Abstract

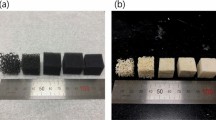

In this study, porous kaolin-based ceramic support materials were successfully fabricated using conventional sintering techniques. The support materials were prepared using two different weight per cent (wt.%) of sawdust addition (10–20 wt.%), compacted at 10–20 MPa and sintered at 900 and 1000 °C. The physical and mechanical properties of the support materials as formed by sintering were examined, while the failure rate of the fabricated support materials was determined using Weibull statistical tool. The experimental data show that the best result for the hardness and fracture toughness was obtained as 0.409 GPa and 0.835 MPa·m1/2 for supports sintered at 1000 °C with 20 wt. % pore formers. The mass loss for the support materials with the best properties was reported to be about 5%, making the support a potential material for use as catalyst support. The Weibull modulus (m) obtained for the ceramic support was in a range of 2.75–4.00, indicating that the samples had a lower failure rate than most ceramic support materials with a Weibull modulus of more than 6. The control samples and samples with the inclusion of pore formers demonstrated acoustic emission (AE) response during the entire cooling process during the acoustic emission test.

Graphical abstract

Similar content being viewed by others

Data availability

The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

References

H.H.S. Villanueva, P.E.B. de Mello, Energy 88, 118–125 (2015)

S. Danwittayakul, J. Dutta, J. Alloys Compd 586, 169–175 (2014)

A. Dey, N. Kayal, O. Chakrabarti, R.F. Caldato, C.M. André, M.D. Innocentini, Ind. Eng. Chem. Res 52(51), 18362–18372 (2013)

M. Fukushima, Y.I. Yoshizawa, J. Eur. Ceram. Soc 36(12), 2947–2953 (2016)

Y. Feng, K. Wang, J. Yao, P.A. Webley, S. Smart, H. Wang, Ceram. Int. 39(7), 7551–7556 (2013)

L. Nie, J. Liu, Y. Zhang, M. Liu, J. Power. Sources 196(23), 9975–9979 (2011)

D.O. Obada, D. Dodoo-Arhin, M. Dauda, F.O. Anafi, A.S. Ahmed, O.A. Ajayi, O.J. Momoh, Appl. Clay Sci. 194, 105698 (2020)

R.W. Rice, Porosity of Ceramics Marcel Dekker (CRC Press, New York, 1998). https://doi.org/10.1201/9781315274539

M. Scheffler, P. Colombo (eds.), Cellular Ceramics: Structure, Manufacturing, Properties and Applications. (John Wiley & Sons, 2006)

A.R. Studart, U.T. Gonzenbach, E. Tervoort, L.J. Gauckler, J. Am. Ceram. Soc. 89(6), 1771–1789 (2006)

B.A. Horri, C. Selomulya, H. Wang, Int. J. Hydrogen. Energy. 37(20), 15311–21539 (2012)

T. Ohji, M. Fukushima, Int. Mater. Rev. 57(2), 115–131 (2012)

V.R. Salvini, V.C. Pandolfelli, D. Spinelli, Recent Advances in Porous Ceramics (2018). https://doi.org/10.5772/intechopen.71612

D.O. Obada, D. Dodoo-Arhin, M. Dauda, F.O. Anafi, A.S. Ahmed, O.A. Ajayi, Appl. Clay Sci. 150, 175–183 (2017)

J. Zuo, T.S. Chung, G.S. O’Brien, W. Kosar, J. Membr. Sci. 523, 103–110 (2017)

D.J. Green, Cambridge University Press. (1998).

D.O. Obada, D. Dodoo-Arhin, M. Dauda, F.O. Anafi, A.S. Ahmed, O.A. Ajayi, Appl. Clay Sci. 132, 194–204 (2016)

S. Bose, C. Das, Mater. Lett. 110, 152–155 (2013)

E.S. Akpan, M. Dauda, L.S. Kuburi, D.O. Obada, N.D. Bansod, D. Dodoo-Arhin, Mater. Today Proceed. 38, 2291–2294 (2020)

D.O. Obada, D. Dodoo-Arhin, M. Dauda, F.O. Anafi, A.S. Ahmed, O.A. Ajayi, Results. Phys. 7, 3838–3846 (2017)

N.N. Nemeth, O.J. Jadaan, J.P. Gyekenyesi, Lifetime reliability prediction of ceramic structures under transient thermomechanical loads (No. E-14061) (2005), pp. 1–179

O.M. Jadaan, N.N. Nemeth, J. Bagdahn, W.N. Sharpe, J. Mater. Sci. 38(20), 4087–4113 (2003)

T. Wu, J. Su, Y. Li, H. Zhao, Y. Zhang, M. Zhang, B. Wu, Materials 11(10), 2054 (2018)

P. O'Connor, A. Kleyner Practical reliability engineering. John Wiley and Sons. 2012

J.B. Quinn, B. Janet, G.D. Quinn, Dental. Mater. 26(2), 135–147 (2010)

B.A. Amlabu, S. Umaru, M. Dauda, D.O. Obada, S. Csaki, N.D. Bansod, O.O. Fasanya, SILICON 12, 1311–1324 (2020)

Y. Sakata, Y. Tamaura, H. Imamura, M. Watanabe, Stud. Surf. Sci. Catal. 162, 331–338 (2006)

Z. Zivcová, E.W.J. Gregorová, Pabst. Mater. Sci. 42, 8760–8764 (2007)

Z. Zivcová, E.W. Gregorová, Pabst Appl. Ceram. 2, 1–8 (2008)

Z. Zivcová, E.W. Gregorová, Pabst. Appl. Starch 61, 495–502 (2009)

Z. Zivcová, E.W. Gregorová, Pabst. Appl. Starch 62, 3–10 (2010)

Z. Zivcová, J. Locs, M. Keuper, I. Sedlárova, M. Chmelicková, J. Eur. Ceram. Soc. 32, 2163–2172 (2012)

I.Y. Guzman, Glass. Ceram. 60, 280–283 (2003)

Yu. Chen, N. Wang, O. Ola, Y. Xia, Y. Zhu, Mater. Sci. Eng. R. Rep. 143, 100589 (2021)

E.F. Krivoshapkina, A.A. Vedyagin, P.V. Krivoshapkin, I.V. Desyatykh, Pet. Chem. 55, 901–908 (2015)

E. Vanhaecke, S. Ivanova, A. Deneuve, O. Ersen, D. Edouard, G. Wine, P. Nguyen, C. Pham, C. Pham-Huu, J. Mater. Chem. 18, 4654 (2008)

N.M.D. Vitorino, A.V. Kovalevsky, M.C. Ferro, J.C.C. Abrantes, J.R. Frade, Mater. Des. 117, 332–337 (2017)

E.C. Hammel, O.R. Ighodaro, O.I. Okoli, Ceram. Int. 40(10), 15351–15370 (2014)

J.K. Efavi, L. Damoah, D.Y. Bensah, D. Dodoo-Arhin, D. Tetteh, Appl. Clay. Sci. 65, 31–36 (2012)

D.O. Obada, D. Dodoo-Arhin, M. Dauda, F.O. Anafi, A.S. Ahmed, O.A. Ajayi, I.A Samotu, World J. Eng. 13(4), 288–293 (2016)

H. Hu, J.H. Xin, H. Hu, X. Wang, D. Miao, Y. Liu, J. Mater. Chem. A 3(21), 11157–11182 (2015)

K.C. Taylor, Springer. Berlin. Heidelb. (1984). https://doi.org/10.1007/978-3-642-69486-8_9

K.A. Salami, D.O. Obada, A.A. Alabi, S. Csaki, A.N. Oyedeji, J. Aust. Ceram. Soc. (2022). https://doi.org/10.1007/s41779-022-00778-3

D.O. Obada, S.A. Osseni, H. Sina, K.A. Salami, A.N. Oyedeji, D. Dodoo-Arhin, E.T. Dauda, Appl. Clay. Sci. 215, 106298 (2021)

O.A. Osuchukwu, A. Salihi, I. Abdullahi, D.O. Obada, Today. Proceed. Mater. (2022). https://doi.org/10.1016/j.matpr.2022.04.696

O.A. Osuchukwu, A. Salihi, I. Abdullahi, D.O. Obada. Data. Brief 108305 (2022). https://doi.org/10.1016/j.dib.2022.108305

D.O. Obada, K.A. Salami, A.N. Oyedeji, O.O. Fasanya, M.U. Suleiman, B.A. Ibisola, E.T. Dauda, Mater. Lett. 304, 130613 (2021)

D.O. Obada, E.T. Dauda, J.K. Abifarin, D. Dodoo-Arhin, N.D. Bansod, Mater. Chem. Phys. 239, 122099 (2020)

S. Bose, C. Das, Sawdust. Wood. Waste. Pore-Former. Fabricat. Ceram. Memb. Ceram. Int. 41(3), 4070–4079 (2015)

K.H. Choi, M. Shokouhimehr, Y.E. Sung, Bull. Korean. Chem. Soc. 34(5), 1477–1480 (2013)

M. Shokouhimehr, J.H. Kim, Y.S. Lee, Synlett 4, 618–620 (2006)

Z. Bakhtiarzadeh, S. Rouhani, Z. Karimi, S. Rostamnia, T.A. Msagati, D. Kim, M. Shokouhimehr, Mol. Catal. 509, 111603 (2021)

C. Duong-Viet, H. Ba, Z. El-Berrichi, J.M. Nhut, M.J. Ledoux, Y. Liu, C. Pham-Huu, New. J. Chem. 40(5), 4285–4299 (2016)

E.M. Petersen, R.G. Rao, B.C. Vance, J.P. Tessonnier, Gyufykjlk. Appl. Catal. B: Env. 286, 119904 (2021)

Acknowledgements

The authors acknowledge the Multifunctional Materials Laboratory, Shell Office in Mechanical Engineering, Department of Mechanical Engineering, and the Department of Metallurgical and Materials Engineering, both of Ahmadu Bello University, Zaria, Nigeria, for providing facilities to carry out this study. In addition, the authors acknowledge the support of the Research and Administrative Assistants, in addition to the Industrial Training Students (2021 cohort) at the Multifunctional Materials Laboratory under the TETFund Project (NRF_SETI_HSW_00714, 2020).

Funding

This research received no specific grant from any funding agency in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Contributions

DO.O: conceptualization, methodology, data curation, writing- original draft, investigation, reviewing and editing, supervision; KA.S: conceptualization, methodology, data curation; writing- original draft; AA.A: data curation, supervision; AN.O: data curation, reviewing and editing. S.C; data curation, reviewing and editing; T.H: data curation; AK.M: reviewing and editing.

Corresponding author

Ethics declarations

Conflict of interests

The authors declare no competing interest.

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Informed consent

Not applicable.

Research involving human participants and/or animals

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Obada, D.O., Salami, K.A., Alabi, A.A. et al. Mechanical behaviour of porous kaolin-based ceramics for potential catalysts support applications. J. Korean Ceram. Soc. 60, 99–112 (2023). https://doi.org/10.1007/s43207-022-00248-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s43207-022-00248-3