Abstract

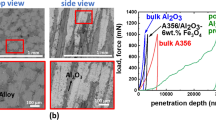

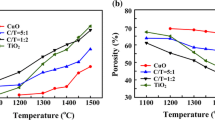

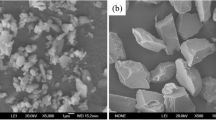

The synthesis of macro-porous calcium-hexaluminate (CaO∙6Al2O3, CA6) aggregates composed of CA6 platelets was examined using various Ca- and Al-precursors. The effects of annealing temperature, time, atmosphere, and AlF3 as a mineralizer on the formation of plate-shaped CA6 were also studied. The Ca:Al ratio was adjusted for full conversion to CA6, which is the most stable phase among the CaO-Al2O3 intermediate compounds. The conditions for the synthesis of plate-shaped CA6 aggregates with adequate strength were uncompromising, requiring heat treatment at ≥ 1500 °C for 15 h, which was also significantly affected by the type and size of the precursors. CA6 aggregate synthesized directly using coarse Al2O3 and CaO with 10 wt% CaO∙Al2O3 cement as a binder phase revealed the optimal macro-porous microstructure for castable refractory applications, showing porosity and compressive strength of 65% and 2.9 MPa, respectively.

Similar content being viewed by others

Data Availability

Data will be made available upon request.

References

Z. Chen, W. Yan, S. Schafföner, S. Ma, Y. Dai, N. Li, Effect of SiC powder content on lightweight corundum-magnesium aluminate spinel castables. J. Alloys Compd. 764, 210–215 (2018). https://doi.org/10.1016/j.jallcom.2018.06.062

B. Pacewska, M. Nowacka, Studies of conversion progress of calcium aluminate cement hydrates by thermal analysis method. J. Therm. Anal. Calorim. 117, 653–660 (2014). https://doi.org/10.1007/s10973-014-3804-5

Y. Zhang, G. Ye, W. Gu, D. Ding, L. Chen, L. Zhu, Conversion of calcium aluminate cement hydrates at 60°C with and without water. J. Am. Ceram. Soc. 101, 2712–2717 (2018). https://doi.org/10.1111/jace.15505

C. Domínguez, J. Chevalier, R. Torrecillas, L. Gremillard, G. Fantozzi, Thermomechanical properties and fracture mechanisms of calcium hexaluminate. J. Eur. Ceram. Soc. 21, 907–917 (2001). https://doi.org/10.1016/S0955-2219(00)00274-0

A. Utsunomiya, K. Tanaka, H. Morikawa, F. Marumo, H. Kojima, Structure refinement of CaO·6Al2O3, J. Solid State Chem. 75, 197–200 (1988). https://doi.org/10.1016/0022-4596(88)90317-9

R. Salomão, V.L. Ferreira, L.M.M. Costa, I.R. de Oliveira, Effects of the initial CaO-Al2O3 ratio on the microstructure development and mechanical properties of porous calcium hexaluminate. Ceram. Int. 44, 2626–2631 (2018). https://doi.org/10.1016/j.ceramint.2017.11.010

S. Jonas, F. Nadachowski, D. Szwagierczak, A new non-silicate refractory of low thermal expansion. Ceram. Int. 24, 211–216 (1998). https://doi.org/10.1016/S0272-8842(97)00004-7

A. Overhoff, A. Buhr, J. Grass, H.M. Wuthnow, New microporous materials for use in modern firing plants. Ceram. Forum Int. 82, 29–33 (2005)

D. Zacherl, M. Schnabel, A. Buhr, G. Büchel, R. Kockegey-Lorenz, J. Dutton, Advantages of calcium hexaluminate in a corrosive environment, Mater. Sci. Technol. Conf. Exhib. 2011, MST’11. 1, 87–94 (2011)

S. Kumar, R. Sarkar, Alumina-Spinel castable for steel ladles: an overview. Int. J. Appl. Ceram. Technol. 20, 410–423 (2023). https://doi.org/10.1111/ijac.14213

D. Holtstam, Iron in hibonite: a spectroscopic study. Phys. Chem. Miner. 23, 452–460 (1996). https://doi.org/10.1007/BF00202031

J. Sakihama, R. Salamão, Microstructure development in porous calcium hexaluminate and application as a high-temperature thermal insulator: a critical review. InterCeram: Int. Ceram. Rev. 68, 58–65 (2019). https://doi.org/10.1007/s42411-019-0034-7

L.P. Li, Y. Yan, X.Z. Fan, Z.H. Hu, C.Y. Zhao, Low-temperature synthesis of calcium-hexaluminate/magnesium-aluminum spinel composite ceramics. J. Eur. Ceram. Soc. 35, 2923–2931 (2015). https://doi.org/10.1016/j.jeurceramsoc.2015.03.041

Y. Wang, X. Li, B. Zhu, P. Chen, Microstructure evolution during the heating process and its effect on the elastic properties of CAC-bonded alumina castables. Ceram. Int. 42, 11355–11362 (2016). https://doi.org/10.1016/j.ceramint.2016.04.058

C.Y. Lee, S. Lee, J.H. Ha, J. Lee, I.H. Song, K.S. Moon, Effect of the processing conditions of reticulated porous alumina on the compressive strength. J. Korean Ceram. Soc. 58, 495–506 (2021). https://doi.org/10.1007/s43207-021-00128-2

S.I. Yun, S. Nahm, S.W. Park, Effects of the particle size composition of sintering additives on pore characteristics, flexural strength, and gas permeability of liquid-phase-bonded macroporous SiC. J. Korean Ceram. Soc. 58, 737–746 (2021). https://doi.org/10.1007/s43207-021-00148-y

C. Zeng, Z. Huang, J. Huang, Y. Li, Y. Xu, S. Yi, M. Fang, Y.G. Liu, Preparation of calcium hexaluminate using Al2O3 and white beach sand from western Australia. Key Eng. Mater. 512–515, 940–944 (2012). https://doi.org/10.4028/www.scientific.net/KEM.512-515.940

E.Y. Sako, M.A.L. Braulio, D.H. Milanez, P.O. Brant, V.C. Pandolfelli, Microsilica role in the CA6 formation in cement-bonded spinel refractory castables. J. Mater. Process. Technol. 209, 5552–5557 (2009). https://doi.org/10.1016/j.jmatprotec.2009.05.013

L. An, H.M. Chan, K.K. Soni, Control of calcium hexaluminate grain morphology in in-situ toughened ceramic composites. J. Mater. Sci. 31, 3223–3229 (1996). https://doi.org/10.1007/BF00354672

J. Khajornboon, K. Ota, K. Washijima, T. Shiono, Control of hexagonal plate-like microstructure of in-situ calcium hexaluminate in monolithic refractories. J. Asian Ceram. Soc. 6, 196–204 (2018). https://doi.org/10.1080/21870764.2018.1484621

F. Wang, X. Li, P. Chen, G.M. Kale, B. Zhu, The adjustment of CA6 morphology and its effect on the thermo-mechanical properties of high temperature composites. J. Ceram. Soc. Japan. 126, 977–983 (2018). https://doi.org/10.2109/jcersj2.18143

D.O. Obada, K.A. Salami, A.A. Alabi, A.N. Oyedeji, S. Csaki, T. Hulan, A.K. Meher, Mechanical behaviour of porous kaolin-based ceramics for potential catalysts support applications. J. Korean Ceram. Soc. 60, 99–112 (2023). https://doi.org/10.1007/s43207-022-00248-3

J. Talaber, Actual views on high alumina cement. Period Polytech. Civ. Eng. 17, 113–119 (1973)

D. Garsel, High alumina cements and chemical binders, Refract. Technol. Introd. Updat. Inst. Refract. Eng. 1–15 (1996)

H. Pöllmann, Calcium aluminate cements - raw materials, differences, hydration and properties. Rev. Mineral. Geochemistry. 74, 1–82 (2012). https://doi.org/10.2138/rmg.2012.74.1

H.S. Kim, N.K. Park, T.J. Lee, M. Kang, Effect of AlF3 seed concentrations and calcination temperatures on the crystal growth of hexagonally shaped α-alumina powders. Ceram. Int. 40, 3813–3818 (2014). https://doi.org/10.1016/j.ceramint.2013.08.033

H.S. Kim, M. Kang, Rapid crystal phase transformation into hexagonally shaped α-alumina using AlF3 seeds. J. Sol-Gel Sci. Technol. 68, 110–120 (2013). https://doi.org/10.1007/s10971-013-3142-2

D. Riello, C. Zetterström, C. Parr, M.A.L. Braulio, M. Moreira, J.B. Gallo, V.C. Pandolfelli, AlF3 reaction mechanism and its influence on α-Al2O3 mineralization. Ceram. Int. 42, 9804–9814 (2016). https://doi.org/10.1016/j.ceramint.2016.03.074

F. Simonin, C. Olagnon, S. Maximilien, G. Fantozzi, L.A. Diaz, R. Torrecillas, Thermomechanical behavior of high-alumina refractory castables with synthetic spinel additions. J. Am. Ceram. Soc. 90, 2481–2490 (2000). https://doi.org/10.1111/j.1151-2916.2000.tb01579.x

C. Domínguez, J. Chevalier, R. Torrecillas, G. Fantozzi, Microstructure development in calcium hexaluminate. J. Eur. Ceram. Soc. 21, 381–387 (2001). https://doi.org/10.1016/S0955-2219(00)00143-6

X. Liu, D. Yang, Z. Huang, J. Ye, S. Zhang, M. Fang, H. Ding, Y.G. Liu, In-situ synthesis of porous calcium hexa-aluminate ceramics and growth mechanism of the plate-like grains. Ceram. Int. 41, 14727–14732 (2015). https://doi.org/10.1016/j.ceramint.2015.07.197

R. Salomão, V.L. Ferreira, I.R. de Oliveira, A.D.V. Souza, W.R. Correr, Mechanism of pore generation in calcium hexaluminate (CA6) ceramics formed in situ from calcined alumina and calcium carbonate aggregates. J. Eur. Ceram. Soc. 36, 4225–4235 (2016). https://doi.org/10.1016/j.jeurceramsoc.2016.05.026

H. Guo, W. Li, Effects of Al2O3 crystal types on morphologies, formation mechanisms of mullite and properties of porous mullite ceramics based on kyanite. J. Eur. Ceram. Soc. 38, 679–686 (2018). https://doi.org/10.1016/j.jeurceramsoc.2017.09.003

M.K. Cinibulk, Reaction between hot-pressed calcium hexaluminate and silicon carbide in the presence of oxygen. J. Am. Ceram. Soc. 81, 2789–2798 (1998). https://doi.org/10.1111/j.1151-2916.1998.tb02698.x

D. Asmi, I.M. Low, S. Kennedy, R.A. Day, Characteristics of a layered and graded alumina/calcium-hexaluminate composite. Mater. Lett. 40, 96–102 (1999). https://doi.org/10.1016/S0167-577X(99)00055-5

K. Kawaguchi, Y. Suzuki, T. Goto, S.H. Cho, T. Sekino, Homogeneously bulk porous calcium hexaaluminate (CaAl12O19): reactive sintering and microstructure development. Ceram. Int. 44, 4462–4466 (2018). https://doi.org/10.1016/j.ceramint.2017.11.138

M.J. Kang, D.H. Yoon, Effects of impurities on the slip viscosity and sintered properties of low-soda easy-sintered α-alumina. J. Korean Ceram. Soc. 59, 595–603 (2022). https://doi.org/10.1007/s43207-022-00192-2

Acknowledgements

This study was supported by the Technology Innovation Program (20012911) funded by the Korean Ministry of Trade, Industry & Energy. The authors also thank the Core Research Support Center for Natural Products and Medical Materials (CRCNM) for technical support regarding the porosimetry measurements.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

There is no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Bae, HM., Tsabit, A.M., Ryu, SS. et al. Direct synthesis of porous calcium-hexaluminate aggregate for refractory applications. J. Korean Ceram. Soc. 61, 104–114 (2024). https://doi.org/10.1007/s43207-023-00352-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s43207-023-00352-y