Abstract

Culvert blockage at the inlet can dramatically alter the local hydraulic characteristics that often increase backwater rise, change the flow patterns, and thereby increase the risk of upstream flooding. The impact of culvert blockage is not usually included in the initial hydraulic design, although it can cause significant losses once the culvert becomes blocked. Culvert hydraulics including backwater rise with respect to blockage slope and ratio has been neglected in the studies conducted so far. In this study, we conducted a series of narrow flume tests to investigate the effects of four bottom blockage slope angles and five blockage ratios on the hydraulic characteristics of box culverts, including backwater rise, and upstream mean velocity at various Froude numbers. The results showed that Froude number, blockage ratio, and slope angle were regarded as the controlling variables for culvert backwater rise. Backwater rise increased dramatically with increasing blockage ratio and Froude number. Compared to blockage ratio B = 0.20, ΔH/hu increased by 2, 5, 9, and 13 times for B = 0.40, 0.60, 0.80, and 1, respectively. However, when the blockage slope angle decreased, the backwater rise reduced and upstream mean velocity increased in compared with vertical blockage. The relative backwater rise reduced from 0.32 to 0.29, when blockage slope angle decreased from 90° to 18.44° at B = 1 and Fo = 0.10. In addition, the length and maximum depth of water surface depression inside the culvert itself were larger with increasing blockage ratio and Froude number. For Fo = 0.10, d/ho = 0.13 and L/ho = 0.94 for B = 0.20 compared to d/ho = 0.32 and L/ho = 4.34 for B = 1. The results were also combined to develop an equation to predict backwater rise in the range 0.10 ≤ Fo ≤ 0.25, 0 ≤ B ≤ 1, and 18.44° ≤ α ≤ 90°. To enhance the accuracy, it is recommended to apply the equation for ΔH/hu ˃ 0.10. It is useful and practical in applications to add the probability of backwater rise or losses owing to culvert blockage within accounting of losses during the hydraulic design of culverts, especially in channels exposed to debris.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Background

Culverts are closed conduits with the primary function of conveying waterways under an obstruction, and are universally applied. They can be structured in different shapes such as box, circle, pipe-arch, elliptical, and arch. Commonly, minimum energy losses should be considered at the design stage of culverts for sufficient performance. Culvert installation is discouraged for a variety of reasons, including the fact that culverts restrict the flow and raise the upstream water level, pose a greater risk of blockage than open channels, are more difficult to maintain and repair, and have negative effects on aquatic environments, health, and safety [1]. Blockage is a common issue associated with culverts, leading to hazard concerns. Culvert blockage by debris or sedimentation can significantly affect the water elevation as a result of the reduction in cross-section, besides the fact that the increasing roughness of the bed is also due to sedimentation [1]. Specifically, blockage accumulations can obstruct the flow through a culvert, reduce the structure capacity, exacerbate hydraulic losses, increase the upstream water elevation and cause flooding. Furthermore, culvert blockage can worsen erosion at the culvert outlet, cause embankment failure or overtopping, and increase scour at abutments [2].

The design of a culvert inlet can considerably affect the cost and hydraulic efficiency. Minor modifications to culvert inlet geometry majorly influence the culvert efficiency [3]. Therefore, culvert blockage at the inlet can have grave consequences. Factors affecting culvert blockage and related hazards were defined using data collected after natural flood events. Rigby et al. [4] reported the blockage of culvert and bridge openings using collected field data after a flood event in 1998 in the city of Wollongong. The results revealed that the greatest factor governing culvert blockage was the clear opening size, and culverts with openings less than 6 m were prone to blockage. Additionally, these blockages could have significant effects, including flow diversions out of the normal stream, increased flood levels, development of overland flood flow paths, and scouring due to overtopped embankments. Rigby et al. [4] suggested that the possibility of culvert blockage and its consequences should be considered in flood studies. Barthelmess and Rigby [5] as cited in Sorourian et al. [6] investigated the mechanisms of culvert blockage and their effects on flood behavior. They remarked that culvert blockage mainly resulted in flow diversion. Even a small amount of blockage at the culvert inlet could restrict the flow and noticeably change the flood behavior comparing with the nonblocked case. Rigby and Barthelmess [7] noted that culvert and bridge visual blockage was determined based on debris availability, transportability, and mobility.

From two basic perspectives, the issue of blockage at cross-drainage hydraulic systems has been studied: hydraulically and visually [8, 9]. Regarding the hydraulic blockage, scaled physical tests have been considered in literature to investigate and understand the hydraulic impacts of blockage related to hydraulic structures. Blanc [10] performed a Froude scaled testes to explore the effect of trash screens on blockages caused by debris at culvert inlets. Throughout the experiments, wooden debris was replicated using simple straight wooden rods of various lengths, and the blockage was unrealistically defined. Results showed that it was more likely for debris to be caught by a trash screen when it was longer. Kramer et al. [11] conducted experiments using physical models to study the impacts of square culvert blocked by large urban debris on the upstream flood level. The debris used in the tests were examples of large items commonly seen in urban catchments, and scaled to provide the greatest visual blockage of the modeled culvert. The study performed through stochastic and hydraulic phases of testing to define the debris orientation and hydraulic blockage. Stochastic testing showed that the long axis of floating debris frequently aligned with the flow direction. However, a lack of significant conclusion was reached from the hydraulic testing that was used in the study. Iqbal et al. [12] studied the impacts of both individual and combination urban and vegetative debris on the hydraulic blockage at culvert models using scaled laboratory tests. Two culvert configurations (i.e., single circular, double circular) were tested for relative scaled sizes of multiple debris to examine the intricate relationships between blocking-related influencing factors (e.g., debris type, debris volume, debris orientation, culvert type, discharge). From the results, when solid-bodied urban objects (i.e., toy car, simple bin, wheelie bin) blocked all of the culvert openings, the hydraulic blockage was dramatically increased. Additionally, the compactness of the debris and its horizontal placement in relation to the culvert entrance were key factors in the hydraulic blockage.

Visual blockage assessment is considered to be a crucial component in identifying the blockage at hydraulic structures for maintenance activities and purposes using visual data. Iqbal et al. [13] used automated analysis to classify the blockage status of culvert from a visual assessment. Convolutional neural network (CNN) model was implemented to categorize the blockage images into clear and blocked sets. The analyses showed that the degraded performance of CNN mode was function of oversimplified labelling and background noise criteria. Barthelemy et al. [14] suggested detection-classification pipeline to enhance classification performance by initially detecting the culvert openings and then classifying the blockage into one of three classes(i.e. clear, partially blocked, blocked).Most recently, Iqbal et al. [9] proposed deep-learning computer vision to quantify percentage of visual blockages at circular shaped culverts. As, estimation of visual blockage can be helpful toward better maintenance-related decisions. Results proposed a potential edge-computing solution to illustrate the implications of presented study. Furthermore, the study believed that the value of visual blockage percentage can be defined as potential future alternative by exploring the utilization of culvert geometry, camera matrix data and shape fitting algorithms. In an effort to quantify the visual blockage at hydropower plant structure, Ibrahim et al. [15] estimated the visual floating debris that was transported to the hydropower plant intake of the new Naga Hammady barrage, which are located across the Nile River. A comprehensive visual investigations were conducted for 38 km upstream the new barrage for maintenance and better managing the station. The amount floating debris that was accumulated at trash racks of hydropower plant intake was estimated using remote sensing, GIS technologies, Echo Sounder device and weed sampling device for identifying the submerged weed till 4 m long below the water surface.

A number of reviews regarding the design and hydraulics of culverts without considering blockage concept are available [16, 17]. Chin [18] cited other studies that have described alternative formulations to define culvert performance under different conditions such as Charbeneau et al. [19], Haderlie and Tullis [20], Tullis and Robinson [21], and Feurich et al. [22]. Chin [18] elucidated and quantified the discrepancies between headwater depths for pipe culverts under any given flow rate using the Federal Highway Administration (FHWA) and United States Geological Survey (USGS) approaches. The results showed that for horizontal culverts with smooth surfaces and square-edge entrances the amount of overestimation in the depth of headwater ranged between 9 and 45% for headwater depths between 1.5 and 3 times the culvert diameters. In addition, the overestimation would be less for culverts with high roughness. Chin [18] stated that the overestimation is a function of culvert slope, roughness, and length-to-diameter ratio when the culvert is not horizontal, and recommended that engineers consider the provided guidelines in their professional judgment while designing culverts design to optimize the design in particular cases.

A proper evaluation of culvert downstream scour is vital to mitigate infrastructure collapse [23]. Various studies have been done with respect to scouring at culvert outlets under different conditions [24,25,26,27,28]. The local scour impacts of blocked culvert inlets were studied by Sorourian et al. [6]. Flume tests were performed for partially blocked and nonblocked conditions in a box culvert under steady flow conditions, and sand bed material at the culvert outlet with d50 between 0.85 and 2 mm. The results indicated that blockages greatly affected the geometry of scour holes at the outlet compared with nonblocked cases. In addition, a dimensionless equation was developed considering the effect of blockage to predict the maximum scour depth. Regarding the upstream water depths for hydraulic structures, Daneshfaraz et al. [29] investigated the effects of standard and labyrinth sliding valve opening on the upstream flow depth. The findings show that, in comparison to the labyrinth sliding valve, the upstream water depth decreased as the standard sliding valve opening was increased. In addition, as the opening of the standard sliding valve increased, the flow depth behind the valve decreased.

1.1 Objectives

Great amounts of data and studies are available with respect to culvert hydraulics. However, limited number of investigations have been done in terms of hydraulic blockage and its effect on culverts. Despite this, a literature search showed that the impact of blockage slope and ratio on culvert hydraulics was neglected so far. Therefore, this study focuses on experimentally examining the effects of bottom culvert blockages of various slopes and ratios on the hydraulics of box culverts, reflecting backwater rise, upstream mean velocity, and water surface elevations for different flow conditions. Furthermore, the study results were combined in an empirical equation to predict backwater rise in terms of blockage slope, ratio, and Froude number.

2 Methods

2.1 Experimental setup

The experiments were conducted using a small-scale model with a scale factor of (λ = 20) in a rectangular flume of 2500 mm length, 90 mm width, and 300 mm depth. The flume tank has glass walls that allow test observation. Two centrifugal pumps discharged the flow into the flume from a constant reservoir. The entering flow rate was measured using a plastic water flowmeter with an accuracy of ± 4% and adjusted via a discharge valve. The flow depth was regulated with a gate at the flume end. A point gauge was used to measure the upstream and downstream flow depths of the modeled culvert with an accuracy of ± 0.1 mm, and the depths through the culvert length were measured using a ruler fixed at the glass-walled flume. Depth measurements were taken along the entire flume length in streamwise direction at midchannel to calculate the backwater rise ΔH, which was the difference between upstream and downstream depths at uniform flow sections away from turbulence zones. Mean flow velocities were obtained as V = Q/At, where V is the mean flow velocity, Q is the flow discharge, and At is the cross-sectional flow area of the channel. For accurate observations of water surface elevations, water depth was measured at 10 mm intervals from relative streamwise distance x/ho = − 2 to + 8, in which the flow noticeably varied (x = 0 m at the inlet of the culvert). In the uniform flow sections, depth was measured at 100 mm intervals. The tailwater level was that associated with the depth profile through the length of the flume downstream the model culvert.

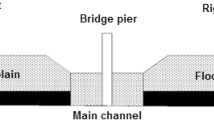

Maintenance difficulties arise in removing debris trapped somewhere inside the culvert body. Box culverts are preferred in many cases due to the facilities of removing inside culvert blockage in compared with circular culvert. As a box shape has a constant width and gaining more space. Additionally, surface slaps of box culvert can be separately designed and removed to manage the inside culvert maintenance. Furthermore, box-shaped culvert is less prone to clogging by debris than the pipe culvert [30]. A 3 mm-thick, clear acrylic sheet was used to construct and simulate a box culvert in the middle of the channel (Fig. 1). The culvert opening was 45 mm × 98.4 mm with square edges and culvert length was 300 mm. The culvert narrowed the channel flow area with a contraction ratio of 0.50 determined based on the cross section flow area of culvert opening, Ac, and cross section flow area of channel, At, as (Cr = 1−Ac/At).Unsubmerged entrance and outlet flows were distinguished by adjusting the water elevation to less than the culvert height in the case of no blockage, as a reference case throughout the experiments. For culvert without blockage, neither the entrance nor the outlet of the box culvert was submerged. In addition, the flow in the barrel over its length was partly full and subcritical. This work applies to inlet control, which is reasonable insofar as a blockage at the inlet will severely compromise the inlet hydraulics.

To assess bottom inlet blockage, various plate sizes were installed at the culvert opening during the tests (Fig. 2). The plate heights were adjusted to obtain blockage ratios of B = 0.20, 0.40, 0.60, 0.80, and 1, and a no-blockage case. The blockage ratio B can be calculated as

where Ab is the area of the culvert inlet blockage, b is the width of the culvert inlet, hb is the height of inlet blockage, and ho is the upstream flow depth in case of a culvert without blockage. Table 1 shows the experimental test conditions. Blockage slope angles between 90° and 18.44° with upstream ramps representing the range between vertical and a slope of 3:1 (H: V), respectively, were tested to evaluate blockage slope effects. The blockage of this type simulated blockage induced by sediment or mud at the inlet of culvert. Flow rates varying from 3.5 × 10–4 to 8.5 × 10–4 m3 s−1 were adopted for each blockage ratio and slope to achieve various ranges of culvert hydraulic operations.

The flow conditions (indicated with subscript o), were measured at the upstream culvert in case of without blockage (reference case). The tested flow rates were defined to cover subcritical flow regimes, resulting in corresponding Froude numbers Fo = Vo/[gho]0.5 ranging from 0.10 to 0.25, based on the velocity Vo, upstream flow depth ho and gravitational acceleration g. The Reynolds number (Ro = 4VoR/υ) varied from 10,112 to 19,197 based on the velocity, hydraulic radius R, and kinematic viscosity υ, ensuring a turbulent flow regime.

2.1.1 Scale effects of culvert width

The influence of culvert model width on ΔH was investigated via repeating the experiments and achieved by varying culvert width for the tested parameters; particularly the effects of aspect ratio b/ho on ΔH was examined. To develop the requirements of various aspect ratios, the culvert width was changed with fixed flow depth. Four culvert width to flow depth aspect ratios, b/ho ≈ 1.52, 1.35, 1.19, and 1, were considered in comparison with the initial b/ho ≈ 0.85 based on ΔH values. Average prediction error was determined using Eq. (2) to estimate uncertainty.

where ΔHr is the repeated backwater rise for different aspect ratios. The average prediction errors were 22%, 19%, 14%, and15% for b/ho ≈ 1.52, 1.35, 1.19, and 1, respectively. This indicated that the maximum error of the tested culvert width occurred at b/ho ≈ 1.52 with average error of 22% at the tested range and flow conditions.

In addition, the experiments were undertaken in a facility that is small and to avoid the effects of viscosity and surface tension as possible, Ro = 4VoR/υ ˃ 104 [31] was achieved, and the flow depth was continuously kept to ho ≥ 50 mm [32], respectively. Most of the results comply with the standard criteria; however, the validation of close-to-prototype scale models is strongly recommended to ensure the extrapolation of the data to full-scale and fully assess the scale effects.

3 Results

3.1 Flow conditions and culvert blockage characteristics

The effect of Fo on ∆H was tested in the range of Fo = 0.10, 0.18, and 0.25, with B = 0.20–1 at the tested blockage slope angles. Figure 3 shows the backwater rise ∆H for various Fo. Figure 4 shows photos for two Froude numbers at constant blockage ratio and slope α = 90°. Furthermore, the impacts of culvert blockage slope angle α, and culvert blockage ratio B on relative backwater rise ∆H/hu were analyzed. Figure 5 shows ∆H/hu for B = 0.20, 0.40, 0.60, 0.80, and 1, and α = 90°, 45°, 26.57°, and 18.44° for various Fo. Culvert blockage characteristics appear to affect relative backwater rise (Fig. 5). With increasing B, the flow resistance and thereby flow upstream of the culvert rapidly increases, resulting in an increased ∆H/hu with the other parameters kept constant. A paired t-test for means was applied to illustrate statistically whether there were significant differences between blockage slope angles based on relative backwater rise values for the average tested blockage ratios at each Fo (Table 2).

3.2 Empirical equation for culvert backwater rise

The basic governing parameters for culvert backwater rise owing to blockage characteristics are discussed hereafter. Relative backwater rise ΔH/hu is described in terms of Froude numbers, blockage ratios, and blockage slope angles. On the basis of multivariable regression analysis, Eq. (3) was developed with 95% confidence level among the dimensionless contributing parameters (i.e., Table 1) to predict backwater rise using 72 experimental datasets.

To estimate the performance of Eq. (3), a comparison between measured ΔH/hu and corresponding predictions using Eq. (3), with the ± 25% prediction range is presented in Fig. 6. The data that was utilized to develop the equation is what this validation is based on.

Comparison between measured and predicted ΔH/hu by Eq. 3, with a ± 25% prediction range

3.3 Upstream velocity and water surface elevation

In this study, to understand the effect of culvert blockage characteristics on relative upstream mean velocity Vu/Vo; B = 0.20, 0.40, 0.60, 0.80, 1; and α = 90°, 45°, 26.57°, and 18.44° were tested under various flow conditions. Figure 7 displays the relationship between Vu/Vo and B for various α in the range of Fo = 0.10, 0.18, 0.25. As the blockage ratio increases, the upstream flow depth increases and subsequently the mean velocity decreases under the same test conditions (Fig. 7). Furthermore, the effects of culvert blockages on water surface elevation upstream, downstream, and through a culvert are described for various Fo = 0.10–0.25. The culvert entrance and outlet were unsubmerged in cases of no blockage, and used as a base case throughout the tests with culvert contraction ratio = 0.50. Figure 8 depicts the variations of water surface elevation around a culvert blockage for B = 0.20, 0.40, 0.60, 0.80, and 1, and a no-blockage case for α = 26.57° at streamwise locations x/ho between − 10 and + 12. The flow surface elevation through the culvert is mainly influenced by blockage ratios and Froude numbers. For the same Fo and α, the length and maximum depth of water surface depression are larger and extend for larger B over a longer streamwise distance (Fig. 9). Table 3 lists the relative maximum depth d/ho and relative length L/ho of dip for B = 0–1 at the range of Fo = 0.10–0.25 for α = 26.57° with culvert contraction ratio = 0.50.

4 Discussion

4.1 Analysis of flow conditions and culvert blockage characteristics

According to Figs. 3, 4, for all configuration, backwater rise ∆H increases linearly as Froude number Fo increases. For B = 0.4 and α = 45°, ∆H = 0.4 cm for Fo = 0.10 and ∆H = 1.45 cm for Fo = 0.25. This trend is noticed for all tested blockage ratios and slope angles. Increasing Froude number results in higher flow velocity that can affect backwater rise.

Figure 5 shows that given α = 90° and Fo = 0.10, ∆H/hu = 0.04 for B = 0.20, and ∆H/hu = 0.33 for B = 1. In addition, for Fo = 0.10, and the average tested slope angles, using blockage ratios of 0.40, 0.60, 0.80, and 1 increase the relative backwater rise by approximately 2, 5, 9, and 13 times, respectively, compared with a blockage ratio of 0.20. This means that when the culvert inlet is blocked, the upstream flow depth is altered, generating a backwater rise. Therefore, for safety, keeping the culvert inlet as unblocked as possible is strongly recommended because it generates the main increase of backwater rise and consequently increases the probability of flooding.

Regarding the slope angle effect, decreasing α changes the shape of the blockage and reduces the inclination of the blockage to the flow, thereby decreasing the amount of drag produced by the given blockage ratio, so that ∆H/hu generally decreases (Fig. 5). For B = 1 and Fo = 0.10, ∆H/hu = 0.29 for α = 18.44° compared with ∆H/hu = 0.32 for α = 90°. This result indicates that the pressure drag force in front of the culvert reduces with decreasing blockage slope, leading to a reduced backwater rise. ∆H/hu results are quite similar for Fo = 0.25 at B = 1 for all tested angles due to the uncertainty. According to Table 2, the differences between slope angles are statistically significant with p-value < 0.05. Hence, the backwater rise is a function of culvert blockage slope angle.

4.2 Proposed equation for culvert backwater rise

For the given test setup, the proposed empirical relationship is valid for 0.10 ≤ Fo ≤ 0.25, 0 ≤ B ≤ 1, and 18.44° ≤ α ≤ 90° for box culvert inlets. The equation provides a good fit to the experimental data with adjusted R2 = 0.99 using all parameters, and the mean absolute error amounted to 0.019. Additionally, the standard errors of the parameter coefficients Fo, α, and B are 0.098, 0.084, and 0.009, respectively. From the above equation, the governing parameters have positive index values to signify positive effects on culvert backwater rise. According to Eq. (3), B yields the strongest impact on ΔH/hu with an exponent of 0.9, followed by Fo with an exponent of 0.81, and slope angle α shows a small influence with an exponent of 0.16. Overall good agreement between measured and predicted ΔH/hu are observed in Fig. 6 with R2 = 0.95, and standard error = 0.028. The figure shows an overestimation for measured ΔH/hu < 0.10. These values are recorded for lower Fo with lower B and caused uncertainty owing to lower amounts of drag and measurement errors. In particular, the suggested Eq. (3) predicted 87% of data within the ± 25% prediction range. Therefore, to enhance the accuracy of Eq. (3), it is recommended to apply the equation for ΔH/hu ˃ 0.10.

4.3 Analysis of upstream mean velocity and water surface elevation

The results in Fig. 7 show that Vu/Vo decreases with increasing B. This trend is noticed at all tested slope angles and Froude numbers. Relative upstream mean velocity Vu/Vo for Fo = 0.10 and α = 90° decreases from Vu/Vo = 0.96 for B = 0.2 to Vu/Vo = 0.67 for B = 1 (Fig. 7). This means that culvert inlet blockages reduce the upstream flow velocity and therefore considerably more sediment deposition may develop, leading to more culvert blockage. Additionally, Vu/Vo decreases with increasing Fo, meaning that upstream mean velocity increases with Fo with the other parameters kept constant.

Regardless of the slope angle impact on Vu/Vo, given Fo = 0.10 and B = 1, Vu/Vo = 0.71 for α = 18.44° compared to Vu/Vo = 0.67 for α = 90° (Fig. 7). Hence, Vu/Vo generally decreases with increasing α, especially when the comparison between maximum and minimum α. Owing to the lower ΔH/hu values that occurred for lower α, as discussed previously, Vu/Vo increases. This effect is observed for all Froude numbers and blockage ratios. Thus, upstream mean flow velocity evidently increases when the blockage slope angle decreases in general because of the reduction in flow depth.

Considering water surface elevation, water level increases upstream of the culvert owing to blocking; additionally, for a given blockage ratio, water level rises with increasing Froude numbers, as seen in Fig. 8. The contracted culvert and blockage results in a depression (dip) in the water surface behind the blockage and the culvert inlet. The degree of flow disturbance is a function of blockage ratio and Froude number. In addition, for a given B and α, the depression characteristics (length and maximum depth) are larger and extend for larger Fo over a longer streamlines distance (Fig. 8). Hence, flow pattern changes with different blockage shapes. This result matches with the results of Daneshfaraz et al. [33] who studied the flow pattern for sill with different geometries. During the experimental observations, the water surface depression was not clearly differentiated between tested α values at the same B and Fo, owing to the extensive flow disturbances that created difficulty in recognizing the differences between slope angles for determining the depression values.

For a constant B = 0.4, d/ho = 0.23 and L/ho = 1.32, for Fo = 0.10 compared to d/ho = 0.34 and L/ho = 2.45 for Fo = 0.18, and for Fo = 0.25, d/ho = 0.58 and L/ho extends over a longer distance to the flume end (Table 3). This means that d/ho and L/ho increase with Fo. This trend is observed for all blockage ratios. Similarly, for Fo = 0.10, d/ho = 0.13 and L/ho = 0.94 for B = 0.2 compared to d/ho = 0.32 and L/ho = 4.34 for B = 1. Fo increases d/ho and L/ho, and this trend is observed for all tested Fo. Actually, the relative maximum depth and length of dip results for α = 26.57° had small difference to the corresponding results for the other tested slopes, with a prediction error < 10%.

Regarding practical engineering implications, studies related to culvert design have illustrated the governing equations for each flow type and its specific conditions [16, 18]. However, in this research, it was evident that for a given flow type through the culvert, the water surface elevation was noticeably changed with the blockage comparing with the nonblocked case; hence, the specific conditions may be continually changed according to the extent of culvert obstruction. Therefore, culvert design and flow types can be dramatically influenced by Froude numbers and blockage ratios. Examining the flow regimes and governing equations for culvert flow under various blockage ratios and Froude numbers is recommended.

Several studies have recognized that culvert blockage is associated with harmful impacts [34,35,36,37]. Hence, adequate culvert design can help reduce the related issues. In this research, culvert backwater rise or head loss results from blockage only under the tested flow conditions proposed using Eq. (3). Quantifying culvert blockage losses can have great impacts on total culvert losses. The question arises: how can these parameters be valuable for adequate design regarding hydraulic issues?

Considering the potential of culvert blockage during the hydraulic design of culverts can be helpful. From design perspectivity, the probability of blockage can be predicted by evaluating the potential for debris and sediment delivery to the culvert site, and predicting the size of accumulation potential. Tasks and phases in estimating debris delivery and accumulation potential to a site were illustrated by Bradley et al. [2]. In addition, the size and slope of culvert blockage may be predicted and determined by surveying the entrance of an existing culvert within the channel and near the site. This method is helpful for estimating the blockage characteristics in such sites. Adding the potential of blockage loss using Eq. (3) within the main accounting of culvert losses will obtain the total head loss of a culvert. Thus, the culvert designer can design with a suitable larger cross section with adequate capacity that would reduce both maintenance difficulty and hydraulic effect issues.

5 Conclusions

A series of tests were conducted to identify the effects of blockage ratios and slopes on backwater rise, upstream mean velocity, and water surface elevation for a modeled box culvert with a contraction ratio of 0.50 and unsubmerged entrance flow. The tests were performed in a narrow channel for varying blockage ratios, blockage slope angles, and flow conditions. The study results can be summarized as follows:

-

Froude number, blockage ratio, and slope angle were considered the governing parameters of culvert backwater rise and upstream mean velocity.

-

Culvert backwater rise significantly increased with increasing blockage ratio. ΔH/hu increased by approximately 2, 5, 9, and 13 times for B = 0.40, 0.60, 0.80, and 1, respectively, compared with B = 0.20. In addition, upstream mean velocity decreased with increasing B and, hence, increased the probability of upstream sediment deposition.

-

Decreasing the blockage slope angle reduced backwater rise hence, increased the upstream mean velocity owing to reductions in the developed drag. Moreover, a paired t-test for means showed significant differences between slope angles based on ΔH/hu values. When Fo increased, backwater rise increased as well.

-

Eq. (3) was deduced to estimate relative backwater rise with uncertainties of ± 25%, which is sufficient only under the tested flow conditions. The governing parameters in Eq. (3) signified positive effects on ΔH/hu, and B exhibited the largest impact followed by Fo, and slope angle α.

-

Free surface elevation through the culvert was mainly influenced by blockage ratio and Froude number. As a result, the length and maximum depth of surface depression became larger with B, and Fo. However, the differences between slope angles for the depression values at the same test conditions were not clearly observed because of the extensive flow disturbances.

-

This study used a small scale model and developed results for box culvert with square edges at the inlet, and unsubmerged entrance and outlet flow. The proposed Eq. (3) is useful for estimating backwater rise in the range 0.10 ≤ Fo ≤ 0.25, 0 ≤ B ≤ 1, and 18.44° ≤ α ≤ 90°. In addition, the effects of aspect ratio b/ho on ΔH results for b/ho ≈ 1.52, 1.35, 1.19, and 1 were examined in contrast to the used b/ho ≈ 0.85.

The validation of close-to-prototype scale models for culverts under the full tested conditions is strongly required to fully assess the scale effects and improve process understandings. In addition, examining the culvert flow regimes and the corresponding governing equations for various blockage ratios and Froude numbers may be useful.

Data availability

All data appeared in the paper.

Abbreviations

- A :

-

Flow area

- A b :

-

Area of blockage in culvert inlet

- A c :

-

Cross section flow area of culvert opening

- A t :

-

Cross section flow area of channel

- b :

-

Width of culvert inlet

- C r :

-

Contraction ratio(1−Ac/At)

- d :

-

Max depth of depression

- d 50 :

-

Median grain size of material

- Fo :

-

Froude number

- g :

-

Gravitational acceleration

- h b :

-

Height of inlet blockage

- h o :

-

Upstream flow depth in case of culvert without blockage

- h u :

-

Upstream flow depth in case of culvert with blockage

- L :

-

Length of depression

- p :

-

Probability

- Q :

-

Flow discharge

- R :

-

Hydraulic radius

- Ro :

-

Reynolds number

- V :

-

Mean flow velocity

- V o :

-

Upstream mean flow velocity in case of culvert without blockage

- V u :

-

Upstream mean flow velocity in case of culvert with blockage

- x, z:

-

Streamwise and vertical directions

- α:

-

Blockage slope angle

- ΔH :

-

Backwater rise

- λ :

-

Scale factor

- υ :

-

Kinematic viscosity

References

Balkham M, Fosbeary C, Kitchen A, Rickard C. Culvert design and operation guide. London: Construction and Industry Research and Information Association; 2010.

Bradley JB, Richards DL, Bahner CD. Debris control structures-evaluation and countermeasures: hydraulic engineering circular 9 (No FHWA-IF-04–016). Washington: Federal Highway Administration Office of Bridge Technology; 2005.

Kells JA. Hydraulic performance of damaged-end corrugated steel pipe culverts. Can J Civ Eng. 2008;35(9):918–24. https://doi.org/10.1139/L08-055.

Rigby EH, Boyd MJ, Roso S, Silveri P, Davis A. Causes and effects of culvert blockage during large storms. In: 9th Int Conference on Urban Drainage. USA: Oregon; 2002. p. 1–16.

Barthelmess A J, Rigby EH Estimating culvert and bridge blockages-a simplified procedure. In: 34th World Congress of the International Association for Hydro-Environment Research and Engineering: 33rd Hydrology and Water Resources Symposium and 10th Conference on Hydraulics in Water Engineering, 2011, p. 39–47, Engineers Australia, Brisbane, Australia

Sorourian S, Keshavarzi A, Ball JE. Scour at partially blocked box-culverts under steady flow. In Proc Inst Civil Eng-Water Manage. 2016;169(6):247–59. https://doi.org/10.1680/jwama.15.00019.

Rigby EH, Barthelmess AJ Culvert blockage mechanisms and their impact on flood behaviour: Are All Blockages Created Equal? In 34th World Congress of the International Association for Hydro-Environment Research and Engineering, Engineers Australia, 2011, p.380–387, Brisbane, Australia

Iqbal U, Barthelemy J, Perez P. Prediction of hydraulic blockage at culverts from a single image using deep learning. Neural Comput Appl. 2022;34:21101–17. https://doi.org/10.1007/s00521-022-07593-8.

Iqbal U, Bin Riaz MZ, Barthelemy J, Perez P. Quantification of visual blockage at culverts using deep learning based computer vision models. Urban Water J. 2023;20(1):26–38. https://doi.org/10.1080/1573062X.2022.2134041.

Blanc J. An analysis of the impact of trash screen design on debris related blockage at culvert inlets. Heriot-Watt: Heriot-Watt University; 2013.

Kramer M, Peirson WL, French R, Smith GP. A physical model study of culvert blockage by large urban debris. Australas J Water Resour. 2015;19(2):127–33. https://doi.org/10.1080/13241583.2015.1116184.

Iqbal U, Barthelemy J, Perez P, Cooper J, Li W. A scaled physical model study of culvert blockage exploring complex relationships between influential factors. Australas J Water Resour. 2021. https://doi.org/10.1080/13241583.2021.1996679.

Iqbal U, Barthelemy J, Li W, Perez P. Automating visual blockage classification of culverts with deep learning. Appl Sci. 2021;11(16):7561. https://doi.org/10.3390/app11167561.

Barthelemy J, Amirghasemi M, Arshad B, Fay C, Forehead H, Hutchison N, Iqbal U, LiY QianY, Perez P. Problem-driven and technology-enabled solutions for safer communities. In: Augusto JC, editor. Handbook of Smart Cities. Cham: Springer International Publishing; 2020. p. 1–28.

Ibrahim H, Osman EA, El-Samman TA, Zayed M Aquatic weeds management upstream new Naga Hammady barrages. In 18th Int water technol conference, 2015, Sharm El-Sheikh, Egypt

Bodhaine GL. Measurement of peak discharge at culverts by indirect methods. Washington: Government Printing Office; 1968.

FHWA, Federal Highway Administration Hydraulic design of highway culverts. 3rd Ed., Washington, D.C. 2012

Chin DA. Hydraulic analysis and design of pipe culverts: USGS versus FHWA. J Hydraul Eng. 2013;139(8):886–93. https://doi.org/10.1061/(ASCE)HY.1943-7900.0000748.

Charbeneau RJ, Henderson AD, Sherman LC. Hydraulic performance curves for highway culverts. J Hydraul Eng. 2006;132(5):474–81. https://doi.org/10.1061/(ASCE)0733-9429(2006)132:5(474).

Haderlie GM, Tullis BP. Hydraulics of multibarrel culverts under inlet control. J Irrig Drain Eng. 2008;134(4):507–14. https://doi.org/10.1061/(ASCE)0733-9437(2008)134:4(507).

Tullis BP, Robinson SC. Quantifying culvert exit loss. J Irrig Drain Eng. 2008;134(2):263–6. https://doi.org/10.1061/(ASCE)0733-9437(2008)134:2(263).

Feurich R, Boubée J, Olsen NRB. Spoiler baffles in circular culverts. J Environ Eng. 2011;137(9):854–7. https://doi.org/10.1061/(ASCE)EE.1943-7870.0000384.

Lim SY, Lim S. Scour below unsubmerged full-flowing culvert outlets. Proc Instit Civil Eng Water Maritime Energy. 1995;112(2):136–49. https://doi.org/10.1680/iwtme.1995.27659.

Abida H, Townsend RD. Local scour downstream of box-culvert outlets. J Irrig Drain Eng. 1991;117(3):425–40. https://doi.org/10.1061/(ASCE)0733-9437(1991)117:3(425).

Liriano SL, Day RA, White WR. Scour at culvert outlets as influenced by the turbulent flow structure. J Hydraul Res. 2002;40(3):367–76. https://doi.org/10.1080/00221680209499951.

Chen KDW, Admiraal D, Hotchkiss R, Donahoo K. Laboratory measurements of scour downstream of box culverts. British Colombia: IAHR CongressVancouver; 2009.

Sorourian S, Keshavarzi A, Ball J, Samali B. Blockage effects on scouring downstream of box culverts under unsteady flow. Australas J Water Resour. 2014;18(2):180–90. https://doi.org/10.7158/W13-031.2014.18.2.

Taha N, El-Feky MM, El-Saiad AA, Fathy I. Numerical investigation of scour characteristics downstream of blocked culverts. Alexandria Eng J. 2020;59(5):3503–13. https://doi.org/10.1016/j.aej.2020.05.032.

Daneshfaraz R, Norouzi R, Ebadzadeh P, Kuriqi A. Influence of sill integration in labyrinth sluice gate hydraulic performance. Innovative Infrastruct Solutions. 2023;8(4):118. https://doi.org/10.1007/s41062-023-01083-z.

Miranzadeh A, Keshavarzi A, Hamidifar H. Blockage of box-shaped and circular culverts under flood event conditions: a laboratory investigation. Int J River Basin Manage. 2022;10(1080/15715124):2064483.

Hughes SA. Physical models and laboratory techniques in coastal engineering, advanced series on ocean engineering 7. Singapore: World Scientific; 2005.

Heller V. Scale effects in physical hydraulic engineering models. J Hydraul Res. 2011;49(3):293–306. https://doi.org/10.1080/00221686.2011.578914.

Daneshfaraz R, Norouzi R, Ebadzadeh P, Di Francesco S, Abraham JP. Experimental study of geometric shape and size of sill effects on the hydraulic performance of sluice gates. Water. 2023;15(2):314. https://doi.org/10.3390/w15020314.

Scottish Executive Scottish planning policy 7: Planning and flooding. Scottish Executive Development Department Edinburgh, Crown Copyright. 2004.

SEPA Scottish Environment Protection Agency. Position statement to support the implementation of the water environment (controlled activities) (Scotland) regulations 2005: culverting of watercourses. Stirling: Scottish Environment Protection Agency; 2006.

CIWEM, Chartered Institution of Water and Environmental Management De-culverting of watercourses. CIWEM Policy Position Statement. 2010.

EA Environment Agency. Fluvial design guide. Bristol: UK; 2010.

Author information

Authors and Affiliations

Contributions

MZ who contributed to the whole work. The author read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Zayed, M. Blockage slope and ratio effects on box culvert hydraulics. Discov Water 3, 23 (2023). https://doi.org/10.1007/s43832-023-00045-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s43832-023-00045-x