Abstract

In this study, we introduce a novel application of wood as the construction material for Microbial Fuel Cell (MFC) containers, developing what we term the Wooden Membrane-less Microbial Fuel Cell (WML-MFC). This innovative approach leverages the natural properties of wood to enhance the sustainability and cost-effectiveness of MFCs. Employing three different types of wood—pine, oak, and black locust—the WML-MFC design incorporates a carbon felt anode inside the wooden container and a carbon cloth cathode wrapped externally. This configuration not only protects the cathode from biofouling but also utilizes the inherent moisture management capabilities of wood to maintain operational stability. The performance of these wooden MFCs was assessed in terms of electricity generation and water treatment efficacy. Pine and oak containers achieved maximum power densities (MPD) of 35 mW/m^2 and 4 mW/m^2, respectively, with corresponding maximum open-circuit voltages of 551 mV and 269 mV. Black locust showed the least effective bioelectricity generation. COD removal efficiency was observed between 18 and 48% for pine and 3% to 39% for oak over hydraulic retention times of 24–48 h. Notable water loss due to moisture diffusion was recorded at 20%/day in pine and 6%/day in oak. Durability assessments through DMA and SEM analyses confirmed the suitability of wood as a container material, emphasizing the dual environmental and economic benefits of this WML-MFC design.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

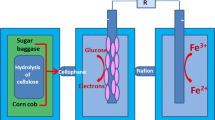

Microbial fuel cells (MFCs) represent a promising technology in the realm of renewable energy, offering a direct conversion of chemical energy into electrical energy through the utilization of microorganisms as biocatalysts [1]. Within the anode chamber, microorganisms metabolize organic materials, producing hydrogen and CO2 as byproducts. Protons generated during this process migrate towards the cathode, where they react with oxygen from the air, driving the oxidation–reduction reaction (ORR) [2], the reduction of oxygen is succeeded by the reaction between hydrogen and oxygen [3] and ultimately generating water and other byproducts [4].

While MFCs have shown great potential, they face several challenges, particularly in membrane-less configurations [5], including biofouling and cathode deterioration. Previous efforts to address these challenges have primarily focused on enhancing performance [6, 7] and efficiency through various design modifications. The air–cathode design of ML-MFCs gains an advantage by eliminating the need for external oxygen supply, mitigating energy consumption associated with aeration [8]. Extensive work has been undertaken to boost the electricity production efficiency of ML-MFCs [9]. However, despite these efforts, commercialization has been hindered by challenges such as a low electron recovery rate, unstable long-term system performance, high construction costs [10, 11], maintenance requirements for water loss, cathode cleaning after biofouling [12], cathode deterioration due to anolyte-catholyte mixing [13], oxygen intrusion into the anode [14], high resistance from the cathode–anode gap [15], salt layer accumulation near the cathode active area [16], and the use of platinum as ORR catalyst for its high catalytic activity [6].

The design of ML-MFCs is pivotal, influencing output parameters and overall efficiency [7, 17]. Researchers have focused on enhancing the long-term operating performance stability of the cathode through various designs [18]. Introducing a barrier between the cathode and anode chambers allows for cathode air-breathing, which prevents electrolyte contact and maintains the cathode electrode dryness. This air-breathing technique not only lowers overall process costs but also ensures the cathode's durability.

This study introduces a novel approach to address the challenges associated with biofouling and cathode deterioration in membrane-less MFCs by utilizing wood as the construction material for the MFC container. The use of wood offers a cost-effective and environmentally friendly solution, potentially mitigating issues such as water leakage and electrode deterioration, while allowing the release of hydrogen. Moreover, the unique properties of different wood species, including porosity and density, can influence MFC performance.

The primary objective of this study was to evaluate the performance efficiency of wooden membrane-less microbial fuel cells (WML-MFCs) constructed from three distinct wood species: pine, oak, and black locust. The performance evaluation included parameters such as open circuit voltage (OCV), power density (PD), current density (CD), chemical oxygen demand (COD) reduction efficiency, moisture-diffusion-induced water loss, pH, and effluent conductivity. Additionally, scanning electron microscopy (SEM) and dynamic mechanical analysis (DMA) were utilized to assess the suitability and durability of the selected wood species for WML-MFC manufacturing.

By focusing on the container material and its impact on MFC performance, this study contributes to the advancement of membrane-less MFC technology, offering insights into potential solutions for biofouling and cathode deterioration issues. Moreover, the use of wood as a construction material aligns with the principles of sustainability and environmental responsibility, further enhancing the appeal of MFCs as a renewable energy technology.

2 Materials and methods

2.1 Air–cathode WML-MFC fabrication

2.1.1 Preparation of electrodes

The anode electrode was fabricated using carbon felt (PXFT-540, Zoltek Corporation, Bridgeton, USA) with a surface area of 114 cm2 and a thickness of 6 mm (considered as a smooth surface). The cathode electrode was constructed from carbon cloth, featuring a surface area of 162 cm2. Both electrodes were rinsed with deionized water and subsequently dried at 80 °C for 24 h. To eliminate surface impurities, the electrodes were immersed in 1M HCl for 24 h, followed by another round of washing with deionized water and a subsequent drying period at 80 °C for 24 h. For the anode electrode, four carbon felt pieces were connected with a copper wire and placed inside each WML-MFC container, occupying a total volume of 24 cm3. The cathode electrode, without any catalyst loading or pre-treatment on the anode and wood plates, was positioned outside the container, enveloping it on all sides (Fig. 1) and secured in place with a fabric thread. A copper wire connected the cathode electrode. Notably, no catalyst was loaded on the cathode in this design, and no pre-treatment was applied to the anode or wood plates. Extending from each WML-MFC container, the anode and cathode wires were connected to a data logger. Prior to current and power measurements, various external resistors ranging from 400 Ω to 1 MΩ were tested.

2.1.2 Fabrication of the WML-MFC container using wood

The untreated wooden plates were sourced from the wood trunks of three common European tree species: oak (Quercus robur), Scots pine (Pinus silvestris), and black locust (Robinia pseudoacacia). These plates, with a thickness of 4 mm, were cut to the required dimensions using a wood cutting machine and assembled using silicone adhesive. The containers’ dimensions were set at 37 × 37 × 59 mm, providing an inner volume of 55 ± 5 ml. After inserting the anode into the container, the inner volume decreased to 20 ± 5 ml. Each box had two holes drilled- one (9 mm diameter) for influent and effluent flow and another (2 mm diameter) for the passage of the copper wire extending from the anode electrode through the container. Three containers of the same size were crafted from each of the three wooden species. These containers were used in their natural state, without any chemical treatment or bleaching. The details of the experimental containers for the WML-MFC are listed in Table 1.

2.2 Inoculation and operation of WML-MFC

To prepare the substrate for inoculating each WML-MFC unit, a mixture was created consisting of 200 ml of anaerobic digestion sludge from a municipal wastewater treatment plant (Sopron, Hungary), 300 ml of distilled water, outdoor mud, and sucrose as a carbon source. The anaerobic digestion sludge was characterized by its biochemical composition, including organic matter content (ranging from 45 to 78% on dry weight basis, daily measurement), pH (ranging from pH: 6.7–8.2), and Methanosarcinaeae, Methanobacteria and Clostridia class bacteria, among others microbial community was identified, which were analyzed prior to use. Similarly, the outdoor mud underwent characterization to determine its physical and chemical properties relevant to microbial growth and substrate metabolism.

The amount of sucrose added as a carbon source was carefully measured to ensure optimal microbial activity and substrate utilization. Specifically, 0.4 g (2% w/v) of sucrose were added to the mixture, providing a suitable carbon source for the microbial community.

Before introducing the substrate mixture into the WML-MFC containers, it was allowed to settle for an hour to facilitate sedimentation of the mud particles. The experiments were conducted in batch-mode, where each cycle had varying durations to simulate different hydraulic retention times (HRTs), ranging from 20 to 120 h.

Initially, each WML-MFC container was inoculated with 20 ± 5 ml of the prepared substrate mixture. Subsequently, the containers operated under open circuit (OC) conditions for a week until a stable voltage was achieved, allowing for the establishment and flourishing of the microbial community in the anode Sect. [19]. During this initial phase, the substrate was completely replaced with fresh influent every three days to provide optimal conditions for microbial growth and activity.

Following the establishment of a stable microbial community, the containers transitioned from OC to closed circuit (CC) operation, and the HRT was adjusted accordingly. Each time the containers were replenished with substrate, either by using residual substrate from the previous batch or entirely replacing it with freshly prepared substrate. Due to the high moisture diffusion rate of the wooden container walls, water loss through evaporation was inevitable. To maintain the anode electrode fully immersed in the substrate, daily additions of substrate were made as necessary.

It is important to note that no chemicals were used to adjust the pH or salinity of the influent substrate, and all experiments were conducted at room temperature, with fluctuations between 15 °C and 25 °C.

2.3 Data acquisition and analysis

Initially, the voltage (whenever voltage is mentioned without a specified unit, it refers to millivolts (mV)) for each WML-MFC unit was manually recorded every 2 h using an oscilloscope (Tektronix MDO3104) for 15 samples across the three species (five samples per species). Based on the preliminary results, bioelectrically productive samples were selected, and the others were discarded. Subsequently, voltage monitoring was conducted using a portable voltage data logger (Tokyo Sokki Kenkyujo Co. Ltd., TDS-302), programmed to measure every 30 min. Initially, the open circuit voltage (OCV) was monitored for all samples until it reached an optimum voltage. Following this, the WML-MFCs switched to CC with an external resistor (R) of 133 kΩ to measure the output current and power output, using the data logger.

The performance of the WML-MFCs was critically evaluated based on power output. Current (I) (mA) and power output (P) (mW) were calculated using Eqs. 1–2. Current density (j) (mA/m2) and power density (Pd) (mW/m2) were calculated as functions of the anodic surface area (114 cm2) using Eqs. 3–4.

Here, V represents the voltage (mV), R is the applied external resistance (Ω), and A is the surface area of the anode electrode (m2).

Considering the performance of WML-MFC containers in terms of electricity production, the freshly prepared influent and discharged effluent were analyzed for chemical oxygen demand (COD), pH, and conductivity. The water loss through moisture-diffusion was recorded and utilized as a benchmark to measure daily water loss from each container, investigating any potential correlation between moisture-diffusion and electricity production.

To determine the optimal external load, external loads ranging from 400 Ω to 1 MΩ were analyzed. The voltage was monitored every minute until it stabilized for each of the different loads (conducted on WP4-MFC-1) and subsequently evaluated based on power output.

2.4 External resistor selection

The selection of resistor value was made based on a thorough evaluation of the performance characteristics of our specific MFC configuration, which includes factors such as electrode materials, substrate composition, and operating conditions. A range of resistor values from 400 Ω to 1 MΩ was systematically assessed during the experimental testing process to identify the optimal resistor for maximizing power density. Remarkably, the 330 kΩ resistor emerged as the optimal choice for achieving maximum power density in our experimental setup. Several factors influenced this choice of resistor value. The observed performance characteristics of the MFC system, including trends in voltage and current measurements, were considered. The 330 kΩ resistor was instrumental in optimizing the balance between voltage and current output, ultimately maximizing power density. Additionally, the selection of a high internal resistance may have been motivated by considerations related to electrode kinetics. By carefully tuning the internal resistance, efforts were made to optimize electron transfer rates, thereby enhancing overall MFC performance. Furthermore, the availability of substrate and the composition of the microbial community within the MFC were considered. These factors can significantly impact MFC performance and may have influenced the choice of internal resistance.

2.5 Morphological analysis through SEM

Scanning electron microscopy (SEM) was conducted on the inner wall of the wooden containers and the cathode on Hitachi S-4800 model. This analysis aimed to explore the impact of bacterial growth and moisture diffusion on the wood surface morphology of different species, as well as to examine the cathode for any potential biofilm development.

2.6 Viscoelastic behavior analysis through DMA

Dynamic mechanical analysis (DMA) using the METRAVIB DMA 50 instrument was performed to ascertain the average elastic modulus of oak and pine before and after their use in the experiments. DMA provides insights into the viscoelastic behavior of wood across a wide range of frequencies. Sinusoidal deformation was applied to the sample at a constant temperature (25 °C), maintaining consistent wood moisture levels (12 ± 2%), and a regulated frequency within the range of 1–100 Hz. The specimens, with dimensions of 4.3 mm × 45 mm × 8.7 mm, were operated in a 3-points bending mode. Ten measurements for storage modulus were recorded at each frequency, and their average was plotted against the frequency.

3 Results and discussion

3.1 Cell voltage with open-circuit and start-up progress to acclimation time

Under standardized experimental conditions, this study assessed the open circuit voltage, current density, and power density for various wood species. Batch-mode experiments were conducted, with HRTs ranging between 24 and 72 h, using manual filling of the containers and substrate replacement cycles. The experiment began in open circuit mode to build biofilm on anode electrode, progressing until the maximum OCV was achieved after 351 h, with WP4-MFC-1 displaying the highest OCV of 0.551 V and a COD removal efficiency of 42%.

Our observed open circuit voltage (OCV) results exhibit variations compared to those reported in existing literature. While some studies have reported higher OCV values in membraneless microbial fuel cells (MFCs), our wood-based MFCs demonstrated lower OCV values. We attribute these differences to factors such as the specific wood materials used, variations in experimental conditions, and differences in MFC design. Despite the variations, our study contributes valuable insights into the performance of wood-based MFCs, highlighting their potential as low-cost and sustainable alternatives in bioelectrochemical systems.

Initial measurements using an oscilloscope for oak, Scots pine, and black locust over 30 days revealed significant differences. Black locust exhibited exceptionally low voltage, reaching a maximum OCV of about 50 mV upon fresh substrate feeding, remaining stable for 2 h, and subsequently dropping to 1 mV. Due to non-productive outcomes, black locust was excluded from further studies.

Subsequently, three containers from each of oak and Scots pine species were connected to a data logger. Post-inoculation, the voltage gradually increased, indicating biofilm development on the anode electrode surface. After 280 h of open circuit operation, WP4-MFC-1 reached an acclimation point at 551 mV. WP4-MFC-3 achieved 321 mV after 371 h, while WP4-MFC-2 took 412 h to reach 269 mV. Among oak containers, WO4-MFC-2 displayed the best performance, touching an OCV of 141 mV within 343 h (Fig. 2).

A study on microfluidic ML-MFC reported a maximum OCV of 102–246 mV with different influent substrates (Wang and Su, 2013). Under the same conditions of untreated carbon felt electrodes, a soil-based ML-MFC produced a maximum OCV of 729 mV [20]. These comparisons validate the OCV achieved in this study as a successful preliminary outcome.

The electric production performance between oak and Scots pine containers exhibited significant differences. Scots pine resulted in a higher OCV by 78–81%, while black locust showed much lower values than oak. This disparity can be attributed to wood density variations and the presence of antibacterial compounds, thus affecting hydrogen passage and microbial culture growth.

After each effluent replacement with fresh seeded substrate, the voltage experienced a sudden drop followed by a rise until reaching a peak, which was stabilizing within 25–30 h. This is primarily attributed to the low conductivity of the substrate, copper galvanic corrosion, and moisture diffusion through wooden plates. Vulnerability to oxygen intrusion in wooden walls also contributes to shifting dominant microbial cultures. Additionally, untreated cathode and anode electrodes play a role in influencing stability.

Within the same wood species, containers exhibited significant voltage differences, ranging from 196 to 215 mV for Scots pine and 60–118 mV for oak. These variations may be due to the uneven distribution of antibacterial compounds, the anisotropic nature of wood, and variations in wood density. The complex cellulose, hemicellulose, and lignin arrangement may create different routes for hydrogen escape, impacting bioelectrical production.

Observations during biofilm development in open circuit mode revealed small voltage jumps, especially for WP4-MFC-2 and WP4-MFC-3 (Fig. 2). These jumps, occurring between 4 and 6 am and 8 pm to 10 pm, coincide with sunrise and sunset times in Central Europe in the month of June, where ambient temperature variations between 15 ℃ and 25 C affect substrate temperature. These temperature changes align with earlier findings that indicate slight voltage changes observed with temperature change of substrate. The rise in ambient temperature influenced substrate temperature more in softwood (WP4-MFC-2 and WP4-MFC-3) compared to oak, reflecting the thermal conductivity variations in wood.

Additionally, post-sunset, WP4-MFC-2 and WP4-MFC-3 exhibited slight voltage increases (Fig. 2), suggesting reduced oxygen diffusion into the anodic chamber during the night. This nocturnal decrease in oxygen concentration aligns with prior studies on oxygen’s impact on the anodic chamber’s microbial activity and power output [21,22,23].

3.2 Bioelectricity generation of WML-MFC as closed circuit

Initially, all containers were filled with freshly prepared influent, with WP4-MFC-2 exhibiting a notable power density of 24 mW/m2, gradually diminishing to 2 mW/m2 after 26 h. Subsequently, as the oak and Scots pine samples lost water at different rates, all containers were filled with the previous day's substrate. However, between 162 and 224 h, distilled water replaced the substrate, causing a halt in current growth due to the washout of microorganisms from the anode. Upon replenishing with freshly seeded substrate, CD faces sudden drop and, in all samples, then gradually recovered, indicating biofilm development on the anode electrode. The power exhibited steady growth until the last cycle when a rapid increase occurred. Notably, WP4-MFC-3 displayed higher CD than WP4-MFC-2 during the final cycles, while oak samples exhibited sluggish performance throughout. This underscores the importance of anode inoculation with a vibrant and dense microbial culture substrate featuring a shorter HRT. Throughout the experimental duration, fluctuations in current were observed, as depicted in Figs. 3 , 4. Factors contributing to these fluctuations included the batch-fed mode, manual sample filling, and high air diffusion during the replacement of wastewater with different substrates and varying HRTs.

Upon transitioning from OC to CC with a 330 kΩ resistor, WP4-MFC-3 achieved the highest MPD and MCD of 35 mW/m2 and 0.09 mA/m2, respectively, after 397 h. Conversely, WO4-MFC-2 reached MPD and MCD of 4 mW/m2 and 0.03 mA/m2, respectively, after 404 h. The CC phase was tested for 420 h, involving five cycles of full substrate replacement. There was non-uniform HRTs between cycles and daily refilling to compensate for moisture-diffusion-induced water loss. Despite low bioelectric production, the findings here highlight the potential of wood as a separator and container in MFCs, signaling a need for further research to optimize performance.

Noteworthy biofilm development during the OC phase, particularly for WP4-MFC-2 and WP4-MFC-3 (Fig. 2), featured small voltage jumps. Temperature-induced voltage changes have been observed in prior studies [24]. The results affirm the potential of wood as a cost-effective solution to enhance cathode performance and durability for bioelectricity generation in ML-MFCs.

Furthermore, following sunset, WP4-MFC-2 and WP4-MFC-3 displayed subtle rises in voltage, as illustrated in Figs. 3, 4. These observations were also made while running as OC. This reduction in nocturnal oxygen concentration corresponds with earlier OC examining the influence of oxygen on microbial activity within the anodic chamber and its subsequent impact on power output.

3.3 Effluent condition and wastewater treatment performance of WML-MFC

In the course of varied fed batch-mode incubation periods, the pH, conductivity, and COD of both influent and effluent were meticulously monitored. Initial measurements were taken a day after the addition of new substrate, followed by subsequent readings at two, three, and four days. Across all instances, the effluent conductivity exhibited a near-doubling in pine samples and a 27–100% increase in oak samples compared to the influent. This variance in conductivity may stem from condensation within the samples due to water loss via moisture-diffusion. Additionally, the release of extractive components from the wood into the water could contribute to effluent conductivity. The pH levels experienced distinct rates of decline in oak and pine samples. This observation is indicative of the unique properties of oak and pine woods, which can influence the acidification process differently. Factors such as wood density, porosity, and extract composition can affect the interaction between the wood material and the surrounding environment, thereby influencing pH dynamics. Oak and pine woods may exhibit varying degrees of acidity buffering capacity and microbial activity, leading to differential rates of pH change over time. Additionally, variations in the initial pH levels of the substrates and the metabolic activity of microorganisms present in the wood samples can contribute to the observed differences in pH decline. Further analysis and investigation into the specific mechanisms underlying these differences will provide valuable insights into the role of wood type in influencing pH dynamics within the microbial fuel cell system.

In the Scots pine container (WP4-MFC-2), COD in the effluent dropped by 18% after 24 h, further decreasing to 40% after 48 h, and reaching 48% between 48 and 72 h. Conversely, in the oak containers, COD witnessed a marginal decrease of 3% after 24 h, followed by a reduction to 22% after 48 h, ultimately reaching 39% after three days of HRT. It’s noteworthy that the apparent higher COD reduction in pine containers compared to oak containers might partly be attributed to the higher water loss rates observed in the pine containers. The refill of distilled water to compensate for water loss could potentially dilute the COD concentration in the effluent, contributing to the observed higher COD reduction rates. Additionally, the slower pace of COD reduction in oak containers compared to pine containers could be influenced by factors such as the lower water loss rates in oak containers, which may result in less dilution of the effluent and hence a more concentrated substrate for microbial activity.

The progression of water treatment showed a sluggish pace in all samples during the three-day HRT period due to various factors. Firstly, the daily average water loss of 4.8 ml/day and 1.3 ml/day for Scots pine and oak, respectively, created an inactive anode electrode region as the water level dropped. Secondly, galvanic corrosion of copper resulted in the formation of copper oxide in the substrate after the second day of HRT. Copper, known for its toxicity to living cells, can hinder microbial growth. The establishment of a continuous-fed WML-MFC system is imperative to mitigate excessive oxygen intrusion, prevent copper oxide accumulation, and avert the detachment of the anode electrode’s top from the substrate. Achieving this necessitates replacing the top and bottom parts of the box with plexiglass, providing both structural support and more controlled hydrogen ion flow.

3.4 Effect of HRT on the bioelectricity production

The impact of HRT on bioelectricity production was investigated across four distinct HRTs (1, 2, 3, and 4 days) and the results are summarized in Table 2. WP4-MFC-1 exhibited the highest OCV of 0.551 V with an HRT of 2 days. Conversely, WP4-MFC-3 demonstrated the most substantial bioelectricity production, achieving MPD and MCD of 35 mW/m2 and 0.09 mA/m2, respectively, at an HRT of 2 days. The observed increase in voltage with longer HRTs is likely attributed to prolonged contact time between the biofilm and organic matter. A stable substrate condition, with minimal movement in the anolyte, facilitates bacterial growth and the formation of a denser biofilm network [25]. However, bioelectricity generation and water treatment efficacy were compromised when the HRT exceeded 2 days, primarily due to a low water level in each sample and an escalation in the galvanic corrosion of copper wire.

A unique evaluation of a one-day HRT was conducted with distilled water over three days (Figs. 3, 4), isolating the impact of water level variation inside the anode chamber on electrical productivity, independent of organic loading rate (OLR) effects. The results revealed a 50% improvement in bioelectrical productivity with Scots pine under a one-day HRT, followed by a slow reduction. Several factors contribute to this enhancement. Firstly, maintaining containers full of anolyte ensures prolonged immersion of the anode under the substrate, with a notable water loss of about 40% and 10% within 48 h in Scots pine and oak containers, respectively, it cause rapid decrease (Table 3). Secondly, a fully filled sample assists in saturating the wooden container walls with water, reducing oxygen intrusion through the wood plate [26]. Thirdly, after a four-day HRT, the anolyte color turned light green, indicative of galvanic corrosion of copper inside the anolyte. This corrosion, leading to copper oxide formation, proved toxic to microorganisms, limiting their growth [27,28,29].

Notably, other MFC prototypes in different studies demonstrated superior bioelectric outcomes and water treatment performance with HRTs extending to four days or more [30, 31]. Given the limited duration of this study, further research is imperative to comprehensively understand the effects of HRT on WML-MFCs.

3.5 Effect of sugar quantity and culture density

Upon initiation of the experiment in an OC configuration, the anode chamber was systematically filled with substrate. The measurement process involved five cycles of effluent replacement and nine cycles of refilling. Each cycle consisted of either introducing newly seeded sludge substrate, substrate from the previous days, or distilled water into the anode chamber (Figs. 3, 4).

Notably, whenever fresh substrate was seeded, influent replaced the effluent, a substantial increase in both current and power was observed. This surge in electrical output could be attributed to the sugar content and elevated density of the mixed microbial culture, promoting heightened microbial activity. Conversely, during cycles where containers were refilled with distilled water between the 164–222 h mark (Figs. 3, 4), there was a pronounced decline in CD, this decline in CD was a consequence of the reduced microbial culture density within the anode chamber.

3.6 Morphological analysis of cathode

One of the main objectives of this study was to find a solution for preventing cathode electrode from microbial attack and deterioration. Following a three-month operational period for the WML-MFCs, a meticulous examination of the cathodes was undertaken. Visual scrutiny revealed a pristine cathode surface with no discernible signs of biofilm or microbial attack, as illustrated in Fig. 5. Impressively, even after three months of continuous operation, the cathodes remained visually intact. To gain deeper insights into the cathode's surface condition, SEM analysis was done, comparing the control sample (unused carbon cloth) with cathodes from oak and Scots pine experimental samples. Remarkably, both oak and Scots pine cathode electrodes exhibited a morphology similar to the clean and smooth surface observed in the control sample, devoid of any apparent microbial degradation or biofilm formation. These findings suggest that the utilization of wood as a separator and container could offer a cost-effective and efficient solution to prevent cathode deterioration, concurrently facilitating sustained bioelectricity production in WML-MFCs.

3.7 Viscoelastic and morphological analysis of WML-MFCs

Following three months of uninterrupted operation of the WML-MFCs, the viscoelastic characteristics of the wooden container walls were explored. This investigation was conducted through DMA, focusing on the average elastic modulus. Intriguingly, a substantial mechanical loss was discerned in the oak samples, contrasting with the modest changes observed in Scots pine (Fig. 6). The pronounced difference might be attributed to variations in moisture-diffusion patterns, a pivotal factor influencing the mechano-reactive diffusion process and significantly impacting the viscoelastic behavior of wood [30, 31].

Average elastic modulus versus frequency for oak and Scots pine at constant temperature (25 ℃) and humidity (14% RH). Blue dots are raw-oak before use in the samples. Red dots are oak after 3 months of continuous use. Grey dots are raw-Scots pine before use in the samples. Yellow dots are Scots pine after 3 months of continuous use

A secondary contributing factor to the observed dissimilarity could be the origin of the oak samples from distinct trees, potentially leading to considerable differences in their mechanical properties. Moreover, the intricate chemical reactions transpiring within the wood during moisture absorption and desorption further complicate the state. However, for the scope of this study, these chemical reactions can be assessed by a characteristic chemical relaxation time. During this relaxation period, the interaction between significant amounts of extracts and reactive products with the mechanical stress field may induce an additional mechanical loss [30].

To deepen our understanding of morphological changes, scanning electron microscopy (SEM) was utilized to examine raw and used samples of oak and Scots pine. The analysis revealed notable differences in surface morphology between the two wood types. While the surface of used Scots pine appeared relatively smooth, cracks were observed on the surface of used oak samples, as depicted in Fig. 7. These cracks signify significant degradation of the oak surface, which can have implications for its strength and durability, particularly in thinner sections. Additionally, both samples exhibited the accumulation of debris on their surfaces. Furthermore, it was observed that oak exhibited a higher degree of color absorbance from the wastewater compared to Scots pine, as illustrated in Fig. 7c, d. These findings underscore the importance of considering wood degradation in evaluating the performance and longevity of wood-based microbial fuel cells.

Collectively, insights gleaned from DMA and SEM examinations unequivocally highlight the superior performance of Scots pine over oak in terms of durability against microbial attack from wastewater and the impacts of moisture diffusion in use of WML-MFC.

4 Conclusion

In this study, wood was used as a container wall to hold the substrate and provide protection to the cathode. The exploration of wooden containers as a biomaterial for ML-MFCs has yielded promising results, demonstrating the potential to effectively safeguard the cathode from biofouling and prevent deterioration. This breakthrough not only enhances the efficiency of ML-MFCs but also significantly reduces construction and maintenance costs, paving the way for future commercialization. Among the investigated wood species, Scots Pine emerged as the top performer, showcasing the highest bioelectricity output of 35 mW/m2 (while close circuit) and 551 mV (open circuit) and an impressive 48% COD removal efficiency within a 48 h hydraulic retention time. With Scots pine exhibiting superior overall performance, including lower water loss rates compared to other samples, these findings underscore its suitability for ML-MFC applications, marking a significant stride in advancing sustainable energy technologies with potential commercial implications.

5 Further study

More research is necessary on the developed WML-MFC model for evaluating the continuous-fed mode, anode/cathode volume ratio, wooden wall thickness effect, using PEM around the box to block oxygen intrusion, different cathode and anode configurations, different anode and cathode materials with different treatments, more types of wood can be tested with different substrates, using different biocatalysts, different treatments of the wooden wall, combining wood with plexiglass or any other model, etc.

Data availability

Not applicable.

Abbreviations

- AEM:

-

Anion exchange membrane

- BOD:

-

Biological oxygen demand

- CE:

-

Coulombic efficiency

- CEM:

-

Cationic exchange membrane

- DMA:

-

Dynamic mechanical analysis

- EDX:

-

Energy-dispersive X-ray spectroscopy

- HMWG:

-

Heavy metal-containing wheat grain

- MC:

-

Moisture content

- MFC:

-

Microbial fuel cell

- ML-MFC:

-

Membrane-less microbial fuel cell

- MPD:

-

Maximum power density

- OCV:

-

Open circuit voltage

- OLR:

-

Organic loading rate

- ORR:

-

Oxygen reduction reaction

- PD:

-

Power density

- PEM:

-

Proton exchange membrane

- PTFE:

-

Polytetrafluoroethylene

- SEM:

-

Scanning electron microscopy

- SMFC:

-

Single chamber microbial fuel cell

- SCE:

-

Saturated calomel electrode

- TMFC:

-

Two-chamber microbial fuel cell

- WML-MFC:

-

Wooden membrane-less microbial fuel cell

- XRD:

-

X-ray diffraction

References

Aelterman P, Rabaey K, Pham HT, Boon N, Verstraete W. Continuous electricity generation at high voltages and currents using stacked microbial fuel cells. Environ Sci Technol. 2006. https://doi.org/10.1021/es0525511.

Dange P, et al. A comprehensive review on oxygen reduction reaction in microbial fuel cells. J Renew Mater. 2022. https://doi.org/10.3604/jrm.2022.015806.

Guerrini E, Grattieri M, Faggianelli A, Cristiani P, Trasatti S. PTFE effect on the electrocatalysis of the oxygen reduction reaction in membraneless microbial fuel cells. Bioelectrochemistry. 2015. https://doi.org/10.1016/j.bioelechem.2015.05.008.

Virdis B, et al. Microbial fuel cells. Treatise Water Sci. 2011. https://doi.org/10.1016/B978-0-444-53199-5.00098-1.

Kim J, Kim B, An J, Lee YS, Chang IS. Development of anode zone using dual-anode system to reduce organic matter crossover in membraneless microbial fuel cells. Bioresour Technol. 2016. https://doi.org/10.1016/j.biortech.2016.03.012.

Song YE, et al. Metal-free cathodic catalyst with nitrogen- and phosphorus-doped ordered mesoporous carbon (NPOMC) for microbial fuel cells. J Power Sources. 2020. https://doi.org/10.1016/j.jpowsour.2020.227816.

Tahir CA, Pásztory Z, Agarwal C, Csóka L. Electricity generation and wastewater treatment with membrane-less microbial fuel cell. Berlin: Springer; 2022. https://doi.org/10.1007/978-981-16-2225-0_8.

Yang F, Ren L, Pu Y, Logan BE. Electricity generation from fermented primary sludge using single-chamber air-cathode microbial fuel cells. Bioresour Technol. 2013. https://doi.org/10.1016/j.biortech.2012.10.021.

Elmekawy A, Hegab HM, Vanbroekhoven K, Pant D. Techno-productive potential of photosynthetic microbial fuel cells through different configurations. Renew Sustain Energy Rev. 2014. https://doi.org/10.1016/j.rser.2014.07.116.

Behera BK, Varma A. Microbial resources for sustainable energy. Microbial Resourc Sustain Energy. 2016. https://doi.org/10.1007/978-3-319-33778-4.

Li WW, Sheng GP, Liu XW, Yu HQ. Recent advances in the separators for microbial fuel cells. Bioresour Technol. 2011. https://doi.org/10.1016/j.biortech.2010.03.090.

Rossi R, Yang W, Zikmund E, Pant D, Logan BE. In situ biofilm removal from air cathodes in microbial fuel cells treating domestic wastewater. Bioresour Technol. 2018. https://doi.org/10.1016/j.biortech.2018.06.008.

Wang H, Jiang SC, Wang Y, Xiao B. Substrate removal and electricity generation in a membrane-less microbial fuel cell for biological treatment of wastewater. Bioresour Technol. 2013. https://doi.org/10.1016/j.biortech.2013.03.172.

Wang HY, Su JY. Membraneless microfluidic microbial fuel cell for rapid detection of electrochemical activity of microorganism. Bioresour Technol. 2013. https://doi.org/10.1016/j.biortech.2013.01.014.

Mohamed HO, et al. Electricity generation from real industrial wastewater using a single-chamber air cathode microbial fuel cell with an activated carbon anode. Bioprocess Biosyst Eng. 2017. https://doi.org/10.1007/s00449-017-1776-0.

Aaron D, Tsouris C, Hamilton CY, Borole AP. Assessment of the effects of flow rate and ionic strength on the performance of an air-cathode microbial fuel cell using electrochemical impedance spectroscopy. Energies. 2010. https://doi.org/10.3390/en3040592.

Pamintuan KRS, Bagumba IHP, Domingo ZDG. Compartmentalization studies of a deep-design batch microbial fuel cell assembly. J Phys Conf Series. 2020. https://doi.org/10.1088/1742-6596/1457/1/012010.

Nawaz A, et al. Upscaling feasibility of a graphite-based truncated conical microbial fuel cell for bioelectrogenesis through organic wastewater treatment. J Colloid Interface Sci. 2020. https://doi.org/10.1016/j.jcis.2020.02.099.

An J, Kim B, Jang JK, Lee HS, Chang IS. New architecture for modulization of membraneless and single-chambered microbial fuel cell using a bipolar plate-electrode assembly (BEA). Biosens Bioelectron. 2014. https://doi.org/10.1016/j.bios.2014.02.063.

Simeon, M. I., Otache, M. Y., Ewemoje, T. A. & Raji, A. O. Application of urine as fuel in a soil-based membrane-less single chamber microbial fuel cell. Agric Eng Int CIGR J 21, 2019.

Liu H, Logan BE. Electricity generation using an air-cathode single chamber microbial fuel cell in the presence and absence of a proton exchange membrane. Environ Sci Technol. 2004. https://doi.org/10.1021/es0499344.

Fan Y, Hu H, Liu H. Enhanced coulombic efficiency and power density of air-cathode microbial fuel cells with an improved cell configuration. J Power Sourc. 2007. https://doi.org/10.1016/j.jpowsour.2007.06.220.

Venkata Mohan S, Mohanakrishna G, Sarma PN. Effect of anodic metabolic function on bioelectricity generation and substrate degradation in single chambered microbial fuel cell. Environ Sci Technol. 2008. https://doi.org/10.1021/es8012529.

Ahn Y, Logan BE. Effectiveness of domestic wastewater treatment using microbial fuel cells at ambient and mesophilic temperatures. Bioresour Technol. 2010. https://doi.org/10.1016/j.biortech.2009.07.039.

Li X, et al. Animal carcass wastewater treatment and bioelectricity generation in up-flow tubular microbial fuel cells: effects of HRT and non-precious metallic catalyst. Bioresour Technol. 2013. https://doi.org/10.1016/j.biortech.2012.10.053.

Sorz J, Hietz P. Gas diffusion through wood: Implications for oxygen supply. Trees—Struct Funct. 2006. https://doi.org/10.1007/s00468-005-0010-x.

Kumar V, et al. Copper bioavailability, uptake, toxicity and tolerance in plants: a comprehensive review. Chemosphere. 2021. https://doi.org/10.1016/j.chemosphere.2020.127810.

Naz S, Gul A, Zia M. Toxicity of copper oxide nanoparticles: a review study. IET Nanobiotechnol. 2019. https://doi.org/10.1049/iet-nbt.2019.0176.

Trevors JT, Cotter CM. Copper toxicity and uptake in microorganisms. J Indust Microbiol. 1990. https://doi.org/10.1007/BF01576426.

Ebrahimzadeh PR, Bertilsson H. Effect of impregnation on mechanosorption in wood and paper studied by dynamic mechanical analysis. Wood Sci Technol. 1998. https://doi.org/10.1007/BF00702591.

Kaboorani A, Blanchet P. Determining the linear viscoelastic region of sugar maple wood by dynamic mechanical analysis. Bioresources. 2014. https://doi.org/10.15376/biores.9.3.4392-4409.

Acknowledgements

CAT is grateful to the Tempus Public Foundation for providing financial assistance under the Stipendium Hungaricum Programme.

Funding

Open access funding provided by Eötvös Loránd University.

Author information

Authors and Affiliations

Contributions

CAT, CA performed the experiment, CAT, CA, ZP and LC made the experiment design, interpreted the data and gave a major contribution to manuscript preparation and writing. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare that they have no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Tahir, C.A., Agarwal, C., Pásztory, Z. et al. A novel membrane-less microbial fuel cell reactor using wood as container and separator to prevent air–cathode deterioration and biofouling. Discov Water 4, 29 (2024). https://doi.org/10.1007/s43832-024-00085-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s43832-024-00085-x