Abstract

A newly developed heat-resistant austenitic steel, Sanicro 25 is currently considered the leading candidate material for an advanced ultra-supercritical installation. The test material was subjected to long-term ageing (up to 30,000 h) at 700 and 750 °C, after which investigations into the microstructure, identification of precipitates, and testing of mechanical properties were conducted. Sanicro 25 had an austenitic microstructure with annealed twins and numerous large primary NbX and Z-phase precipitates in the as-received condition. It was found that the long-term ageing of the steel resulted in numerous precipitation processes. For example, M23C6 carbides, Laves, σ and G phases occurred at the grain boundaries. However, Z-phase precipitates, ε_Cu particles, and Laves phase were observed inside the grains. At the same time, compound complexes of precipitates based on the primary Z-phase precipitates were revealed in the microstructure. The ageing process increased the particle size of M23C6 carbides and the σ phase. After longer ageing times, a precipitate-free zone (PFZ) near the grain boundaries was observed. The precipitation processes initially lead to an increase in the strength properties of the steel. However, after 5000 h, an over-ageing effect was observed at 750 °C, which was not observed at 700 °C.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The overall development of the power industry stimulates the growth of new creep-resistant steels. In addition, economic and environmental considerations and continuous improvements in the thermal efficiency of power units have forced the introduction of newer and newer materials for use in modern conventional power industries, including steels with an austenitic matrix [1].

The scope of using modern materials for boiler components, including new-generation ferritic and austenitic steels and nickel superalloys, depends on the temperature and stress conditions [2]. Bainitic and heat-resistant martensitic steels of 9–12% chromium, currently most commonly used in the power industry, are designed for operation at temperatures not exceeding 620–630 °C. However, due to the low corrosion resistance of 9% Cr steels and the low microstructural stability of 12% Cr steels, the use of creep-resistant austenitic steels is required at higher parameters. Austenitic steels show higher creep strength than ferritic steels and higher heat resistance and can be used at temperatures up to around 700 °C [3]. Compared to the currently available austenitic steels and nickel alloys (which can be used at above 700 °C but are considerably more expensive), the best alternative is Sanicro 25 stainless steel, which can significantly reduce the investment cost of the plant [4].

Sanicro 25 steel (X7NiCrWCuCoNbNB25) was developed under the European Therme AD700 program by AB Sandvik Material Technology in Sweden. Like other austenitic steels, Sanicro 25 has high plastic properties and ductility with relatively low strength properties. These properties are mainly linked to the solid solution-strengthening mechanism of steel, primarily provided by nitrogen, tungsten, and cobalt atoms. In addition, the balanced chemical composition of Sanicro 25 allows significant resistance to high-temperature corrosion and oxidation. It gives a higher creep strength compared to other austenitic steels, e.g., Super 304H and HR3C [4].

The creep strength of austenitic steels is associated with two strengthening mechanisms: solid solution strengthening and precipitation hardening. The precipitation hardening mechanism is dominant during service under creep conditions. It is related to the presence of particles (carbides, nitrides, intermetallic phases) interacting with dislocations in the microstructure provided by the so-called carbide-forming elements (i.e., Cr, niobium, Nb, and tungsten, W, as well as the addition of copper, Cu, which is released as ε_Cu nanoparticles). The value of creep strength determined for a 100,000 h service at 700ºC is 95 MPa, comparable to that of the HR6W nickel-base alloy. The high functional properties of Sanicro 25 make it one of the primary materials eligible for implementation in supercritical and ultra-supercritical power units with an efficiency of approximately 50% [4].

In previous literature, two main directions of the research on Sanicro 25 steel were observed—investigations of creep and low-cycle fatigue [5] and investigations of corrosion [6] and oxidation resistance in steam [7]. In both cases, one of the main focuses was the analysis of changes in the microstructure of Sanicro 25. The low-cycle fatigue resistance tests were conducted at both room temperature and 700 °C. At room temperature, Sanicro 25 is characterized by cyclic hardening at the initial stage, followed by cyclic softening, which is related to the specificity of the deformation of austenitic steel and the supersaturation state of the Sanicro 25 structure. At 700 °C, Sanicro 25 shows the cyclic hardening effect associated with precipitation of the Z-phase inside the grains and M23C6 carbides at the grain boundaries. According to the researchers, these carbides were mainly observed in the test steel at the low-angle grain boundaries. They were the reason for the formation of Cr-depleted areas near the boundaries. Additionally, according to [5], the cyclic hardening of Sanicro 25 at 700 °C is related to the presence of numerous dispersive ε_Cu and NbC precipitates.

To this date, research carried out on Sanicro 25 mainly covers issues related to low-cycle fatigue, weldability, and corrosion resistance. Tests were carried out on material aged for no more than 25,000 h. However, there is currently no information on the stability of microstructure or the course of precipitation processes in Sanicro 25 for ageing /service times longer than 25,000 h. Studies on the impact of longer ageing times are essential to obtain the complete picture of changes in the microstructure and understand the properties of steels intended for long-term operation. This article presents the results of investigations on the microstructure and properties of Sanicro 25 steel after 30,000 h ageing at 700 and 750 °C.

2 Material and research methodology

Investigations were carried out on specimens of ϕ38 × 8.8 mm taken from superheater coils in the form of a tube along the axial direction and were composed of creep-resistant austenitic steel Sanicro 25 (X7NiCrWCuCoNbNB25-23-3-3-3-2). Details of the chemical composition of the test steel in the as-received condition are presented in Table 1.

The investigations of microstructure and mechanical properties were carried out on steel in the as-received condition at both 700 and 750 °C. Various ageing times were investigated at these temperatures and were chosen to be 1,000, 5,000, 10,000, 20,000, and 30,000 h. All tests were carried out in the air.

The steel microstructure was analyzed using an Inspect F scanning electron microscope (SEM). The samples were prepared as metallographic cross-sections. The samples were ground on papers and polished on polishing wheels. Then it was electrolytically etched in 50% HNO3.

TEM samples for phase identification of precipitates in Sanicro 25 were prepared in the form of thin foils and lamellae. Thin foils were made from the bulk samples by cutting into plate forms, mechanically polished and ion milled by Ar plasma at 5 keV to create a hole at the center. Lamellae were made by the focused ion beam (FIB) technique using an SEM/Ga-FIB Helios NanoLabTM 600i microscope (FEI Company). TEM investigations were performed using an S/TEM Titan 80–300 microscope (FEI Company) equipped with a Cetcor Cs probe corrector (CEOS, Germany) and EDS spectrometer for chemical composition analysis. Crystal Maker and Single Crystal software (version 10.4.1) were used to simulate the crystal structure and diffraction patterns.

The qualitative and quantitative analysis of the chemical composition of the test steel was performed using the EDS energy-dispersive X-ray spectrometer (from EDAX), which is attached to TITAN 80–300 high-resolution electron microscope.

The mechanical properties were determined by hardness measurements and static tensile tests at room temperature. The hardness measurement was performed by the Vickers method: HV10, using the Swiss Max 300 hardness tester in accordance with EN ISO 6507-1. Mechanical property measurements were carried out on specimens aged 1,000, 10,000, 20,000, and 30,000 h.

Investigations into the strength properties of Sanicro 25 were also carried out using a static tensile test according to EN 10002-1:2002 at room temperature and, according to EN ISO 6892-2:2011, at elevated temperature on flat test specimens. The tests at room temperature were performed using a Zwick 200 kN tensile testing machine, and tests at 700 °C were performed using an Amsler 200 kN tensile testing machine in the load range of 40 kN.

The computer-based image analysis, including measuring the average diameter of M23C6 carbide and σ-phase precipitates, was performed using Image ProPlus software. The calibration was performed using a scale marker on the microstructure images, assuming a calibration factor of 1 pixel = 0.040 µm. All image analysis was carried out on pre-conditioned binary microstructure images.

3 Results and discussion

3.1 Initial microstructure of Sanicro 25 steel

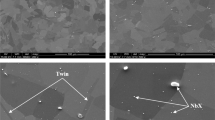

The Sanicro 25 steel, as-received, had a fine-grained austenitic microstructure with numerous annealing twins and primary precipitates (Fig. 1). The grain size in the tested steel was determined to be 7 according to the ASTM standard scale [8] (which corresponds to an average diameter of 31.2 μm). The precipitates observed in the microstructure of Sanicro 25 (Fig. 1) were identified as NbX carbonitrides and NbCrN (Z-phase) precipitates (Fig. 2). These precipitates are considered primary particles that nucleate during the solidification process and grow during the production process. They are, therefore, mainly observed at or near the grain boundaries (Fig. 1). Primary precipitates of NbX and Z-phase in the microstructure of Sanicro 25 steel as delivered were observed by Rutkowski [7] and Czempura [9]. On the other hand, Zurek [6] observed only particles of the Z-phase in this steel in the as-received state, while Zhou [10, 11] reported only particles of the MX type. The purpose of primary precipitates in austenitic steels is mainly to bind carbon and/or nitrogen atoms to limit the possibility of precipitating particles rich in chromium, but also these precipitates limit grain growth.

Fine grain and numerous twins in the microstructure in austenitic steels have a positive effect on obtaining high basic mechanical properties (yield strength, elongation, impact energy) with creep resistance comparable to coarse-grained steels [3]. In addition, fine grain in these alloys also positively affects corrosion resistance [12].

3.2 Microstructure of Sanicro 25 after ageing

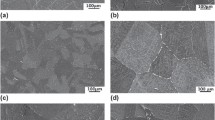

The primary microstructure degradation mechanism of creep-resistant austenitic steels is the precipitation processes occurring at the grain and twin boundaries and within the grains. The morphology and type of precipitates in the austenitic steel, both in the as-received condition and after ageing/service, depending on the chemical composition of the steel itself, the heat (thermomechanical) treatment parameters, and the holding temperature and time. The microstructure of Sanicro 25 steel after 1000 and 30,000 h ageing at 700 and 750 °C is shown in Fig. 3.

As shown in Fig. 3, many secondary phases precipitated both within and at the grain boundaries, where, at the latter, particles formed a so-called continuous grid of precipitates. As high-energy surface defects and grain misalignment areas allow faster diffusion compared to that within the grains, grain boundaries are preferred sites for the precipitation of secondary phases. At the grain boundaries in the tested steel, the presence of M23C6 carbides was revealed (Figs. 4, 5), and precipitation of the Laves phase was also shown (Fig. 5). Similar results, i.e., the presence of M23C6 carbides and Laves phase precipitates at grain boundaries, were reported by Zurek [6], and Rutkowski [7] who investigated the microstructure Sanicro 25 after oxidation at 700 °C. However, Zhou [11], who examined the steel after ageing and creep at 700 °C, showed the presence of only M23C6 carbides at the grain boundaries. The preferential precipitation of M23C6 carbides at grain boundaries was associated with the limited carbon solubility in the austenitic matrix and the short-range diffusion of chromium atoms [3]. In turn, the Laves phase in austenitic steels can be precipitated dependently and independently as neighborhoods of other phases within the grains and at the grain boundaries. Precipitations of the Laves phase at grain boundaries were observed near the M23C6 carbides (Fig. 5b). In austenitic steel, the Laves phase particles nucleated in the neighborhood of either Si-enriched spots present in the bulky M23C6 carbides or to the grain boundary areas rich in silicon. This made the bulky M23C6 carbides gradually divide into small pieces, eventually forming a refined mixture of M23C6 and Laves phase at the grain boundaries [13]. The M23C6 carbides, in contrast, Laves phase precipitates, are characterized by relatively low thermodynamical stability [14], which results in them tending to grow relatively quickly (Fig. 6) and form a so-called continuous grid at the grain boundaries (Figs. 3, 5). The size and relative amount of particles precipitated at the grain boundaries increase with the ageing time, which is reflected in the increase in the widening of grain boundaries.

The M23C6 carbides are also observed at the twin boundaries. Still, their precipitation takes place at a later stage of ageing due to the lower energy of these boundaries (Fig. 3). The free surface energy of the incoherent twin boundary represents approximately 0.7 of the large-angle boundary. In contrast, the coherent boundary represents approximately 0.2–0.3 [15].

For longer ageing times, both at 700 and 750 °C, the occurrence of morphologically different precipitates are observed at the grain boundaries. These particles were identified as intermetallic σ phase (Fig. 7), which were initially observed at the intersection of three-grain boundaries (which gather in the σ phase) as preferred sites for nucleation and growth [15]. Precipitation of σ phase particles at the interface of three-grain boundaries as the preferred places in austenitic steels was also reported by Zieliński [3] and Sourmail [15]. The nucleation rate and σ phase growth in austenitic steels depend mainly on the chromium content, where the higher content, the faster the precipitation of this phase. The rate of nucleation and the increase in the size of the σ phase precipitates are influenced by the content of carbide-forming elements such as titanium or niobium, as well as the content of silicon [3, 16]. The amount and size of precipitates of this phase increase with increasing ageing time, which results from the high coagulability of the σ phase (Fig. 8). The increase in the size of the σ phase is mainly achieved by the consumption of M23C6 carbides [15]. The disappearance of M23C6 carbides ‘releases’ C and/or N atoms, and the lack of solubility of these elements in σ phase leads to their enrichment of them at the near-boundary micro-areas. This results in the precipitation of M23C6 carbides within the grains and at the ends of the twin boundaries [3]. However, according to [17], the growth of the σ phase at the cost of M23C6 carbides results in the diffusion of carbon at the grain boundaries and a further increase in the size of other carbides of this type.

In addition to M23C6 carbides, Laves phase and σ phase precipitated at the grain boundaries at the longest ageing times, and G phase precipitates were also revealed (Fig. 9). Precipitations of the G phase in the tested steel were observed in the neighborhood of M23C6 carbides. Precipitates of the G phase in the tested steel were rich in iron, nickel and chromium, but also in silicon (Fig. 9c). As in the case of the σ phase, silicon also strongly affects the process of G phase precipitation. An increase in the content of this element in steel leads to a shortening of the incubation time of G phase precipitation [17].

Precipitations of the G phase in austenitic 321H steel after a long-term operation, in the order of 200,000 h at 540 °C, were reported by Purzyńska [18]. According to the authors of this paper [18], the precipitation of the G phase was related to the disappearance of M23C6 carbides precipitated at grain boundaries. Also, in [17], the authors indicate that the G phase precipitates in Ti and Nb-stabilized austenitic steels due to the in situ transformation of M23C6 since the G phase and M23C6 carbide have similar lattice constants. However, Vache [19] found the MC particles could transform into a G phase enriched with silicon and nickel atoms.

In addition to precipitation processes at the grain/twin boundaries, the ageing of Sanicro 25 also contributed to the precipitation of secondary phases that are different in terms of dispersion and morphology within the grains. These particles' relative amount and size increase with temperature and ageing time. The precipitates observed within the grains were distributed both randomly and systematically. In austenitic steels containing copper, the first precipitates occurring within the grains are those rich in this element, referred to as ε_Cu (Fig. 10). The precipitation of numerous, excellent, coherent Cu particles in austenitic steels takes place within the first hours of ageing [20]. The fast precipitation process and the high density of these precipitates (approx. 1022 m−3 [11]) in the steel microstructure are likely because of the low solubility of Cu in the steel. Heat treatment of austenitic steels contributes to the supersaturation of the solid solution with Cu, which will develop a high driving force for Cu to precipitate from the matrix at an ageing temperature. Also, ε_Cu /matrix low interphase energy lead to the quick formation of many particles [21]. The interphase energy of ε_Cu precipitates coherent with the matrix, which is approximately 0.017 J/m2 [20]. Thus, according to [21], it depends on manganese segregation to the interface of this phase and changes from 8.1 to 16.7 J/m2 after 10 and 10,000 h of ageing of Sanicro 25 steel at 700 °C, respectively.

The ε_Cu precipitates revealed in the tested steel were rich in copper but contained iron, nickel and chromium (Fig. 10c, d). The work [20] showed that the chemical composition of ε_Cu particles changes with ageing time. In the initial ageing period, these particles may contain only up to 20% of copper atoms, which increases to 90%.

In addition to the ε_Cu precipitates inside the grains, a fine-dispersive secondary Z-phase was revealed in the microstructure of the tested steel (Fig. 11). Dispersive precipitations of ε_Cu and Z-phase in aged Sanicro 25 steel were observed by both Zurek [6], Cempura [9] and Zhou [10]. Secondary Z-phase precipitates are mainly observed within the grains on dislocations, which not only leads to the dislocation pinning but also results in the formation of the characteristic arrangement of these particles (Fig. 12). The high dispersion and high stability of these secondary particles contribute to their beneficial effect on both the strength properties and creep resistance. The precipitation of the Z-phase in the microstructure of austenitic steels is mainly related to the in situ transformation of metastable NbX particles into the higher stability of the Z-phase [22].

The Laves phase precipitates are observed not only at the grain boundaries, but also within the grains as particles nucleating independently (Fig. 13). The shape of these precipitates—needle-like shape is related to the compromise between minimum distortion energy and the total surface energy, which translates into the precipitate/matrix interphase energy. In turn, the value of this energy affects the stability of the Laves phase precipitates coagulability [23]. Precipitations of the Laves phase inside grains in Sanicro 25 steel were observed by Zurek [6] and Rutkowski [7]. Zurek [6] reported particles nucleating independently inside grains. On the other hand, in Rutkowski [7], precipitations of the Laves phase nucleating heterogeneously on particles rich in niobium were reported. However, Suo et al. [13] showed these particles' presence in Sanicro 25 steel after 5665 h of creep at 700 °C. Precipitations of the Laves phase were observed on the grain boundaries near the M23C6 carbides and inside as particles nucleating independently and nucleating on the primary precipitates of the Z-phase. Stress and enrichment of the areas near the M23C6 carbides in silicon promoted phase formation [13].

In addition to the precipitates described above, compound complexes of precipitates were revealed in the test steel, consisting of primary Z-phase precipitates, Laves phase, and M23C6 carbides (Fig. 14), where the M23C6 particles and the Laves phase nucleate heterogeneously on the primary Z-phase precipitates. Similar heterogeneous nucleation and growth of M23C6 carbides and Laves phase precipitates on Z-phase primary particles were reported by Zurek [6] and Rutkowski [7] after oxidizing at 700 °C. Also, Suo [13] observed the formation of complex precipitates based on Z-phase primary particles in Sanicro 25 steel after creep.

The most promising nucleation sites are grain boundaries and precipitates (carbides and nitride). Heterogeneous nucleation of the secondary phase particles on the primary Z-phase precipitates may result from favorable crystalline relationships among the networks of precipitates, fluctuations in chemical composition, and higher activation energy for nucleation at the inter-crystalline boundaries compared to that inside the grain. The presence of precipitate-free zones (PFZs) near the grain boundaries was also revealed in the tested steel—Figs. 14a, 15. The zones are observed mainly in precipitation-hardened materials, e.g., austenitic [24] and ferritic [25] stainless steel, and also titanium [26] and aluminum [27] alloys. PFZs occur in the alloy because grain boundary precipitates coarsen more rapidly than those in bulk, forcing the elements from these areas to diffuse to growing precipitates. The formation of PFZs in Super 304H steel was associated with the precipitation and growth of the σ-phase particles at the grain boundaries [24]. The increase in the size of the σ phase causes the consumption of M23C6 carbides that precipitated at the grain boundaries near this phase. At the same time, the aggregation of the Cu phase at the interface between the σ phase and the austenitic matrix occurs. However, the work [25] demonstrated that the Laves phase coagulating at the grain boundaries contributed to the formation of PFZs.

In the test steel, we believed there is most likely a combination of these mechanisms, i.e., the creation of compound complexes (Fig. 14) and the precipitation and growth of the σ phase (Fig. 7) and also Laves phase, resulting in the formation and growth of the PFZ. The width of the PFZ depends not only on the service/ ageing temperature, type and stability of precipitates at the grain boundaries or the diffusion rate of the dominant component of the particles precipitated at the boundaries [24], but also on the construction of its grain boundary [28].

3.3 Properties of Sanicro 25 steel

Austenitic steels, including creep-resistant austenitic steels, are delivered in a supersaturated condition, which is reflected in the relatively low strength properties and good plasticity and toughness of these steels, which is due to the dominant solid solution-strengthening mechanism.

In general, the increase in the strength properties is linked to the reduction of dislocation mobility. In austenitic steels, the important mechanism causing the boundary growth is the solid solution-strengthening mechanism involving the precipitation of secondary dispersive phases. The impact of this mechanism is mainly related to the type, size, shape and dispersion of these secondary particles. At equal volume fractions, particles of nanometric dimensions (but larger than the critical average radius) and precipitates with a plate shape rather than a round shape increase the hardening level [29]. From the point of view of both the interaction of the precipitates with dislocations and their thermodynamic stability, the expected presence of particles coherent or semi-coherent with the matrix is essential. There is a high-energy strain between the secondary particles in the grain that remain coherent and/or semi-coherent with the matrix, which can strongly affect the block dislocation slip during plastic deformation [29].

The ageing process of the tested steel increased in yield stress (YS) and tensile strength (TS), as well as hardness (Figs. 16, 17), regardless of the ageing temperature. The increase in the value of these properties should be mainly caused by the precipitation strengthening of the ε_Cu and Z-phase particles (Figs. 10, 11) precipitate within the grains, and also the M23C6 carbides and Laves phase are observed at the grain boundaries (Figs. 4, 6).

The secondary dispersive precipitates within the grains constitute a considerable barrier to the free movement of dislocations and, to a predominant extent, contribute to significant hardening of the alloy (as precipitates in creep-resistant austenitic steels are too hard to be cut by dislocations [16]). The precipitates, with a coherent (semi-coherent) boundary and nanometric dispersion dimensions, mainly the ε_Cu and Z-phase, contribute to significant hardening of the test alloy. The pinning force of the Z-phase and ε_Cu at the initial ageing stage is approximately 130 and 65 MPa, respectively [11]. In turn, for M23C6 carbide, this value is approximately 30 MPa. This translates into 58, 28 and 9% fractions of the Z-phase, ε_Cu particles and M23C6 carbides in the precipitation hardening of the steel, respectively [11]. However, according to [30], the Z-phase precipitates are responsible for approximately 75% of the hardening in HR3C steel. In work [21], he showed that the important precipitate in Sanicro 25 steel is ε_Cu particles. These divisions constitute an impact as a barrier to distribution movement depending on the volume fraction and the average diameter. Ɛ_Cu particles, at the initial stage of ageing, act through the cutting mechanism and later through the bypassing mechanism due to their size being smaller than the critical average radius (which is 13 nm for such particles). This work [21] also indicated the negligibly small role of M23C6 carbides in the hardening of this material. Compared to the Z-phase precipitates and ε_Cu particles, the pinning force of M23C6 carbides is 10 and 27 times lower, respectively [30]. Therefore, it should be assumed that the increase in the strength properties of the tested steel is mainly due to the ε_Cu particles and the precipitation of the Z-phase.

However, for longer holding times, the secondary dispersive Z-phase particles show a relatively more dispersive form and higher stability compared to ε_Cu particles. It is also important that the Z-phase particles precipitate on dislocations (Fig. 12), resulting in their piling up. A significant increase in the size of ε_Cu precipitates is observed after approximately 3000 h of ageing at 700 °C, accompanied by a decrease in the density of precipitates by Oswald ripening phenomena [11]. The increase in the size of ε_Cu particles in Sanicro 25 steel aged for 5000 h at 700 °C was also reported in [8]. The increase in the size of these particles results in a significant reduction of the pinning effect of ε_Cu particles by approximately 50% while increasing the pinning force of the Z-phase and M23C6 by 14 and 5%, respectively [10]. The reduction of hardening due to the coagulation of ε_Cu particles is also compensated by the Laves phase precipitating within the grains (Fig. 6). The precipitation hardening by the Laves phase particles depends on the Si content in the steel. It can range between 41.1 and 72.8 MPa [31]. The increase in the volume fraction of M23C6 carbides, and the precipitation of the σ phase, can also counterbalance a small extent, the coagulation of dispersive particles [15]. A similar effect was seen in aged HR3C steel [3]. It should be assumed that the Laves phase precipitates at the grain boundaries also positively impact the strength [14]. Therefore, the continuous increase in the strength properties and hardness is most likely observed for an ageing temperature of 700 °C (Fig. 16). In turn, for 750 °C, the increase in the strength properties and hardness was seen until the ageing time of 5000 h, whereas further holding leads to an over-ageing effect (Fig. 17). Raising the ageing temperature increases the rate of the coagulation since the activity of substitution solute atoms increases. This leads to an increase in the size of particles (Figs. 6 and 8) and, according to Ostwald's rule of ripening, takes place at the expense of the number of particles and increases the free path of particle motion, which translates into a reduction of the pinning force of particles. The result of this is a progressive reduction in strength properties.

Regardless of the ageing temperature, changes in the strength properties and hardness are accompanied by a plasticity drop, specifically elongation. The reduction of plasticity of the test steel is related to the changes in the morphology of secondary precipitates. The precipitation of the M23C6 carbides and Laves phase particles at the boundaries contributes to a reduction in the strength cohesion of the grain boundaries and are easier to nucleate and spread along the grain boundaries. In addition, M23C6 carbides and Laves phase particles at the grain boundaries promote faster nucleation of cavities. Also, the precipitates within the grains themselves have a negative effect on plasticity. At the interphase boundary of primary precipitates, easy nucleation of microcracks may occur, while the needle morphology of Laves phase promotes a concentration of stress and the nucleation of cavities [31]. Also, the recovery and recrystallization of the matrix that takes place during the ageing and manifests themselves, among other things, in an increase in the grain size and decrease in the number of twins, have a negative effect not only on plasticity or ductility but also reduce the strength. Also, PFZs (Figs. 14a, 15) observed in the steel microstructure impact the mechanical properties. The absence of precipitates in this area indicates that it most likely has a lower hardness than inside the grain. Therefore, the preferential deformation occurs within PFZ in the initial stage of deformation. This causes lower elongation regardless of the level of proof stress.

Furthermore, the softness of a PFZ compared to the adjacent zones is much different, so cracks are likely to nucleate early at the boundaries. This leads to intergranular fracture, weakens the ductility, and reduces the tensile strength [32]. However, according to [26], in the alloy with a PFZ, the ease with which dislocations are generated, and the resulting dislocation pile-ups, lead to the reduction of the yield stress in this area. In turn, [27] indicates that a PFZ in the material does not affect yield strength. However, it does contribute to the reduction of ductility.

4 Conclusions

In conclusion, investigations into the changes in the microstructure and mechanical properties of Sanicro 25 austenitic steel after ageing at 700 and 750 °C at ageing times up to 30,000 h have been conducted. The tests performed allow the following conclusions to be drawn:

-

1.

In the as-received condition, the primary NbC and Z-phase particles are observed. However, long-term ageing leads to the precipitation of secondary phase particles in the steel microstructure, which were found to be M23C6, Laves phase, σ phase, and G phase at the grain boundaries, and ε_Cu, Z-phase, and Laves phase within the grains. At the same time, compound complexes of precipitates based on the primary Z-phase precipitates were revealed.

-

2.

In the steel microstructure, the presence of the PFZ was observed in the near-boundary areas of the grains for material ageing at both 700 and 750 °C. The formation of the PFZ in the tested steel was related to the precipitation processes at the grain boundaries and in the border areas.

-

3.

The increase in strength properties, the effect of over-ageing and the decrease in the plastic properties of the aged Sanicro 25 steel was associated with the precipitation and changes in the morphology of the secondary particles.

Data availability

The raw/processed data required to reproduce these findings cannot be shared at this time as the data also form part of an ongoing study.

References

Zieliński A, Wersta R, Sroka M. Analysis of the precipitation process of secondary phases after long-term ageing of the S304H steel. Bull Pol Acad Sci-Te. 2021;69(5): e137520. https://doi.org/10.24425/bpasts.2021.137520.

Golański G, Zieliński A, Sroka M, Słania J. The effect of service on microstructure and mechanical properties of HR3C heat-resistant austenitic stainless steel. Materials. 2020;13:1297. https://doi.org/10.3390/ma13061297.

Zieliński A, Golański G, Sroka M. Evolution of the microstructure and mechanical properties of HR3C austenitic stainless steel after ageing for up to 30,000 h at 650–750 °C. Mat Sci Eng A-Struct. 2020;796:1394. https://doi.org/10.1016/j.msea.2020.139944.

Chai G, Forsberg U. Sanicro 25: An advanced high-strength, heat-resistant austenitic stainless steel. In: Di Gianfrancesco WA, editor. Materials for ultra-supercritical and advanced ultra-supercritical power plants. Woodhead Publishing; 2017. p. 391–421.

Calmunger M, Chai G, Johansson S, Moverare J. Creep and fatigue interaction behavior in Sanicro 25 heat resistant austenitic stainless steel. T Indian I Met. 2016;69(2):337–42. https://doi.org/10.1007/s12666-015-0806-3.

Zurek J, Yang S-M, Lin D-Y, Huttel T, Singheiser L, Quadakkers WJ. Microstructural stability and oxidation behavior of Sanicro 25 during long-term steam exposure in the temperature range 600–750°C. Mater Corros. 2015;66:315–27. https://doi.org/10.1002/maco.201407901.

Rutkowski B, Gil A, Aguero A, Gonzalez V, Czyrska-Filemonowicz A. Microstructure, chemical- and phase composition of Sanicro 25 austenitic steel after oxidation in steam at 700°C. Oxid Met. 2018;89:183–95. https://doi.org/10.1007/s11085-017-9824-3.

EN ISO 643 Steels - Micrographic determination of the apparent grain size, 2012

Czempura G, Gil A, Aguero A, Gutierrez M, Kruk A, Czyrska-Filemonowicz A. Microstructural studies of the scale on Sanicro 25 after 25 000 h of oxidation in steam using advanced electron microscopy techniques. Surf Coat Tech. 2019;377:124901. https://doi.org/10.1016/j.surfcoat.2019.124901.

Zhou R, Zhu L, Liu Y, Lu Z, Chen L, Ma X. Microstructural evolution and the effect on hardness of Sanicro 25 welded joint base after creep at 973K. J Mater Sci. 2017;52:6161–72. https://doi.org/10.1007/s10853-017-0758-6.

Zhou R, Zhu L, Yang Y, Lu Z, Chen L. Microstructural evolution and the effect on hardness and impact toughness of Sanicro 25 welded joints after aging at 973K. Metall Mater Trans A. 2018;49:6290–307. https://doi.org/10.1007/s11661-018-4906-7.

Chen AY, Hu WF, Wang D, Zhu YK, Wang P, Yang H, Wang XY, Gu JF, Lu J. Improving the intergranular corrosion resistance of austenitic stainless steel by high density twinned structure. Scripta Mater. 2017;13:264–8. https://doi.org/10.1016/j.scriptamat.2016.11.032.

Suo J, Peng Z, Yang H, Chai G, Yu M. Formation of Laves phase in Sanicro 25 austenitic steel during creep-rupture test at 700°C. Metallogr Microstruct Anal. 2019;8(2):281–6. https://doi.org/10.1007/s13632-019-00529-0.

Chen SW, Zhang C, Xia ZX, Ishikawa H, Yang ZG. Precipitation behavior of Fe2Nb Laves phase on grain boundaries in austenitic heat resistant steels. Mat Sci Eng A-Struct. 2014;615:183–8. https://doi.org/10.1016/j.msea.2014.07.104.

Sourmail T. Precipitation in creep resistant austenitic stainless steel. Mater Sci Tech-Lond. 2001;14:1–14. https://doi.org/10.1179/026708301101508972.

Padilha F, Rios PR. Decomposition of austenite in austenitic stainless steels. ISIJ Int. 2002;42(4):325–37. https://doi.org/10.2355/isijinternational.42.325.

Wang JZ, Liu Z-D, Bao H-S, Cheng S-C. Evolution of precipitates of S31042 heat resistant steel during 700°C aging. J Iron Steel Res Int. 2013;20:113–21. https://doi.org/10.1016/s1006-706x(13)60186-7.

Purzynska H, Golański G, Zieliński A, Dobrzański J, Sroka M. Precipitation study in Ti-stabilized austenitic stainless steel after 207000 h of service. Mater High Temp. 2019;36:296–303. https://doi.org/10.1080/09603409.2018.1546919.

Vaché N, Steyer P, Duret-Thual C, Perez M, Douillard T, Rauch E, Véron M, Renou G, Dupoiron F, Augustin C, Cazottes S. Microstructural study of the NbC to G-phase transformation in HP-Nb alloys. Materialia. 2020;9:100593. https://doi.org/10.1016/j.mtla.2020.100593.

Chi C, Yu H, Dong J, Liu W, Cheng S, Liu Z, Xie X. The precipitation strengthening behavior of Cu-rich phase in Nb contained advanced Fe–Cr–Ni type austenitic heat resistant steel for USC power plant application. Prog Nat Sci. 2012;22(3):175–85. https://doi.org/10.1016/j.pnsc.2012.05.002.

Zhou R, Zhu L. Growth behavior and strengthening mechanism of Cu-rich particles in Sanicro 25 austenitic heat-resistant steel after aging at 973 K. Mat Sci Eng A-Struct. 2020;796:1373. https://doi.org/10.1016/j.msea.2020.139973.

Li Y, Liu Y, Liu Ch, Li Ch, Li H. Mechanism for the formation of Z-phase in 25Cr-20Ni-Nb-N austenitic stainless steel. Mater Lett. 2018;233:16–9. https://doi.org/10.1016/j.matlet.2018.08.141.

Chiu Y-T, Lin C-K. Effects of Nb and W additions on high-temperature creep properties of ferritic stainless steels for solid oxide fuel cell interconnect. J Power Sour. 2012;198:149–57. https://doi.org/10.1016/j.jpowsour.2011.09.056.

Sawada K, Hatakeyama T, Sekido K, Kimura K. Microstructural changes and creep-strength degradation in 18Cr-9Ni-3Cu-Nb-N steel. Mater Charact. 2021;178:111286. https://doi.org/10.1016/j.matchar.2021.111286.

Liu H, Wei L, Ma M, Zheng J, Chen L, Misra RDK. Laves phase precipitation behavior and high-temperature strength of W-containing ferritic stainless steel. J Mater Res Tech. 2020;9:2127–35. https://doi.org/10.1016/j.jmrt.2019.12.043.

Lütjering G, Albrecht J, Sauer C, Krull T. The influence of soft, precipitate- free zones at grain boundaries in Ti and Al alloys on their fatigue and fracture behavior. Mat Sci Eng A-Struct. 2007;468–470:201–9. https://doi.org/10.1016/j.msea.2006.07.168.

Ryum N. The influence of a precipitate-free zone on the mechanical properties of an Al-Mg-Zn alloy. Acta Metall Mater. 1968;16:327–322. https://doi.org/10.1016/0001-6160(68)90018-7.

Cai B, Adams BL, Nelson TW. Relation between precipitate free zone with and grain boundary type in 7075–T7 Al alloy. Acta Mater. 2007;55:1543–53. https://doi.org/10.1016/j.actamat.2006.10.015.

Ahmadi MR, Povoden-Karadeniz E, Sonderegger B, Öksüz KI, Falahati A, Kozeschnik E. A model for coherency strengthening of large precipitates. Scripta Mater. 2014;84:47–50. https://doi.org/10.1016/j.scriptamat.2014.04.019.

Peng B, Zhang H, Hong J, Gao J, Zhang H, Li J, Wang Q. The evolution of precipitates of 22Cr-25Ni-Mo-Nb-N heat-resistant austenitic steel in long term creep. Mat Sci Eng A-Struct. 2010;527:4424–30. https://doi.org/10.1016/j.msea.2010.03.089.

Zhang Y, He H, Wang H, Chen G, An X, Wang Y. Evolution of microstructure and mechanical properties of 9Cr ferrite/martensite steels with different Si content after long-term aging at 550 °C. J Alloy Compd. 2021;873:159817. https://doi.org/10.1016/j.jallcom.2021.159817.

Liu CM, Wang HM, Tian XJ, Tang HB. Subtransus triplex heat treatment of laser melting deposited Ti–5Al–5Mo–5V–1Cr–1Fe near β titanium alloy. Mat Sci Eng A-Struct. 2014;604:176–82. https://doi.org/10.1016/j.msea.2013.10.002.

Acknowledgements

The results in this publication were obtained as a part of research co-financed by the National Science Centre under contract 2011/01/D/ST8/07219—Project: “Creep test application to model lifetime of materials for modern power generation industry”, and co-financed rector's grant in the area of scientific research and development works, Silesian University of Technology, 10/010/RGJ23/1142.

Funding

Narodowe Centrum Nauki, 2011/01/D/ST8/07219, Adam Zieliński, Silesian University of Technology, 10/010/RGJ23/1142, Marek Sroka.

Author information

Authors and Affiliations

Contributions

MS: conceptualization, writing—original draft, investigation, resources. AZ: formal analysis, visualization, writing—review and editing. GG: formal analysis, investigation, writing—review. MP: investigation, data analysis. HP: investigation, data analysis. FN: investigation.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Sroka, M., Zieliński, A., Golański, G. et al. Evolution of the microstructure and mechanical properties of Sanicro 25 austenitic stainless steel after long-term ageing. Archiv.Civ.Mech.Eng 23, 149 (2023). https://doi.org/10.1007/s43452-023-00690-y

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s43452-023-00690-y