Abstract

Herein, an efficient approach using aerosol deposition (AD) is proposed to fabricate a porous ceramic film with high thermal insulating and adhesive properties. Polyethylene powder (PE) is incorporated to regulate the kinetic energy of the ZrSiO4 powder, which hinders the formation of structurally stable film layers. During the high-energy milling process, the ZrSiO4-PE composite powder agglomerates suitably and exhibits adequate kinetic energy to produce a porous film. Despite its exceptional thermally insulating characteristics, the ZrSiO4-PE composite film demonstrates relatively poor adhesion properties. Consequently, an optimized quantity of Y2O3 powder is blended to modulate the thermal insulating and mechanical adhesion properties of the porous coating films. The Y2O3-(ZrSiO4-PE) composite film (approximately 60 μm) exhibits low density (2.2 g/cm3), low thermal conductivity (at ambient temperature, approximately 0.64 W/m∙K), and excellent adhesion strength (37 MPa) attributes. This research offers valuable guidance for fabricating composite porous ceramic films with low thermal conductivity and high adhesion at room temperatures using AD.

Similar content being viewed by others

Data availability

The datasets used and/or analysed during the current study available from the corresponding author on reasonable request.

References

Y. Chen, N. Wang, O. Ola, Y. Xia, Y. Zhu, Porous ceramics: light in weight but heavy in energy and environment technologies. Mater. Sci. Eng. R. Rep. 143, 100589 (2021)

P. Boch, J.C. Niepce, Ceramic Materials: Processes, Properties, And Applications. Wiley. 98, 261–324 (2010)

L.R. Meza, S. Das, J.R. Greer, Strong, lightweight, and recoverable three-dimensional ceramic nanolattices. Science 345, 1322–1326 (2014)

X. Jiang, X. Zhu, X. Ai, H. Yang, Y. Cao, Novel ceramic-grafted separator with highly thermal stability for safe lithium-ion batteries. ACS Appl. Mater. Interfaces 9, 25970–25975 (2017)

C. Oses, C. Toher, S. Curtarolo, High-entropy ceramics. Nat. Rev. Mater. 5, 295–309 (2020)

S.-M. Park, S. Nahm, Y.-S. Oh, Thermal durability of ytterbium silicate environmental barrier coating prepared by suspension plasma spray. J. Korean Ceram. Soc. 58, 192–200 (2021)

R. Malik, Y.W. Kim, Effect of nitride addition on the electrical and thermal properties of pressureless solid-state sintered SiC ceramics. J. Korean Ceram. Soc. 59(5), 589–594 (2022)

M.R. Loghman Estarki, F. Abedi Vellashani, F. Moinifard, M. Milani, A. Kumar, M.R. Ghazi, M. Sardarian, Investigations of selected mechanical, wear properties and transparency of alumina obtained by combined PIM and SPS techniques. J. Korean Ceram. Soc. 59(6), 909–919 (2022)

S. Salifu, P.A. Olubambi, Transparent aluminium ceramics: fabrication techniques, setbacks and prospects. J. Korean Ceram. Soc. 60(1), 24–40 (2023)

R.A. Shishkin, Y.V. Yuferov, B.P. Karagergi, A.V. Schak, Microstructural and mechanical properties of pressureless sintered high-wear-resistant SiC composite materials. J. Korean Ceram. Soc. 60(1), 75–89 (2023)

M.A. Kaiyum, A. Ahmed, M.H. Hasnat, S. Rahman, Effect of MgO on physical and mechanical properties of dental porcelain. J. Korean Ceram. Soc. 58, 42–49 (2021)

S. Lee, J.H. Ha, J. Lee, I.H. Song, Enhanced mechanical strength of talc-containing porous kaolin prepared by a replica method. J. Korean Ceram. Soc. 58, 123–133 (2021)

Y.X. Wang, S. Zhang, Toward hard yet tough ceramic coatings. Surf. Coat. Technol. 258, 1–16 (2014)

S. Mehla, J. Das, D. Jampaiah, S. Periasamy, A. Nafady, S.K. Bhargava, Recent advances in preparation methods for catalytic thin films and coatings. Catal. Sci. Technol. 9, 3582–3602 (2019)

H. Palneedi, M. Peddigari, G.-T. Hwang, D.-Y. Jeong, J. Ryu, High-performance dielectric ceramic films for energy storage capacitors: progress and outlook. Adv. Funct. Mater. 28, 1803665 (2018)

S. Pandya, J. Wilbur, J. Kim, R. Gao, A. Dasgupta, C. Dames, L.W. Martin, Pyroelectric energy conversion with large energy and power density in relaxor ferroelectric thin films. Nat. Mater. 17, 432–438 (2018)

S.-Y. Hong, S. Nahm, Y.-S. Oh, Effect of heat treatment on the wear behavior of WC-Ni-Cr and WC-Ni-Cr+ Cr3C2 coatings fabricated by high-velocity oxy-fuel method. J. Korean Ceram. Soc. 59(4), 465–472 (2022)

M. Park, A. Choi, S. Kim, W. Shim, Y. Kim, Study of SiO2 coating and carboxylic surface-modification on Mg-based inorganic fiber by one-step reflux reaction. J. Korean Ceram. Soc. 59(6), 869–875 (2022)

Y. Wakisaka, M. Inayoshi, K. Fukui, H. Kosaka, Y. Hotta, A. Kawaguchi, N. Takada, Reduction of heat loss and improvement of thermal efficiency by application of “temperature swing” insulation to direct-injection diesel engines. SAE Int. J. Engines 9, 1449–1459 (2016)

H. Kosaka, Y. Wakisaka, Y. Nomura, Y. Hotta, M. Koike, K. Nakakita, A. Kawaguchi, Concept of “temperature swing heat insulation” in combustion chamber walls, and appropriate thermo-physical properties for heat insulation coat. SAE Int. J. Engines 6, 142–149 (2013)

A. Mehta, H. Vasudev, S. Singh, C. Prakash, K. Saxena, E. Linul, J. Xu, Processing and advancements in the development of thermal barrier coatings: a review. Coatings 12, 1318 (2022)

R.A. Miller, Thermal barrier coatings for aircraft engines: history and directions, Therm. Spray. Technol. 6, 35–42 (1997)

B.S. Vasile, A.C. Birca, V.A. Surdu, I.A. Neacsu, A.I. Nicoară, Ceramic composite materials obtained by electron-beam physical vapor deposition used as thermal barriers in the aerospace industry. Nanomaterials 10, 370 (2020)

M.S. Al-Homoud, Performance characteristics and practical applications of common building thermal insulation materials. Build. Environ. 40, 353–366 (2002)

R. Han, H. Liu, L. Zhao, J. Luo, J. Wang, X. Cui, T. Xiong, Development of high infrared emissivity porous ceramic coating using pre-synthesized flower-like CeO2 powder for high temperature applications. Ceram. Int. 48(1), 1340–1348 (2022)

P. Lukes, M. Clupek, V. Babicky, P. Sunka, Pulsed electrical discharge in water generated using porous-ceramic-coated electrodes. IEEE Trans. Plasma Sci. 36, 1146–1147 (2008)

K.L. Choy, Chemical vapour deposition of coatings. Prog. Mater. Sci. 48(2), 57–170 (2003)

L. Guo, X. Tao, Z. Gong, A. Guo, H. Du, J. Liu, Preparation of MoSi2-SiC-Al2O3-SiO2 coating on mullite fibrous insulation with silica sol as binder by non-firing process. Ceram. Int. 45, 2602–2611 (2019)

A. Joseph, S. Mohan, C.S. Kumar, A. Mathew, S. Thomas, B.R. Vishnu, S.P. Sivapirakasam, An experimental investigation on pool boiling heat transfer enhancement using sol-gel derived nano-CuO porous coating. Exp. Therm. Fluid Sci. 103, 37–50 (2019)

L. Łatka, L. Pawłowski, M. Winnicki, P. Sokołowski, A. Małachowska, S. Kozerski, Review of functionally graded thermal sprayed coatings. Appl. Sci. 10(15), 5153 (2020)

J. Akedo, Room temperature impact consolidation (RTIC) of fine ceramic powder by aerosol deposition method and applications to microdevices. J. Therm. Spray Technol. 17, 181–198 (2008)

D. Hanft, J. Exner, M. Schubert, T. Stöcker, P. Fuierer, R. Moos, An overview of the aerosol deposition method: process fundamentals and new trends in materials application. J. Ceram. Sci. Technol. 6, 147–181 (2015)

Y.-H. Yun, J.-K. Lee, Wollastonite coating on zirconia substrate by room temperature spray processing. J. Korean Ceram. Soc. 59(3), 393–400 (2022)

C. Lee, M.-Y. Cho, M. Kim, J. Jang, Y. Oh, K. Oh, S. Kim, B. Park, B. Kim, S.-M. Koo, J.-M.D. Oh Lee, Applicability of aerosol deposition process***** for flexible electronic device and determining the film formation mechanism with cushioning effects. Sci. Rep. 9, 2166 (2019)

J.-J. Choi, J.-H. Choi, J. Ryu, B.-D. Hahn, J.-W. Kim, C.-W. Ahn, W.-H. Yoon, D.-S. Park, Microstructural evolution of YSZ electrolyte aerosol-deposited on porous NiO-YSZ. J. Eur. Ceram. Soc. 32, 3249–3254 (2012)

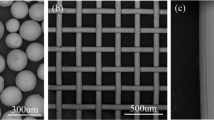

I.-S. Kim, P.-J. Ko, M.-Y. Cho, Y.-S. Lee, H. Sohn, C. Park, W.H. Shin, S.-M. Koo, D.-W. Lee, J.-M. Oh, Fabrication of high-quality alumina coating through novel, dual-particle aerosol deposition. Ceram. Int. 46, 23686–23694 (2020)

Y. Imanaka, N. Hayashi, M. Takenouchi, J. Akedo, Aerosol deposition for post-LTCC. J. Eur. Ceram. Soc. 27, 2789–2795 (2007)

J. Akedo, Aerosol deposition of ceramic thick films at room temperature: densification mechanism of ceramic layers. J. Am. Ceram. Soc. 89, 1834–1839 (2006)

K. Yuuki, Y. Sato, S. Yoshikado, Fabrication of nanoporous titanium dioxide films using aerosol deposition. Key Eng. Mater. 582, 141–144 (2013)

J. Ryu, B.-D. Hahn, J.-J. Choi, W.-H. Yoon, B.-K. Lee, J.H. Choi, D.-S. Park, Porous photocatalytic TiO2 thin films by aerosol deposition. J. Am. Ceram. Soc. 93, 55–58 (2010)

S.-J. Yun, J.-H. Kim, J. Jang, C.-W. Ahn, W.-H. Yoon, Y. Min, J.-J. Choi, B.-D. Hahn, B. D, Granule spray process***** for fabrication of adherent, low thermal conductivity ceramic coatings. Ceram. Int. 47(13), 17921–17929 (2021)

S.-J. Yun, J.-H. Kim, J. Jang, H.-A. Cha, C.-W. Ahn, W.-H. Yoon, J.-J. Choi, B.-D. Hahn, Fabrication of highly porous and adhesive thick Y2O3 film by room-temperature spray process for thermal insulation coating. Ceram. Int. 49(10), 16216–16224 (2023)

J. Exner, M. Schubert, D. Hanft, J. Kita, R. Moos, How to treat powders for the room temperature aerosol deposition method to avoid porous, low strength ceramic films. J. Eur. Ceram. Soc. 39, 592–600 (2019)

H. Kwon, H. Park, C. Lee, Roles of particle size distribution in bimodal feedstocks on the deposition behavior and film properties in vacuum kinetic spraying. J. Therm. Spray technol. 27, 857–869 (2018)

D.D. Kaombe, M. Lenes, K. Toven, W.R. Glomm, Turbiscan as a tool for studying the phase separation tendency of pyrolysis oil. Energy Fuels 27, 1446–1452 (2013)

C. Celia, E. Trapasso, D. Cosco, D. Paolino, M. Fresta, Turbiscan Lab® Expert analysis of the stability of ethosomes® and ultradeformable liposomes containing a bilayer fluidizing agent. Colloids Surf. B Biointerfaces 72(1), 155–160 (2009)

X. Qi, H. Wang, C. Wang, F. Li, Application of Turbiscan in the homoaggregation and heteroaggregation of copper nanoparticles. Colloids Surf A Physicochem Eng Asp 535, 96–104 (2017)

L. Delforce, E. Hofmann, V. Nardello-Rataj, J.M. Aubry, TiO2 nanoparticle dispersions in water and nonaqueous solvents studied by gravitational sedimentation analysis: complementarity of Hansen Parameters and DLVO interpretations. Colloids Surf A Physicochem Eng Asp 628, 127333 (2021)

H. Eilers, Fabrication, Optical transmittance, and hardness of IR-transparent ceramics made from nanophase yttria. J. Eur. Ceram. Soc. 27, 4711–4717 (2007)

P. Roy, G. Bertrand, C. Coddet, Spray drying and sintering of zirconia based hollow powders. Powder technol. 157(1–3), 20–26 (2005)

D.S. Rickerby, A review of the methods for the measurement of coating substrate adhesion. Surf. Coat. Technol. 36, 541–557 (1988)

S. Shaikh, L. Li, K. Lafdi, J. Huie, Thermal conductivity of an aligned carbon nanotube array. Carbon 13, 2608–2613 (2007)

Acknowledgements

This work was supported by the Technology Innovation Program (Development of 30 μm ceramic beads and reliability evaluation technology, No. 20011008) funded by the Ministry of Trade, Industry & Energy (MOTIE, Korea) and the Korea Institute of Materials Science (KIMS) internal R&D program (No. PNK8830).

Funding

Korea Evaluation Institute of Industrial Technology, 20011008, JongJin Choi, Korea Institute of Materials Science, PNK8830.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors have no competing interests to declare that are relevant to the content of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yun, SJ., Kim, JH., Cha, HA. et al. Low thermal conductivity and high durability porous thermal insulation coating via room–temperature spray coating process. J. Korean Ceram. Soc. 61, 142–152 (2024). https://doi.org/10.1007/s43207-023-00337-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s43207-023-00337-x