Abstract

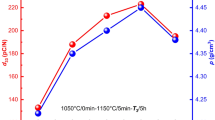

0.95(Li0.02Na0.50K0.48)(Nb0.95Sb0.05)O3-0.05AgTaO3 (0.95LNKNS-0.05AT) lead-free piezoelectric ceramics were prepared by conventional ceramic processing via the two-step sintering process (abbreviated as TSS). The influences of sintering conditions in the first stage of the TSS process on densification, dielectric and piezoelectric properties of the 0.95LNKNS-0.05AT ceramics prepared by the TSS were deeply studied. By introducing TSS for preparing the 0.95LNKNS-0.05AT ceramics, the volatilization of alkali metal elements can be decreased and all the 0.95LNKNS-0.05AT ceramics show high densification. By optimizing the T1 sintering temperature and t1 holding time in the first stage of the TSS, the relative permittivity of the 0.95LNKNS-0.05AT ceramics sintered at 1140 °C for 0.5 h and 1050 °C for 8 h is increased to 5957 at 1 kHz, while the relative permittivity of the 0.95LNKNS-0.05AT ceramics prepared by the conventional sintering method (abbreviated as CS) is only 5205. The d33, g33, and Kp values are increased from 134 pC/N, 14.6 × 10–3 Vm/N, and 17.4% to 224 pC/N, 25.5 × 10–3 Vm/N, and 31.9%, respectively. The 0.95LNKNS-0.05AT ceramics exhibit thermal activation relaxation behavior, and the high-temperature Cole–Cole impedance performance can be fitted well by the equivalent circuit (RQC) and equivalent circuit (RC) connected in series. The space charge effect conforms to the Arrhenius relationship, which presents a thermally activated hopping type process and relates to the oxygen vacancies generated by the evaporation of alkali metals during the TSS process.

Similar content being viewed by others

References

N. Setter, R. Waser, Acta Mater. 48, 151–178 (2000)

G.H. Haertling, J. Am. Ceram. Soc. 82, 797–818 (1999)

J. Hao, W. Li, J. Zhai, H. Chen, Mater. Sci. Eng. R. 135, 1–57 (2019)

I. Coondoo, N. Panwar, A. Kholkin, J. Adv. Dielectr. 03, 1330002 (2013)

J. Wu, D. Xiao, J. Zhu, Chem. Rev. 115, 2559–2595 (2015)

T. Zheng, J. Wu, D. Xiao, J. Zhu, Prog. Mater Sci. 98, 552–624 (2018)

C. Liu, D. Xiao, T. Huang, J. Wu, F. Li, B. Wu, J. Zhu, Mater. Lett. 120, 275–278 (2014)

T. Zheng, J. Wu, X. Cheng, X. Wang, B. Zhang, D. Xiao, J. Zhu, X. Lou, X. Wang, Dalton Trans. 43, 11759–11766 (2014)

F.K. Bahanurdin, J.J. Mohamed, Z.A. Ahmad, Mater. Sci. Forum. 888, 42–46 (2017)

B. Fang, N. Jiang, J. Ding, Phys. Status Solidi A. 209, 1239–1244 (2012)

J.P. Sharma, D. Kumar, A.K. Sharma, Solid State Commun. 334, 114345 (2021)

J. Li, K. Wang, F. Zhu, L. Cheng, F. Yao, J. Am. Ceram. Soc. 96, 3677–3696 (2013)

H. Tao, H. Wu, Y. Liu, Y. Zhang, J. Wu, F. Li, X. Lyu, C. Zhao, D. Xiao, J. Zhu, S.J. Pennycook, J. Am. Chem. Soc. 141, 13987–13994 (2019)

F. Rubio-Marcos, J.F. Fernandez, D.A. Ochoa, J.E. Garcia, R.E. Rojas-Hernandez, M. Castro, L. Ramajo, J. Eur. Ceram. Soc. 37, 3501–3509 (2017)

J. Eduardo Garcia, F. Rubio-Marcos, J. Appl. Phys. 127, 131102 (2020)

N.J. Loh, L. Simao, C.A. Faller, A. De Noni, O.R.K. Montedo Jr., Ceram. Int. 42, 12556–12572 (2016)

C.A. Souza, J.A. Eiras, M.H. Lente, Ferroelectr. 499, 47–56 (2016)

J.-H. Ji, U.-C. Moon, H.-I. Kwon, J.-H. Koh, Ceram. Int. 43, S97–S101 (2017)

C. Wang, B. Fang, Y. Qu, Z. Chen, S. Zhang, J. Ding, J. Alloys Compd. 832, 153043 (2020)

P.D. Gio, L.D. Vuong, L.T.U. Tu, J. Mater. Sci. Mater. Electron. 32, 13738–13747 (2021)

R. Zhu, B. Fang, X. Zhao, S. Zhang, Z. Chen, J. Ding, H. Luo, J. Alloys Compd. 735, 496–509 (2018)

J.-H. Ji, J. Kim, J.-H. Koh, J. Alloys Compd. 698, 938–943 (2017)

C. Ding, B. Fang, Q. Du, L. Zhou, Phys. Status Solidi A. 207, 979–985 (2010)

X. Liu, M. Zhu, Z. Chen, B. Fang, J. Ding, X. Zhao, H. Xu, H. Luo, J. Alloys Compd. 613, 219–225 (2014)

Y. Zhang, B. Shen, J. Zhai, H. Zeng, J. Am. Ceram. Soc. 99, 752–755 (2016)

N. Jiang, B. Fang, J. Wu, Q. Du, J. Alloys Compd. 509, 2420–2424 (2011)

A.P. Espinosa, L. Ramajo, F. Rubio-Marcos, C. Macchi, A. Somoza, M. Castro, J. Eur. Ceram. Soc. 41, 1288–1298 (2021)

H. Zhang, X. Li, X. Chen, H. Zhou, X. Li, X. Yan, G. Liu, J. Sun, J. Electron. Mater. 48, 4017–4024 (2019)

F. Rubio-Marcos, M.A. Banares, J.J. Romero, J.F. Fernandez, J. Raman Spectrosc. 42, 639–643 (2011)

P. Li, Y. Huan, W.W. Yang, F.Y. Zhu, X.L. Li, X.M. Zhang, B. Shen, J.W. Zhai, Acta Mater. 165, 486–495 (2019)

K. Kakimoto, K. Akao, Y.P. Guo, H. Ohsato, Jpn. J. Appl. Phys. 44, 7064–7067 (2005)

F. Bortolani, A. del Campo, J.F. Fernandez, F. Clemens, F. Rubio-Marcos, Chem. Mater. 26, 3838–3848 (2014)

M.R. Bafandeh, R. Gharahkhani, J.S. Lee, Ceram. Int. 41, 163–170 (2015)

F. Rubio-Marcos, J.J. Romero, M.S. Martin-Gonzalez, J.F. Fernandez, J. Eur. Ceram. Soc. 30, 2763–2771 (2010)

Y. Cheng, J. Xing, T. Wang, F. Wang, R. Li, X. Sun, L. Xie, Z. Tan, J. Zhu, J. Mater. Sci. Mater. Electron. 32, 20211–20224 (2021)

K. Uchino, S. Nomura, Ferroelectr. 44, 55–61 (1982)

W. Xiaoyong, F. Yujun, Y. Xi, Appl. Phys. Lett. 83, 2031–2033 (2003)

R. Zhu, B. Fang, X. Zhao, S. Zhang, D. Wu, J. Ding, J. Eur. Ceram. Soc. 38, 1463–1472 (2018)

N. Zidi, A. Chaouchi, S. d’Astorg, M. Rguiti, C. Courtois, J. Alloys Compd. 590, 557–564 (2014)

X. Dong, X. Li, X. Chen, J. Wu, H. Zhou, Chem. Eng. J. 409, 128231 (2021)

T. Yan, K. Chen, C. Li, M. Liu, J. Wang, L. Fang, L. Liu, J. Adv. Ceram. 10, 809–819 (2021)

Acknowledgements

The authors thank the Top-notch Academic Programs Project of Jiangsu Higher Education Institutions, the Priority Academic Program Development of Jiangsu Higher Education Institutions and the Key Laboratory of Surface Engineering and Advanced Materials for Petroleum and Chemical Industry (Changzhou University) for financial support.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflicts of interest

We confirm that this work does not have conflicts of interest existed with others.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhou, Y., Fang, B., Zhang, S. et al. Enhancing densification and electrical properties of KNN-based lead-free ceramics via two-step sintering. J. Korean Ceram. Soc. 59, 551–564 (2022). https://doi.org/10.1007/s43207-022-00215-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s43207-022-00215-y