Abstract

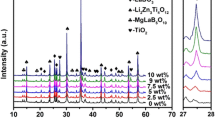

LTCC applications require densification at temperatures lower than 950 °C to allow co-firing with metal electrodes, lower dielectric constant to increase signal transmission speed, a thermal expansion coefficient matched to Si for reliability and higher thermal conductivity to dissipate heat. For this purpose, (SiO2–Al2O3–CaO)-based glass (50–60 wt%)/ceramic (Al2O3 or mullite) composites with nano-hBN (0–10 wt%) addition were investigated. Al2O3 was replaced by mullite to decrease dielectric constant and to match thermal expansion coefficient to Si, and hBN was incorporated to increase thermal conductivity and to decrease dielectric constant. Densification at temperatures ≤ 900 °C was easily achieved for all compositions due to viscous sintering of the glass matrix. hBN did not react chemically with crystalline and amorphous phases, which effectively decreased dielectric constant and increased thermal conductivity. Hence, both mullite and nano-hBN strongly improved dielectric and thermal properties required for the LTCC applications. Dense mullite/glass (55 wt%) base composite with 10 wt% hBN addition was successfully engineered and had comparable dielectric and thermal properties (i.e., 2.3 gcm−3 after sintering at 900 °C, dielectric constant (loss) = 5.13 (0.003) at 5 MHz, thermal conductivity = 1.91 Wm−1 K−1 at 25 °C, and thermal expansion coefficient for the base composite = 4.75 ppm°C−1) with respect to the commercial LTCC products.

Graphical abstract

Similar content being viewed by others

References

R.J. Cava, Dielectric materials for applications in microwave communications. J Mater Chem 11, 54–62 (2001). https://doi.org/10.1039/b003681l

K. Niwa, N. Kamehara, H. Yokoyama, K. Kurihara, Multilayer ceramic circuit board with copper conductor. Am Ceram Soc 19, 41–48 (1986)

G. Chen, X. Liu, Fabrication, characterization and sintering of glass-ceramics for low-temperature co-fired ceramic substrates. J Mater Sci Mater Electron 15, 595–600 (2004). https://doi.org/10.1023/B:JMSE.0000036038.51510.fb

D. Thomas, P. Abhilash, M.T. Sebastian, Casting and characterization of LiMgPO4 glass free LTCC tape for microwave applications. J Eur Ceram Soc 33, 87–93 (2013). https://doi.org/10.1016/j.jeurceramsoc.2012.08.002

M.T. Sebastian, H. Jantunen, Low loss dielectric materials for LTCC applications: A review. Int Mater Rev 53, 57–90 (2008). https://doi.org/10.1179/174328008X277524

D. Wang, Y. Fu, C. Zhang, H. Zhou, Fabrication of low dielectric constant film based on CaO–B2O3–SiO2 glass/mullite composites for LTCC application. J Mater Sci Mater Electron 31, 8884–8892 (2020). https://doi.org/10.1007/s10854-020-03422-7

C.C. Chiang, S.F. Wang, Y.R. Wang, Y.F. Hsu, Characterizations of CaO-B2O3-SiO2 glass-ceramics: Thermal and electrical properties. J Alloys Compd 461, 612–616 (2008). https://doi.org/10.1016/j.jallcom.2007.07.073

X. Luo, L. Ren, W. Xie et al., Microstructure, sintering and properties of CaO–Al2O3–B2O3–SiO2 glass/Al2O3 composites with different CaO contents. J Mater Sci Mater Electron 27, 5446–5451 (2016). https://doi.org/10.1007/s10854-016-4448-y

H. Zhu, R. Fu, S. Agathopoulos et al., Crystallization behaviour and properties of BaO-CaO-B2O3-SiO2 glasses and glass-ceramics for LTCC applications. Ceram Int 44, 10147–10153 (2018). https://doi.org/10.1016/j.ceramint.2018.03.003

L. Ren, M. Zhang, H. Zhou, Application of composite binders in the fabrication of LTCC green tape based on the borosilicate glass/Al2O3 system with optimized Ca/Mg ratios. Ceram Int 46, 25979–25986 (2020). https://doi.org/10.1016/j.ceramint.2020.07.087

G. R. Bhimanapati, N. R. Glavin, J. A. Robinson, 2D Boron Nitride: Synthesis and Applications, 1st ed. Elsevier Inc. (2016)

T.H. Chiang, T.E. Hsieh, A study of encapsulation resin containing hexagonal boron nitride (hBN) as inorganic filler. J Inorg Organomet Polym Mater 16, 175–183 (2006). https://doi.org/10.1007/s10904-006-9037-8

www.makeitfrom.com/materialproperties/Hexagonal-Boron-Nitride-BN. Accessed 26 Jan 2020

R. H. Cary, Avionic Radome Materials: Advisory group for aerospace research and development. France (1974)

O. Bilaç, C. Duran, Al2O3/glass/hBN composites with high thermal conductivity and low dielectric constant for low temperature cofired ceramic applications. J Asian Ceram Soc 9, 260–267 (2021). https://doi.org/10.1080/21870764.2020.1864897

Q. Li, D. Cai, Z. Yang et al., Thermal properties and thermal shock resistance of BAS-BN composite ceramics. Ceram Int 45, 8181–8187 (2019). https://doi.org/10.1016/j.ceramint.2019.01.120

H. Jin, Z. Shi, X. Li et al., Effect of rare earth oxides on the microstructure and properties of mullite/hBN composites. Ceram Int 43, 3356–3362 (2017). https://doi.org/10.1016/j.ceramint.2016.11.179

G.M. Dursun, C. Duran, Glass alumina composites for functional and structural applications. Ceram Int 45, 12550–12557 (2019). https://doi.org/10.1016/j.ceramint.2019.03.194

N. Ecebaş, G.M. Dursun, A.H. Yeşilova, C. Duran, Gel casting of mullite for radome applications. Int J Appl Ceram Technol 17, 264–273 (2020). https://doi.org/10.1111/ijac.13269

J. F. Shackelford, R. H. Doremus, Ceramic and glass materials: Structure, properties and processing (2008)

D. G. Burks, Radomes in Antenna Engineering Handbook: 4th New York Chicago San Francisco Lisbon London Madrid Mexico City Milan New Delhi San Juan Seoul Singapore Sydney Toronto (2007)

Q. Li, D. Cai, Z. Yang et al., Effects of BN on the microstructural evolution and mechanical properties of BAS-BN composites. Ceram Int 45, 1627–1633 (2019). https://doi.org/10.1016/j.ceramint.2018.10.039

W.S. Cho, Z.H. Piao, K.J. Lee et al., Microstructure and mechanical properties of AlN-hBN based machinable ceramics prepared by pressureless sintering. J Eur Ceram Soc 27, 1425–1430 (2007). https://doi.org/10.1016/j.jeurceramsoc.2006.05.044

W. Pabst, E. Gregorová, E. Rambaldi, M.C. Bignozzi, Effective elastic constants of plagioclase feldspar aggregates in dependence of the anorthite content - A concise review. Ceram Silikaty 50, 326–330 (2015)

http://physics.bu.edu/~duffy/semester2/c08_dielectric_constant.html. Accessed 26 Aug 2021

S.A.M. Abdel-Hameed, A.A. El-kheshen, Thermal and chemical properties of diopside-wollastonite glass-ceramics in the SiO2-CaO-MgO system from raw materials. Ceram Int 29, 265–269 (2003). https://doi.org/10.1016/S0272-8842(02)00114-1

S.J. Penn, N.M.N. Alford, A. Templeton et al., Effect of porosity and grain size on the microwave dielectric properties of sintered alumina. J Am Ceram Soc 80, 1885–1888 (1997). https://doi.org/10.1111/j.1151-2916.1997.tb03066.x

Y. Zhang, C. Jia, High-performance cyanate ester composites with plasma-synthesized MgSiO3-SiO2-hBN powders for thermally conductive and dielectric properties. Ceram Int 45, 6491–6498 (2019). https://doi.org/10.1016/j.ceramint.2018.12.138

S. Wang, D. Jia, Z. Yang et al., Effect of BN content on microstructures, mechanical and dielectric properties of porous BN/Si3N4 composite ceramics prepared by gel casting. Ceram Int 39, 4231–4237 (2013). https://doi.org/10.1016/j.ceramint.2012.11.005

Yoshihiko Imanaka, multilayered low temperature cofired ceramics (LTCC) Technology, Japan (2005)

D.M. Mattox, S.R. Gurkovich, A.M.K. Olenick, Low dielectric constant, alumina-compatible, Co-Fired multilayer substrate. Ceram Eng Sci 9, 1567–1578 (1988)

W.D. Kingery, Introduction to ceramics. J. Electrochem. Soc. 124(3), 152C (1977)

Ferro Ceramic INC. http://www.ferroceramic.com/mullite_table.htm. Accessed 30 Aug 2021

V.M.F. Marques, D.U. Tulyaganov, S. Agathopoulos et al., Low temperature synthesis of anorthite based glass-ceramics via sintering and crystallization of glass-powder compacts. J Eur Ceram Soc 26, 2503–2510 (2006). https://doi.org/10.1016/j.jeurceramsoc.2005.07.055

D.R. Lide, CRC handbook of chemistry and physics (CRC Press, Washington, 2003)

U.C. Sleight, Ceramic substrates for microelectronic packaging. Annu Rev Mater Sci 17, 323–340 (1987)

X. Luo, L. Ren, Y. Xia et al., Microstructure, sinterability and properties of CaO-B2O3-SiO2 glass/Al2O3 composites for LTCC application. Ceram Int 43, 6791–6795 (2017). https://doi.org/10.1016/j.ceramint.2017.02.096

I.J. Induja, P. Abhilash, S. Arun et al., LTCC tapes based on Al2O3-BBSZ glass with improved thermal conductivity. Ceram Int 41, 13572–13581 (2015). https://doi.org/10.1016/j.ceramint.2015.07.152

Heraeus, Commercial LTCC Data Sheet. https://www.heraeus.com/%0Amedia/media/het/doc_het/products_and_solu%0Ations_het_documents/thick_film/thick_film_data_%0Asheets/passive_components/ltcc/LTCC_Materials_%0AX200.pdf. Accessed 30 Aug 2021

Ferro, LTCC Data Sheet. https://www.etsmtl.ca/Unites-de-recherche%0A/LTCC/Services-offerts/Ferro_A6M.pdf. Accessed 30 Aug 2021

Kyocera, LTCC Data Sheet. https://global.kyocera.com/prdct/semicon/material/. Accessed 30 Aug 2021

Micro Systems Engineering GmbH (MSE) Data Sheet. https://www.mst.com/%0Amsegmbh/products_services/substrates/ltcc/ltcc_%0Aproperties/index.html. Accessed 30 Aug 2021

Funding

The authors did not receive support from any organization for the submitted work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

The authors have no conflicts of interest to declare that are relevant to the content of this article.

Ethical statement

No animal or human studies were carried out by the authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Bilaç, O., Dursun, G.M. & Duran, C. Processing and properties of nano-hBN-added glass/ceramic composites for low-temperature co-fired ceramic applications. J. Korean Ceram. Soc. 59, 383–392 (2022). https://doi.org/10.1007/s43207-021-00185-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s43207-021-00185-7