Abstract

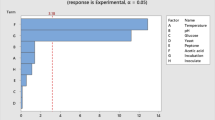

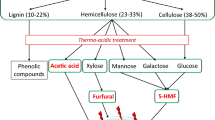

In the present study, Paenibacillus lautus strain BHU3 isolated from landfill soil was evaluated for the presence of potential endoglucanases which are the first candidate of cellulase enzyme system to act on cellulose. In-silico analysis revealed high potential thermostable endoglucanases which can efficiently interact with cellulose. The most potent and thermostable endoglucanase (locus tag id. CPZ30_18280) belonged to glycosyl family-5 and had interaction energy of − 12.981 kcal/mol for the best docked cluster containing three out of ten docking conformations, and Tm value of 73.3 °C. MD simulation of 100 ns proved highly stable binding interactions of CPZ30_18280 endoglucanase with cellulose with root mean square deviation (RMSD) values ranging from 0.15 to 0.30 nm. Consistent interactions with characteristic active site residues (tyrosine, tryptophan and aspartate) of glycosyl family-5 endoglucanases were found. Further, to enhance the production of endoglucanases, the fermentation conditions were optimized employing approaches like one factor at a time (OFAT) and response surface methodology (RSM). Maximum activity of endoglucanase was determined at 60 °C. The optimized conditions for enhanced production of endoglucanase (10.15 U/mL) were pH 6.63, yeast extract conc. 3.44 g/L, wheat bran 3.59%, and inoculum size 2.65%. Hence, P. lautus strain BHU3 has enormous potential to synthesize highly efficient thermostable endoglucanases under optimized regime using agro-wastes. Thus, it could find immense industrial applications including large scale cellulose conversion to bioethanol.

Similar content being viewed by others

Availability of data and materials

All data generated during this study have been incorporated in this communication either as main data or as a supplementary electronic file.

Code availability

Not applicable.

References

Sadhu S, Maiti TK. Cellulase production by bacteria: a review. Microbiol Res J. 2013;3:235–58.

Gastelum-Arellanez A, Paredes-López O, Olalde-Portugal V. Extracellular endoglucanase activity from Paenibacillus polymyxa BEb-40: production, optimization and enzymatic characterization. World J Microbiol Biotechnol. 2014;30:2953–65.

Pandey A. Biofuels: alternative feedstocks and conversion processes. Cambridge: Academic Press; 2011.

Maki M, Leung KT, Qin W. The prospects of cellulase-producing bacteria for the bioconversion of lignocellulosic biomass. Int J Biol Sci. 2009;5(5):500–16.

Zhang XZ, Zhang YHP. Cellulases: characteristics, sources, production, and applications, Bioprocessing technologies in biorefinery for sustainable production of fuels, chemicals, and polymers. Hoboken: Wiley; 2013. p. 131–46.

Balan V. Current challenges in commercially producing biofuels from lignocellulosic biomass. Int Sch Res Not. 2014;1:31.

Zhao C, Deng L, Fang H. Mixed culture of recombinant Trichoderma reesei and Aspergillus niger for cellulase production to increase the cellulose degrading capability. Biomass Bioenerg. 2018;112:93–8.

Ariffin H, Abdullah N, Kalsom MU, Shirai Y, Hassan M. Production and characterization of cellulase by Bacillus pumilus EB3. Int J Eng Technol. 2006;3(1):47–53.

Rastogi G, Bhalla A, Adhikari A, Bischoff KM, Hughes SR, Christopher LP, Sani RK. Characterization of thermostable cellulases produced by Bacillus and Geobacillus strains. Bioresour Technol. 2010;101(22):8798–806.

Patel MA, Ou MS, Ingram LO, Shanmugam K. Simultaneous saccharification and co-fermentation of crystalline cellulose and sugar cane bagasse hemicellulose hydrolysate to lactate by a thermotolerant acidophilic Bacillus sp. Biotechnol Prog. 2005;21(5):1453–60.

Zhuang J, Marchant MA, Nokes SE, Strobel HJ. Economic analysis of cellulase production methods for bio-ethanol. Appl Eng Agric. 2007;23(5):679–87.

Chellapandi P, Jani HM. Production of endoglucanase by the native strains of Streptomyces isolates in submerged fermentation. Braz J Microbiol. 2008;39(1):122–7.

Annamalai N, Rajeswari MV, Balasubramanian T. Enzymatic saccharification of pretreated rice straw by cellulase produced from Bacillus carboniphilus CAS 3 utilizing lignocellulosic wastes through statistical optimization. Biomass Bioenerg. 2014;68:151–60.

Deka D, Bhargavi P, Sharma A, Goyal D, Jawed M, Goyal A. Enhancement of cellulase activity from a new strain of Bacillus subtilis by medium optimization and analysis with various cellulosic substrates. Enzyme Res. 2011;2011:1–8.

Ma L, Lu Y, Yan H, Wang X, Yi Y, Shan Y, Liu B, Zhou Y, Lü X. Screening of cellulolytic bacteria from rotten wood of Qinling (China) for biomass degradation and cloning of cellulases from Bacillus methylotrophicus. BMC Biotechnol. 2020;20:1.

Cho KM, Hong SY, Lee SM, Kim YH, Kahng GG, Kim H, Yun HD. A cel44C-man26A gene of endophytic Paenibacillus polymyxa GS01 has multi-glycosyl hydrolases in two catalytic domains. Appl Microbiol Biotechnol. 2006;73(3):618–30.

Mormeneo M, Pastor FJ, Zueco J. Efficient expression of a Paenibacillus barcinonensis endoglucanase in Saccharomyces cerevisiae. J Ind Microbiol Biotechnol. 2012;39(1):115–23.

Akaracharanya A, Taprig T, Sitdhipol J, Tanasupawat S. Characterization of cellulase producing Bacillus and Paenibacillus strains from Thai soils. J Appl Pharm Sci. 2014;4(5):6.

Liang YL, Zhang Z, Wu M, Wu Y, Feng JX. Isolation, screening, and identification of cellulolytic bacteria from natural reserves in the subtropical region of China and optimization of cellulase production by Paenibacillus terrae ME27-1. Biomed Res Int. 2014;2014:1.

Madhaiyan M, Poonguzhali S, Saravanan VS, Duraipandiyan V, Al-Dhabi NA, Kwon SW, Whitman WB. Paenibacillus polysaccharolyticus sp. nov., a xylanolytic and cellulolytic bacteria isolated from leaves of Bamboo Phyllostachys aureosulcata. Int J Syst Evol Microbiol. 2017;67(7):2127–33.

Almuharef I, Rahman MS, Qin W. High production of cellulase by a newly isolated strain Paenibacillus sp. IM7. J Waste Biomass Valori. 2019;2019:1–10.

Yang L, Peplowski L, Shen Y, Yang H, Chen X, Shen W, Xia Y. Enhancing thermostability and activity of sucrose phosphorylase for high-level production of 2-O-α-D-glucosylglycerol. Syst Microbiol and Biomanuf. 2022. https://doi.org/10.1007/s43393-022-00090-y.

Zhou H, Zheng P, Chen P, Yu X, Wu D. Enhanced thermostability and catalytic efficiency of glucose oxidase in Pichia Pastoris. Syst Microbiol and Biomanuf. 2022;2:296–304.

Schaechter M. Encyclopedia of microbiology. Cambridge: Academic Press; 2009.

Nigam P, Singh D. Solid-state (substrate) fermentation systems and their applications in biotechnology. J Basic Microbiol. 1994;34(6):405–23.

Reczey K, Szengyel Z, Eklund R, Zacchi G. Cellulase production by T. reesei. Bioresour Technol. 1996;57(1):25–30.

Balusu R, Paduru RM, Seenayya G, Reddy G. Production of ethanol from cellulosic biomass by Clostridium thermocellum SS19 in submerged fermentation: screening of nutrients using Plackett-Burman design. Appl Biochem Biotechnol. 2004;117(3):133–41.

Stevenson L, Phillips F, O’Sullivan K, Walton J. Wheat bran: its composition and benefits to health, a European perspective. Int J Food Sci Nutr. 2012;63(8):1001–13.

Vasudeo Z, Lew C. Optimization of culture conditions for production of cellulase by a thermophilic Bacillus strain. J Chem Chemical Eng. 2011;5(6):521–7.

Li Y, Cui F, Liu Z, Xu Y, Zhao H. Improvement of xylanase production by Penicillium oxalicum ZH-30 using response surface methodology. Enzyme Microb Technol. 2007;40(5):1381–8.

Ferreira S, Duarte AP, Ribeiro MH, Queiroz JA, Domingues FC. Response surface optimization of enzymatic hydrolysis of Cistus ladanifer and Cytisus striatus for bioethanol production. Biochem Eng J. 2009;45(3):192–200.

Xu R, Ma S, Wang Y, Liu L, Li P. Screening, identification and statistic optimization of a novel exopolysaccharide producing Lactobacillus paracasei HCT. Afr J Microbiol Res. 2010;4:783–95.

Özer A, Gürbüz G, Çalimli A, Körbahti BK. Biosorption of copper (II) ions on Enteromorpha prolifera: application of response surface methodology (RSM). Chem Eng Technol. 2009;146(3):377–87.

Sreena CP, Sebastian D. Augmented cellulase production by Bacillus subtilis strain MU S1 using different statistical experimental designs. J Genet Eng Biotechnol. 2018;16(1):9–16.

Yadav S, Dubey SK. Cellulose degradation potential of Paenibacillus lautus strain BHU3 and its whole genome sequence. Bioresour Technol. 2018;262:124–31.

Yadav S, Pandey AK, Dubey SK. Molecular modeling, docking and simulation dynamics of β-glucosidase reveals high-efficiency, thermo-stable, glucose tolerant enzyme in Paenibacillus lautus BHU3 strain. Int J Biol Macromol. 2020;168:371–82.

Pucci F, Kwasigroch JM, Rooman M. SCooP: an accurate and fast predictor of protein stability curves as a function of temperature. J Bioinformatics. 2017;33(21):3415–22.

Jumper J, Evans R, Pritzel A, Green T, Figurnov M, Ronneberger O, Tunyasuvunakool K, Bates R, Žídek A, Potapenko A. Highly accurate protein structure prediction with AlphaFold. Nature. 2021;596(7873):583–9.

Krieger E, Joo K, Lee J, Lee J, Raman S, Thompson J, Tyka M, Baker D, Karplus K. Improving physical realism, stereochemistry, and side-chain accuracy in homology modeling: four approaches that performed well in CASP8. Proteins Struct Funct Bioinform. 2009;77(S9):114–22.

Schüttelkopf AW, Van Aalten DM. PRODRG: a tool for high-throughput crystallography of protein–ligand complexes. Acta Crystallogr D Biol Crystallogr. 2004;60(8):1355–63.

Teather RM, Wood PJ. Use of Congo red-polysaccharide interactions in enumeration and characterization of cellulolytic bacteria from the bovine rumen. Appl Environ Microbiol. 1982;43(4):777–80.

Ghose T. Measurement of cellulase activities. Pure Appl Chem. 1987;59(2):257–68.

López-Mondéjar R, Zühlke D, Becher D, Riedel K, Baldrian P. Cellulose and hemicellulose decomposition by forest soil bacteria proceeds by the action of structurally variable enzymatic systems. Sci Rep. 2016;6:25279.

Lee YJ, Kim BK, Lee BH, Jo KI, Lee NK, Chung CH, Lee YC, Lee JW. Purification and characterization of cellulase produced by Bacillus amyoliquefaciens DL-3 utilizing rice hull. Bioresour Technol. 2008;99(2):378–86.

Vasic K, Knez Z, Leitgeb M. Bioethanol production by enzymatic hydrolysis from different lignocellulosic sources. Molecules. 2021;26:1–23.

Ejaz U, Sohail M, Ghanemi A. Cellulases: from bioactivity to a variety of industrial applications. Biomimetics (Basel, Switzerl). 2021;6:1–11.

Lemos LN, Pereira RV, Quaggio RB, Martins LF, Moura L, da Silva AR, Antunes LP, da Silva AM, Setubal JC. Genome-centric analysis of a thermophilic and cellulolytic bacterial consortium derived from composting. Front Microbiol. 2017;8:644.

Wang W, Archbold T, Lam JJ. A processive endoglucanase with multi-substrate specificity is characterized from porcine gut microbiota. Sci Rep. 2019;9:1–13.

Petersen L, Ardèvol A, Rovira C, Reilly PJ. Mechanism of cellulose hydrolysis by inverting GH8 endoglucanases: a QM/MM metadynamics study. J Phys Chem. 2009;113(20):7331–9.

Abdel-Mawgoud AM, Aboulwafa MM, Hassouna NAH. Optimization of surfactin production by Bacillus subtilis Isolate BS5. Appl Biochem Biotechnol. 2008;150(3):305–25.

Reddy L, Wee YJ, Yun JS, Ryu HW. Optimization of alkaline protease production by batch culture of Bacillus sp. RKY3 through Plackett-Burman and response surface methodological approaches. Bioresour Technol. 2008;99(7):2242–9.

Sukumaran RK, Singhania RR, Pandey A. Microbial cellulases-production, applications and challenges. 2005.

Yin LJ, Huang PS, Lin HH. Isolation of cellulase-producing bacteria and characterization of the cellulase from the isolated bacterium Cellulomonas sp. YJ5. J Agric Food Chem. 2010;58(17):9833–7.

Swathy R, Rambabu K, Banat F, Ho SH, Chu DT, Show PL. Production and optimization of high grade cellulase from waste date seeds by Cellulomonas uda NCIM 2353 for biohydrogen production. Int J Hydrogen Energ. 2020;45(42):22260–70.

Waeonukul R, Kyu KL, Sakka K, Ratanakhanokchai K. Isolation and characterization of a multienzyme complex (cellulosome) of the Paenibacillus curdlanolyticus B-6 grown on Avicel under aerobic conditions. J Biosci Bioeng. 2009;107(6):610–4.

Asha BM, Revathi M, Yadav A, Sakthivel N. Purification and characterization of a thermophilic cellulase from a novel cellulolytic strain, Paenibacillus barcinonensis. J Microbiol Biotechnol. 2012;22(11):1501–9.

Paudel YP, Qin W. Characterization of novel cellulase-producing bacteria isolated from rotting wood samples. Appl Biochem Biotechnol. 2015;177(5):1186–98.

Tangüler H, Erten H. The effect of different temperatures on autolysis of baker’s yeast for the production of yeast extract. Turk J Agric For. 2009;33(2):149–54.

Mihajlovski KR, Davidović SZ, Carević MB, Radovanović NR, Šiler-Marinković SS, Rajilić-Stojanović MD, Dimitrijević-Branković SI. Carboxymethyl cellulase production from a Paenibacillus sp. Hemijska Industrija. 2016;70(3):329–38.

Almuharef I, Rahman MS, Qin W. High production of cellulase by a newly isolated strain Paenibacillus sp. IM7. J Waste Biomass Valoriz. 2019;11:1–10.

Sun S, Zhang Y, Liu K, Chen X, Jiang C, Huang M, Zang H, Li C. Insight into biodegradation of cellulose by psychrotrophic bacterium Pseudomonas sp. LKR-1 from the cold region of China: optimization of cold-active cellulase production and the associated degradation pathways. Cellulose. 2020;27(1):315–33.

Acknowledgements

Authors are gratefully acknowledged to Coordinator, Centre of Advanced Study, Botany, for providing essential facilities related to this study.

Funding

This research work was financially assisted by University Grants Commission, Government of India, New Delhi, in the form of Junior and Senior Research Fellowship to Suman (Grant No. 09/013 (0617)/2016-EMR-I).

Author information

Authors and Affiliations

Contributions

SKD: conceptualization, supervised the research work. SY: performed the research and analyzed the wet lab data. AKP: ran the MD simulations and analyzed the data. SY, AKP, SKD: writing and review the ms.

Corresponding author

Ethics declarations

Conflict of interest

The authors that declare there is no conflict of interest for the present manuscript.

Compliance with ethics requirements

This article does not contain any studies with human or any animals participants.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Yadav, S., Pandey, A.K. & Dubey, S.K. Evaluation of thermostable endoglucanase in Paenibacillus lautus strain BHU3 for yield enhancement. Syst Microbiol and Biomanuf 2, 607–622 (2022). https://doi.org/10.1007/s43393-022-00105-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s43393-022-00105-8