Abstract

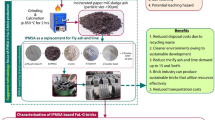

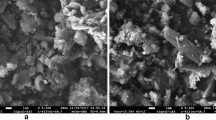

The experimental study investigates the feasibility of using two extensively waste (wastewater treatment sludge and oak wood ash) as raw materials in the manufacture of clay-free bricks. The wastes were characterized by particle-size distribution, chemical composition (EDX), X-ray diffraction (XRD), thermal analysis, and scanning electron microscopy (SEM). The oak wood ash replaced the water treatment sludge in different amounts (10–30 wt.%) in brick manufacture. The properties of clay-free green building brick were compared with the conventional bricks (obtained by standard methods). The properties depended of waste proportion. The 30 wt.% oak wood ash content achieved increase apparent porosity, with direct effect over water absorption and decreasing compressive strength. By replacing the water treatment sludge with oak wood ash, the CaO content increased, with negative effect over efflorescence on the surface; however, for 30 wt.% oak wood ash is below the imposed limits. Amounts of heavy metals in the leachates of fired samples are observed below the specified limits of the EPA (Environment Protection Authority). Additionally, the clay-free green bricks showed properties similar to the commercial bricks and improved thermal conductivity. The bricks containing 80 wt.% wastewater treatment sludge and 20 wt.% oak wood ash fulfilled standard requirements for clay masonry materials.

Similar content being viewed by others

References

Erdogmus E, Harja M, Gencel O, Sutcu M, Yaras A. New construction materials synthesized from water treatment sludge and fired clay brick wastes. J Build Eng. 2021;42: 102471. https://doi.org/10.1016/j.jobe.2021.102471.

Ibrahim JEF, Kotova OB, Sun S, Kurovics E, Tihtih M, Gömze LA. Preparation of innovative eco-efficient composite bricks based on zeolite-poor rock and Hen’s eggshell. J Build Eng. 2021. https://doi.org/10.1016/j.jobe.2021.103491.

Ibrahim JEF, Tihtih M, Gömze LA. Environmentally-friendly ceramic bricks made from zeolite-poor rock and sawdust. Constr Build Mater. 2021;297: 123715. https://doi.org/10.1016/j.conbuildmat.2021.123715.

Riaz MH, Khitab A, Ahmed S. Evaluation of sustainable clay bricks incorporating brick kiln dust. J Build Eng. 2019;24: 100725. https://doi.org/10.1016/j.jobe.2019.02.017.

Hoła A. Methodology for the in situ testing of the moisture content of brick walls: an example of application. Archiv Civ Mech Eng. 2020;20:114. https://doi.org/10.1007/s43452-020-00120-3.

Heniegal AM, Ramadan MA, Naguib A, Agwa IS. Study on properties of clay brick incorporating sludge of water treatment plant and agriculture waste. Case Stud Constr Mater. 2020;13: e00397. https://doi.org/10.1016/j.cscm.2020.e00397.

Gencel O, Munir MJ, Kazmi SMS, Sutcu M, Erdogmus E, Velasco PM, Quesada DE. Recycling industrial slags in production of fired clay bricks for sustainable manufacturing. Ceram Int. 2021;47:30425–38. https://doi.org/10.1016/j.ceramint.2021.07.222.

Akintola GO, Amponsah-Dacosta F, Mhlongo SE. Geotechnical evaluation of clayey materials for quality burnt bricks. Heliyon. 2020;6: e05626. https://doi.org/10.1016/j.heliyon.2020.e05626.

Munir MJ, Kazmi SMS, Gencel O, Ahmad MR, Chen B. Synergistic effect of rice husk, glass and marble sludges on the engineering characteristics of eco-friendly bricks. J Build Eng. 2021;42: 102484. https://doi.org/10.1016/j.jobe.2021.102484.

Eliche-Quesada D, Felipe-Sesé MA, López-Pérez JA, Infantes-Molina A. Characterization and evaluation of rice husk ash and wood ash in sustainable clay matrix bricks. Ceram Int. 2017;43:463–75. https://doi.org/10.1016/j.ceramint.2016.09.181.

De Silva GS, Surangi MLC. Effect of waste rice husk ash on structural, thermal and run-off properties of clay roof tiles. Constr Build Mater. 2017;154:251–7. https://doi.org/10.1016/j.conbuildmat.2017.07.169.

Hegazy BE, Fouad HA, Hassanain AM (2012) Brick manufacturing from water treatment sludge and rice husk ash. Aus J Bas Appl Sci 6: 453–461. https://sswm.info/node/4027

Ramadan MO, Fouad HA, Hassanain MA. Reuse of water treatment plant sludge in brick manufacturing. J Appl Sci Res. 2008;4:1223–9.

Kizinievič O, Kizinievič V, Pundiene I, Molotokas D. Eco-friendly fired clay brick manufactured with agricultural solid waste. Arch Civ Mech Eng. 2018;18(4):1156–65. https://doi.org/10.1007/s43452-020-00120-3.

Saleem MA, Kazmi SMS, Abbas S. Clay bricks prepared with sugarcane bagasse and rice husk ash—a sustainable solution. MATEC Web Conf. 2017;120:03001. https://doi.org/10.1051/matecconf/201712003001.

Srisuwan A, Sompech S, Saengthong C, Thaomola S, Chindraprasirt P, Phonphuak N. Preparation and properties of fired clay bricks with added wood ash. J Met Mater Miner. 2020;30:84–9.

Kotova OB, Ignatiev GV, Shushkov DA, Harja M, Broekmans MA. Preparation and properties of ceramic materials from coal fly ash. In: Minerals: structure, properties methods of investigation. Cham: Springer; 2020. p. 101–7.

Maraveas C. Production of sustainable construction materials using agro-wastes. Materials. 2020;13:262. https://doi.org/10.3390/ma13020262.

Barbuta M, Diaconescu RM, Harja M. Using neural networks for prediction of properties of polymer concrete with fly ash. J Mater Civil Eng. 2012;24:523–8. https://doi.org/10.1061/(ASCE)MT.1943-5533.0000413.

Ramachandra R, Mandal S. Prediction of fly ash concrete compressive strengths using soft computing techniques. Comput Concr. 2020;25:83–94. https://doi.org/10.12989/cac.2020.25.1.083.

Li Y, Liu X, Li Z, Ren Y, Wang Y, Zhang W. Preparation, characterization and application of red mud, fly ash and desulfurized gypsum based eco-friendly road base materials. J Clean Prod. 2021;284: 124777. https://doi.org/10.1016/j.jclepro.2020.124777.

Harja M, Cimpeanu SM, Dirja M, Bucur D (2016) Synthesis of zeolite from fly ash and their use as soil amendment. Zeolites: useful minerals, pp. 43–66. https://www.intechopen.com/chapters/51961

Fořt J, Šál J, Ševčík R, Doleželová M, Keppert M, Jerman M, Černý R. Biomass fly ash as an alternative to coal fly ash in blended cements: functional aspects. Constr Build Mater. 2021;271: 121544. https://doi.org/10.1016/j.conbuildmat.2020.121544.

Alabduljabbar H, Benjeddou O, Soussi C, Khadimallah MA, Alyousef R. Effects of incorporating wood sawdust on the firing program and the physical and mechanical properties of fired clay bricks. J Build Eng. 2021;35: 102106. https://doi.org/10.1016/j.jobe.2020.102106.

Ikotun BD, Raheem AA. Characteristics of wood ash cement mortar incorporating green-synthesized nano-TiO2. Int J Concr Struct Mater. 2021;15:1–9. https://doi.org/10.1186/s40069-021-00456-x.

Raju K, Ravindhar S. Multiple categories of bricks used for construction—a review. IOP Conf Series: Mat Sci Eng. 2020;993: 012122. https://doi.org/10.1088/1757-899X/993/1/012122.

Girondi GD, Marvila MM, de Azevedo ARG, de Souza C, Souza D, de Brito J, Vieira CM. Recycling potential of powdered cigarette waste in the development of ceramic materials. J Mater Cycles Waste Manag. 2020;22:1672–81. https://doi.org/10.1007/s10163-020-01058-7.

Huang C, Pan JR, Liu Y. Mixing water treatment residual with excavation waste soil in brick and artificial aggregate making. J Environ Eng. 2005;131:272–7. https://doi.org/10.1061/(ASCE)0733-9372(2005)131:2(272).

Deighton HD, Watmough SA, Basiliko N, Hazlett PW, Reid CR, Gorgolewski A. Trace metal biogeochemical responses following wood ash addition in a northern hardwood forest. Can J For Res. 2021;51:817–33. https://doi.org/10.1139/cjfr-2020-0320.

Mañosa J, Cerezo-Piñas M, Maldonado-Alameda A, Formosa J, Giro-Paloma J, Rosell JR, Chimenos JM. Water treatment sludge as precursor in non-dehydroxylated kaolin-based alkali-activated cements. Appl Clay Sci. 2021;204: 106032. https://doi.org/10.1016/j.clay.2021.106032.

Liu C, Chen J. High temperature degradation mechanism of concrete with plastering layer. Materials. 2022;15:398. https://doi.org/10.3390/ma15020398.

Buema G, Lisa G, Kotova O, Ciobanu G, Ivaniciuc L, Favier L, Harja M. Application of thermal analysis to improve the preparation conditions of zeolitic materials from flying ash. Env Eng Manag J. 2021;20:377–88.

Bülbül S, Akçakale N, Yasar M, Gökmese H. The effect of wood ash on the mechanical properties of rubber compounds. Mater Tehnol. 2019;53:333–9.

ASTM-C20. Standard test methods for apparent porosity, water absorption, apparent specific gravity, and bulk density of burned refractory brick and shapes by boiling water. West Conshohocken, PA: ASTM C20-00; 2015.

ASTM C67/C67M-20. Standard test methods for sampling and testing brick and structural clay tile. West Conshohocken, PA: American Society of Testing Materials; 2020.

Sutcu M, Alptekin H, Erdogmus E, Er Y, Gencel O. Characteristics of fired clay bricks with waste marble powder addition as building materials. Constr Build Mater. 2015;82:1–8. https://doi.org/10.1016/j.conbuildmat.2015.02.055.

Yaras A, Sutcu M, Gencel O, Erdogmus E. Use of carbonation sludge in clay based building materials processing for eco-friendly, lightweight and thermal insulation. Constr Build Mater. 2019;224:57–65. https://doi.org/10.1016/j.conbuildmat.2019.07.080.

TS EN 771-1 (2005) Specification for masonry units—part 1: clay masonry units

https://www.quantity-takeoff.com/variations-among-1st-class-2nd-class-and-3rd-class-bricks.htm (Accessed 24.01.2022)

Sutcu M. Influence of expanded vermiculite on physical properties and thermal conductivity of clay bricks. Ceram Int. 2015;41:2819–27. https://doi.org/10.1016/j.ceramint.2014.10.102.

SR EN 771-1:2003/A1:2005: https://www.utilul.ro/continut/documente/3214_dp-41.1-p63_335.pdf (Accessed 24.01.2022)

Nhabih HT, Arat KK, Haidi AS. Methods of processing efflorescence of clay Brick. Int J Scient Eng Sci. 2020;3:48–56.

Environmental Protection Agency (US). Code of federal regulations, Section 261.24—toxicity characteristic. Washington, DC: National Archives and Records Administration; 2012.

Funding

This research received no external funding.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Harja, M., Gencel, O., Sarı, A. et al. Production and characterization of natural clay-free green building brick materials using water treatment sludge and oak wood ash. Archiv.Civ.Mech.Eng 22, 79 (2022). https://doi.org/10.1007/s43452-022-00400-0

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s43452-022-00400-0