Abstract

Titanium dioxide is known as a photocatalyst, that may be activated by UV-A light and thus be able to lead to chemical reactions, to mineralize organic compounds, to inactivate biomolecules and to kill microorganisms, respectively. To estimate the capability of the photocatalytic activity a novel experimental setup using photovoltage measurements was studied. A distinct correlation between the photocatalytic activity of the titanium dioxide samples and the measurable photovoltages could be demonstrated. The experimental setups included the construction of different electrochemical cells based on TiO2 and using different liquid and gel electrolytes. The investigations were carried out on titanium dioxide layers as well as on TiO2 particle materials. The electrochemical measurement of the resulting voltage was optimised and the results were compared with conventionally used methods for the determination of the photocatalytic activity like the decolourization of methylene blue solutions. Additionally, the increase of carbon dioxide concentration in the gas phase was taken as a measure for total mineralization. Results indicate strong correlations between the different methods.

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Certain modifications of titanium dioxide (TiO2) show photocatalytic activity during irradiation [3, 6, 16]. Photocatalytic reactions may lead to mineralization of organic compounds, inactivation of biomolecules and killing of microorganisms [9, 10, 17]. However, the activity may differ widely depending on the type of modification and on its purity [4, 13]. Activity may further be influenced by doping with other elements and a variety of other strategies [1, 12, 20]. In any case, the unambiguous definition of the activity is mandatory. Most methods to estimate the photocatalytic activity of Titanium dioxide (TiO2) powders or coatings are based on the tracking of the decolourization of a dye using spectrometric measurements. To this end, the redox indicator Methylene Blue (MB) is used frequently. However, there is a number of uncertainties that may lead to inaccuracies in the estimation of the photocatalytic activity. The main and most important issues are, amongst others, the capability of MB to form colourless leuco MB under reductive conditions and the photolysis of the dye by visible light without the action of the photocatalyst [11, 19]. The latter can occur if modified TiO2-catalysts like doped TiO2 specimen are tested using visible light [5]. In addition, there are procedural sources of error like inconsistent purity of the used MB, pH-dependent adsorption of the dye to the TiO2 surface and effects due to inhomogeneous mixing of the dye solution during the test [14]. All these issues may impede a direct comparison of different test results and will lead to increased time and money consuming testing efforts.

To find a reproducible way for the measurement of the photocatalytic activity and to overcome the aforementioned uncertainties, a physical measurement instead of the commonly used chemical effect monitoring was studied. Electrons and “holes” are involved in all photocatalytic activities [8, 15]. The measurement of a related voltage should be a promising strategy. In this context, differences concerning the use of semiconductors for photovoltaic processes and for photo-oxidations, respectively, should be mentioned.

Solar cells and systems for photo-oxidation processes show some common properties. However, they differ in significant details. Solar cells are based on semiconductors with a forbidden band gap (Eg) that may be overcome by irradiation with light of certain wavelengths. The maximum current of solar cells is limited by Eg and is connected to the maximum achievable photovoltage. During irradiation of solar cells, the resulting current is harvested and the maximum achievable photocurrent may be taken as a measure for the efficiency of the photovoltaic module. In oxidation processes, however, the extend of the desired chemical reaction is generally defined by the normal potential of the oxidant. The oxidation (or reduction) potential of a certain reaction may be calculated using the Nernst equation. The extend of a particular oxidation reaction is defined by the potential differences. Thus, in case of semiconductors for photo-oxidation processes, the maximum achievable photovoltage of the system under certain irradiation conditions will be the critical factor whether or not a certain oxidation reaction is generally feasible at all.

The electrical potential differences arising from reductive and oxidative processes during the irradiation of TiO2 were analysed and included in a new measurement strategy. The aim of this study was to develop a simple and reproducible method for the quantitative evaluation of voltage phenomena related to the electrochemical potential. To this end, a variety of experimental setups were analysed and evaluated and ongoing optimizations were carried out. To prove the feasibility of the concept, photovoltages resulting from the new setup were finally correlated with data from chemical and microbiological monitoring systems.

2 Methods

2.1 Experimental Setup A.1: proof of principle

For the proof of principle, a first setup was assembled using two basically identical half-cells made of Platinum cups (diameter = 100 mm, height = 50 mm). Both vessels were filled each with 50 mL aqueous potassium chloride electrolyte (c = 1 gL−1) and the solutions were electrically connected via a salt bridge. TiO2 powder dispersions (P25, Evonik Industries AG, Essen, Germany; Hombikat UV100 Sachtleben Chemie GmbH, Duisburg, Germany) were placed in equal amounts one at a time into both half-cells. The basic setup is illustrated in Fig. 1. During the experiment, one half-cell was illuminated using light with a wavelength maximum of 370 nm (Philips F8T5 BLB 8 W), while the second was shielded from any light. The resulting photovoltage was measured as a potential difference between the half-cells using a high impedance voltmeter (yt writer Goerz Servogor 120). Different tests were performed under variation of the irradiance and the amounts of the applied TiO2 dispersion.

2.2 Experimental Setup A.2: coated glass plates in platinum vessels

With an adjusted setup, TiO2-coated glass plates were used instead of the powder dispersions. All specimen were made by IST Fraunhofer, Braunschweig, Germany, by Pulse Magnetron Sputtering (PMS), a common variation of Physical Vapor Deposition (PVD). Pre-sputtering was carried out in argon atmosphere for 5 min to remove contaminations from the target surface. Subsequently, the targets were operated in the oxide mode with a reactive gas flow of 20 cm3STP/min O2 for 15 min. During the main coating process, the TiO2 thin-films were deposited on unheated 50 × 50 mm2 non-alkali glass substrates by reactive PMS using a dual magnetron source equipped with two titanium PK 500 cathodes. [18]. The glass plates were inserted into the platinum cells and completely submerged in electrolyte so that the TiO2-coated side faced the platinum bottom. Irradiation was done as described before.

2.3 Experimental Setup B: use of ITO electrodes

Whilst Experimental Setups A.1 and A.2 were necessary first steps for the proof of principle and as a prerequisite to further optimize the method, the next setup aimed on the optimization for coated TiO2 samples. To this end, the main progress was the use of a translucent electrode material instead of platinum vessels. For this purpose, Indium-Tin-Oxide (ITO) glass electrodes initially developed for the use in photovoltaic systems were used. ITO shows a fairly good UV-A transmission of about 70% and is electrically conductive. This allows a more compact and cheaper setup with better defined distances between the test specimen and the electrode. Additionally, less electrolyte is necessary. The voltages were measured and stored with a digital multimeter (Agilent, model 34401A).

2.3.1 Preparation of ITO electrodes

The ITO electrodes were manufactured in our laboratory from an Indium-Tin-coated float glass plate as a precursor (www.fluessigkristalle.com, Dr. Feodor Oestreicher). The precursor plate was cut to the appropriate size and the layout of the electrode surfaces was designed. Subsequently, the desired shape of the electrode was masked with adhesive tape. Using this method, a pair of electrodes was created on one shared plate by removing the indium-tin layer between the covered areas by etching with diluted hydrochloric acid (c = 1 mol L−1). The transparent, electrically conductive ITO was formed from the metallic precursor layer by annealing in a muffle oven (Uhlig, U24) at 400 °C for 30 min. Integrity of the electrode surface was finally assessed using conductivity measurements. Figure 2 shows a photo of the structured ITO glass electrode (left). The two conductive ITO layers have a size of 70 × 20 mm2 each. On the right, the side-view of the Experimental Setup B is shown. The ITO electrode was placed above the TiO2-coated sample with a liquid potassium chloride electrolyte (c = 1 g L−1) layer in between. One side of the ITO electrode was covered while the other side was illuminated with UV-A light (Philips F8T5 BLB 8 W). Potential differences were tracked by measuring the voltage between the both ITO electrodes.

2.4 Experimental Setup C: assessment of TiO2 particle material using stainless steel electrodes

This setup was designed for voltage measurements of TiO2 particle materials. Three different TiO2 materials were used which are pure rutil material (Kronos Worldwide Inc., Leverkusen, Germany), pure anatase material (Hombikat UV100 Sachtleben Chemie GmbH, Duisburg, Germany) and the rutil/anatase mixed material P25 (Evonik Industries AG, Essen, Germany). TiO2 powder suspensions were applied onto stainless steel plates (50 × 50 mm2) and air-dried under ambient room conditions. Afterwards, the TiO2-coated plate was linked with an uncoated plate via an agarose gel electrolyte to set up a connection between these two half-cells. Figure 3 shows this Experimental Setup C. The assembly was illuminated with UV-A light and the resulting photovoltage was measured between the two stainless steel half-cells. TiO2 powders of different modifications were tested and data were compared with results from other methods for the evaluation of the photocatalytic activity.

2.5 Test methods for comparison

For comparison of the voltage measurements the commonly used standardised Methylene Blue test was used [2]. For the measurement of the total mineralization capability, photocatalytic oxidation of D-Glucose was assessed. For the latter, 50 µL TiO2 suspension (c = 15 mg L−1) was given into a headspace vial together with 1 mL of an aqueous solution of D-Glucose (c = 0.1 M), flushed with air and sealed gas-tight. The vials were irradiated in an illumination chamber (MRC Systems, Heidelberg, Germany) by UV-A light (p = 1.2 mW cm−2, λmax = 370 nm, Philips Actinic BL TL-D 18 W/10) for 17.5 h under rotation. The irradiance measured on the catalytic surface was 1 mW/cm2 measured with a calibrated photo diode included in the illumination chamber. UV measurements were taken outside and inside of the vials. The carbon dioxide (CO2) concentration of the gas phase inside the vial was determined with a non-dispersive infrared (NDIR) analyser (Shimadzu TOC Analysator TOC-V-CPH).

3 Results and discussion

3.1 Experimental Setup A.1: proof of principle

For the proof of principle, both half-cells were filled with 50 mL electrolyte (KCl; c = 1 gL−1). TiO2 powder dispersions (2 g suspended in 50 mL electrolyte) containing 0.04 g ±2% TiO2 per mL were used. Subsequently, in steps of 1 mL of the dispersion was added to the electrolyte in both cells. Two different TiO2 powder dispersions (P25, Evonik Industries AG, Essen, Germany; Hombikat UV100 Sachtleben Chemie GmbH, Duisburg, Germany) were analysed.

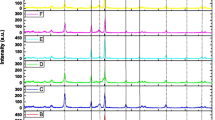

The lamp was positioned above one half-cell and the other half-cell was carefully shaded. The voltage was recorded until a constant value was obtained. To vary the irradiance, the distance between the lamp and the electrolyte surface was adjusted. Experiments were repeated three times, using slightly different distances. Figure 4 shows the resulting voltages for P25 and UV100 suspensions in one diagram for different light intensities. Results indicate first that a potential is measurable between both cells and second that the voltage decreases with an increasing distance of the lamp resulting in a lower irradiance of the irradiated half-cell.

Using the same setup, the P25 TiO2 concentration in both vessels was varied under constant light conditions. As in the previous approach, one half-cell was illuminated, while the other was covered. The distance between the lamp and the electrolyte surface was 83 mm. To increase the amount of nanoparticles in the vessel, repeatedly one mL of TiO2 suspension was added. Before each addition, the stabilisation of the voltage reading was awaited. Values were accepted as soon as the voltage readout was constant (± 5 mV within 30 s; average time of measurement: 5 min). Mean and standard deviations were depicted in Fig. 5.

3.2 Experimental Setup A.2: coated glass plates in platinum vessels

Photovoltage of TiO2-coated glass plates (IST Fraunhofer, Braunschweig, Germany) with various layer thicknesses were studied using Experimental Setup A.2. Using this approach, the applicability of the method for the evaluation of surface coatings is to be tested. Basically, the same setup as described for Experimental Setup A.1 was employed. Whilst for the first setup, TiO2 suspensions in water were used, this approach focusses on immobilized TiO2 with eminent practical significance. All measurements were done as described before and in Table 1, results are summarised. TiO2 layer thickness is indicated in the top row (nm).

3.3 Comparison with the decolourization of MB

All test samples were subsequently tested for photocatalytic activity using the common standardised methylene blue test method. Comparison of test results indicates similar trends for both methods. Increasing thickness of the TiO2 layer leads to an increase of photovoltage as well as to an increased MB decolourization capacity (Fig. 6).

Table 2 shows the measured absorbance of the MB solutions. With these data, the MB transmission was calculated with a set starting value of 0. The table also shows the residual colouration as a percentage of the starting point and the decrease in colouration as an indicator of the relative decrease in MB concentration.

3.4 Experimental Setup C: measurements on TiO2 particle materials

With Experimental Setup C voltage measurements on TiO2 particle material were investigated applying ascending TiO2 powder loads of P25. These measurements resulted in a linear increasing correlation of the maximum voltages with higher powder loads (Fig. 7). The y-axis intercept in Fig. 7 (150–500 mV) was chosen to visualize the trend of the response of the system.

Experimental Setup C was also used to perform measurements with particle material of different TiO2 modifications. The comparison of different TiO2 modifications indicates different voltages for each material. Furthermore, a strong correlation between the measured photovoltage and the CO2 release from photocatalytic mineralization of D-Glucose for the different TiO2 modifications was found. Figure 8 displays the results and the correlation between the two methods for the three different TiO2 modifications.

3.5 Mechanistic considerations under use of Experimental Setup B with ITO electrodes

Using the optimised Experimental Setup B with ITO electrodes voltage measurements over time where carried out. The coated TiO2 specimen (Fraunhofer IST; Braunschweig) were used as described above and shown in Fig. 2. An exemplary voltage–time curve is depicted in Fig. 9. The curve is comparable to the charging and discharging curves of a plate capacitor and follows the exponential functions for the charging U(t)=Umax(1−e −t/τ) and discharging processes U(t)=Umax e–t/τ. The time constant τ = R⋅C describes the required time until the capacitor is charged to 63%. In the exemplary voltage curve, the exponential fit functions with the above equations are drawn for the charging and discharging processes. The regression values of both curves were R2 > 0.96. The voltage increase would thus correspond to the charging of a capacitor. The hypothesis for explanation is that a Helmholtz double layer is formed on the illuminated side of the sample due to oxidation reactions which leads to the measurable potential difference compared to the non-illuminated side. As reactive species hydroxyl radicals, which are formed by photocatalysis under the influence of UV-A light, can be considered. The discharging process corresponds to the degradation of the Helmholtz double layer after switching off the UV-A light source. Without light, no further hydroxyl radicals are generated to maintain the voltage, following charges gradually flow away until a state of equilibrium is reached again. This can mainly take place through the electrolyte, since the conductivity within the TiO2 layer is very low at 10–9 Ω cm−1 [7].

4 Conclusions

The results presented here open up a new way to determine the photocatalytic activity of TiO2. It was shown that photocatalytically activated TiO2 sampled generate a measurable voltage. A correlation between the photocatalytic activity and the measurable voltages was shown. This procedure can be a possible new route to estimate the photocatalytic activity via a physical method. This study also lays a groundwork on which a physical measuring device for the objectifiable determination of the photocatalytic activity can possibly be developed.

Data Availability

The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

Change history

05 April 2023

A Correction to this paper has been published: https://doi.org/10.1007/s43630-023-00416-2

References

Basavarajappa, P. S., Patil, S. B., Ganganagappa, N., Reddy, K. R., Raghu, A. V., & Reddy, C. V. (2020). Recent progress in metal-doped TiO2, non-metal doped/codoped TiO2 and TiO2 nanostructured hybrids for enhanced photocatalysis. International Journal of Hydrogen Energy, 45(13), 7764–7778. https://doi.org/10.1016/j.ijhydene.2019.07.241

DIN-52980:2020–11, E. (2020). Photokatalytische Aktivitat von Oberflachen—Bestimmung der photokatalytischen Aktivitat von Oberflachen in wassrigem Medium durch Abbau von Methylenblau. Beuth Verlag GmbH. https://doi.org/10.31030/3205030

Fujishima, A., & Honda, K. (1972). Electrochemical photolysis of water at a semiconductor electrode. Nature, 238, 37–38.

Hou, L., Guan, Z., Liu, T., He, C., Li, Q., & Yang, J. (2019). Synergistic effect of 101 crystal facet and bulk/surface oxygen vacancy ratio on the photocatalytic hydrogen production of TiO2. International Journal of Hydrogen Energy, 44, 8109–8120.

Huang, J., Dou, L., Li, J., Zhong, J., Li, M., & Wang, T. (2021). Excellent visible light responsive photocatalytic behavior of N-doped TiO2 toward decontamination of organic pollutants. Journal of Hazardous Material, 403, 123857. https://doi.org/10.1016/j.jhazmat.2020.123857

Kavan, L., Gratzel, M., Gilbert, S. E., Klemenz, C., & Scheel, H. J. (1996). Electrochemical and photoelectrochemical investigation of single-crystal anatase. Journal of the American Chemical Society, 118(28), 6716–6723.

Koenenkamp, R., Henninger, R., & Hoyer, P. (1993). Photocarrier transport in colloidal titanium dioxide films. The Journal of Physical Chemistry, 97(28), 7328–7330. https://doi.org/10.1021/j100130a034

Kormann, C., Bahnemann, D. W., & Hoffmann, M. R. (1991). Photolysis of chloroform and other organic-molecules in aqueous TiO2 suspensions. Environmental Science & Technology, 25(3), 494–500.

Kuhn, K. P., Chaberny, I. F., Massholder, K., Stickler, M., Benz, V. W., Sonntag, H. G., & Erdinger, L. (2003). Disinfection of surfaces by photocatalytic oxidation with titanium dioxide and UVA light. Chemosphere, 53(1), 71–77.

Kurz, J., Eberle, F., Graumann, T., Kaschel, M.-E., Sähr, A., Neumann, F., Dalpke, A. H., & Erdinger, L. (2011). Inactivation of LPS and RNase A on photocatalytically active surfaces. Chemosphere (Oxford), 84, 1188–1193.

Lee, S. K., Mills, A., & Wells, N. (2018). Assessing photocatalytic activity using methylene blue without dye sensitisation. Catalysis Today, 313, 211–217. https://doi.org/10.1016/j.cattod.2017.11.011

Li, C., Sun, Z., Song, A., Dong, X., Zheng, S. und Dionysiou, D. D. (2018). Flowing nitrogen atmosphere induced rich oxygen vacancies overspread the surface of TiO2/kaolinite composite for enhanced photocatalytic activity within broad radiation spectrum. Applied catalysis. B, Environmental 236, 12 S.

Linsebigler, A. L., Lu, G. Q., & Yates, J. T. (1995). Photocatalysis on TiO2 surfaces - principles, mechanisms and selected results. Chemical Reviews, 95(3), 735–758.

Mills, A. (2012). An overview of the methylene blue ISO test for assessing the activities of photocatalytic films. Applied Catalysis B-Environmental, 128, 144–149. https://doi.org/10.1016/j.apcatb.2012.01.019

Nosaka, Y., & Nosaka, A. Y. (2017). Generation and Detection of reactive oxygen species in photocatalysis. Chemical Reviews, 117(17), 11302–11336. https://doi.org/10.1021/acs.chemrev.7b00161

Odling, G., & Robertson, N. (2015). Why is anatase a better photocatalyst than rutile? The importance of free hydroxyl radicals. Chemsuschem, 8(11), 1838–1840. https://doi.org/10.1002/cssc.201500298

Peiris, S., Silva, H. B., Ranasinghe, K. N., Bandara, S. V. und Perera, I. R. (2021). Recent development and future prospects of TiO2 photocatalysis. Journal of the Chinese Chemical Society (Taipei) 68, 32 S.

Vergoehl, M., Werner, O., & Bruns, S. (2008). New developments in magnetron sputter processes for precision optics. Glasgow: SPIE.

Yan, X. L., Ohno, T., Nishijima, K., Abe, R., & Ohtani, B. (2006). Is methylene blue an appropriate substrate for a photocatalytic activity test? A study with visible-light responsive titania. Chemical Physics Letters, 429(4–6), 606–610. https://doi.org/10.1016/j.cplett.2006.08.081

Zhao, Z., Zhang, X., Zhang, G., Liu, Z., Qu, D., Miao, X., Feng, P., & Sun, Z. (2015). Effect of defects on photocatalytic activity of rutile TiO2 nanorods. Nano Research, 8(12), 4061–4071. https://doi.org/10.1007/s12274-015-0917-5

Acknowledgements

We acknowledge financial support from the Federal Ministry of Education and Research of Germany (Project Number 01RI0637). Our special acknowledgement for technical support goes to IST Fraunhofer Institute, Braunschweig, Germany Dipl.-Ing. Frank Neumann and Dr. Tobias Graumann and MRC Systems GmbH Heidelberg, Germany.

Funding

Open Access funding enabled and organized by Projekt DEAL. This work was supported by the Federal Ministry of Education and Research of Germany (BMBF) project “Photokat – Photocatalytic surface design for applications in medicine and production technology” (Project Number 01RI0637).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

The original online version of this article was revised: the given and family names were exchanged.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Kurz, J., Erdinger, L. A novel route to estimate the photocatalytic activity of titanium dioxide via voltage measurements. Photochem Photobiol Sci 22, 595–601 (2023). https://doi.org/10.1007/s43630-022-00337-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s43630-022-00337-6