Abstract

With the development of the petrochemical industry, the demand for light olefins is rapidly increasing. The separation of olefin/paraffin by membrane technology can save energy consumption and improve separation efficiency. This article reviews the latest progress in facilitated transport membranes for olefin/paraffin separation. The separation mechanism and common types of facilitated transport membranes are briefly introduced. Meanwhile, the mechanism of carrier deactivation and the corresponding strategies to improve the stability of the membranes are summarized. In concluding, current developments regarding facilitated transport membranes are summarized and directions for future development are proposed.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Background

Light olefins such as ethylene and propylene are important raw materials for the petrochemical industry. The most widely used process for olefin production is the steam cracking of naphtha or light alkanes, followed by catalytic dehydrogenation, which leads to the production of olefin/paraffin mixtures [1]. Therefore, olefins must be separated from the mixtures before further utilization, and the most common method for olefin/paraffin separation is cryogenic distillation, which is extremely energy-intensive.

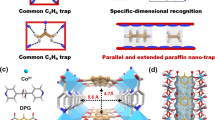

Membrane separation technology has been proposed to replace the cryogenic distillation or be integrated with it to reduce the energy consumption [2,3,4]. At present, several membranes for olefin/paraffin separation have been reported [5,6,7,8,9]. Generally, membranes based on the solution-diffusion mechanism are not ideal for olefin/paraffin separation, because the physicochemical properties of olefins and paraffins are too close [10]. In addition, the difference in their molecular dynamic diameters are very small (e.g., the difference between ethylene and ethane is only ~ 0.3 Å), so even using molecular sieve membranes the selectivity is not high [3, 11]. With the rise of metal organic frameworks (MOFs), pure MOF membranes were developed for the separation of olefins and paraffins, some of which (e.g., ZIF-8) have achieved quite high separation selectivity [12, 13]. However, such membranes face the challenge in mechanical strength and scale-up fabrication [14]. Alternatively, zeolites and MOFs particles were incorporated into polymer matrix to fabricate mixed-matrix membranes (MMMs) [15, 16], while the membrane permeance is still not attractive towards practical application. To overcome the difficulty of separation due to the similarity of olefins and paraffins, facilitated transport mechanism has been proposed to achieve a simultaneous increase in olefin permeability and olefin/paraffin selectivity. The so-called facilitated transport mechanism is that the chemically distinct carrier in the membrane layer can form complexes with a specific component (such as ethylene) in the feed side, thereby increasing the permeation rate of this component relative to other components [17]. The olefin/paraffin separation performance of the facilitated transport membranes is far beyond the permeability-selectivity upper-bound based on solution-diffusion transport mechanism [18], but for practical application the stability remains to be solved.

In this paper, the latest progress in facilitated transport membrane is briefly reviewed covering aspects of transport mechanisms, membrane types and the stability issue. Moreover, comments on the challenges and prospects of developing facilitated transport membranes are given.

2 Main text

2.1 Transport mechanism and structures of facilitated transport membranes

The separation of ethylene and ethane is chosen as an example for demonstrating the facilitated transport process (Fig. 1). The carrier selectively and reversibly interacts with the target molecule (e.g., ethylene), which increases the driving force of the target molecule through the membrane layer and thus the permeation rate. Because the inert molecule ethane cannot form specific interaction (e.g., π complexation) with the carrier and be facilitated to permeate, the concentration of ethane molecules at the permeate side is relatively low. Therefore, compared with membranes based on solution-diffusion mechanism, such facilitated transport membranes tend to show extremely high separation selectivity [19, 20]. In order to realize facilitated transport, the carriers need to be effectively dispersed on the diffusion path of gases, and a threshold concentration of carriers is required to activate the facilitated transport mechanism. In addition, the carrier must maintain its activity to reversely interact with the target molecule, otherwise it will lose the facilitating effect.

2.2 Facilitated transport mechanism

The first metal-olefin complex platinum (II)-ethylene, which is called Zeise complex, was discovered in 1827. In the early twentieth century, researchers tried to employ silver (Ag+) salts in olefin absorption systems; however, the mechanism was not clear until Dewar proposed a preliminary explanation for the interaction mechanism between ethylene and Ag+ in 1951 [21]. Chatt and Duncanson further developed Dewar's theory and proposed the interaction mechanism of π-bond complexation [22]. This complexation occurs when the bonding orbital of the olefin donates electronic density to the outermost empty orbital of Ag+ (5 s) to form a σ bond, the strength of which depends on the positive charge of the metal (such as silver, copper, and gold). The second bond is a π bond, which is formed by the backdonation of the electronic density from the outermost 4d atomic orbital of the metal to the π*-antibonding molecular orbital of the olefin [23] (Fig. 2). In 1960, Scholander et al. reported a groundbreaking work on the facilitated transport of oxygen by the liquid membranes containing hemoglobin as transport carriers [24]. Then the studies related to facilitated transport membranes has been extended to various fields. Owing to the extraordinary separation performance, facilitated transport membranes have attracted great research interest worldwide.

The schematic of the π complexation effect between olefin and Ag(I) [23].

Due to the reversible interaction between olefins and some transition metals (especially silver, copper and gold), the facilitated transport membranes containing these metal ions can realize the efficient olefin/paraffin separation. It is worth noting that the π complexation between ions and olefins should be strong enough to form interactions while allowing reversible complexation under appropriate conditions. Among the transition metals, the complexation of silver is prominent, and its electronegativity is 2.2, which is within the range of 1.6–2.3 and can realize reversible complexation [25]. Moreover, silver salts possess the lowest lattice energy compared with other metal salts used for facilitated transport. The low lattice energy is beneficial to improving the solubility of metal cations, and therefore enhancing interaction with olefins [26]. Because of these characteristics, silver is the most commonly used metal for the preparation of olefin/paraffin separation membranes. In addition, copper is another option because of the relatively low price. However, due to the instability of Cu+ in the presence of oxidants, very few work on copper serving as carrier has been reported [27]. On the basis of the coordination complexation between silver salts and olefins, the facilitated transport membranes for olefin/paraffin separation was developed based on supported liquid membranes as the initial form. To further improve the stability of the separation performance, the researchers proposed ion exchange membranes and polymer electrolyte membranes for the separation of olefin/paraffin, which will be further discussed.

2.3 Facilitated transport membranes with different structures

2.3.1 Supported liquid membranes

Supported liquid membrane is the simplest liquid membrane and the fabrication process is convenient. The microporous membrane is chosen as the support, which is immersed into the carrier solution (such as silver nitrate). The carrier is absorbed into the porous support by capillary force (Fig. 3). In 1973, Steigelmann and Hughes from Standard Oil Company proposed to load the silver nitrate solution in the pores of cellulose acetate membrane to prepare supported liquid membranes [28]. The mixed ethylene/ethane selectivity of the as-prepared membrane is up to 1280, and the permeance of the mixture is 30 GPU. Driven by such high performance, they continued their study of this kind of membrane for more than 10 years. Nevertheless, they were not successful in commercializing this technology. The critical problem lied in the poor stability of the silver nitrate solution in the membrane pores. During the separation process, owing to the drag of the gas stream, the carrier solution was gradually swept out from the pores, leading to the decrease of the membrane selectivity [28]. In order to solve this problem, Teramoto et al. proposed a humidification method extended the lifetime of the membranes [29], and several subsequent work focused on improving the stability of the solution in the pores of the supported liquid membranes [30, 31]. However, the inherent instability of the supported liquid membranes, as well as the demand for humidification of the feed and sweep gas, limits the practical application of the supported liquid membranes.

2.3.2 Ion exchange membranes

Ion exchange membranes are usually prepared by introducing silver salts into polymer membrane with an acid group (such as sulfonic acid groups), and then the proton is exchanged by the silver ion. To realize the ion exchange, the polymer is immersed in a solution containing silver or other metal salt solution (Fig. 4). The polymer materials commonly chosen as the matrix of the ion exchange membrane were Nafion and sulfonated polyphenoxy (SPPO) [32]. During the operation process, the membranes need to be humidified. Otherwise, the silver ions are strongly bound to the anion sites of the membranes in the absence of water, making them difficult to interact with olefins. Eriksen et al. pretreated Nafion membrane in glycerin and soaked them in 6 M AgBF4 aqueous solution to fabricate ion exchange membranes for the separation of humidified ethylene/ethane (1:1, molar ratio) mixture. The as-prepared membranes showed a super-high selectivity of 1930 and ethylene permeability of 26,800 Barrer (~ 83 GPU) [33]. Since the carrier is not easily taken out of the membrane by the gas flow, the ion exchange membranes have a huge advantage compared with the supported liquid membrane. Although the stability of ion-exchange membranes has been improved, they are generally more costly, and the necessary humidification step is undesirable for practical application because it brings additional steps to dry the outlet gas stream from the membrane unit.

2.3.3 Polymer electrolyte membranes

The polymer electrolyte membrane is another facilitated transport membrane, which is composed of a polymer matrix and metal salt distributed in the polymer. In the polymer matrix, both anions and cations are sufficiently mobile without the need of solvents or plasticizers to promote ionic motion and conductivity [34]. Therefore, the dissolution behavior of the metal salt in the polymer matrix and its ionic composition are very important for the ion conduction and mass transfer properties inside the membrane. Unlike the liquid membrane in which the carrier solution is confined in the pores of the membrane, the dense electrolyte membrane can maintain the complexing agent even under relatively high pressure difference across the membrane. In the polymer electrolyte membranes, the salts can dissociate into anions and cations in the solid state. The interaction between the metal cation of the dissolved salt and the electron donor pairs of the heteroatoms of the polymer matrix could contribute to the ion-pair separation of the of the dissolved salt, forming a new ion-pair between the cation of the salt and the heteroatoms of the polymer [1]. This new ion-pair interaction produces a conductive solid for various application, and most related work has been reported on poly(ethylene oxide) (PEO) conductors for lithium ion conduction in high energy batteries [35]. Nevertheless, the mass transfer characteristics of silver-based electrolyte membranes have attracted extensive attention in the field of olefin/paraffin separation in the past few decades.

The hopping mechanism was proposed to explain the facilitated transport phenomenon in the membranes [36] (Fig. 5). Silver ions are fixed in the polymer by coordination with polymer oxygen. When the olefin permeates through the membrane layer, the olefin can form coordination complexation with the silver ions, and hop to another neighboring silver ion. After many times of hoping along the silver ions, the olefin can be released at the downstream of the membrane. In contrast, the paraffin cannot complex with silver ion, leading to the preferential permeation of olefins through the membrane.

Pinnau and Toy firstly developed poly(ethylene oxide) (PEO)-based electrolyte membranes for olefin/paraffin separation [37]. The polar functional groups of PEO could coordinate with silver ions and contribute to the dissociation of salts. Compared with ion-exchange membranes, this membrane realized facilitated transport of ethylene without the humidification of feed gas, which is a great breakthrough for the facilitated transport membranes. Kang et al. dissolved silver salts into other polar polymers, such as poly(2-ethyl-2-oxazoline) (POZ), polyvinylpyrrolidone (PVP) and poly(styrene-b-butadiene-b-styrene) (SBS), and the performances of the membranes far exceeded those of the previous supported liquid membrane and ion exchange membrane [38, 39]. They studied different types of silver salts and polymers to prepare electrolyte membranes, which exhibited extremely high selectivity and permeability [26]. However, the interaction between functional groups of polymer and silver ions may cause silver ions to be reduced to elemental silver. Over time, the growth and agglomeration of elemental silver led to the formation of pores or defects at the interface of metal nanoparticles and polymer chains. In the long-term permeation experiment, the gases can easily pass through the defects with low mass transfer resistance, severely reducing the selectivity [40]. In addition, the reducing gas (such as H2) in the feed gas will aggravate the deactivation of silver ions, further decreasing the membrane performance. Therefore, the stability of membrane performance is a key factor restricting the development of polymer electrolyte membranes, and some solutions are summarized in detail below.

The polymer electrolyte membranes can be regarded as a solid mixture of the polymer and the metal salt, and the movement of ions in the polymer electrolyte is realized by the thermal motion of the polymer segment. The polymer chain of the polymer electrolyte membrane generally contains electron-donating groups (O, S, N, etc.), which can complex with the cation of the metal salts to form a coordination bond. Commonly used polymer materials include PEO, POZ, PVP, polyacrylamide (PAAm), polyetherblockamide (PEBAX) [41, 42]. In solid polymer electrolyte membranes, the permeation of olefins mainly relies on the facilitated transport mechanism, and traditional solution-diffusion process is not dominant. Therefore, the intrinsic separation performance of the polymer material in the polymer electrolyte membrane has little effect on the separation performance, as long as the main chains of the polymer material possess flexibility and a certain number of polar groups for coordination with the transition metal ions.

Pinnau et al. found that the presence of heteroatom oxygen in the polymer could accelerate the complexation of silver ions with the polymer, enhancing the solubility of the silver salt in the polymer [37]. Kim and co-workers proposed the facilitated transport will not work until the concentration of the carrier reaches a threshold, which depends on the relative magnitude of the interaction strength of silver ions with polymer ligands and that with their counter-anions [43]. When the interaction strength of silver ions with polymer ligands is weaker than that with their counter-anions, the threshold concentration is low, and vice versa. For various polymer ligands, the threshold concentration of silver ions followed this order: phthalate > amide > ketone≈C=C > ester. PEO is a polymer material commonly used to prepare solid polymer electrolytes. Its main chain possesses relatively regular polyether groups, but its high crystallinity reduces the flexibility of the polymer segment. The polyether-containing block copolymer PEBAX is a thermoplastic elastomer material which is composed of rigid polyamide segments and flexible polyether segments, and the heteroatom oxygen can coordinate with transition metal ions especially silver ions. Moreover, PEBAX with different compositions has been commercialized and owns good mechanical property and chemical stability, exhibiting great potential in the fabrication of olefin/paraffin separation membranes.

In the facilitated transport membrane, the carrier forms complexation with olefins and transport olefins via the hopping mechanism. Therefore, the selection of carrier has significant influence on membrane performance. The carrier is usually transition metal salt, which dissociates into cations and counter-ions in the membrane, and the cations can complex with olefins. The stronger the electronegativity of the metal ion is, the stronger the electron-withdrawing ability is, and the complex formed by the metal ion and the olefin is more stable. When designing facilitated transport membrane, the complexation and decomplexation ability of metal ion should be considered at the same time. The reasonable electronegativity range of metal ions is 1.6–2.3 [25]. Bearing this in mind, metals including Mn, Fe, Co, Ni, Cu, Mo, Rh, Pd, Ag and Pt can be chosen as facilitated transport carriers. Considering the factors including performance and cost, Ag (I) and Cu (I) ions are suitable carriers for olefin/paraffin separation. Due to the instability of Cu (I) when exposed to oxidants, silver salts are the most widely investigated carriers.

One critical factor influencing the efficiency of cation is the relative strength of the interaction between cations and olefins and that between cation and counter-ion. If the interaction between the cation and the counter-ion is weaker, it is easier for the cation to complex with olefins, contributing to more efficient facilitated transport. The criteria for evaluating the interaction strength between cation and its counter-ions is the lattice energy of the corresponding salt. The smaller the radius of counter-ion, the greater the electrostatic force between counter-ion and cation, and the corresponding lattice energy is higher. Taking the silver salts as an example, the lattice energy order of the commonly used salts is: AgNO3 > AgCF3SO3 > AgClO4 > AgBF4. Accordingly, the facilitated transport membranes containing AgBF4 generally exhibited the highest separation performance [44].

3 Stabilization of facilitated transport membranes

Though the olefin/paraffin separation performance of the polymer electrolyte membranes can be quite high, how to maintain membrane performance in long-term operation remains great challenge. The silver ions in the membrane could react with other substances to be inactivated, resulting in a sharp decrease in membrane performance. For instance, silver ions will be reduced to elemental silver (Ag0) and inactivated when exposed to light or reductants such as H2. In addition, it will react with the impurity such as H2S and C2H2 in the feed stream to form Ag2S and Ag2C2. It is worth mentioning that Ag2C2 is very explosive, making the entire separation process extremely dangerous. A small amount (~ 10 ppm) of these impurities in the feed stream is sufficient to cause a sharp drop in the selectivity of the facilitated transport membranes [42].

The key step for improving the stability of the polymer electrolyte membranes is suppressing the inactivation of the carrier (mainly Ag+). To this end, many attempts have been made to improve the stability of Ag+ (Table 1). The strategies summarized in the table can be divided into four categories: (1) introducing additives into membranes; (2) designing the structure of polymers; (3) replacing Ag+ with silver nanoparticles; (4) regenerating deactivated Ag+ with oxidants. These methods will be introduced and compared in detail.

3.1 Introducing additives

The first method is to introduce additives such as surfactants, HBF4 and Al(NO3)3. The stabilizing mechanism of these additives varies from each other. Park et al. introduced a nonionic surfactant (n-octyl β-d-glucopyranoside (8G1)) into the membrane to suppress the growth and agglomeration of metal particles via steric hindrance (Fig. 6). The protective layer formed on the surface of the silver particles maintained the separation performance for 30 days [45]. However, this strategy did not solve the reduction problem. Researchers found that the reduction of Ag+ by POZ or other polymers usually led to the increase of H+ concentration in the membrane [50].

In order to suppress the reduction process, Kim and co-workers tried to introduce HBF4 in the AgBF4/POZ membrane, which is aimed at shifting the balance of the reduction reaction to the direction of Ag+ regeneration and preventing the formation of elemental silver [41]. The control experiments verified that the addition of a small amount of HBF4 can efficiently inhibit the reduction of Ag+. Kang et al. proposed introducing Al(NO3)3 into the AgBF4/POZ membrane to inhibit Ag+ reduction [46]. The addition of Al(NO3)3 could weaken the interaction between polymer functional groups and Ag+ with the use of electrostatic interaction between Ag+ and NO3−. The interaction between Ag+/NO3− and Al3+/BF4− is the reason for adjusting the chemical environment of Ag+. X-ray photoelectron spectroscopy (XPS) results showed that the presence of Al(NO3)3 reduced the binding energy of valence electrons in silver ions compared with that in the original membrane. Therefore, the electron density of Ag+ can be adjusted to reduce the oxidation ability of Ag+. The results showed that the introduction of Al(NO3)3 maintained the performance of polymer electrolyte membranes for 14 days.

The introduction of ionic liquids (ILs) can also improve the stability of membrane performance. In this case, Ag+ was distributed in both the polymer matrix and the ILs phase, which promotes the transport via fixed and mobile carriers at the same time, leading to higher permeability and selectivity. Ortiz et al. introduced 1-butyl-3-methylimidazole tetrafluoroborate (BMImBF4)/AgBF4 into the polyvinylidene fluoride-hexafluoropropylene copolymer (PVDF-HFP). The as-prepared membrane showed the propylene permeability of 6630 Barrer and propylene/propane selectivity of 700, which was maintained for 10 days [18].

3.2 Designing polymer structures

Researchers have tried to design the polymer structure to improve the stability of membrane performance, selecting inert polymers or fluorinated polymers. Kang et al. dispersed silver salts in an inert polymer polydimethylsiloxane (PDMS) to fabricate facilitated transport membranes [47]. Unlike the dissociation of salt into cation and anion in a polar matrix, silver ionic aggregates were formed in the inert polymer. This does not seem to work because only free silver ions interact with olefins. However, when the olefin permeated through the membrane, the coordination of olefin to the silver ions gradually converted the silver ionic aggregates into the free ions that could work. It took 100 h to completely dissolve the silver salt, and then the membrane reached steady state. The propylene/propane selectivity of the membrane reached 200, and the propylene permeance is 15 GPU, which could be kept for one week. This remarkable result proved that it is feasible to introduce silver salts into inert polymers, even though these polymers do not possess functional groups that can dissolve silver salts.

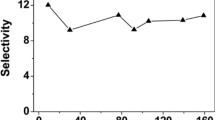

Another effective polymer is the fluorinated polymer. Generally, fluorinated polymers can withstand harsh conditions such as chemical corrosion and not be easily oxidized by Ag+. In 2016, CMS Company reported facilitated transport membranes based on fluorinated polymers [48]. Silver ion was introduced into the polymer matrix by ion exchange with the proton of the sulfonic acid group on the polymer chain. Different from the previous immersion of the membrane into the silver salt solution to achieve ion exchange, the polymer and the silver salt can be dissolved in the same solvent, so the silver ionomers can be formed to realize the facilitated transport. They prepared two types of fluorinated polymers. One of them was based on PDD/VF/PPSF polymer, showing relatively high propylene/propane selectivity of 95.7 and propylene permeance of 276 GPU; the other was based on Aquivion D79-25BS polymer, showing relatively higher propylene permeance of 311 GPU and comprised selectivity of 52.1. Long-term test demonstrated that the membrane could continuously operate for 270 days, and has been moved to a pilot-scale separation test in May of 2017 [51].

3.3 Other strategies

Apart from designing the structures of polymers, researchers have also tried to employ silver nanoparticles to replace Ag+ as a facilitated transport carrier, which can avoid the problem of silver reduction during membrane operation. However, in order to make zero-valent nanoparticles capable of facilitating the transport of olefins, it is necessary to introduce an electron acceptor molecule, such as p-benzoquinone (p-BQ) [49] or 7,7,8,8-tetracyanoquinodimethane (TCNQ) [52] to form charge polarization on the surface of the nanoparticles (Fig. 7). Moreover, some other relevant factors including the loading amount and size of nanoparticles, and their distribution along the gas diffusion pathway are important as well. The concentration of silver nanoparticles reported in literature is higher than 30 wt%, and the diameter should be less than 30 nm [52]. Smaller silver nanoparticles can further improve the mass transfer efficiency of olefins.

The schematic of the possible polarization mechanism of the Ag nanoparticles by 7,7,8,8-tetracyanoquinodimethane (TCNQ) [28].

In addition, Merkel et al. proposed in-situ regeneration of Ag+ through oxidants as studying the stability of AgBF4/PEBAX 2533 membrane [42]. They tested the membrane in the feed containing Ag+-inactivating components, and found that the selectivity dropped sharply. Nevertheless, when the tested membranes were exposed to mixed steam of H2O2/HBF4 or directly immersed into the solution, the membrane performance can be partially or completely recovered. Therefore, they considered that the recycled regeneration step can extend the lifetime of the membranes. Nevertheless, they pointed out that the inactivation caused by H2S has not been solved, and the feasibility of the industrial application of the recycled regeneration process needed to be further evaluated.

4 Conclusion

At present, the technology of facilitated transport membranes for olefin/paraffin is still in the research stage, among which polymer electrolyte membranes are the most promising membrane material. Although some companies have developed membranes with excellent performance and relatively good stability, the practical application of such membranes remains to be further demonstrated. The critical problem lies in the deactivation of silver ions in the polymer. Some strategies including the addition of additives, design of polymers, selection of silver nanoparticles, and recycled oxidation regeneration methods have been proposed. However, the effect of impurities that deactivate silver ions in the feed stream has not been studied in most works, which should be emphasized in the following work. Secondly, more convenient and efficient strategies for improving the stability of silver-based membranes should be explored. Thirdly, it is necessary to further study the mechanism of facilitated transport, and establish reasonable models to describe the facilitated transport phenomenon and better guide the design of membrane structure and optimization of separation performance. Finally, the feasibility of industrial scale-up should be considered during the design and fabrication of the facilitated transport membranes towards the practical olefin/paraffin separation.

Availability of data and materials

Not applicable.

Abbreviations

- BMImBF4 :

-

1-Butyl-3-methylimidazole tetrafluoroborate

- ILs:

-

Ionic liquids

- MOFs:

-

Metal organic frameworks

- MMMs:

-

Mixed-matrix membranes

- PAAm:

-

Polyacrylamide

- PDMS:

-

Polydimethylsiloxane

- PEBAX:

-

Polyetherblockamide

- PEO:

-

Poly(ethylene oxide)

- POZ:

-

Poly(2-ethyl-2-oxazoline)

- PVDF-HFP:

-

Polyvinylidene fluoride-hexafluoropropylene copolymer

- PVP:

-

Polyvinylpyrrolidone

- p-BQ:

-

p-Benzoquinone

- SBS:

-

Poly(styrene-b-butadiene-b-styrene)

- SPPO:

-

Sulfonated polyphenoxy

- TCNQ:

-

7,7,8,8-Tetracyanoquinodimethane

- XPS:

-

X-ray photoelectron spectroscopy

- 8G1:

-

n-Octyl β-d-glucopyranoside

References

Faiz R, Li K. Olefin/paraffin separation using membrane based facilitated transport/chemical absorption techniques. Chem Eng Sci. 2012;73:261–84.

Baker RW, Low BT. Gas separation membrane materials: a perspective. Macromolecules. 2014;47(20):6999–7013.

Xu L, Rungta M, Brayden MK, Martinez MV, Stears BA, Barbay GA, Koros WJ. Olefins-selective asymmetric carbon molecular sieve hollow fiber membranes for hybrid membrane-distillation processes for olefin/paraffin separations. J Membr Sci. 2012;423:314–23.

Zarca R, Ortiz A, Gorri D, Biegler LT, Ortiz I. Optimized distillation coupled with state-of-the-art membranes for propylene purification. J Membr Sci. 2018;556:321–8.

Kim YR, Lee JH, Choi H, Cho W, Kang YS. Chemical stability of olefin carrier based on silver cations and metallic silver nanoparticles against the formation of silver acetylide for facilitated transport membranes. J Membr Sci. 2014;463:11–6.

Ho W, Dalrymple D. Facilitated transport of olefins in Ag+-containing polymer membranes. J Membr Sci. 1994;91(1–2):13–25.

Li Y, Wang S, He G, Wu H, Pan F, Jiang Z. Facilitated transport of small molecules and ions for energy-efficient membranes. Chem Soc Rev. 2015;44(1):103–18.

Pollo L, Duarte L, Anacleto M, Habert A, Borges C. Polymeric membranes containing silver salts for propylene/propane separation. Braz J Chem Eng. 2012;29(2):307–14.

Antonio MR, Tsou DT. Silver ion coordination in membranes for facilitated olefin transport. Ind Eng Chem Res. 1993;32(2):273–8.

Staudt-Bickel C, Koros WJ. Olefin/paraffin gas separations with 6FDA-based polyimide membranes. J Membr Sci. 2000;170(2):205–14.

Liu J, Calverley EM, McAdon MH, Goss JM, Liu Y, Andrews KC, Wolford TD, Beyer DE, Han CS, Anaya DA. New carbon molecular sieves for propylene/propane separation with high working capacity and separation factor. Carbon. 2017;123:273–82.

Wei R, Chi HY, Li X, Lu D, Wan Y, Yang CW, Lai Z. Aqueous cathodic deposition: aqueously cathodic deposition of ZIF-8 Membranes for Superior Propylene/Propane Separation (Adv Funct Mater 7/2020). Adv Funct Mater. 2020;30(7):2070042.

Jiang X, Li S, Bai Y, Shao L. Ultra-facile aqueous synthesis of nanoporous zeolitic imidazolate framework membranes for hydrogen purification and olefin/paraffin separation. J Mater Chem A. 2019;7(18):10898–904.

Lee U, Kim J, Chae IS, Han C. Techno-economic feasibility study of membrane based propane/propylene separation process. Chem Eng Process. 2017;119:62–72.

Kwon HT, Jeong H-K. In situ synthesis of thin zeolitic–imidazolate framework ZIF-8 membranes exhibiting exceptionally high propylene/propane separation. J Am Chem Soc. 2013;135(29):10763–8.

Giannakopoulos IG, Nikolakis V. Separation of propylene/propane mixtures using faujasite-type zeolite membranes. Ind Eng Chem Res. 2005;44(1):226–30.

Koros W, Ma Y, Shimidzu T. Terminology for membranes and membrane processes (IUPAC Recommendations 1996). Pure Appl Chem. 1996;68(7):1479–89.

Fallanza M, Ortiz A, Gorri D, Ortiz I. Polymer–ionic liquid composite membranes for propane/propylene separation by facilitated transport. J Membr Sci. 2013;444:164–72.

Kang SW, Hong J, Park JH, Mun SH, Kim JH, Cho J, Char K, Kang YS. Nanocomposite membranes containing positively polarized gold nanoparticles for facilitated olefin transport. J Membr Sci. 2008;321(1):90–3.

Kim JH, Min BR, Won J, Joo SH, Kim HS, Kang YS. Role of polymer matrix in polymer/silver complexes for structure, interactions, and facilitated olefin transport. Macromolecules. 2003;36(16):6183–8.

Dewar J. A review of the pi-complex theory. Bull Soc Chim Fr. 1951;18(3–4):C71–9.

Safarik DJ, Eldridge RB. Olefin/paraffin separations by reactive absorption: a review. Ind Eng Chem Res. 1998;37(7):2571–81.

Eldridge RB. Olefin/paraffin separation technology: a review. Ind Eng Chem Res. 1993;32(10):2208–12.

Scholander P. Oxygen transport through hemoglobin solutions. Science. 1960;131(3400):585–90.

Hou J, Liu P, Jiang M, Yu L, Li L, Tang Z. Olefin/paraffin separation through membranes: from mechanisms to critical materials. J Mater Chem A. 2019;7(41):23489–511.

Kim JH, Kang YS, Won J. Silver polymer electrolyte membranes for facilitated olefint transport: carrier properties, transport mechanism and separation performance. Macromol Res. 2004;12(2):145–55.

Bryan PF. Removal of propylene from fuel-grade propane. Separat Purif Rev. 2004;33(2):157–82.

Campos ACC, dos Reis RA, Ortiz A, Gorri D, Ortiz I. A perspective of solutions for membrane instabilities in olefin/paraffin separations: a review. Ind Eng Chem Res. 2018;57(31):10071–85.

Teramoto M, Matsuyama H, Yamashiro T. Separation of ethylene from ethane by supported liquid membranes containing silver nitrate as a carrier. J Chem Eng Jpn. 1986;19(5):419–24.

Kárászová M, Kacirková M, Friess K, Izák P. Progress in separation of gases by permeation and liquids by pervaporation using ionic liquids: a review. Sep Purif Technol. 2014;132:93–101.

Duan S, Ito A, Ohkawa A. Separation of propylene/propane mixture by a supported liquid membrane containing triethylene glycol and a silver salt. J Membr Sci. 2003;215(1–2):53–60.

LeBlanc OH Jr, Ward WJ, Matson SL, Kimura SG. Facilitated transport in ion-exchange membranes. J Membr Sci. 1980;6:339–43.

Eriksen OI, Aksnes E, Dahl IM. Facilitated transport of ethene through Nafion membranes. Part II. Glycerine treated, water swollen membranes. J Membr Sci. 1993;85(1):99–106.

Allcock HR. Rational design and synthesis of new polymeric material. Science. 1992;255(5048):1106–12.

Zhang SS, Wan GX. Single-ion conduction and lithium battery application for ionomeric cross-linking polymer. J Appl Polym Sci. 1993;48(3):405–9.

Cussler E, Aris R, Bhown A. On the limits of facilitated diffusion. J Membr Sci. 1989;43(2–3):149–64.

Pinnau I, Toy LG. Solid polymer electrolyte composite membranes for olefin/paraffin separation. J Membr Sci. 2001;184(1):39–48.

Kim JH, Min BR, Kim CK, Won J, Kang YS. New insights into the coordination mode of silver ions dissolved in poly (2-ethyl-2-oxazoline) and its relation to facilitated olefin transport. Macromolecules. 2002;35(13):5250–5.

Kim JH, Won J, Kang YS. Silver polymer electrolytes by π-complexation of silver ions with polymer containing C–C bond and their application to facilitated olefin transport membranes. J Membr Sci. 2004a;237(1–2):199–202.

Park YS, Chun S, Kang YS, Kang SW. Durable poly (vinyl alcohol)/AgBF4/Al (NO3) 3 complex membrane with high permeance for propylene/propane separation. Sep Purif Technol. 2017;174:39–43.

Kim JH, Min BR, Kim HS, Won J, Kang YS. Facilitated transport of ethylene across polymer membranes containing silver salt: effect of HBF4 on the photoreduction of silver ions. J Membr Sci. 2003;212(1–2):283–8.

Merkel TC, Blanc R, Ciobanu I, Firat B, Suwarlim A, Zeid J. Silver salt facilitated transport membranes for olefin/paraffin separations: carrier instability and a novel regeneration method. J Membr Sci. 2013;447:177–89.

Kim JH, Kang SW, Kang YS. Threshold silver concentration for facilitated olefin transport in polymer/silver salt membranes. J Polym Res. 2012;19(1):9753.

Sunderrajan S, Freeman BD, Hall C, Pinnau I. Propane and propylene sorption in solid polymer electrolytes based on poly (ethylene oxide) and silver salts. J Membr Sci. 2001;182(1–2):1–12.

Park HH, Won J, Oh S-G, Kang YS. Effect of nonionic n-octyl β-d-glucopyranoside surfactant on the stability improvement of silver polymer electrolyte membranes for olefin/paraffin separation. J Membr Sci. 2003;217(1–2):285–93.

Kang SW, Kim JH, Won J, Kang YS. Suppression of silver ion reduction by Al (NO3) 3 complex and its application to highly stabilized olefin transport membranes. J Membr Sci. 2013;445:156–9.

Kim JH, Won J, Kang YS. Olefin-induced dissolution of silver salts physically dispersed in inert polymers and their application to olefin/paraffin separation. J Membr Sci. 2004b;241(2):403–7.

Majumdar S, Feiring AE, Shangguan N, Koizumi Y. Thin film composite membranes for separation of alkenes from alkanes. Google Patents; 2019.

Kang YS, Kang SW, Kim H, Kim JH, Won J, Kim CK, Char K. Interaction with olefins of the partially polarized surface of silver nanoparticles activated by p-benzoquinone and its implications for facilitated olefin transport. Adv Mater. 2007;19(3):475–9.

Pastoriza-Santos I, Liz-Marzán LM. Formation and stabilization of silver nanoparticles through reduction by N,N-dimethylformamide. Langmuir. 1999;15(4):948–51.

CMS Optiperm Membrane. A Breakthrough Innovation for the Separation of Olefins and Paraffins. In: White Paper, Compact Membrane Systems; 2016.

Lee JH, Kang SW, Yeom MS, Kim YR, Choi H, Song D, Won J, Kang YS. A strong linear correlation between the surface charge density on Ag nanoparticles and the amount of propylene adsorbed. J Mater Chem A. 2014;2(19):6987–93.

Acknowledgements

Not applicable.

Funding

The National Natural Science Foundation of China (21922805, 21776125) afforded the access to the database of literature. The Postgraduate Research & Practice Innovation Program of Jiangsu Province (Grant No. KYCX20_1015) provided the cost for designing some of the schematics.

Author information

Authors and Affiliations

Contributions

WJ and GL conceived the project. LC constructed the framework of the manuscript and summarized the literature. All the authors were involved in writing the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

All the authors agree with the publication.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Cheng, L., Liu, G. & Jin, W. Recent advances in facilitated transport membranes for olefin/paraffin separation. Discov Chem Eng 1, 1 (2021). https://doi.org/10.1007/s43938-020-00001-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s43938-020-00001-4