Abstract

Water conservation has become a global problem as the population increases. In many densely populated cities in China, leaks from century-old pipe works have been widespread. However, entirely eradicating the issues involves replacing all water networks, which is costly and time-consuming. This paper proposed an AI-enabled water-saving control system with three control modes: time division control, flow regulation, and critical point control according to actual flow. Firstly, based on the current leaking situation of water supply networks in China and the capability level of China’s water management, a water-saving technology integrating PID control and a series of deep learning algorithms was proposed. Secondly, a multi-jet control valve was designed to control pressure and reduce water distribution network cavitation. This technology has been successfully applied in industrial settings in China and has achieved gratifying water-saving results.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

According to the OECD Environmental Outlook for 2050, global water demand is expected to increase by 55% between 2000 to 2050 [1]. Rapid urbanization and climate change are growing water demand and putting pressure on current water resource management. In China, the annual water loss caused by leakages of urban water supply networks exceeds the actual storage capacity of Taihu Lake, which is enough to meet the water demand of 100 million urban populations. Leakages of water supply networks not only cause waste of large amounts of quality water resources and disrupt average production and living order but also may bring secondary hazards such as water quality risks and damage to underground utilities [2]. The development of IT, new information and communication technologies (ICT), sensing and driving devices of IOT (Internet of Things), and machine learning algorithms provide new tools for intelligent decision-making in designing, monitoring, and controlling urban water supply systems.

Water loss in water supply systems significantly contributes to water shortage. From the perspective of sustainable and integrated water resource management, it is necessary to reduce water leakage rates by monitoring system elements and enhancing network maintenance or management. Most current studies mainly focus on using technologies to monitor water supply systems and detect water network failures and leakages, with a large portion being based on simulation experiments. Not much research and practice has been done on water network control, and existing research often studies specific areas unsuitable for China. In light of this problem, this paper proposed an AI-enabled water-saving control system based on the current situation of leakages in China’s water supply networks and the capability level of China’s water management. Firstly, the water-saving technology integrates PID control and a series of deep learning algorithms, and secondly, the multi-jet control valves are installed in water supply networks. The system has three modes to control water pressure: time-division control mode, flow-regulation mode and critical point control mode according to the actual flow. It is an intelligent water solution jointly developed by Shanghai Karon Eco-valve Manufacturing Co., Ltd., Tongji University and Shanghai Ustart Intelligent Water Research Institute. This technology has been successfully applied in the industrial field in China, including projects in water conservancy and hydropower engineering, municipal systems and civil engineering systems, achieving gratifying water-saving results.

The remainder of this article is organized as follows: a literature review is provided in Sect. 2, while a description of our proposed water-saving system based on artificial intelligence for managing water pressure is provided in Sect. 3; as part of Sect. 4, some successful industrial applications of the technology are described, including the renovation of pipeline networks in Danyang Yuling Town, Changzhou, and the construction of Dashijian reservoirs in Sanmenxia; Sect. 5 summarizes our water-saving technology proposals and provides an overview of future developments.

2 Literature review

Essential as water to human being, the inhabitants within the catchment areas are counting on the local authorities to provide them with a clean and reliable water service. Called running water, to mean water coming by itself, the expectation of clean and reliable water supply has been paramount. To meet this expectation, numerous studies have been conducted by industry and researchers alike [3] on reliable water supply, by monitoring leakages, learning inhabitant’s usage pattern within the catchment area, so as to better maintain and deliver the water services efficiently [4]. Smart meters, as the names implied, are electronic devices that record information – such as consumption of electric energy, voltage levels, current, and power factor – and communicates the information to the consumer and electricity suppliers. However, unlike the automatic meter reading (AMR), an advanced metering infrastructure (AMI) has the capability on two-way communication between the meter and the supplier [5].

To know the customers and their habit on water usages better, to manage and deliver an efficient water service, Panda et al. [6] proposed a PWD (priority-based water distribution) system to regulate water flow according to priority values in water network control. A digital water tank was created by Rahman et al. [7] could even allow users to monitor the water level and temperature via an Android apps to set control of the water level automatically on line. Using programmable logic controller (PLC), Miloudi et al. [8] used the information monitored by sensors to control the pump of a water tower, Here in China, Zeng et al. [9] of Wuhan Water Supply Co., Ltd., had proposed a time-division regulatory model to manage the water distribution at different time-periods. As a paradigm shift, a Water Wise System (W2S) was put forwarded by Figueiredo et al. [10] to learn and analyse water usage convergence, using machine learning, with deep learning integrated with SCADA (Supervisory Control and Data Acquisition), GIS and EPANET, to develop regulatory and distribution plan to better manage the water resources. Similarly, Fazal et al. [11] also created a water monitoring system manageable via website to display water data.

Works by Rayed et al. on better monitoring on water distribution performance, had led to development of a better supervision of water service delivery within the distribution networks in Aracatuba, Brazil [12]. About the same time, Kyudae et al. [3] had developed an IoT SWM (intelligent water management) system that could detect water shortage or malfunction (such as breaks of valve, pump or pipeline) hidden in undergrounds tanks, so that emergency provision could be activated to rectify the pitfalls as they occur. Helena et al. [13] had even gone further to developed an intelligent water grid (SWG) with a digital twin (DT) to monitor the water infrastructure.

However, as far as leakage detection is concerned; acoustic emission, fibre optic detection, ground-penetrating radar, and infrared thermography were classic hardware solutions [14]. Nonetheless, other technology such as sound signal had also been attempted in WSN to determine whether a pipeline is leaking by Zhang of Xiamen Water Group Co., Ltd. [15].

On the other hand, prevention is better than cure, there are others like Shao et al. [16] and Alves et al. [17] who took the views that dependent origination, the fundamental principle at work is that of cause and effect, therefore, by looking into the leakages data locating in water distribution networks (WDNs), one could predict the chances of leakage occurrence to develop preventive plans. This initiative had led to the design of a Minimum Night Flow early-warning model based on the DMA (District Metering Area) partition integrated with a SCADA-based leakage warning and location model [18].

There are also Kowalski et al. [19] who presented works on quasi-intelligent method to detecting abnormity in the WSS (water supply systems) functioning. While Armon et al. [20] put forward TaKaDu, a real-time algorithmic Water Infrastructure Monitoring solution, to focus strongly on water loss reduction and control. It has been provided as a commercial service to several customers worldwide, and it can also detect sensor and SCADA (Supervisory Control and Data Acquisition) failures, various water quality issues, and other events that may occur in water networks.

Nevertheless, as learning has to be undertaken in a continuous basis, many machine learning algorithms using support vector machines [21, 22], convolutional neural networks [23–25], artificial neural networks [26], have found their ways into these proposals.

In summary, many existing research mainly focuses on using technologies to monitor water supply systems for, water network failures and pipeline leakage. However, to fully eradicate the problems involves the replacement of literally the entire water networks, which are both costly and time-consuming. Hence, development of a decision-supported system with capability to manage the water distribution in peak and off-peak periods to efficiently provide water service in the catchment areas, to stabilize the situation; contain the leakage problem, as much as humanly possible to repair, or isolate them from the network if required, to reduce the wastage to save water on the water supply side, will go along-way to meet the local inhabitants expectation of provision of a clean and reliable water supply, running by itself. Therefore, this paper proposes an AI-enabled water-saving system and designs a multi-jet control valve using PID control and a series of deep learning algorithms to control the valve opening with three modes: time-division control mode, flow-regulation mode and critical point control mode, according to the actual flow.

3 AI-enabled water-saving system

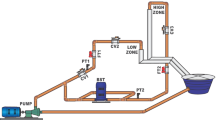

As shown in Fig. 1, the designed water-saving system uses a water pressure management valve with superior linearity of flow and pressure regulation, configured with an AI-based intelligent control system, with time-division pressure management technology as the control core. The system comprises four parts: the control system, pressure relief valve (PRV), valve control box, and valve electric actuator.

3.1 AI-based intelligent control system

As shown in Fig. 2, the AI-based intelligent control system of the proposed water-saving system integrates PID control and a series of deep learning algorithms, which are responsible for processing and analysis of collected data and can accept various control commands sent from the remote central control room to control the valve opening and can transmit the collected data of pressure, flow and valve status from the site to the central control room in turn. The system uses a touch screen as a human-machine dialogue window for field valve operation.

3.2 Three control modes of the system

Three control modes of our proposed AI-based intelligent control system are selected according to actual operation requirements to meet the needs of different water-using scenes. Through TabNet-LSTM, LSTM (Long Short-Term Memory) and a “parameter-aware” deep learning model, we can find out the periodicity and regularity of water consumption based on which we calculate the variables to be regulated and then realize adaptive time-division pressure control for different periods.

3.2.1 Time-division control mode

In time-division control mode, staff can set each period’s period and corresponding pressure value through the valve parameter setting window of the touch screen (as shown in Fig. 3). The PLC control system can automatically regulate time division according to settings. When the PLC system receives a pressure regulation command, it first calculates the approximate opening of the valve based on the pressure opening curve of the valve (as shown in Fig. 4). It automatically adjusts the valve opening (coarse adjustment). Then, the control system compares the measured pressure value with the set value for feedback and uses PID control for fine adjustment, which can reduce valve adjustment frequency, avoid adjustment oscillation, achieve dynamic adjustment, and obtain stable flow or voltage regulation effects.

The time-division control mode is based on the traditional fixed pressure control method with the addition of time settings. When the valve is running, the fixed pressure control method first makes a rough adjustment that regulates the opening of the valve according to the corresponding relationship of the pressure-opening curve. Secondly, when the valve runs to the set opening, the system automatically switches to PID control for fine adjustment. This way, we can avoid pipeline damage from adjustment oscillation and realize stable pressure regulation.

Actual water consumption scenes demonstrate apparent periodicity and regularity in water consumption. For example, there are significant differences between winter and summer water demand during a year, as well as between weekdays and weekends during a week. In addition, different factors affect water demand at various times of the year. So, it’s necessary to introduce intelligent algorithms to learn the cyclical and regular changes in water consumption over time, predict water demand and adjust water pressure. As shown in Fig. 5, we propose a multi-feature short-term water demand prediction model based on TabNet and LSTM, which determines the distribution of critical features affecting water demand and their weights depending on TabNet’s sequential attention mechanism. We construct the input data of the LSTM model through sliding windows and use single-step prediction. We adopt a combined variance-covariance prediction method to determine the weights of TabNet and LSTM models and obtain water demand prediction results. To improve the accuracy of water demand prediction, the proposed model adopts two strategies, including mining short-term local dependency patterns and long-term patterns of time series trends between data sequences and mining categories and discontinuous features in historical data.

3.2.2 Flow-regulation mode

Although time-division pressure regulation can meet the pressure demand at each specific period of the day, it cannot respond to changes in water flow on time. Therefore, we add a flow-regulation mode. When the flow of water networks changes abnormally, leakages may exist. The control system will automatically switch to flow-regulation mode to avoid water supply interruption caused by abnormal changes in the flow (such as fire, pipeline burst, etc.).

The centralized water supply system has a high time delay, large inertia, and time variation, making it difficult for PID control, commonly used in industrial control, to operate effectively. To solve the problems caused by the extended time delay of the system, model-based predictive control methods are often employed in industry, i.e., values of long-time-delay variables at the future moment are predicted by using low-time-delay variables in the system, usually water supply pressure or valve opening, and the differences between the value of a high-time-delay variable at the future moment and the optimization target are taken as the input of PID control to regulate variables. However, due to the complexity of centralized water supply systems, predicting low-time-delay variables to high-time-delay variables is difficult to achieve by parsing. Deep learning, a statistical-based prediction method, predicts high-latency variables with sufficient data and computational resources. Considering the enormous inertia of centralized water supply systems, i.e., the system’s output depends not only on the inputs at the current moment but also on the inputs at previous N moments, we adopt LSTM, which is good at processing time series data. LSTM is a variant of RNN (Recurrent Neural Network) because of RNN’s weakness in long-term memory. As shown in Fig. 6, the core of LSTM is the cell state, which determines whether the information should be retained or forgotten. We use all measurable system parameters as model inputs, including valve opening, water pressure, water temperature, flow rate, and noise. To solve the overfitting problem of LSTM models with small sample data, we reconstructed the model by splitting it into two cascade models, each using only part of the data dimension. The feedback-based model correction mechanism in this method also effectively solves the problem of model accuracy degradation caused by neural network simplification.

3.2.3 Critical point control mode

In actual water supply networks, it is often necessary to adjust water pressure according to the end users’ requirements or changes in water consumption. The adjustment of pressure is not arbitrary and infinite. Each water supply system has a critical pressure value; once the pressure exceeds this value, the system will collapse. Therefore, we designed the critical control mode to prevent excessive pressure that might cause the system to collapse.

We install remotely controlled pressure sensors at critical points to detect water pressure and predict water demands that meet critical points within networks. After the monitoring data from pressure sensors are transmitted back to the server through wireless networks (e.g. NB, 4G, etc.), we extract the physical indicators characterizing water flow in pipelines from the perspective of average pipe pressure, fluctuation index of water flow velocity, and uniformity of water network structure distribution, respectively. Based on the critical moderation theory, we analyze indicators’ critical correlations using autocorrelation coefficients, biases, and variance changes. As shown in Fig. 7, we design a deep learning model with parameter channels to enable the model to identify the evolution of system indicator variables caused by parameter drift by exploring the correlation between risk drift and the critical evolution of the system. A global-local attribute-based node influence algorithm is designed to remove nodes one by one com, compare the network with the original one to find each node’s ind critical value difference and obtain the node indicator matrix of water networks. We developed an innovative combination weighting method based on the least square method to assign weights to each node indicator. We introduced the concept of node importance to rank each node. Then, we classified the nodes into core nodes, common nodes and edge nodes to realize a critical analysis of heterogeneous nodes of water networks and evaluate and predict water demand that satisfies the crucial point.

3.3 Multi-jet control valves

When the liquid flows through the throttle of the valve, the cross-section gradually decreases as the flow rate increases, and the static pressure of the liquid here decreases. When the static pressure becomes lower than the saturation vapour pressure of the liquid at the current temperature, part of the liquid will vaporize into bubbles, discharged to the back end of the throttle. With the expansion of the cross-section of the flow beam, the static pressure gradually recovers. Bubbles quickly break and liquefy when it recovers to a higher-than-saturation vapour pressure. As a result, this local solid pressure is generated by released energy from the rapid collapse of those bubbles. In the process, harmful cavitation and noise are generated during valve operation, which erodes the valve body and pipelines and damages the material. To solve this problem, we designed a multi-jet control valve, as shown in Fig. 8, to rectify this traditional valve technical defects using a symmetrical and uniformly distributed conical hole spray on the circumference of the sleeve to collide and absorb energy. As shown in Fig. 9, the product causes water to spray out through each spray hole and collide with each other on the central axis of the valve, completely dissipating velocity energy. This multi-jet control valve is more durable, has anti-cavitation, low vibration, and automatic control, and does not require additional power sources (without an external power supply, simply use the hydraulics to power a variety of valve action functions).

4 Case study

With priority-based water distribution to priority values in water network control at different periods, the decision support system has been successfully implemented in the Sanmenxia urban drinking water project, Guizhou Huairen water construction project, Beijing new airport water supply station project, etc. Industry design units and users have gradually accepted it and have achieved a gratifying water-saving effect. We shall feature two of them here: the pipeline networks case study of Danyang Yuling Town and the Dashijian reservoir of Sanmenxia. a case study in Changzhou.

4.1 A case study in pipeline networks of Danyang Yuling Town, Changzhou

To apply the AI-enabled water-saving technology proposed to DanyangYuling Town, Changzhou pipeline networks, we set up eight pressure control periods according to water consumption characteristics at different times. We collected actual water consumption data, weather data and dates from January 1, 2017, to December 31, 2018, as experimental data, accumulating 24 points daily. We divided the collected data into a training set, validation set and test set according to 8:1:1. To verify the effectiveness of the combined model, the first 50% of the data are used to calculate the error between actual and predicted values, providing a basis for combination for the second 50% data, and then these data were evaluated to verify the prediction accuracy of the model. We used indicators such as mean absolute percentage error, mean absolute error and root mean square error to assess the model’s prediction ability. Based on the water demand prediction at different periods, the valve automatically adjusts to reach the appropriate water pressure to achieve the best water-saving efficiency.

Water consumption in the town of Danyang Yuling varies significantly between different periods. Before the renovation, butterfly valves without a linear adjustment function were used as the flow regulator of the water networks. No time-division pressure regulation was used, which could not effectively control the pressure and flow and could not meet the water demands of customers at different times. Before the renovation, the pipeline leakage rate was high, with a rate of 10% or more. After the renovation, the time-sharing control valve designed in this paper was installed in the leading network. At the same time, other equipment remained the same, and an intelligent control system was implemented to regulate pressure. The project implementation time is from August 2019 to September 2019. We chose the period from January to December 2018 as the base period and from January to December 2020 as the reporting period. The water supply data are obtained from Danyang Water Group Co., Ltd., and the consumption water data are obtained from the business office of Danyang Water Group Co., Ltd. The water supply curves before and after the renovation are shown in Fig. 10.

According to the Leakage Control and Assessment Standards for Urban Water Supply Network of China, the comprehensive leakage rate of water supply units \(R_{WL}\) is calculated according to (1):

where \(Q_{s}\) is the total water supply capacity (m3), \(Q_{a}\) is the water consumption capacity of registered users (m3) and the calculation results are shown in Table 1.

Based on the total water supply capacity of 1,614,834 m3 in 2020, plus the saving on water processing cost due to the effectiveness of the time-sensitive scheme of (1,621,270 m3- 1,614,834 m3), the annual water-saving capacity \(W_{s}\) can be calculated as (2),

The cost of producing 1 m3 of water is 1.2 RMB in Danyang Yuling Town (including tax). Thus, the annual saving on water losses \(E_{s}\) can be calculated as (3),

The project costs 287,000 RMB, including 137,000 RMB for the valve and intelligent control system and 150,000 RMB for the valve construction. The payback period (T) of this project is calculated as (4)

In conclusion, when the project was implemented in March 2021, 1) the leakage rate was reduced from 10.31% to 6.03%, achieving an annual water-saving capacity of nearly 70,000 tons, plus saving of another 6436 tons, benefited from the introduction of time-sensitive distribution scheme, resulted in contribution to the bottom-line of a total saving on annual water costs of more than 90,661 RMB in Year 2020, 2) the investment for renovation and installation of DSS estimate will take just over three years to return in investment.

4.2 A case study in Dashijian Reservoir of Sanmenxia

Sanmenxia Dashijian Reservoir is a demonstration project developed for dual irrigation and water diversion, irrigating while supplying water to downstream waterworks. Before the renovation, due to the topography, the diversion pipelines had problems with extreme noise, high vibration, high leakage rate and inability to achieve stable back-end flow, with a noise level of 95–98 decibels. After replacing the valve and the system proposed by our team, the noise of the valve dropped to about 70 decibels, and the outlet pressure control of the valve fluctuated less and was more accurate. The leakage rate of the downstream pipeline significantly decreased. Before replacement, the piston valve motor was rated at 7.5 kW, with a regular daily power consumption of about 15 kW⋅h. After replacement, the engine’s rated power is 0.55 kW, and the actual power used is about 0.3 kW, which reduces the daily electricity consumption to about 0.5 kW⋅h. A preliminary estimate is that after the replacement, the average daily electricity saving is 14.5 kW⋅h, the average annual electricity saving is about 5293 kW⋅h and the average daily leakage loss is reduced by about 300 m3.

5 Conclusion

The AI-enabled water-saving system uses data analysis technology and deep learning algorithms to upgrade water supply systems, which increase water pressure during peak periods to meet customers’ demands and reduce pressure during off-peak periods to minimize leakage. It is a reliable and effective control execution model suitable for regional water-saving treatment equipment, which can enhance water supply systems’ intelligence, efficiency, and automation. The case studies show it can effectively control the pressure and flow of the networks, reasonably and scientifically utilize water resources, and effectively reduce leakages. In addition, it can be achieved without large-scale network renovations and has a short investment recovery period so that the investment cost can be recovered in 3–5 years.

Water resources will become more precious. The algorithm can be enhanced by adding vibration, noise, acceleration, and other parameters in conjunction with SCADA, GIS, DMA, and other existing technologies. Combining distributed wireless sensor networks and landscape complementary power supply technology to achieve multi-data high-frequency real-time dynamic acquisition and transmission and leakage detection, positioning and burst warning.

Although the decision-support system we have proposed is, by no means, a fully autonomous system, it works autonomously without human supervision to learn and understand the water supply-and-demand pattern in the catchment areas, develop a cost-effective plan to regular the water provision and distribution, dealt with the accidental water leakage as they appear, and rectify them by isolation, and provide alternative paths to by-pass part of the system, to balance the water pressure to ensure regular service is possible. Several field trials have been conducted with encouraging results and feedback to indicate that although we had not developed a fully singing-and-dancing autonomous intelligent system, we have, by and large, delivered what was feasible, given the circumstances, a workable solution to the local catchment areas a reliable water supply they desired, without large-scale network renovations, and long idle-time to wait for the construction of new and complex water distribution network.

Data availability

Not applicable.

Code availability

Not applicable.

References

OECD, OECD environmental outlook to 2050: the consequences of inaction. OECD Environment & Sustainable Development 2012(3), 353–354 (2012). https://doi.org/10.1039/P29950002375

X.F. Yang, Q. Xu, D.S. Wang, Development and prospects of leakage control technology for urban water supply networks in China: evaluation, monitoring, and control technology for pipeline leakage based on water balance analysis and partitioning management. Water & Wastewater Eng. 43(5), 1–120 (2017)

S. Kyudae, B. Eduardo, P. Yong-Gyun, Smart water solutions for the operation and management of a water supply system in Aracatuba. Brazil. Water 14(3965), 3965 (2022). https://doi.org/10.3390/w14233965

M.P. Marios, M. Iven, F.T. Ahmad et al., Special section: smart water systems. Annu. Rev. Control 55, 390–391 (2023). https://doi.org/10.1016/j.arcontrol.2023.04.003

Y.S. Meric, H. Halil, Review on environmental aspects in smart city concept: water, waste, air pollution and transportation smart applications using IoT techniques. Sustain. Cities Soc. 94, 104567 (2023). https://doi.org/10.1016/j.scs.2023.104567

H. Panda, H. Mohapatra, WSN based water channelization: an approach of smart water. Lect. Notes Civil Eng. 58, 157–166 (2020).

Md.S. Rahman, A.B. Sazzad, Md.A. Hossainet al., Bondhu tank: an automated smart water management system. Lect. Notes Data Eng. Commun. Technol. 62, 143–154 (2021)

L. Miloudi, A. Djenadi, Y.A. Hadj, Control and supervision of water tower in smart city. Lect. Notes Netw. Syst. 174, 178–183 (2021). https://doi.org/10.1007/978-3-030-63846-7_18

X. Zeng, W.X. Qiu, W.J. Li et al., Development of time-division pressure relief valve and its application in urban water supply. Water & Wastewater Eng. 43(12), 92–96 (2017)

F. Inês, E. Paulo, C. Paulo, Water wise – a digital water solution for smart cities and water management entities. Proc. Comput. Sci. 181, 897–904 (2021). https://doi.org/10.1016/j.procs.2021.01.245

Q.K. Fazal, A. Ibrar, F.K. Enas et al., Real-time consumer aware and alert system based on smart water tank. Mater. Today Proc. 63, 790–797 (2022). https://doi.org/10.1016/j.matpr.2022.05.506

A.Rayed, K.S. Sunil, IoT-based smart water management systems for residential buildings in Saudi Arabia. Processes 10(2462), 2462 (2022). https://doi.org/10.3390/pr10112462

M.R. Helena, K. Alban, B. Mohsen et al., Smart water grids and digital twin for the management of system efficiency in water distribution networks. Water 15(1129), 1129 (2023). https://doi.org/10.3390/w15061129

Y.L. Zhao, X. Liu, Z.Y. Lu, Overview of research on pipeline leakage detection and location technology. Mech. Electr. Inf. 673(1), 86–88 (2022)

Y.J. Zhang, Study on the application of monitoring system of water leakage. Intelli. Build. Smart City 236(7), 79–80 (2016)

Y. Shao, X. Li, T. Zhang et al., Time-series-based leakage detection using multiple pressure sensors in water distribution systems. Sensors 19(14), 3070 (2019). https://doi.org/10.3390/s19143070

D. Alves, J. Blesa, E. Duviella et al., Robust data-driven leak localization in water distribution networks using pressure measurements and topological information. Sensors 21(22), 7551 (2021). https://doi.org/10.3390/s21227551

F. Huang, Research on MNF and exiting leakage location Model of DMA. M.S. thesis, Hunan University (2019)

D. Kowalski, B. Kowalska, P. Suchorab, Smart water supply system: a quasi intelligent diagnostic method for a distribution network. Appl. Water Sci. 12(6), 135 (2022). https://doi.org/10.1007/s13201-022-01656-w

A.Armon, S. Gutner, A. Rosenberg et al., Algorithmic network monitoring for a modern water utility: a case study in Jerusalem. Water Sci. Technol. 63(2), 233–239 (2011). https://doi.org/10.2166/wst.2011.041

Z.H. Cheng, Research and implementation of water supply pipeline leak detection and location based on SVM and improved EWT: M.S. thesis, Chongqing University of Posts and Telecommunications (2021)

T.B. Quy, J.M. Kim, Leak detection in a gas pipeline using spectral portrait of acoustic emission signals. Meas. J. Int. Meas. Confed. 152, 107403 (2020). https://doi.org/10.1016/j.measurement.2019.107403

C. Zhang, J.A. Bradley, L.S. Mark et al., A convolutional neural network for pipe crack and leak detection in smart water network. Struct. Health Monit. 22(1), 232–244 (2023). https://doi.org/10.1177/14759217221080198

J. Kang, Y.J. Park, J. Lee et al., Novel leakage detection by ensemble CNN-SVM and graph-based localization in water distribution systems. IEEE Trans. Ind. Electron. 65(5), 4279–4289 (2018). https://doi.org/10.1109/TIE.2017.2764861

C. Marco, D.I. Salvatore, D.L. Giuseppe et al., Smart water meter based on deep neural network and undersampling for PWNC detection. IEEE Trans. Instrum. Meas. 72, 1–11 (2023). https://doi.org/10.1109/TIM.2023.3242018

J. Bohorquez, B. Alexander, A.R. Simpson et al., Leak detection and topology identification in pipelines using fluid transients and artificial neural networks. Water Resour. Plan. Manag. 146(6), 04020040 (2020). https://doi.org/10.1061/(ASCE)WR.1943-5452.0001187

Funding

This work was supported in part by the National Natural Science Foundation of China under Grant Nos. 72171172 and 92367101; the Aeronautical Science Foundation of China under Grant No. 2023Z066038001; the National Natural Science Foundation of China Basic Science Research Center Program under Grant No. 62088101; Shanghai Municipal Science and Technology Major Project under Grant No. 2021SHZDZX0100; Chinese Academy of Engineering, Strategic Research and Consulting Program, under Grant No. 2023-XZ-65.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study’s conception and design. Fengnian Liu performed material preparation, coding, data collection and analysis. Fengnian Liu wrote the first draft of the manuscript, and all authors commented on previous versions. Junya Tang revised and checked the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

All authors declare that there are no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Liu, F., Yu, X. & Tang, J. Water-saving control system based on multiple intelligent algorithms. Auton. Intell. Syst. 4, 13 (2024). https://doi.org/10.1007/s43684-024-00068-8

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s43684-024-00068-8