Abstract

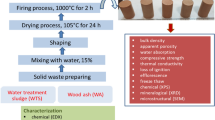

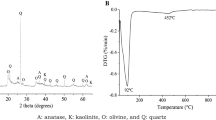

This paper aims to study the effect of adding sludge from wastewater treatment plants (WWTPs) in Eastern Algiers on swelling clay brick as a natural substitute for a degreaser to valorize it and minimise the risks related to its storage. First, physico-chemical analyses for clay and dried sludge were carried out using X-ray fluorescence (XRF), Scanning Electron Microscopy (SEM) analysis, Atterberg limits, and laser granulometry. Cylindrical brick specimens were prepared by compaction at 10 MPa, incorporating 0%, 5%, 10%, and 15% of dried sludge depending on the weight of the clay, then fired at 600 °C, 800 °C, and 1000 °C. Brick density, mass absorption, porosity, and compressive strength were evaluated at different temperatures for each sludge dosage. The results show that adding dried sludge to swelling clay improves compressive strength and reduces shrinkage. In contradiction to what has been published in the literature. The addition of 5% sludge to the weight of the clay in the brick composition fired at 800 °C resulted in the highest compressive strength of 32.26 MPa, twice the control bricks' compressive strength. Therefore, using sewage sludge from WWTPs in brick production is an essential sustainable development choice that benefits both the environment and the economy.

Similar content being viewed by others

References

Andreola NM, Barbieri L, Lancellotti I, Pozzi P (2005) Recycling industrial waste in brick manufacture. Part 1. Materiales De Construccion. https://doi.org/10.3989/mc.2005.v55.i280.202

Donguy G, Chenon P (2017) Ecotoxicological risk assessment for the spreading of limed WWTP sludge on agricultural land. DST. https://doi.org/10.4267/dechets-sciences-techniques.3643

Romero C, Ramos P, Costa C, Márquez MC (2013) Raw and digested municipal waste compost leachate as potential fertilizer: comparison with a commercial fertilizer. J Clean Prod. https://doi.org/10.1016/j.jclepro.2013.06.044

Urban RC, Isaac RdDL (2018) WTP and WWTP sludge management: a case study in the metropolitan area of Campinas, southeastern Brazil. Environ Monit Assess. https://doi.org/10.1007/s10661-018-6972-0

Martínez-García C, Eliche-Quesada D, Pérez-Villarejo L, Iglesias-Godino F, Corpas-Iglesias F (2012) Sludge valorization from wastewater treatment plant to its application on the ceramic industry. J Environ Manag. https://doi.org/10.1016/j.jenvman.2011.06.016

Algerian standard NA 17671 (2010) Fertilizing materials, sludge from urban wastewater treatment plants, names and specifications. Adoption of NF U44–041 1985. https://www.boutique.afnor.org/en-gb/standard/nf-u44041/fertilizers-and-soil-conditioners-sludge-resulting-from-the-treatment-of-se/fa017120/13728

NA (2013) 442, Cements: composition, specifications and conformity criteria for common cements. Ministère de l'Industrie et des Mines. Algeria

EN (2016) 196–1, Methods of testing cement - part 1: determination of strength. European Committee for Standardization (CEN)

Liu M, Liu X, Wang W, Guo J, Zhang L, Zhang H (2018) Effect of SiO2 and Al2O3 on characteristics of lightweight aggregate made from sewage sludge and river sediment. Ceram Int. https://doi.org/10.1016/j.ceramint.2017.12.022

Liew AG, Idris A, Samad AA, Wong CHK, Jaafar MS, Baki AM (2004) Reusability of sewage sludge in clay bricks. J Mater Cycles Waste Manag. https://doi.org/10.1007/s10163-003-0105-7

Kadir AA, Salim NSA, Sarani NA, Rahmat NAI, Abdullah MMAB (2017) Properties of fired clay brick incorporating with sewage sludge waste. AIP Conf Proc. https://doi.org/10.1063/1.5002344

Areias I, Vieira C, Manhães R, Intorne A (2017) Incorporação de lodo da estação de tratamento de esgoto (ETE) em cerâmica vermelha. Cerâmica. https://doi.org/10.1590/0366-69132017633672004

Lin D-F, Weng C-H (2001) Use of sewage sludge ash as brick material. J Environ Eng. https://doi.org/10.1061/(ASCE)0733-9372(2001)127:10(922)

Cusidó JA, Cremades LV (2012) Environmental effects of using clay bricks produced with sewage sludge: leachability and toxicity studies. Waste Manag. https://doi.org/10.1016/j.wasman.2011.12.024

Eliche-Quesada D, Martínez-García C, Martínez-Cartas M, Cotes-Palomino M, Pérez-Villarejo L, Cruz-Pérez N, Corpas-Iglesias F (2011) The use of different forms of waste in the manufacture of ceramic bricks. Appl Clay Sci. https://doi.org/10.1016/j.clay.2011.03.003

Esmeray E, Atıs M (2019) Utilization of sewage sludge, oven slag and fly ash in clay brick production. Constr Build Mater. https://doi.org/10.1016/j.conbuildmat.2018.10.231

Montero MA, Jordán M, Hernández-Crespo M, Sanfeliu T (2009) The use of sewage sludge and marble residues in the manufacture of ceramic tile bodies. Appl Clay Sci. https://doi.org/10.1016/j.clay.2009.10.013

Wang Z, Li B, Liang X (2022) Utilization of river sediment, sewage sludge and wheat straw as the primary raw material in sintered-shale bricks. J Mater Cycles Waste Manag. https://doi.org/10.1007/s10163-022-01487-6

Zat T, Bandieira M, Sattler N, Segadães AM, Cruz RC, Mohamad G, Rodríguez ED (2021) Potential re-use of sewage sludge as a raw material in the production of eco-friendly bricks. J Environ Manag. https://doi.org/10.1016/j.jenvman.2021.113238

Chen Z, Poon CS (2017) Comparative studies on the effects of sewage sludge ash and fly ash on cement hydration and properties of cement mortars. Constr Build Mater. https://doi.org/10.1016/j.conbuildmat.2017.08.003

Krejcirikova B, Ottosen LM, Kirkelund GM, Rode C, Peuhkuri R (2019) Characterization of sewage sludge ash and its effect on moisture physics of mortar. J Build Eng. https://doi.org/10.1016/j.jobe.2018.10.021

Liu M, Zhao Y, Yu Z (2021) Effects of sewage sludge ash produced at different calcining temperatures on pore structure and durability of cement mortars. J Mater Cycles Waste Manag. https://doi.org/10.1007/s10163-021-01174-y

Naamane S, Rais Z, Taleb M (2016) The effectiveness of the incineration of sewage sludge on the evolution of physicochemical and mechanical properties of Portland cement. Constr Build Mater. https://doi.org/10.1016/j.conbuildmat.2016.02.121

Naamane S, Rais Z, Taleb M (2013) Influence of the addition of the sludge obtained after wastewater treatment on the physico-chemical characteristics of cements. Mater Tech. https://doi.org/10.1051/mattech/2014001

Alleman JE, Berman NA (1984) Constructive sludge management: biobrick. J Environ Eng. https://doi.org/10.1061/(ASCE)0733-9372(1984)110:2(301)

Lynn CJ, Dhir RK, Ghataora GS (2016) Sewage sludge ash characteristics and potential for use in bricks, tiles and glass ceramics. Water Sci Technol. https://doi.org/10.2166/wst.2016.040

Tay J-H (1987) Bricks manufactured from sludge. J Environ Eng. https://doi.org/10.1061/(ASCE)0733-9372(1987)113:2(278)

Hua AK (1982) Use of sludge as a consturction material undergradrate thesis. Dept. of Civil Engineering. National University of Singapore, Singapore

Lin D-F, Luo H-L, Zhang S-W (2007) Effects of Nano-SiO2 on tiles manufactured with clay and incinerated sewage sludge ash. J Mater Civ Eng 19:801–808

Weng C-H, Lin D-F, Chiang P-C (2003) Utilization of sludge as brick materials. Adv Environ Res. https://doi.org/10.1016/S1093-0191(02)00037-0

Amin SK, Abdel Hamid E, El-Sherbiny S, Sibak H, Abadir M (2018) The use of sewage sludge in the production of ceramic floor tiles. HBRC J. https://doi.org/10.1016/j.hbrcj.2017.02.002

Chiang K-Y, Chou P-H, Hua C-R, Chien K-L, Cheeseman C (2009) Lightweight bricks manufactured from water treatment sludge and rice husks. J Hazard Mater. https://doi.org/10.1016/j.jhazmat.2009.05.144

Monteiro S, Alexandre J, Margem J, Sánchez R, Vieira C (2008) Incorporation of sludge waste from water treatment plant into red ceramic. Constr Build Mater. https://doi.org/10.1016/j.conbuildmat.2007.01.013

Ukwatta A, Mohajerani A, Setunge S, Eshtiaghi N (2015) Possible use of biosolids in fired-clay bricks. Constr Build Mater 91:86–93

Sawadogo Y, Zerbo L, Sawadogo M, Seynou M, Gomina M, Blanchart P (2020) Characterization and use of raw materials from Burkina Faso in porcelain formulations. Results Mater. https://doi.org/10.1016/j.rinma.2020.100085

NF (2000) NF EN 12880: 2000. Sludge characterisation - Determination of dry matter and water content. https://www.boutique.afnor.org/fr-fr/norme/nf-en-12880/caracterisation-des-boues-determination-de-la-teneur-en-matiere-seche-et-de/fa045942/17897

NF (1998) NF P94-068: 1998. Measurement of the methylene blue adsorption capacity of a soil or rock material. https://www.boutique.afnor.org/fr-fr/norme/nf-p94068/sols-reconnaissance-et-essais-mesure-de-la-capacite-dadsorption-de-bleu-de-/fa043689/394

NF (2017) NF ISO 11272: 2017. Soil quality - Determination of dry bulk density. https://www.iso.org/fr/standard/68255.html

NF (2017) NF EN ISO 11508: 2017. Soil quality - Determination of particle density. https://www.boutique.afnor.org/fr-fr/norme/nf-en-iso-11508/qualite-du-sol-determination-de-la-masse-volumique-des-particules/fa186760/80628

NF (2010) NF P18-459: 2010. Test for hardened concrete - porosity and density test. https://www.boutique.afnor.org/fr-fr/norme/nf-p18459/beton-essai-pour-beton-durci-essai-de-porosite-et-de-masse-volumique/fa160729/34961

El-Fgaier F (2013) Conception, production and qualification of fired and unfired clay bricks. Ecole Centrale de Lille, Villeneuve-d’Ascq

Jeans CEEPD (1989) Clay minerals for geologists and petroleum engineers. SEPM Short Course vol. 3: Tulsa: Société des paléontologues et minéralogistes économiques. Geol Mag 126(3):324. https://doi.org/10.1017/S0016756800022718

Alcântara ACS, Beltrão M, Oliveira H, Gimenez IF, Barreto L (2008) Characterization of ceramic tiles prepared from two clays from Sergipe—Brazil. Appl Clay Sci. https://doi.org/10.1016/j.clay.2007.05.004

Wetshondo Osomba D (2012) Characterisation and valorisation of clay materials from the Province of Kinshasa (DR Congo). Université de Liège, Liège

Benoudjit F (2016) Characterisation and valorisation of sludge from a sewage treatment plant. Case study ONA boumerdès (STEP Boumerdès). DOCTORAT Thèse de Doctorat, Faculté des Sciences de l’Ingénieur, UNIVERSITE M’HAMED BOUGARA-BOUMERDES

El Fgaier F, Lafhaj Z, Antczak E, Chapiseau C (2016) Dynamic thermal performance of three types of unfired earth bricks. Appl Therm Eng. https://doi.org/10.1016/j.applthermaleng.2015.09.009

Samara M, Lafhaj Z, Chapiseau C (2009) Valorization of stabilized river sediments in fired clay bricks: factory scale experiment. J Hazard Mater. https://doi.org/10.1016/j.jhazmat.2008.07.153

Benoudjit F (2016) Caractérisation et valorisation des boues issues d’un office d’assainissement. Université M’Hamed Bougara: Faculté des sciences de l’ingénieur, Boumerdes

Lin K-L, Chiang K-Y, Lin D-F (2006) Effect of heating temperature on the sintering characteristics of sewage sludge ash. J Hazard Mater. https://doi.org/10.1016/j.jhazmat.2005.07.051

Jordán M, Sanfeliu T, De la Fuente C (2001) Firing transformations of Tertiary clays used in the manufacturing of ceramic tile bodies. Appl Clay Sci. https://doi.org/10.1016/S0169-1317(00)00044-2

Aklouche N (2009) Preparation and study of CORDIERITE and ANORTHITE compounds. Doctorat Sciences, Sciences des matériaux, Université MENTOURI Constantine Faculté des Sciences Exactes Département de Physique

Acknowledgements

The support of the Environment, Water, Geomechanics and Structures Laboratory (Faculty of Civil Engineering, University of Sciences and Technology Houari Boumediene, USTHB), Building Materials Laboratory, (Faculty of Civil Engineering, USTHB), Materials Science and Engineering Laboratory (Faculty of Mechanics, USTHB), CRAPC (Centre of Scientific and Technical Research in Physical and Chemical Analysis, Tipaza, Biskra, Algeria), CNERIB (National Centre for Integrated Building Studies and Research, Algiers, Algeria) and the LNHC ( National Laboratory of Housing and Construction, Algiers, Algeria) for their assistance in conducting the experimental work is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Mekbel, S., Debieche, M. & Nechnech, A. The potential of sludge from wastewater treatment plants to improve the mechanical properties of bricks. J Mater Cycles Waste Manag 25, 3286–3302 (2023). https://doi.org/10.1007/s10163-023-01752-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10163-023-01752-2