Abstract

Purpose of Review

With the increasing global demand for protein, there is a critical need to make nutritious and cost-effective protein from alternative sources widely accessible. Dry fractionation emerges as a promising technology for producing sustainable, protein-rich raw materials from plants such as pulses. This paper offers an overview of recent advancements in the extrusion of dry-fractionated plant proteins (DFPPs) for applications in meat analogues.

Recent Findings

Fibrous meat analogues can be produced from plant-based proteins through both high- and low-moisture extrusion processes. Dry-fractionated pulse proteins, which are products with high protein content (exceeding 70%), can be utilised either independently or blended with protein isolates or other ingredients. However, it is important to note that dry-fractionated protein can have adverse effects on the colour, sensory characteristics, and textural properties of the extruded products. Consequently, adjustments in extruder parameters are necessary to create fibrous materials incorporating DFPPs effectively.

Summary

This review article provides insights into technologies employed for protein extraction, options for enhancing their functional and sensory properties (including addressing beany tastes), and various techniques developed to achieve a fibrous and meat-like texture.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The global demand for protein is expected to grow remarkably over the next decades. Although animal proteins, and in particular, meat from ruminant animals such as beef have a high impact on the environment, their consumption is increasing even faster than that for protein overall [1, 2] The FAO (Food and Agriculture Organization) [3] estimates an increase of 14% in meat protein consumption until 2030, compared to the period average of 2018–2020. Eleven percent are due to global population growth, whereas the remaining 3% are connected to an increased per capita meat consumption. On the other hand, plant-based proteins are gaining increased interest as some consumers shift their diet towards more sustainable options [4, 5]. Wheat gluten and soy are the main sources of plant-based protein in the human diet but come with several limitations. Wheat gluten can cause celiac disease, and soy is not only a common allergen but also is grown under extensive monocultural production that contributes to deforestation and destruction of natural habitat [6]. Therefore, there is a need to explore other, more environmentally sustainable, sources of plant-based proteins. Other plant-based protein sources include oilseeds, nuts, algae, and cereals, but pulse crops in particular are attractive due to their high protein content (19–43%) [6], cheap production cost, and resource efficiency [6, 7, 8•]. Extrusion has become the most commonly used technology to create plant-based meat analogues, but while it can be used for a large variety of proteins, the use of air-classified pulse proteins is still largely unknown [9]. This article aims to provide insight into recent advances of sustainably extracted pulse proteins used in the manufacture of plant-based meat analogues. For this, the promising potential and current challenges of high-moisture extrusion in combination with air-classified pulse protein concentrates have been reviewed.

Dry and Wet Fractionation of Pulse Proteins

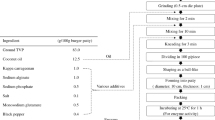

A commonly employed method for obtaining protein-rich fractions from pulses is wet extraction. This method, outlined schematically in Fig. 1, encompasses several steps. Following grinding or milling, a defatting step is typically carried out, utilising techniques such as cold pressing or solvent extraction to yield defatted legume flour. Next, the legume flour is mixed with water to eliminate insoluble fibres under alkaline conditions (~ pH 9) and subsequently remove soluble fibres through protein precipitation at their isoelectric point (~ 4.5–4.8). In the final step, the resulting slurry is dried to yield protein isolates with a protein content exceeding 90% and a yield ranging from 60 to 90% [10,11,12].

Wet fractionation yields protein isolates with a notably higher level of purity and a lower concentration of anti-nutritional factors compared to dry fractionation. However, this method demands a substantial amount of energy and necessitates the use of various chemicals and substantial volumes of water, resulting in the generation of wastewater. Consequently, it is not considered an environmentally friendly technique when compared to dry fractionation [10, 13]. Protein isolates obtained through wet fractionation are vulnerable to losing their functionality, such as solubility, as they may undergo significant denaturation due to exposure to harsh processing conditions such as high temperatures and acidic and alkaline solutions. The denaturation of proteins has a notable adverse impact on their subsequent processing in the food manufacturing industry [8•]. Nevertheless, despite these drawbacks, wet fractionation remains a preferred method for producing soy and pea protein isolates, especially for the creation of meat analogues [9, 14,15,16].

Dry fractionation is a process that produces protein concentrates by mechanically segregating proteins from starches and other impurities based on their particle size and density. In this method, pulses are first finely milled to separate proteins from starches and other cellular components. Subsequently, the milled flour undergoes air classification, which divides it into two fractions: a coarse fraction rich in starch and a fine fraction rich in proteins. The protein-rich fraction typically contains between 40 and 65% protein content and can be used as an ingredient in meat analogue applications. Dry fractionation has been successfully used for a wide range of pulses, including peas, chickpeas, faba beans, mung beans, and lentils [7, 17].

Dry fractionation offers several advantages over wet fractionation, primarily in terms of environmental impact and preservation of protein structure and functionality. Unlike wet fractionation, dry fractionation does not necessitate the use of chemicals or a significant amount of water and does not produce wastewater. Consequently, it eliminates the need for energy-intensive drying processes and results in lower water consumption [18]. Furthermore, this method maintains the native structure and functionality of proteins. However, it is important to note that dry-fractionated proteins often exhibit lower yields and protein content. They may also contain significant amounts of starch and other impurities, including oils and fibres, which, in turn, can influence their functionality and performance during storage and processing [19, 20]. Additionally, pulses are known for their characteristic “beany” and “grassy” off-flavours, attributed to volatile components [7].

Functional Properties of Dry-Fractionated Pulse Proteins

When substituting protein isolates with dry-fractionated pulse proteins, it is crucial to preserve their functional properties to not compromise the quality of the final product [6]. Key functional properties for meat analogue applications include solubility, gelation, water-holding capacity (WHC), and oil-holding capacity (OHC) [14, 21, 22••]. Additionally, emulsification and foaming properties are highly relevant for a wide range of food applications, including baked goods, pastas, beverages, and dairy alternatives [11]. An overview of selected functional properties of dry-fractionated pulse proteins and soy protein isolate is provided in Table 1.

Solubility refers to a protein’s ability to dissolve in an aqueous solvent. In its native state, a protein exposes its hydrophilic groups, enhancing solubility. However, increased denaturation and aggregation lead to reduced solubility. These structural changes often occur during the wet extraction of commercial protein concentrates and isolates, making this process less suitable for food applications. Vogelsang-O’Dwyer et al. [23] compared the solubility of air-classified faba bean protein flour (FPF) and wet-fractionated faba bean protein isolate (FPI). FPF exhibited higher protein solubility than FPI at both the isoelectric point of pH 4.5 (15% vs. 3%) and neutral pH 7 (85% vs. 32%).

Water-holding capacity (WHC) and oil-holding capacity (OHC) describe the maximum amounts of water and oil a protein can retain, respectively. Unlike solubility, WHC and OHC of plant proteins can be increased by partial protein unfolding during denaturation [24, 25]. An increased WHC can be partly attributed to the fact that denatured protein is less soluble (and thus is not discarded as part of the watery supernatant) and due to the greater exposure of the proteins’ hydrophobic core, respectively [14]. Both WHC and OHC have distinct effects on the texture and sensory properties of meat analogues. Proteins high in WHC enhance product juiciness by retaining more water, while OHC contributes to mouthfeel and texture. Bühler et al. increased the water-holding capacity of dry-fractionated faba bean concentrates through dry heating treatment, illustrating the impact of processing history on plant protein functionality [21]. Schlangen et al. [17] reported comparable WHCs for air-classified pulse proteins, including mung bean, yellow pea, and cowpea (2.1, 1.5, and 2.1 g/g, respectively), which is slightly higher than the WHC of wet-fractionated faba and pea protein (1.8 and 1.7 g/g, respectively) [14].

Protein gelation is the process in which protein solutions transform into semi-solid structures through unfolding, dissociation, association, and aggregation of the proteins. These three-dimensional, cross-linked networks have an isotropic structure (direction-independent) and impact various specific characteristics of food systems, including thickening and water retention. Protein gelation can be employed for the structuring of foods like yogurts, desserts, or jellies. Various techniques, including heat, pressure, pH shifting, salt addition, or enzymes, can induce gelation, each with different underlying mechanisms [26,27,28]. Heat-induced gelation of proteins is a common practice in food manufacturing, typically occurring when proteins are heated above their denaturation temperature, causing them to unfold and form network structures.

Schlangen et al. [17] demonstrated that dry-fractionated pulse proteins, including those from mung bean, yellow pea, and cowpea, can form heat-induced gels. These rheological properties have the potential to be suitable for plant-based food applications. Furthermore, they emphasised that rheological properties change between pulse varieties, likely due to their unique protein compositions. This suggests that certain food applications may be especially suited for certain pulse varieties based on their distinct protein composition and characteristics.

Protein Texturisation Using Low- and High-Moisture Extrusion to Create Meat Analogues

Meat analogues are developed to replicate the texture and flavour of meat products, providing consumers with a sensory experience similar to traditional animal protein sources, in the absence of using animal-derived ingredients [31, 32]. An essential aspect of meat analogues lies in their capacity to develop anisotropic, fibrillar structures akin to animal muscle tissues [28]. Various techniques, such as shear cell, freeze casting, spinning, and self-assembly, have been explored to achieve these structures. However, their practical application currently remains mostly limited to laboratory-scale or initial scaling-up phases [26].

Extrusion technology emerges as the standout method with substantial commercial viability and utilisation. Extrusion technology can be classified into two approaches based on the moisture content employed during the extrusion process. Low-moisture extrusion deals with protein slurries containing less than 40% moisture content, while high-moisture extrusion handles mixtures with over 40% moisture content [9]. Low-moisture extrusion is a well-established technique for texturising plant proteins, yielding textured vegetable proteins (TVPs) characterised by their slightly expanded structure [33]. The process involves a rapid pressure drop as the material exits the extruder die, resulting in water evaporation, cooling, increased viscosity, and a transition to a glassy state. This evaporation induces bubble expansion and stabilises the material’s structure. TVP serves as a foundational ingredient for various meat analogue products such as burgers, nuggets, and mince but requires rehydration and further processing [34].

In contrast, high-moisture extrusion represents a more recent method for creating larger chunks with meat-like fibrous structures and desired sensory attributes. It entails combining proteins with other components at low temperatures, followed by heating and shearing within the extruder. This process induces the denaturation and melting of protein structures. The cooling die, located in the final section of the extruder, cools the melt to below its boiling point, preventing expansion and water evaporation upon exit. The slow and controlled flow of the melt in the cooling die aids in the shear alignment and stabilisation of fibrous structures [14]. This technique offers versatility in producing various fibrous textures, including extrudates resembling whole cuts [16, 35]. Despite its widespread commercial adoption, there remains a limited understanding of the underlying mechanisms in extrusion that contribute to the formation of fibrous structures in plant proteins [9, 36].

Texturisation of Dry-Fractionated Pulse Proteins Using Extrusion Technology

The use of extrusion technology for creating meat analogues has been extensively explored, particularly for soy, wheat gluten, and pea protein concentrates and isolates obtained through wet fractionation [37,38,39]. However, applying extrusion technology to dry-fractionated pulse proteins presents certain challenges. These challenges arise from their heterogeneous chemical composition, which includes higher levels of starch and oil and lower protein content compared to isolates, as well as pulse-typical off-flavours. Additionally, there is a limited understanding of how the functional properties of proteins interact with fibre formation in extrusion processes.

Few studies have investigated the impact of extrusion cooking on dry-fractionated pulse proteins. Some of the pulses used and their effects on meat analogues are summarised in Table 2. For instance, De Angelis et al. [40••] combined dry-fractionated pea protein (DF-pea), wet-fractionated pea protein isolate, and soy protein isolates with oat protein from a hybrid dry- and wet-milling process. They then subjected these mixtures to low-moisture extrusion (20–25% moisture content) and analysed their chemical composition, functionality, and sensory attributes. The mixture containing DF-pea and oat protein exhibited the highest carbohydrate content and the lowest protein content before extrusion, attributed to the typical composition of dry-fractionated pulse proteins. While the protein content remained suitable for meat analogue applications, the high carbohydrate content had the potential to negatively impact fibre formation by absorbing water and expanding the extrudate at the expense of fibre formation. The DF-pea and oat protein extrudate also displayed the lowest hardness and the highest overall odour and taste intensity, including the pulse-typical bitterness and aftertaste. These findings underscore the challenges related to the functional and sensory properties of DF-pea proteins in meat analogue applications, emphasising the need for further improvement in extraction methods and formulation.

The feasibility of high-moisture extrusion using dry-fractionated faba bean concentrate (protein content 63.5%, dry basis) to create meat analogues was explored by do Carmo et al. [41••]. The study assessed the impact of specific process parameters on the physicochemical, functional, and sensory properties of meat analogues. It demonstrated the possibility of producing fibrous meat analogues with dry-fractionated faba bean as the sole source of protein, with an optimal combination of barrel temperature and moisture content for improved sensory profiles. Similarly, Ferawati et al. [22••] created fibrous meat analogues from dry-fractionated faba bean concentrate (protein content 56%) and compared them to meat analogues made from wet-extracted yellow pea and faba bean protein isolate using high-moisture extrusion. They aimed to identify critical factors influencing texture properties. The study revealed that dry-fractionated faba bean produced meat analogues with lower water-holding capacity (WHC) and firmer texture due to its low protein and high carbohydrate content, favouring protein-carbohydrate interactions over protein–protein interactions during extrusion cooking. This underscores the importance of considering the composition of dry-fractionated protein ingredients to achieve optimal fibre formation, particularly when used as the primary protein source.

Furthermore, Kantanen et al. [42••] used different blends of DF-faba bean concentrate (protein content of 55.2%) and wet-fractionated faba bean isolate (protein content of 80.1%, dry basis) to create meat analogues through high-moisture extrusion. Their study revealed that a higher proportion of DF-faba bean in the blend resulted in a lighter colour, higher WHC, and a more organised fibre structure, all desirable attributes in meat analogues. This suggests that blending dry-fractionated and wet-fractionated faba bean proteins may offer an opportunity to improve the textural properties of meat analogues. However, the functional properties and chemical composition can vary significantly with different extraction methods and pulse cultivars, necessitating further investigation to determine whether these findings can be replicated with different pulses and varying functional properties. Additionally, De Angelis et al. [43••] characterised the rheological properties of dry-fractionated mung bean concentrate (protein content of 55%) using a closed cavity rheometer, simulating extruder-like conditions. They subsequently developed meat analogues through high-moisture extrusion (moisture content of 40–50%). The resulting meat analogues exhibited clear fibrous structures, and texture properties such as hardness and chewiness in the extrudate correlated directly with the extruder temperature, resembling the properties of some commercial meat analogues. These findings suggest that further investigation is needed to establish a connection between raw material properties and extrudate characteristics to design improved texture and structure for meat analogues.

In the reviewed studies, DFPPs from three pulse varieties (pea, mung bean, and faba bean) could successfully form fibrous meat analogue structures using low- and high-moisture extrusion, both as a single protein source and blended with other proteins. However, DFPPs required adjusted processing parameters and showed a negative impact on colour, fibre formation, functional properties, and sensory properties of the meat analogues.

Various pulse cultivars and diverse parameters employed during milling and air classification have a notable impact on the chemical composition, nutritional quality, and functional properties of the resulting pulse fractions [7]. The dry fractions of different pulse cultivars, such as yellow pea and cowpea, have been comprehensively characterised and have exhibited functional properties comparable to those of pea, mung bean, and faba bean. This similarity suggests that they might be suitable for the manufacture of plant-based meat analogues using extrusion technology [17]. An alternative approach could involve the blending of these pulse proteins to address potential nutritional deficiencies and enhance fibre formation [44]. Consequently, further research is essential in both the extraction and texturisation of dry-fractionated pulse proteins to develop protein-rich food products that are both sustainable and appealing to consumers.

Conclusion and Future Directions

Pulses, renowned for their rich protein content and sustainable cultivation practices, present an attractive source of nutritious protein for human food applications. Dry fractionation, a technology used to separate protein fractions from pulses, excels in preserving the inherent functionality of the proteins and boasts superior environmental sustainability when compared to traditional wet fractionation methods. Nevertheless, the utilisation of dry-fractionated pulse proteins (DFPPs) for meat analogue applications is still limited, because of the presence of unwanted impurities and typical pulse-related off-flavours. Thus, it is imperative to explore treatment methods such as heat treatments of the raw legume flours that not only enhance protein purity but also mitigate off-flavours to improve DFPPs for human food applications. Furthermore, the intricate impact of protein texturisation technologies on fibre formation in DFPPs is largely unknown and hampers the development of analogues that closely mimic meat’s texture.

Data Availability

No new data was generated.

References

Papers of particular interest, published recently, have been highlighted as: • Of importance •• Of major importance

Weindl I, Ost M, Wiedmer P, Schreiner M, Neugart S, Klopsch R, et al. Sustainable food protein supply reconciling human and ecosystem health: a Leibniz position. Glob Food Sec. 2020;25. https://doi.org/10.1016/j.gfs.2020.100367.

Henchion M, Moloney AP, Hyland J, Zimmermann J, McCarthy S. Review: Trends for meat, milk and egg consumption for the next decades and the role played by livestock systems in the global production of proteins. Animal. 2021;15. https://doi.org/10.1016/j.animal.2021.100287.

OECD-FAO Agricultural Outlook 2021–2030. FAO. 2021. https://doi.org/10.1787/agr-outl-data.

Tziva M, Negro SO, Kalfagianni A, Hekkert MP. Understanding the protein transition: the rise of plant-based meat substitutes. Environ Innov Soc Transit. 2020;35:217–31. https://doi.org/10.1016/j.eist.2019.09.004.

Tachie C, Nwachukwu ID, Aryee ANA. Trends and innovations in the formulation of plant-based foods. 2023;5. https://doi.org/10.1186/s43014-023-00129-0.

Day L, Cakebread JA, Loveday SM. Food proteins from animals and plants: differences in the nutritional and functional properties. Trends Food Sci Technol. 2022;119:428–42. https://doi.org/10.1016/j.tifs.2021.12.020.

Skylas DJ, Johnson JB, Kalitsis J, Richard S, Whiteway C, Wesley I, et al. Optimised dry processing of protein concentrates from Australian pulses: a comparative study of faba bean, yellow pea and red lentil seed material. Legume Sci. 2022. https://doi.org/10.1002/leg3.161.

• Schutyser MAI, Pelgrom PJM, van der Goot AJ, Boom RM. Dry fractionation for sustainable production of functional legume protein concentrates. Trends Food Sci Technol 2015;45:327–35. https://doi.org/10.1016/j.tifs.2015.04.013. Paper reviews dry fractionation as a potentially more sustainable substitute for wet extraction of legume protein concentrates.

Zhang Z, Zhang L, He S, Li X, Jin R, Liu Q, et al. High-moisture extrusion technology application in the processing of textured plant protein meat analogues: a review. Food Rev. Int. 2022:1–36. https://doi.org/10.1080/87559129.2021.2024223.

Pelgrom PJM, Boom RM, Schutyser MAI. Functional analysis of mildly refined fractions from yellow pea. Food Hydrocoll. 2015;44:12–22. https://doi.org/10.1016/j.foodhyd.2014.09.001.

Boye J, Zare F, Pletch A. Pulse proteins: processing, characterization, functional properties and applications in food and feed. Food Res Int. 2010;43:414–31. https://doi.org/10.1016/j.foodres.2009.09.003.

Dumoulin L, Jacquet N, Malumba P, Richel A, Blecker C. Dry and wet fractionation of plant proteins: how a hybrid process increases yield and impacts nutritional value of faba beans proteins. Innov Food Sci Emerg Technol. 2021;72:102747. https://doi.org/10.1016/j.ifset.2021.102747.

Schutyser MAI, van der Goot AJ. The potential of dry fractionation processes for sustainable plant protein production. Trends Food Sci Technol. 2011;22:154–64. https://doi.org/10.1016/j.tifs.2010.11.006.

Osen R, Toelstede S, Wild F, Eisner P, Schweiggert-Weisz U. High moisture extrusion cooking of pea protein isolates: raw material characteristics, extruder responses, and texture properties. J Food Eng. 2014;127:67–74. https://doi.org/10.1016/j.jfoodeng.2013.11.023.

Cornet SHV, Snel SJE, Schreuders FKG, van der Sman RGM, Beyrer M, van der Goot AJ. Thermo-mechanical processing of plant proteins using shear cell and high-moisture extrusion cooking. Crit Rev Food Sci Nutr. 2022;62:3264–80. https://doi.org/10.1080/10408398.2020.1864618.

Schmid EM, Farahnaky A, Adhikari B, Torley PJ. High moisture extrusion cooking of meat analogs: a review of mechanisms of protein texturization. Compr Rev Food Sci Food Saf. 2022;21:4573–609. https://doi.org/10.1111/1541-4337.13030.

Schlangen M, Taghian Dinani S, Schutyser MAI, van der Goot AJ. Dry fractionation to produce functional fractions from mung bean, yellow pea and cowpea flour. Innov Food Sci Emerg Technol. 2022;78. https://doi.org/10.1016/j.ifset.2022.103018.

Fernando S. Production of protein-rich pulse ingredients through dry fractionation: a review. LWT. 2021;141. https://doi.org/10.1016/j.lwt.2021.110961.

Vogelsang-O’Dwyer M, Zannini E, Arendt EK. Production of pulse protein ingredients and their application in plant-based milk alternatives. Trends Food Sci Technol. 2021;110:364–74. https://doi.org/10.1016/J.TIFS.2021.01.090.

Sim SYJ, Srv A, Chiang JH, Henry CJ. Plant proteins for future foods: a roadmap. Foods. 2021;10. https://doi.org/10.3390/foods10081967.

Bühler JM, Dekkers BL, Bruins ME, Van Der Goot AJ. Modifying faba bean protein concentrate using dry heat to increase water holding capacity. Foods. 2020;9. https://doi.org/10.3390/foods9081077.

•• Ferawati F, Zahari I, Barman M, Hefni M, Ahlström C, Witthöft C, et al. High-moisture meat analogues produced from yellow pea and faba bean protein isolates/concentrate: effect of raw material composition and extrusion parameters on texture properties. Foods, 2021;10. https://doi.org/10.3390/foods10040843. Paper describes production of meat analogues using high-moisture extrusion and a blend of DF-faba bean (dry-fractionated faba bean concentrate) and wet-extracted faba bean isolate. It describes the impact of DF-faba bean protein on extrudate texture.

Vogelsang-O’Dwyer M, Petersen IL, Joehnke MS, Sørensen JC, Bez J, Detzel A, et al. Comparison of faba bean protein ingredients produced using dry fractionation and isoelectric precipitation: techno-functional, nutritional and environmental performance. Foods. 2020;9. https://doi.org/10.3390/foods9030322.

Shrestha S, Hag L van ’t, Haritos V, Dhital S. Rheological and textural properties of heat-induced gels from pulse protein isolates: lentil, mungbean and yellow pea. Food Hydrocoll. 2023;143. https://doi.org/10.1016/j.foodhyd.2023.108904.

Joshi M, Adhikari B, Aldred P, Panozzo JF, Kasapis S. Physicochemical and functional properties of lentil protein isolates prepared by different drying methods. Food Chem. 2011;129:1513–22. https://doi.org/10.1016/j.foodchem.2011.05.131.

Tan M, Nawaz MA, Buckow R. Functional and food application of plant proteins–a review. Food Rev Int. 2021. https://doi.org/10.1080/87559129.2021.1955918.

Grossmann L, Weiss J. Alternative protein sources as technofunctional food ingredients. 2021.https://doi.org/10.1146/annurev-food-062520

Ma KK, Grossmann L, Nolden AA, McClements DJ, Kinchla AJ. Functional and physical properties of commercial pulse proteins compared to soy derived protein. Future Foods. 2022;6. https://doi.org/10.1016/j.fufo.2022.100155.

Saldanha do Carmo C, Silventoinen P, Nordgård CT, Poudroux C, Dessev T, Zobel H, et al. Is dehulling of peas and faba beans necessary prior to dry fractionation for the production of protein- and starch-rich fractions? Impact on physical properties, chemical composition and techno-functional properties. J Food Eng. 2020;278. https://doi.org/10.1016/j.jfoodeng.2020.109937.

de Paiva Gouvêa L, Caldeira R, de Lima Azevedo T, Galdeano MC, Felberg I, Lima JR, et al. Physical and techno-functional properties of a common bean protein concentrate compared to commercial legume ingredients for the plant-based market. Food Hydrocoll. 2023;137. https://doi.org/10.1016/j.foodhyd.2022.108351.

Goldstein N, Reifen R. The potential of legume-derived proteins in the food industry. Grain Oil Sci Technol. 2022. https://doi.org/10.1016/j.gaost.2022.06.002.

Boukid F, Rosell CM, Rosene S, Bover-Cid S, Castellari M. Non-animal proteins as cutting-edge ingredients to reformulate animal-free foodstuffs: present status and future perspectives. Crit Rev Food Sci Nutr. 2022;62:6390–420. https://doi.org/10.1080/10408398.2021.1901649.

Dekkers BL, Boom RM, van der Goot AJ. Structuring processes for meat analogues. Trends Food Sci Technol. 2018;81:25–36. https://doi.org/10.1016/j.tifs.2018.08.011.

Ozturk OK, Hamaker BR. Texturization of plant protein-based meat alternatives: processing, base proteins, and other constructional ingredients. Future Foods. 2023;8. https://doi.org/10.1016/j.fufo.2023.100248.

Vatansever S, Tulbek M, Riaz MN. Low- and high-moisture extrusion of pulse proteins as plant-based meat ingredients: a review. Cereal Food World. 2020;65. https://doi.org/10.1094/cfw-65-4-0038.

Sandoval Murillo JL, Osen R, Hiermaier S, Ganzenmüller G. Towards understanding the mechanism of fibrous texture formation during high-moisture extrusion of meat substitutes. J Food Eng. 2019;242:8–20. https://doi.org/10.1016/j.jfoodeng.2018.08.009.

Osen R, Toelstede S, Eisner P, Schweiggert-Weisz U. Effect of high moisture extrusion cooking on protein-protein interactions of pea (Pisum sativum L.) protein isolates. Int J Food Sci Technol. 2015;50:1390–6. https://doi.org/10.1111/ijfs.12783.

Wu M, Sun Y, Bi C, Ji F, Li B, Xing J. Effects of extrusion conditions on the physicochemical properties of soy protein/gluten composite. Int J Agric Biol Eng. 2018;11:205–10. https://doi.org/10.25165/j.ijabe.20181104.4162.

Pietsch VL, Bühler JM, Karbstein HP, Emin MA. High moisture extrusion of soy protein concentrate: influence of thermomechanical treatment on protein-protein interactions and rheological properties. J Food Eng. 2019;251:11–8. https://doi.org/10.1016/j.jfoodeng.2019.01.001.

•• de Angelis D, Kaleda A, Pasqualone A, Vaikma H, Tamm M, Tammik ML, et al. Physicochemical and sensorial evaluation of meat analogues produced from dry-fractionated pea and oat proteins. Foods. 2020;9. https://doi.org/10.3390/foods9121754. Paper describes production of meat analogues using (DF) dry-fractionated pea protein, blended with oat protein, and the impact of DF pea protein on the sensory properties of meat analogue.

•• Saldanha do Carmo C, Knutsen SH, Malizia G, Dessev T, Geny A, Zobel H, et al. Meat analogues from a faba bean concentrate can be generated by high moisture extrusion. Future Foods. 2021;3. https://doi.org/10.1016/j.fufo.2021.100014. Paper shows that meat analogue production using high-moisture extrusion and dry-fractionated faba bean as the sole source of protein is possible. It describes the impact of extruder parameters on extrudate texture.

•• Kantanen K, Oksanen A, Edelmann M, Suhonen H, Sontag-Strohm T, Piironen V, et al. Physical properties of extrudates with fibrous structures made of faba bean protein ingredients using high moisture extrusion. Foods. 2022;11. https://doi.org/10.3390/foods11091280. Paper describes the production of meat analogue using dry-fractionated faba bean concentrate blended with wet-extracted faba bean isolate. It describes the impact of DF-faba bean protein on the sensory properties of meat analogues.

•• De Angelis D, Opaluwa C, Pasqualone A, Karbstein HP, Summo C. Rheological properties of dry-fractionated mung bean protein and structural, textural, and rheological evaluation of meat analogues produced by high-moisture extrusion cooking. Curr Res Food Sci. 2023;7. https://doi.org/10.1016/j.crfs.2023.100552. Paper describes the production of meat analogue using dry-fractionated faba bean. It compares the extrusion parameters with rheological testing of the raw material, highlighting that they display different behaviours.

Wittek P, Karbstein HP, Azad Emin M, José M, Apesteguía B. Blending proteins in high moisture extrusion to design meat analogues: rheological properties, morphology development and product properties. 2021. https://doi.org/10.3390/foods.

Acknowledgements

The authors acknowledge the financial support from the Global Innovation Linkages Program—Round 3—Transitioning Australian Pulses into Protein-Based Food Industries (GILIII000048). In addition, AH acknowledges the University of Sydney for providing his PhD scholarship.

Funding

Open Access funding enabled and organized by CAUL and its Member Institutions

Author information

Authors and Affiliations

Contributions

Andreas Hopf: Conceptualisation; Writing – Original Draft; Visualisation Fariba Dehghani: Review & Editing; Funding Acquisition; Supervision Roman Buckow: Conceptualisation; Writing – Original Draft, Review and Editing; Supervision

Corresponding authors

Ethics declarations

Ethics Statement

This study does not require any ethical approval.

Conflict of Interest

The authors declare no competing interests.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Hopf, A., Dehghani, F. & Buckow, R. Dry Fractionation of Plant-Based Proteins for Better Meat Analogue Applications. Curr Food Sci Tech Rep 1, 91–98 (2023). https://doi.org/10.1007/s43555-023-00009-1

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s43555-023-00009-1