and characterization of cellulose fibers from corn straw as natural oil sorbents. Ind Eng Chem Res. 2013. https://doi.org/10.1021/ie302288k.

Silva RCFS, Almeida DG, Meira HM, Silva EJ, Farias CBB, Rufino RD, Luna JM, Sarubbo LA. Production and characterization of a new biosurfactant from Pseudomonas cepacia grown in low-cost fermentative medium and its application in the oil industry. Biocatal Agric Biotechnol. 2017. https://doi.org/10.1016/j.bcab.2017.09.004.

Mendes MF, Pessoa FLP, Coelho GV, Uller AMC. Recovery of the high aggregated compounds present in the deodorizer distillate of the vegetable oils using supercritical fluids. J Supercrit Fluids. 2005. https://doi.org/10.1016/j.supflu.2004.11.009.

Qin L, Zhang J, Cheng H, Chen L, Qi Z, Yuan W. Selection of imidazoliumbased ionic liquids for vitamin E extraction from deodorizer distillate. ACS Sustain Chem Eng. 2015. https://doi.org/10.1021/acssuschemeng.5b01330.

Albuquerque RMB, Meira HM, Silva IDL, Silva CJG, Almeida FCG, Amorim JDP, Vinhas GM, Costa AFS, Sarubbo LA. Production of a bacterial cellulose/poly (3-hydroxybutyrate) blend activated with clove essential oil for food packaging. Polym Polym Compos. 2020. https://doi.org/10.1177/09673911209120.

Oliveira BC. Complexidade em biorrefinarias. Dissertation, Federal University of Rio de Janeiro. 2016.

Author information

Authors and Affiliations

Contributions

JSM: performed the literature search and data analysis. ACAJ: writing, editing, and review. RFS: conceptualization and review. JCCM: idea for the article, project administration and critically revised the work. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Matos, J.S., Justi, A.C.A., Souza, R.F. et al. Building and evaluating prospective scenarios for corn-based biorefineries. Discov Chem Eng 3, 20 (2023). https://doi.org/10.1007/s43938-023-00036-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s43938-023-00036-3