Abstract

The use of plastics in products and packaging is growing. At the same time, the lifespan of packaging is short and consequently plastic waste volumes are growing in Finland and globally. Although separate collection and recycling of plastic packaging waste exists in Finland, it needs to be strengthened to reach the European Union’s targets. The separately collected plastic waste is mechanically recycled, but the recycling capacity is small, as is the process’s yield of secondary polymers. Hence, a large share of plastic packaging waste remains being recovered for energy. In our study, we first apply material flow analysis (MFA) to identify different routes of plastic packaging waste in Finland, and then we apply life cycle assessment (LCA) to quantify greenhouse gas (GHG) emissions of the current system and of alternative scenarios based on improvement measures. Domestic GHG emissions of the studied system were estimated to be 178 kt CO2e. Net GHG emissions including exports and credits from avoided production were estimated to be 155 kt CO2e. The results of the scenario assessment indicate that combining more measures offer significantly greater potential to reduce the system’s climate impacts, compared to individual measures. The results are complemented by a sensitivity analysis, helping with the interpretation of the results, understanding modelling challenges, and supporting robust decision-making. The study contributes to academic literature in two ways; it presents a robust, yet flexible way to integrate scenario-based, future-oriented modelling techniques into decision-making, and it assesses the various possibilities to improve the plastic recycling system to identify the quantitative improvement potential.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Plastics are an extensive group of polymeric materials with specific properties and various additives, such as pigments, fillers, or softeners. The versatility of the different plastic types makes them suitable for different applications and has been one of the drivers for the growing demand [1]. Global plastic production has nearly doubled in volume in the last decades, growing from 200 million t in 2002 to 368 million t in 2019 [2, 3]. The extensive use of conventional plastics throughout the global economy also contributes to greenhouse gas (GHG) emissions, which were estimated to 1.7 Gt CO2e, or 3.5% of the global annual GHG emissions in 2015 [4]. In Europe, the most common type of plastic waste is packaging plastics, amounting to around 60% (29.1 million t) of all plastic waste types in 2018. Out of this, 42.6% were incinerated, 32.5% were recycled, and 24.9% were landfilled in 2018 [2]. On a policy level, EU’s targets for recycling plastics have been tightened, and the new targets for recycling separately collected plastic packaging are 50 % in 2025 and 55 % by weight in 2030 (Directive 2018/852; packaging and packaging waste directive). The action on plastics was also identified as a priority in the EC’s Circular Economy Action Plan [5], implying that the recovery and recycling of all plastics will have to be improved. Even though the EU waste framework directive (Directive 2008/98/EC) stipulates that prevention of waste, as well as reuse options, should be prioritised before material recycling options, the recycling system needs to be profoundly improved [1]. In Finland, a national Plastic Roadmap was published in 2018 [6], which compiles actions to reduce the harm caused by plastics, avoid unnecessary consumption, improve the recycling of plastics, and find alternative solutions. The Finnish waste legislation has been updated to implement the renewed waste directive (Government Decree 1029/202; [7]) covering all plastic packaging in Finland and increasing the recycling targets as per the European strategy for plastics.

The challenges of plastics relate foremost to plastic packaging, which are often single-use items and available in large quantities [8]. Plastic packaging has gained increasing attention in waste management [9], driving policy initiatives to improve their circularity to reduce related environmental impacts, and improve resource efficiency [10, 11]. From an environmental standpoint, and in line with the hierarchy of circular economy strategies (see e.g. [12]), it is preferable to prioritize smarter product use and manufacture (e.g. reducing demand, implementing more efficient production, and use practices), and extending the life cycles of plastic packages (e.g. reuse, remanufacture) [13,14,15,16]. After these options have been exhausted and the material is not suitable for any life cycle extension possibilities, recycling becomes a viable option. Recycling, nevertheless, is an important part of the circular economy, but it also requires a closer examination of the potential improvement options available and the environmental benefits that they may offer. As substitutes for plastics in packaging applications are still limited, a well-functioning recycling system needs to retain the material value as high as possible and avoid fast downcycling. Existing plastic waste collection and recycling schemes, as well as related regulation, need to be developed to support the processing of new waste streams, as well as sorting and recycling technologies. When increasing recycling volumes and modifying the recycling system for plastic packaging, it is important to understand the climate impacts and how they are being affected by these changes. In sum, the plastic waste markets are facing a transformation, and the way plastic waste is collected, recycled, and offered as recycled materials to the markets is being reshaped [1].

From an academic viewpoint, this paper contributes to the need of a detailed mapping of how materials move within the economy [10], as well as a more detailed assessment of the GHG emissions of alternative solutions to address the regional plastic waste volumes [17]. Through this approach, stakeholders can make well-informed decisions that support both the increase in recycling rates and the reduction of GHG emissions of recycling systems. Moreover, this paper contributes to academic literature by presenting a robust, yet flexible way to integrate scenario-based, future-oriented modelling techniques into life cycle assessment (LCA)-based decision-making. Hence, in line with the policy goals named by the European Commission and Finland, as well as to tackle the general challenges of the plastics recycling system discussed above, this study intends to provide insights for policy making with regards to future plastic waste management in Finland and to facilitate the development of plastic waste recycling towards a low-carbon circular economy. To reach this goal, we address the following research questions:

-

1)

In the absence of reliable and up-to-date data about the recycling system’s material flows and process parameters, how can we support robust decision-making?

-

2)

How much do individual improvements contribute to the system’s GHG emissions reduction?

-

3)

How much does a set of alternative improvement measures reduce system’s GHG emissions?

-

4)

How sensitive are the results on changes in the underlying assumptions?

The explorative part of the study, including the scenarios assessment and sensitivity analysis, demonstrates our approach to overcoming modelling uncertainty to support sound decision making. Our study deepens private and public stakeholders’ understanding of the different caveats of post-consumer plastic packaging management. A study of this kind has not yet been conducted in Finland, making it particularly crucial considering the implementation of the Plastics Roadmap for Finland.

The remainder of this paper is organized as follows. “Background” presents the literature background related to plastics recycling technologies, relevant LCA studies, as well as combination studies utilising both LCA and material flow analysis (MFA). “Materials and Methods” introduces the methods and data used for the modelling, along with any assumptions that have been made, following the requirements of the ISO14040 standard [18]. The “Results” section reports the results of the modelling and the “Discussion” section discusses the results in the context of previous literature findings. This paper is concluded by the “Conclusions” section.

Background

Literature Related to Plastic Recycling Technologies

Plastics can be recycled in different ways that have different yields, resource uses, and recyclate qualities. These factors play an important role when considering their unique environmental (i.e. climate) benefits and concerns. Plastic packaging waste is most often recycled mechanically, which is especially advantageous for homogenous, clean plastic fractions in large quantities [3]. The process of mechanical recycling includes separating, sorting, washing, grinding, compounding, and pelletising phases (see e.g. [14]). Additives, fillers, and other components in plastics, however, cause heterogeneity in the waste stream which negatively affects mechanical recycling [19]. Additives and other components in plastics thus pose a challenge to circular economy [20].In recent years, the technologically oriented literature related to plastics recycling has therefore focused on chemical recycling which has a high potential for processing heterogeneous and contaminated plastic waste material [14, 21, 22]. Chemical recycling is based on converting polymers into smaller molecules and can be divided into thermochemical and catalytic conversion processes, such as gasification, pyrolysis, fluid-catalysed cracking, and hydrocracking [14]. Pyrolysis, as the main technology, converts mixed plastics into pyrolysis oil, which can be cracked down and further refined to naphtha, a feedstock in new plastics production [21]. Chemical recycling, due to its ability to process very heterogenous and reduced-quality waste streams [22], is often considered as a supporting technology for mechanical recycling, rather than its substitute [23]. It is also referred to as a “drop-in” solution for its ability to cope with diverse types of feedstocks, such as plastic waste or vegetable oils [24]. Lee and Liew [25] have presented a classification of various plastic waste processing technologies and compared their advantages and disadvantages. However, the literature focusing on recycling technologies may not always contain a more profound assessment of the related environmental (i.e. climate) impacts of these specific technologies.

Life Cycle Assessments for Plastics

Plastic wastes have been extensively studied from the environmental perspective by using life cycle assessment (LCA). LCA has been primarily applied to compare alternative end-of-life treatment options (for review, see [26]) in particular to study mechanical plastics recycling and re-granulate performance (e.g. [9, 27,28,29,30]) and chemical recycling (for review, see [23]). In particular, the studies focusing on chemical recycling have compared the process with other plastic waste management techniques or regarded chemical recycling as complementary with other plastic waste management methods, as discussed [23]. Pyrolysis is the most researched chemical recycling process and an extensive LCA study of pyrolysis has been published by Russ et al. [21] and Jeswani et al. [31], concluding that mechanical and chemical technologies should be considered as complementary technical solutions for the use of mixed plastic waste rather than competitive ones. Additionally, Khan et al. [32] have studied the chemical recycling of liquid packaging boards as a feed for chemical recycling. Horodystka et al. [33], although focusing mainly on the upcycling of plastics, have made a relevant contribution by discussing the substitution impacts in the context of plastic recycling and incineration. Das et al. [34] studied the conversion of plastic waste through pyrolysis to a fuel and a secondary plastic material and concluded that in the European context the material conversion is less GHG-intensive. Due to LCA being mostly a product- or process-specific analysis method, it remains uncertain about what the limits of these assessments on a national scale are; is there a sufficient volume of material to be processed, how should exported flows be treated, or what kind of impacts are expected in other systems (e.g. energy provision).

Material Flow Analyses in the Context of Plastics

Several plastic waste-related material flow analyses (MFAs) have been performed with different geographic or material coverage. Plastic-related MFAs have, for example, been carried out for Austrian plastic flows [35], post-consumer plastic packaging waste flows in Finland [36], EU28’s plastic flows ]37], plastic waste flows in China [37], single-use plastic packaging in Japan [38], and national comparisons between countries [39]. Reijonen et al. [9] carried out a further study for the plastic material flows with an assessment of the current and future policy targets, which included a dynamic, future-oriented dimension. The study concluded that the MFAs could, at best, be accompanied with an LCA to study the environmental efficiency of the full system, and consequently, several other studies have combined MFAs and LCAs. For example, Sevigné-Itoiz [40] performed a dynamic MFA and LCA study for Spain, which indicated benefits for recycling, instead of incinerating or landfilling the wastes, even though the quality of the recovered plastic plays a crucial role in the results. Khoo [17] assessed different scenarios for Singapore, which resulted in benefiting the most from a combination of higher recycling rates, mechanical and chemical recycling, and energy production. Kerdlap et al. [41] concluded, also for Singapore, that centralised plastic waste processing strategies outweigh distributed ones. Volk et al. [42] studied the lightweight packaging recycling pathways in Germany, combining mechanical and chemical recycling and assessing selected environmental impacts and processing costs. The study concluded that the combination of both recycling technologies significantly reduces environmental impacts and costs. An et al. [43] integrated MFA with LCA and illustrated GHG emissions throughout plastic life cycles in China. The results show that plastic packaging is the major contributor to the emissions, largely due to the waste management. However, even though some studies [10, 42, 44] have taken a future-oriented approach and assessed future pathways and scenarios, a clear majority of the studies have not focused on studying the modelling and data related uncertainties related to these assessments, which is particularly important for subsequent decision-making.

Materials and Methods

In our study, we applied a combination of LCA and MFA to quantify potential GHG emissions of the Finnish post-consumer plastic packaging waste management system.

LCA is a method used to assess the potential environmental impacts throughout a product’s life cycle i.e., from cradle to grave, and is generally seen as the most established and well-developed method in the area (see e.g., [45, 46]). We followed the framework defined in the ISO 14040 standard [18] and included the following main steps: goal and scope definition, inventory modelling, impact assessment, and interpretation. In addition, we carried out a scenario assessment to model alternative system configurations [47] and performed a sensitivity analysis to identify whether any of the assumptions made has a considerable influence on the results [48]. Scenarios are designed to reflect possible future changes in consumers behaviour, governance, and technical advancements, but do not represent the future per se.

MFA assesses the flows and stocks of materials through a system that is defined in space and time (see e.g., [49]). MFA is also commonly applied in waste management (e.g., [50] or [16]). In this study, the combination of both methods takes a region’s post-consumer plastic packaging waste flows and stocks for a given year as a starting point to represent the specific waste management system. We assign each process step within this system with respective potential GHG emissions obtained from literature, in line with the LCA methodology, and system-level potential GHG emissions are estimated.

Goal and Scope

The goal of the exploratory part of our study is to model the post-consumer plastic packaging waste system in Finland in 2019 (falling under the extended producer responsibility, EPR, excluding the deposit-based plastic beverage packages), to estimate its GHG emissions, to explore the potential GHG emissions of alternative improvement scenarios, and to test if general conclusions hold under the sensitivity analysis. This way, the aim is to facilitate the development of plastic waste recycling towards a low-carbon circular economy, and to deepen private and public stakeholders’ understanding of different caveats to support policy and decision making through a set of scenarios.

System Description

There are challenges related to plastic packaging waste statistics [51] as the data can be inconsistent, incomplete, and often available with a significant delay. In our case, the most up-to-date and sufficiently reliable data at the time of modelling were available for the year 2019.

All Finnish collected post-consumer source-separated plastic packaging waste that reaches recycling, except for deposit-based beverage packages, is currently processed in a mechanical recycling plant in Riihimäki, Finland. Secondary plastic granulates produced in mechanical recycling are used as a feedstock for new plastic products, replacing primary plastics. Additionally, some of the plastic waste is exported and the recycling reject is incinerated. Chemical recycling is anticipated to be introduced once deployed on an industrial scale. It will yield recycled naphtha, replacing fossil naphtha in the petrochemical industry.

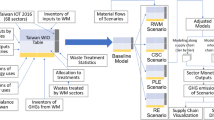

Figure 1 illustrates the system boundaries from the point when plastic packaging becomes waste to becoming new products (secondary plastics, energy, and naphtha) and includes exports.

Function, Functional Unit, and Reference Flow

The function of the studied system is to handle Finnish post-consumer plastic packaging waste, either through recycling, energy recovery, or by exporting it for treatment.

The functional unit of the study was defined as the collection and treatment of plastic packaging waste falling under the EPR (excluding deposit packaging) in Finland in 1 year. The selected baseline year was 2019. The same functional unit was used for calculating the results for scenarios of alternative system configurations.

The reference flow was 76, 573 tons of post-consumer plastic packaging waste falling under the EPR.

Impact Assessment

The life cycle impact assessment (LCIA) was carried out by using the IPCC 2013 GWP 100a V1.03 characterisation method to calculate the potential climate impacts, expressed as GHG emissions, or global warming potential (GWP). At the time of performing the analysis, this was the most recent IPCC method available.

Scenarios

In addition to the baseline, we defined five scenarios of alternative system configurations to study potential impacts of the system under various conditions (Table 1) in collaboration with industry stakeholders. The scenarios are based on the total volumes of 2019 but differ in ways the waste is collected, treated, and recycled. In addition to estimating the impacts of each scenario as a standalone solution, scenarios are also presented as a consecutive sequence of modifications to the system. Hence, each scenario is additive to the preceding one, resulting in a reinforcing effect on the system changes.

The individual scenarios as well as their sequence have been defined jointly with industry stakeholders. Five stakeholders representing companies from primary plastics production, waste management and processing, as well as an NGO from the field, were included in the process to ensure that the scenarios represent the current directions of plastics recycling in Finland. The potential scenarios were discussed in a series of two workshops to reach a consensus about the general assumptions of the scenarios, in terms of (a) which potential changes are most likely to the system in the future (Table 1), and (b) what the most viable sequence of these changes are. The scenario definition followed a stepwise process between the authors and the stakeholders, starting with the authors’ initial drafting of possible changes to the plastic recycling system (as well as inventory assumptions), followed by a joint workshop to further refine and define these (at this stage, for example, the mechanical plant capacity was redefined, the option of improved sorting was removed and the sequence was changed between improved recycling yield and chemical recycling). Subsequently, the authors modelled the future scenarios accordingly, and finally, based on the preliminary modelling, the logical sequence, along with other assumptions, was confirmed in a joint workshop. As a result, the scenarios followed this sequence (Table 1): first, separate collection must increase to supply sufficient feedstock for a new mechanical recycling facility that is currently planned. In the short term, the recycling yield of the existing facility may be improved. Only after the collection has been increased can recycling capacity be expanded. Chemical recycling is not yet operating on an industrial scale; thus, it is expected to be the last measure implemented.

Data Inventory and Modelling

Foreground data were collected from literature and industry stakeholders through workshops and individual interviews. No primary process data were used. Most background data were sourced from the ecoinvent database (v 3.7.1) [52]. The list of datasets used in the model is provided in the Table 1 of the Supplementary information. The cut-off system model was chosen for modelling recycling systems, in line with [53]. For transport processes, the Finnish Lipasto database [54] was used. For the purposes of the system-level assessment, these data sources were considered sufficient. Inventory data are presented in the Supplementary information.

The model was created in SimaPro 9.2 software [55]. The cut-off with credits modelling principle was applied in the study [56]. Hence, no impacts of the production and use phases are allocated to the waste which enters the studied system burden-free. The avoided impacts from substitution of primary production are credited to the system.

The manufacture, maintenance, and decommissioning of capital equipment were not considered in our study. According to [57], capital goods should be included in the LCA modelling of waste management, unless the only impact category considered is global warming, which is the case of our study.

Material Flow Analysis

The MFA was performed for the baseline year 2019. The material flow amounts for the baseline and scenarios are presented in Table 2 and presented as a Sankey diagram for the baseline scenario and the final, chemical recycling-based scenario in Fig. 2. The flow abbreviations from Table 2 are visually highlighted also in Fig. 1. The basic assumption is that plastic packaging is short-lived, which is why the amount of packaging placed on the market equals the amount of post-consumer plastic packaging plastic waste generated and no stocks are considered [51].

In 2019, 76, 573 t of post-consumer plastic packaging falling under the EPR entered the market, out of which 10, 403 t were collected via collection points [58] as post-consumer plastic packaging waste and 10, 027 t were collected from households (personal communication with Peter Rasmussen, Finnish Plastics Recycling Ltd., March 2022). The remaining plastic packaging that was not separately collected was disposed of in mixed municipal solid waste (MSW) (56, 143 t, calculated).

The capacity of mechanical recycling in 2019 was 18, 000 t/a [58] and it was fully utilised. The remaining 2430 t of collected waste, that was not mechanically recycled, was considered exported to Sweden where approximately half of the waste was considered to be mechanically recycled and half was recovered for energy [59]. From a technical point of view, mechanical recycling in Sweden can be considered comparable to the one in Finland although some differences may occur.

The final products from mechanical recycling are low-density polyethylene (LDPE), high-density polyethylene (HDPE), polypropylene (PP), and polyethylene terephthalate (PET), with a minor flow of mixed plastics. The reject from mechanical recycling is incinerated.

Chemical recycling is currently being developed by Finnish industrial actors and once operational, reject from mechanical recycling, or excess collected waste, can be further chemically recycled. The process will produce pyrolysis oil, further upgraded to naphtha—a petrochemical feedstock.

The collected MFA data has several limitations to be highlighted. The mass of plastic waste entering waste management could only be estimated based on the data from [58] and personal communications (Peter Rasmussen, Finnish Plastics Recycling Ltd., March 2022). We followed a mass-balance approach in which we assumed this mass to be equal to the mass of plastic packaging introduced in the given year to the market. The amount of plastic waste recovered for energy was calculated based on the mass-balance and on the information on the efficiency of the mechanical recycling process. We did not consider any stocks in the MFA model; therefore, the difference between collected plastic waste and the capacity of the mechanical recycling plant was modelled as exports. The actual export destinations vary depending on market conditions which means that the destiny of exported waste changes in time.

Transport

For transport emissions, the Finnish LIPASTO emissions database [54] was used (see Supplementary Information). The database holds data on direct emissions (tank-to-wheel) and on fuel consumption. To account for the well-to-tank emissions i.e. supply chain emissions of diesel production, the ecoinvent database was used.

Finland is a large country with a low population density. Separate collection of post-consumer plastic waste is mainly an option in larger population centres. The separately collected waste is transported to sorting terminals, from which it is transported to different treatment facilities. Due to the uncertainty related to transport distances (see Supplementary Information), a sensitivity analysis is carried out to test whether significantly longer distances affect the results.

Sorting

The separately collected plastic packaging waste is sorted prior to recycling. The process was modelled based on Jeswani et al. [31]. It was regionalized by using the Finnish average medium voltage electricity grid mix as an input, like in all other modelled processes located in Finland.

Depending on the scenario, collected waste is sorted into mechanical recycling, exported, and rejected for energy recovery, as shown in Fig. 1. Table 2 contains the amounts of the flows for the baseline and scenarios. Mechanical post-sorting of MSW may also be a solution in the future but was not considered explicitly.

Energy Recovery

Plastic packaging waste that is not separately collected or that cannot be recycled due to low quality or limited recycling capacity is recovered for energy. Here, waste is incinerated in a waste-to-energy plant (WtE), and heat and electricity are produced in a cogeneration unit. Currently, it is the dominant way of treating plastic waste in Finland.

In Finland, just like in Sweden, the recovery of heat is prioritised over electricity, contrary to continental Europe. Heat values of mixed and non-recyclable plastic wastes are 38.94 MJ/kg and 32.26 MJ/kg, respectively [60]. Incineration of non-recyclable plastic waste in Sweden was used as the basis of the WtE inventory for both Finland and Sweden (see Supplementary Information).

Market electricity grid mix and biomass heat are assumed to be avoided by energy recovery of mixed plastic waste.

Mechanical Recycling

Sorted plastic waste is crushed and extruded into pellets of different fractions to be used as secondary raw materials. The process requires mainly inputs of electricity and yields a recyclate (secondary raw material) and a reject (non-recyclable fraction). The inventory data are presented in Supplementary Information.

We consider the same material composition for incoming sorted plastic waste and for recycled outputs: LDPE (40%), PP (30%), PET (20%), and HDPE (10%). The shares are based on Horodytska et al. [33], who reported the composition of the plastic fraction in Finnish MSW based on two sorting studies. They were consulted with industrial actors and were found consensual.

The ability of mechanically recycled polymers to substitute primary polymers depends on their quality [61]. It is commonly expressed as substitution coefficient or similar [33, 62]. We used default substitution values based on quality coefficients defined in the EU Product Environment Footprint Guidance [63]. These are 0.75 and 0.9 for LDPE and for HDPE, PP, and PET, respectively. Assumptions about the virgin material substitution ratio can have a significant influence on the results [26]; therefore, the impact of different substitution coefficients on the results is tested in a sensitivity analysis.

In 2019, the recovery rate in mechanical recycling in Finland was 37% [64]. The reject (63%) was incinerated and, in the future, it can be chemically recycled.

Chemical Recycling

For chemical recycling, we consider a pyrolysis process that yields pyrolysis oil which is further upgraded to naphtha. The process was simplified for the purposes of our study. The inventory data of the pyrolysis process were adapted from Jeswani et al. [31] and Khan et al. [32], see Supplementary Information. The process of the conversion of a solid plastic waste into liquid naphtha is considerably more complex than what the inventory suggests. In Finland, the process is not yet operating on an industrial scale, and primary data are not available, but the data used are considered sufficient for the model.

Pyrolysis oil is hydrotreated before it becomes naphtha [53]. Pyrolysis and hydrogenation steps are not separately inventoried. The inventory values were consulted with industry stakeholders, and they were assessed to be higher than those of the pyrolysis alone; thus, they were considered to also cover the consecutive steps producing naphtha. Naphtha produced in chemical recycling substitutes fossil naphtha 1:1 thanks to the same chemical composition.

Sensitivity Analysis

Given the limited availability and quality of inventory data and due to the numerous modelling assumptions, it is important to find out whether general conclusions hold also under different modelling setups. To test the sensitivity of results on data or model uncertainties, we performed a series of sensitivity analyses. While some uncertainties reflect unavailability of data (e.g. for the chemical recycling process), some uncertainties are related to the chosen methodology (e.g. substitution), or are inherent to forecasting (e.g. future collection rates). The sensitivity analyses are presented in Table 3. The “default set-up” refers to the parameters used in the original model.

Results

GWP results are presented for the current system, the standalone improvement measures applied to the current system, and for cumulative scenarios. Sensitivity analysis is performed for selected parameters. First, the different improvement measures to the existing system are compared against the current baseline situation in isolation. Subsequently, they are assessed as a sequence. Detailed numerical results are presented in the Supplementary Information.

Current System

The potential GHG emissions of the post-consumer plastic packaging waste processing system in Finland in 2019 were 178 kt CO2e (Fig. 3; Baseline), excluding exports and credits from avoided production. Including exports, the total impacts were 182 kt CO2e. The contribution of exports, energy recovery, and mechanical recycling are 2.3%, 95.7%, and 1.5%, respectively. The remaining 0.5% is attributed to collection and sorting. When avoided production is included in the equation, the potential net GHG emissions of the system are 155 kt CO2e or 151 kt CO2e if export is excluded.

The impacts allocated per tonne of waste are 2.3 t CO2e/t when export is excluded, 2.4 t CO2e/t when export is included, 1.9 t CO2e/t for net impacts without export, and 2 t CO2e/t for net impacts with export.

Standalone Measures

Figure 3 illustrates the effect that individual improvement measures have on the results if no other measure is implemented. The results show net impacts and separately avoided and direct emissions. In isolation, each individual measure leads to a reduction of net potential GHG emissions of the system between −2.2% and −11.2%. The results indicate that the introduction of chemical recycling has the highest net reduction potential. The second most promising measure is increasing the yield of mechanical recycling (−9.4%). Increasing separate collection and mechanical recycling capacity deliver smaller reductions to net impacts (−3.3% and −2.2%, respectively).

Cumulative Scenarios

The scenarios’ results in Fig. 4 represent a logical sequence of the cumulative implementation of different measures. The results illustrate how adding more measures creates synergies, effectively decreasing impacts.

In the first scenario, the separate collection increases by 75%. This means that less plastic waste is disposed in MSW. At the same time, as the capacity of mechanical recycling has been saturated already in the baseline, exports of separately collected waste increase. Less plastic waste disposed in MSW means less impact from energy recovery. The gross potential GHG emissions of this scenario are 175 kt CO2e, including exports, and the decrease compared to the baseline is 3.7%. The net emissions are 150 kt CO2e, representing a 3.2% reduction.

In the second scenario, the yield of mechanical recycling is increased to 55.5%; less mechanical recycling reject is recovered for energy and more primary materials are avoided. The gross emissions (165 kt CO2e) decrease by 9.1% compared to the baseline and by 5.6% compared to the previous scenario. The net emissions are 137 kt CO2e, representing an 11.6 % reduction to the baseline.

In the third scenario, the capacity of mechanical recycling is increased to 50,000 t. Due to the sufficient recycling capacity all collected waste is mechanically recycled and none is exported or recovered for energy directly after the collection. The amount of reject from mechanical recycling will increase and will be recovered for energy. The gross emissions (152 kt CO2e) decrease by 16.6% compared to the baseline and by 8.3% compared to the previous scenario. The net emissions are 104 kt CO2e, representing a 32.9 % decrease to the baseline.

The fourth scenario adds chemical recycling to all previous measures. With this, more of the previously rejected waste can be recycled. Although potential GHG emissions of chemical recycling are greater than those of mechanical recycling, the combination of all measures leads to the gross emissions (127 kt CO2e) reduction by 30.4% compared to the baseline and by 16.6% compared to the previous scenario. The net emissions are 85 kt CO2e, representing a 45.2 % decrease to the baseline. Allocated per tonne of generate waste, the gross emissions decrease from 2.3 t CO2e/t in the baseline to 1.6 t CO2e in this scenario. The net emissions decreased from approximately 2 to 1 t CO2e/t.

Sensitivity Analysis

The results of the sensitivity analyses indicate how sensitive the results are on individual parameters (Fig. 5). Of the selected parameters, the results are the most sensitive to the heat type avoided through energy recovery. If coal was avoided, the net emissions of the scenarios would be between 63.1 and 76.6% lower than the default set-up, in which biomass is avoided. The sensitivity of the results to the quality of mechanical recycling recyclate increases with each scenario. If the quality of the recyclate is the same as virgin material, we use a quality coefficient (Qc) equal to 1. In this case, the net emissions decrease by 1.5% in the baseline and by 7.8% in the last scenario. On the other hand, if Qc = 0.5, i.e. the quality of produced secondary materials is low, or there is not a sufficient market for it, the net emissions increase by 3.4% in the baseline and up to 17.3% in the last scenario. A smaller increase in separate collection (50%), or no increase at all, leads to an increase of net emissions between 2 and 3.4% for the first scenarios and 17.9–50.3% for the last one. Longer transport distances contribute to an overall increase of net emissions between 1.5% for the baseline and 2.3% for the last scenario. Lastly, increasing the direct emissions of pyrolysis by 50% and 100%, the net emissions of the last scenario involving chemical recycling increase by 3.1% and 6.1%, respectively.

Discussion

The goals of this study were to assess how decisions of the plastic waste management system can be robustly supported in the absence of up-to-date and fully robust data (as often is the case in planning for future system-level changes), to estimate the GHG emission reduction potential of the Finnish post-consumer plastic packaging waste system resulting from individual improvements as opposed to alternative improvement scenarios, as well as to test if general conclusions hold under the sensitivity analysis. Studying improvement scenarios is particularly important, as it responds to the recent circular economy policy developments on EU-level [5] and Finnish national level (Government Decree 1029/2021; [7]) combined with the radical increases of plastics market size [2, 3]. Hence, the study contributes to two fields within plastic waste management: first, it supports policy development by providing a detailed, quantitative examination of the climate impacts of various changes that can be implemented and politically incentivized; and second, from a methodological viewpoint, the study contributes to the development of a robust, yet flexible way to integrate scenario-based, future-oriented modelling techniques into decision-making.

Regarding the contribution to the quantitative impact assessment, the gross domestic GHG emissions of the studied system in 2019 were 178 kt CO2e, excluding including exports and potential credits. To put the number into perspective, post-consumer plastic packaging waste represented less than 3% of municipal waste generated in Finland in 2019 [65]. Yet, it contributed to almost 10% of GHG emissions from the whole waste management sector (1793 Mt CO2; [66]). Given that the vast majority of the emissions of the plastic packaging waste treatment result from incineration (95.7%) and that incineration also destroys the plastic waste, resulting in loss of material from the value chain [23], it is important to divert as much of this waste to recycling. Recycling not only reduces the emissions of waste plastic waste treatment but also generates secondary plastics that can substitute primary plastics [14, 21, 23]. When allocated per tonne of plastic packaging waste, the GHG emissions were 2.4 t CO2e/t in 2019. This result is in line with findings in the recent study of [16] who studied plastic flows in the UK. Under the assumption of plastic packaging being short lived, as presented in [51], a closer analysis of [16] figures indicate GHG emissions of approximately 2.2 t CO2e/t of packaging waste in 2019. Similarly to Finland, also in the UK the share of recycling was then low and incineration dominated the waste treatments portfolio.

When estimating the GHG emission reduction potential, we found that when introduced in isolation, the individual measures (increased collection, increased recycling yield, increased recycling capacity, chemical recycling) lead to only a small reduction of net potential GHG emissions; between 2.2 and 11.2%. However, with some of the measures being mutually reinforcing, the joint implementation of various measures was found to be more effective, similarly as the results of Khoo [17] indicate, who also concluded the highest environmental benefits to be reached with a combination of different modifications to the system. In 2019, the amounts of separately collected plastic waste exceeded the total capacity of mechanical recycling. Therefore, an increase in separate collection alone did not deliver substantial reductions of the overall impacts (3.7%). The small impact reduction is mainly a result of less plastic waste reaching energy recovery as a fraction of MSW. The further sequential results revealed that increased collection, coupled with improved operational yields of mechanical recycling, can lead to an up to 9.1% reduction of potential GHG emissions, but the reduction can be further facilitated by the currently planned increase of the capacity of mechanical recycling (16.6%). In the scenario implementing all measures, including chemical recycling, the emissions reduction can reach up to 30.4% in total. This is due to the system being able to deal better with challenging and previously unrecyclable waste fractions, diverting plastic waste from energy recovery and bridging the gap to the recycling targets.

The results support the findings of Davidson et al. [23], by considering both mechanical and chemical recycling as complementary, rather than alternatives to each other. From a policy perspective, this means that it is crucial to consider a set of several options. The implementation of any of the considered modifications of the current system takes time, which makes it invaluable to consider all options as early as possible.

One of the main contributions of this study relate to the treatment of uncertainty. Results of the sensitivity analysis indicate that the net impacts of the analysed system can vary significantly depending on modelling and data choices. The highly aggregated background assumptions of the material flows, as well as uncertainties related to process data, collection rates and substitution impacts of both plastics and energy, pose a risk to subsequent decision-making. The sensitivity analysis results highlight the importance of substitution assumptions, as also acknowledged by Jeswani et al. [31] and Khan et al. [32]. The sensitivity analysis illustrates that, for example, the net impacts are significantly lower if fossil energy source is assumed to be avoided, even though this approach has been contested e.g. by Horodytska et al. [33]. The energy market is complex and fast evolving, hence the choice of the type of energy sources to be substituted by energy recovery of plastic waste in the future is highly speculative. These assumptions have a considerable effect on the net results, as illustrated also by Eriksson et al. [60]. Increased collection and recycling of plastics may intensify the demand for marginal energy production to fill the gap of lower waste energy recovery, especially in heat production. The installed capacity of electricity production in Finland is growing due to the deployment of a new nuclear reactor and a strong increase in wind power. Thus, waste-to-energy will itself become the marginal source of electricity production in the foreseeable future, reducing the potential benefits from avoided production.

The rate at which recycled plastics replace primary plastics depends on market demand and the output quality. As [30] showed, the evaluation of the quality is crucial to determine which applications can be targeted with the produced recyclates. In the study by Neo et al. [39], the percentage of plastic rejects from mechanical recycling and the replacement of virgin plastics were identified as key parameters. The GHG emissions caused by the system increase with lower quality of the mechanical recyclate, as the sensitivity analysis indicates. With the introduction of chemical recycling, however, the quality of mechanical recyclate increases, which further decreases the net climate impacts of the last studied scenario. Nevertheless, we demonstrate that the general conclusion holds i.e. the combination of improvement measures always leads to a decrease in net impacts of the studied system.

The scenarios defined in our study were developed together with main industry stakeholders and are considered as feasible. Nevertheless, other sequences of improvement measures are possible and offer a path for future research, including the expansion of the system boundary to cover more waste flows and other forms of treatment. As for the further limitations of the study, it needs to be highlighted, that particularly from the viewpoint of circular economy, recycling is in fact one of the last alternatives to be implemented, after the options of smarter product use and extension of life spans have been exhausted. Hence, also the impacts of various system changes targeting reduction of plastic demand and increasing reusability should be studied closer.

Conclusions

The results of our study provide insights for policy making on how to plan future plastic waste management as a part of Finnish low-carbon circular economy in the absence of comprehensive data sets about the related material flows. The use of extensive sensitivity analyses and combination of various data sources support decision-making by illustrating the ranges behind the result uncertainty. In conclusion, the results illustrate that achieving substantial GHG emission savings within the plastic recycling system is possible through combined implementation of improvement measures, rather than relying on individual or isolated measures. Improved collection rates, i.e. increased separate collection, ensure constant material supply for recycling processes. Optimized recycling processes yield more, and better quality recyclates for less resources, and increasing the recycling capacity allows for a higher volume to be processed especially in the case of increasing the separately collected plastic waste flows. Finally, introducing chemical recycling offers benefits by being able to deal with more heterogenous and lower quality of waste flows to improve recycling efficiencies and yields.

The approach presented in this paper provides relevant information for various stakeholders involved in planning waste management systems. Understanding the contributions of distinct parts of the system to the overall impacts helps focusing actions to those parts of the system where they yield most benefits. Recycling, as a part of the circular economy, requires much more transparency about the concrete benefits it delivers and what sort of actions support each other and in which magnitude. The sensitivity analysis mitigates the risks of making false conclusions associated with the modelling approach and data quality, and in our case, the results of the sensitivity analysis support the general conclusions. The modelling approach presented in our study can be applied to the assessment of other similar systems globally, but defining the realistic sequence of different measures and how the measures reinforce each other will largely depend on the context of a given region. We demonstrate that, even with limited data and a simplified model, targeted sensitivity analysis helps to obtain objective conclusions that support sound decision making. However, it needs to be kept in mind that recycling is only one part of circular economy; focus should also be given to study the options of reducing and repairing, or even rethinking the entire system. Hence, the future research should broaden the scope of what changes can be carried out. Also, improving the transparency throughout the value chain may make intensive sensitivity analyses redundant, as more up-to-date, high-quality data becomes available.

Data Availability

All data are available in the supplementary materials.

References

European Commission (EC) (2018) Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions. A European Strategy for Plastics in a Circular Economy. COM (2018) 28 final. Available in: https://eur-lex.europa.eu/legal-content/EN/TXT/?qid=1516265440535&uri=COM:2018:28:FIN. Accessed 22 Sept 2023

Plastics Europe (2020) Plastics – the facts 2020. Available in: https://plasticseurope.org/knowledge-hub/plastics-the-facts-2020/ (accessed 29 August 2023).

Plastics Europe (2021) Annual production of plastics worldwide from 1950 to 2020 (in million metric tons) [Graph]. Available at: https://www.statista.com/statistics/282732/global-production-of-plastics-since-1950/ (accessed 29 August 2023).

Zheng J, Suh S (2019) Strategies to reduce the global carbon footprint of plastics. Nat Clim Chang 9:374–378. https://doi.org/10.1038/s41558-019-0459-z

European Commission (EC) (2020) Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions A new Circular Economy Action Plan For a cleaner and more competitive Europe. COM/2020/98 final. Available in: https://eur-lex.europa.eu/legal-content/EN/TXT/?qid=1583933814386&uri=COM:2020:98:FIN. Accessed 22 Sept 2023

Ministry of the Environment (2018) Reduce and refuse, recycle and replace – a Plastics Roadmap for Finland. Available in https://ym.fi/en/plastics-roadmap-for-finland (accessed 29 August 2023).

Ministry of the Environment (2021) Valtioneuvoston asetus pakkauksista ja pakkausjätteistä (1029/2021) https://finlex.fi/fi/laki/smur/2021/20211029 (accessed 29 August 2023)

Chen Y, Awasthi A, Wei F, Tan Q, Li J (2021) Single-use plastics: production, usage, disposal, and adverse impacts. Sci Total Environ 752:141772. https://doi.org/10.1016/j.scitotenv.2020.141772

Reijonen H, Bellman S, Murphy J, Kokkonen H (2021) Factors related to recycling plastic packaging in Finland’s new waste management scheme. Waste Manag 131:88–97. https://doi.org/10.1016/j.wasman.2021.05.034

Van Eygen E, Laner D, Fellner J (2018) Circular economy of plastic packaging: current practice and perspectives in Austria. Waste Manag 72:55–64. https://doi.org/10.1016/j.wasman.2017.11.040

Syberg K, Nielsen MB, Clausen LPW, van Calster G, van Wezel A, Rochman C, Koelmans AA, Cronin R, Pahl S, Hansen SF (2021) Regulation of plastic from a circular economy perspective. Curr Opin Green Sust Chem 29:100462. https://doi.org/10.1016/j.cogsc.2021.100462

Potting J, Hekkert M, Worrell E, Hanemaaijer A (2017) Circular economy: measuring innovation in the product chain. Policy Report 2544 PBL Netherlands Environmental Assessment Agency, The Hague. Available in: https://www.pbl.nl/sites/default/files/downloads/pbl-2016-circular-economy-measuring-innovation-in-product-chains-2544.pdf. Accessed 22 Sept 2023

European Commission (EC) (2013) Green paper on a European strategy on plastic waste in the environment. COM (2013) 123 final. Available in: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=celex%3A52013DC0123. Accessed 22 Sept 2023

Ragaert K, Delva L, van Geem K (2017) Mechanical and chemical recycling of solid plastic waste. Waste Manag 69:24–58. https://doi.org/10.1016/j.wasman.2017.07.044

Grosso M (2021) How to improve an advanced waste management system. Waste Manag Res 39(6):765–766. https://doi.org/10.1177/0734242X211016975

Drewniok MP, Gao Y, Cullen JM, Serrenho AC (2023) What to do about plastics? Lessons from a study of United Kingdom plastics flows. Environ Sci Technol 57(11):4513–4521. https://doi.org/10.1021/acs.est.3c00263

Khoo H (2019) LCA of plastic waste recovery into recycled materials, energy and fuels in Singapore. Resour Conserv Recycl 145:67–77. https://doi.org/10.1016/j.resconrec.2019.02.010

ISO 14040 (2006) Environmental management. In: Life cycle assessment. Life cycle impact assessment. International Organization for Standardization, Brussels

Vogt BD, Stokes KK, Kumar SK (2021) Why is recycling of postconsumer plastics so challenging? ACS Appl Polym Mater 3(9):4325–4346. https://doi.org/10.1021/acsapm.1c00648

Wagner S, Schlummer M (2020) Legacy additives in a circular economy of plastics: current dilemma, policy analysis, and emerging countermeasures. Resour Conserv Recycl 158:104800. https://doi.org/10.1016/j.resconrec.2020.104800

Russ M, Gonzalez M, Horlacher M (2020) Evaluation of pyrolysis with LCA – 3 case studies. Commissioned by BASF SE. July 31, 2020. Available in: https://www.basf.com/global/documents/en/sustainability/we-drive-sustainable-solutions/circular-economy/selected-down_load/BASF_ChemCycling_LCA_Study.pdf (accessed 29 August 2023).

Liu H, Wang C, Zhang J (2020) Pyrolysis kinetics and thermodynamics of typical plastic waste. Energy Fuel 34:2385–2390. https://doi.org/10.1021/acs.energyfuels.9b04152

Davidson MG, Furlong RA, McManus MC (2021) Developments in the life cycle assessment of chemical recycling of plastic waste – a review. J Clean Prod 293:126163. https://doi.org/10.1016/j.jclepro.2021.126163

Jiang H, Liu W, Zhang X, Qiao J (2020) Chemical recycling of plastics by microwave-assisted high-temperature pyrolysis. Global Chall 4:1900074. https://doi.org/10.1002/GCH2.201900074

Lee A, Liew MS (2020) Tertiary recycling of plastics waste: an analysis of feedstock, chemical and biological degradation methods. J Mater Cycles Waste Manag 23:32–43. https://doi.org/10.1007/s10163-020-01106-2

Lazarevic D, Aoustin E, Buclet N, Brandt N (2010) Plastic waste management in the context of a European recycling society: comparing results and uncertainties in a life cycle perspective. Resour Conserv Recycl 55(2):246–259. https://doi.org/10.1016/j.resconrec.2010.09.014

Chen X, Xi F, Geng Y, Fujita T (2011) The potential environmental gains from recycling waste plastics: simulation of transferring recycling and recovery technologies to Shenyang. China Waste Manag 31(1):168–179. https://doi.org/10.1016/j.wasman.2010.08.010

Turner DA, Williams ID, Kemp S (2015) Greenhouse gas emission factors for recycling of source-segregated waste materials. Resour Conserv Recycl 105(A):186–197. https://doi.org/10.1016/j.resconrec.2015.10.026

Gu F, Guo J, Zhang W, Summers PA, Hall P (2017) From waste plastics to industrial raw materials: a life cycle assessment of mechanical plastic recycling practice based on a real-world case study. Sci Total Environ 601–602:1192–1207. https://doi.org/10.1016/j.scitotenv.2017.05.278

Demets R, Van Kets K, Huysveld S, Dewulf J, De Meester S, Ragaert K (2021) Addressing the complex challenge of understanding and quantifying substitutability for recycled plastics. Resour Conserv Recycl 174:105826. https://doi.org/10.1016/j.resconrec.2021.105826

Jeswani H, Krüger C, Russ M, Horlacher M, Antony F, Hann S, Azapagic A (2021) Life cycle environmental impacts of chemical recycling via pyrolysis of mixed plastic waste in comparison with mechanical recycling and energy recovery. Sci Total Environ 769:144483. https://doi.org/10.1016/j.scitotenv.2020.144483

Khan MMH, Laitinen V, Havukainen J, Horttanainen M (2021) Carbon footprint of different recovery options for the repulping reject from liquid packaging board waste treatment process. Waste Manag 136:93–103. https://doi.org/10.1016/J.WASMAN.2021.10.003

Horodytska O, Kiritsis D, Fullana A (2020) Upcycling of printed plastic films: LCA analysis and effects on the circular economy. J Clean Prod 268:122138. https://doi.org/10.1016/J.JCLEPRO.2020.122138

Das S, Liang C, Dunn JB (2022) Plastics to fuel or plastics: life cycle assessment-based evaluation of different options for pyrolysis at end-of-life. Waste Manag 153:81–88. https://doi.org/10.1016/j.wasman.2022.08.015

Van Eygen E, Feketitsch J, Laner D, Rechberger H, Fellner J (2017) Comprehensive analysis and quantification of national plastic flows: the case of Austria. Resour Conserv Recycl 117(B):183–194. https://doi.org/10.1016/j.resconrec.2016.10.017

Dahlbo H, Poliakova V, Mylläri V, Sahimaa O, Anderson R (2018) Recycling potential of post-consumer plastic packaging waste in Finland. Waste Manag 71:52–61. https://doi.org/10.1016/j.wasman.2017.10.033

Jiang X, Wang T, Jiang M, Xu M, Yu Y, Guo B, Chen D, Hu S, Jiang J, Zhang Y, Zhu B (2020) Assessment of plastic stocks and flows in China: 1978-2017. Resour Conserv Recycl 161:104969. https://doi.org/10.1016/j.resconrec.2020.104969

Nakatani J, Maruyama T, Moriguchi Y (2020) Revealing the intersectoral material flow of plastic containers and packaging in Japan. PNAS 117(33):19844–19853. https://doi.org/10.1073/pnas.2001379117

Neo ERK, Soo GCY, Tan DZL, Cady K, Tong KT, Low JSC (2021) Life cycle assessment of plastic waste end-of-life for India and Indonesia. Resour Conserv Recycl 174:105774. https://doi.org/10.1016/J.RESCONREC.2021.105774

Sevigné-Itoiz E, Gasol MG, Rieradevall J, Gabarrell X (2015) Contribution of plastic waste recovery to greenhouse gas (GHG) savings in Spain. Waste Manag 46:557–567. https://doi.org/10.1016/j.wasman.2015.08.007

Kerdlap P, Purnama AR, Low J, Tan D, Barlow C, Ramakrishna S (2021) Comparing the environmental performance of distributed versus centralized plastic recycling systems: applying hybrid simulation modelling to life cycle assessment. J Ind Ecol 26(1):252–271. https://doi.org/10.1111/jiec.13151

Volk R, Stallkamp C, Steins J, Yogish SP, Müller RC, Stapf D, Schultmann F (2021) Techno-economic assessment and comparison of different plastic recycling pathways: a German case study. J Ind Ecol 25(5):1318–1337. https://doi.org/10.1111/jiec.13145

An J, Wu F, Wang D, You J (2022) Estimated material metabolism and life cycle greenhouse gas emission of major plastics in China: a commercial sector-scale perspective. Resour Conserv Recycl 180:106161. https://doi.org/10.1016/j.resconrec.2022.106161

Hsu WT, Domenech T, McDowall W (2021) How circular are plastics in the EU?: MFA of plastics in the EU and pathways to circularity. Clean Environ Syst 2:100004. https://doi.org/10.1016/j.cesys.2020.100004

Wäger PA, Hischier R (2015) Life cycle assessment of post-consumer plastics production from waste electrical and electronic equipment (WEEE) treatment residues in a Central European plastics recycling plant. Sci Total Environ 529:158–167. https://doi.org/10.1016/j.scitotenv.2015.05.043

Ness B, Urbel-Piirsalu E, Anderberg S, Olsson L (2007) Categorising tools for sustainability assessment. Ecol Econ 60:498–508. https://doi.org/10.1016/j.ecolecon.2006.07.023

Pesonen H-L, Ekvall T, Fleischer G, Huppes G, Jahn C, Klos ZS, Rebitzer G, Sonnemann G, Tintinelli A, Weidema B, Wenzel H (2000) Framework for scenario development in LCA. Int J Life Cycle Assess 5:21–29. https://doi.org/10.1007/BF02978555

Khandelwal H, Dhar H, Thalla AK, Kumar S (2019) Application of life cycle assessment in municipal solid waste management: a worldwide critical review. J Clean Prod 209 https://www.sciencedirect.com/science/article/pii/S0959652618332591

Brunner PH, Rechberger H (2004) Practical handbook of material flow analysis. CRC Press LLC, Boca Raton, Florida

Aslam S, Ali F, Naseer A, Sheikh Z (2022) Application of material flow analysis for the assessment of current municipal solid waste management in Karachi, Pakistan. Waste Manag Res 40(2):185–194. https://doi.org/10.1177/0734242x211000427

Somlai C, Bullock C, Gallagher J (2023) Plastic packaging waste in Europe: addressing methodological challenges in recording and reporting. Waste Manag Res 41(6):1134–1143. https://doi.org/10.1177/0734242X221142192

Wernet G, Bauer C, Steubing B, Reinhard J, Moreno-Ruiz E, Weidema B (2016) The ecoinvent database version 3 (part I): overview and methodology. Int J Life Cycle Assess 21:1218–1230. https://doi.org/10.1007/s11367-016-1087-8

Gala A, Catalán-Martínez D, Guerrero M, Serra JM (2021) Simulation-assisted design of a catalytic hydrogenation reactor for plastic pyrolysis fuels. Fuel 287:119400. https://doi.org/10.1016/j.fuel.2020.119400

Technical Research Center of Finland (VTT) (2017) Lipasto unit emissions database. Available in http://lipasto.vtt.fi/yksikkopaastot/indexe.htm (accessed 3 Mar 2022).

PRé-Consultants (2021) SimaPro 9.2 Full update instructions. Amersfoort, The Netherlands. Available in https://simapro.com/wp-content/uploads/2021/07/FullUpdateInstructionsToSimaPro920.pdf. Accessed 22 Sept 2023

Ekvall T, Björklund A, Sandin G, Jelse K, Lagergren J, Rydberg M (2020) Modeling recycling in life cycle assessment. IVL Swedish Environmental Research Institute C551. Available in https://www.diva-portal.org/smash/get/diva2:1549446/FULLTEXT01.pdf (accessed 7 Mar 2022).

Brogaard LK, Christensen TH (2016) Life cycle assessment of capital goods in waste management systems. Waste Manag 56:561–574. https://doi.org/10.1016/J.WASMAN.2016.07.037

RINKI (2022) Muovipakkaukset kiertoon [Plastic packaging for recycling]. Available in https://rinkiin.fi/kotitalouksille/pakkausten-kierratys/muovipakkaukset/ (accessed 7 Mar 2022).

Swedish Institute (2023) Swedish recycling and beyond. Available in https://sweden.se/climate/sustainability/swedish-recycling-and-beyond (accessed 24 Aug 2023).

Eriksson O, Finnveden G (2009) Plastic waste as a fuel–- CO2-neutral or not? Energy Environ Sci 2:907–914. https://doi.org/10.1039/B908135F

Rigamonti L, Niero M, Haupt M, Grosso M, Judl J (2018) Recycling processes and quality of secondary materials: food for thought for waste-management-oriented life cycle assessment studies. Waste Manag 76:261–265. https://doi.org/10.1016/j.wasman.2018.03.001

Rigamonti L, Taelman SE, Huysveld S, Sfez S, Ragaert K, Dewulf J (2020) A step forward in quantifying the substitutability of secondary materials in waste management life cycle assessment studies. Waste Manag 114:331–340. https://doi.org/10.1016/j.wasman.2020.07.015

European Commission (EC) (2017) PEFCR Guidance document, - guidance for the 14 development of Product Environmental Footprint Category Rules (PEFCRs), version 6.3, December 15, 2017. Available in: https://eplca.jrc.ec.europa.eu/permalink/PEFCR_guidance_v6.3-2.pdf. Accessed 22 Sept 2023

Fortum (2021) Muovin tehokas kiertokulku vaatii pullonkaulojen poistamista [The efficient recycling of plastics requires the removal of bottlenecks]. Available in: https://www.fortum.fi/tietoa-meista/forthedoers-blogi/muovin-tehokas-kiertokulku-vaatii-pullonkaulojen-poistamista (accessed 7 March 2022).

Official Statistics of Finland (OSF) (2020) Waste statistics. Municipal Waste Helsinki: Statistics Finland Available in: https://www.stat.fi/til/jate/2019/13/jate_2019_13_2020-12-09_tie_001_en.html (accessed 10.3.2023)

Official Statistics of Finland (OSF) (2019) Greenhouse gases [e-publication]. Helsinki: Statistics Finland. ISSN=1797-6065. Available in: http://www.stat.fi/til/khki/2019/khki_2019_2020-05-28_tie_001_en.html. Accessed 15 Feb 2022.

Acknowledgements

The paper was developed in the frame of the project “PLASTin – All-in for Plastics Recycling project” financed by Business Finland. The authors gratefully acknowledge the invaluable contributions from research participants.

Funding

Open access funding provided by Finnish Environment Institute (SYKE). This work was carried out as a part of the PLASTin – All-in for Plastics Recycling project (8907/31/2019), funded by Business Finland.

Author information

Authors and Affiliations

Contributions

Jáchym Judl and Susanna Horn initiated the paper, developed the framework, and conducted the main research and writing. Jachym Judl carried out the LCA modelling. Susanna Horn led the work package. Tiina Karppinen contributed with her expertise on waste systems in Finland and material flow quantities.

Corresponding author

Ethics declarations

Ethics Approval and Consent to Participate

Not applicable.

Consent for publication

Not applicable.

Competing Interests

The authors declare no competing interests.

Supplementary Information

ESM 1

(DOCX 67 kb)

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Judl, J., Horn, S. & Karppinen, T.K.M. Towards a Low-Carbon Plastic Waste Recycling in Finland: Evaluating the Impacts of Improvement Measures on GHG Emissions. Circ.Econ.Sust. 4, 755–776 (2024). https://doi.org/10.1007/s43615-023-00306-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s43615-023-00306-w