Abstract

The large amounts of polyurethane foam wastes (PUFWs) produced in the automobiles, buildings, and furniture industries cause many environmental problems. Therefore, the recycling of PUFWs has acquired great interest worldwide. In this study, the PUFWs were converted to new nanocomposite. The chemical modification of PUFWs was conducted through reflux with potassium permanganate in 0.1 M H2SO4. The produced PUF-COO@MnO2 nanocomposites was characterized by scanning electron microscope, energy-dispersive X-ray spectrometry, X-ray diffraction, and Magnetic susceptibility. PUF-COO@MnO2 has been used for the removal of cationic (Methylene blue) and anionic (Trypan blue) dyes from industrial wastewater. The antibacterial effect of PUF-COO@MnO2 was also examined against Gram-positive and Gram-negative bacterial strains. The adsorption capacities of PUF-COO@MnO2 for tested dyes were 277 and 269 mg/g. Moreover, PUF-COO@MnO2 showed a potent antibacterial action against B. cereus (8.8 mm) followed by S. aureus (7.5 mm) and E. coli (7.1 mm). It was concluded that PUF-COO@MnO2 can be employed as antibacterial low-cost material and for the removal of synthetic dyes from industrial effluents.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Polyurethane foam (PUF) has special properties such as high resilience, good mechanical property, abrasion resistance, and good flexibility (Moawed and El-Shahat 2016; Zhou et al. 2022). Therefore, it is widely used in the automotive, building industries, footwear, furniture, construction, and electronics (Bergamonti et al. 2018; Dou et al. 2014; Moon et al. 2020). PUF represent almost 8% of produced.

plastics (annual production of up to 360 million tons) which place them as the sixth most used polymer in the world (Kemona & Piotrowska 2020). Owing to the considerable development in the production of polyurethane foam, large amounts of polyurethane foam wastes (PUFWs) are produced which are not used optimally and cause many environmental problems (Gómez-Rojo et al. 2019; Lei et al. 2019). PUFWs belong to white pollution and affect living organisms. At the same time, the pile-up density of polyurethane foam plastics is small (about 30 kg/m3), thus, stockpiling will take up a large area. In addition, it will cause adverse effects on the ecological environment because of the difficulty of degradation (Kemona and Piotrowska 2020). However, various governmental regulations have been implemented to reduce the waste creation through solid waste management which is usually controlled by the “Ladder of Lansink” (reduce, reuse, recycle, energy recovery, incineration, and landfill) (Nikje et al. 2011). Landfilling is the most common approach to processing polyurethane waste but a great amount of air contained inside foam cells may provide oxygen for deep-seated fires and impede efforts to extinguish flames (Kemona and Piotrowska 2020). As a result, recycling of PUFWs or scraps has acquired a great interest worldwide. PUFWs can be recycled by various methods, all have their advantages and drawbacks. Physical recycling will be an effective means due to the simple operation and relatively active application, in the short term. Chemical recycling (hydrolysis, hydroglycolysis, aminolysis, phosphorolysis, gasification, pyrolysis, hydrogenation, and glycolysis) is difficult to achieve large-scale industrialized production in the short term due to higher technical difficulty but in the long run, it will be the ultimate and effective recycling method (Kemona and Piotrowska 2020). Thus, chemical treatment of PUFW for converting to valuable products is one of the main challenges of today’s society (Abdel-Rahman et al. 2019; Simón et al. 2018).

Water resources, being the substantial foundation for the existence of humans, become seriously polluted due to anthropogenic activities, particularly rapid industrialization (Graca et al. 2020; Hasanpour and Hatami 2020; Schmidt et al. 2020; Zheng et al. 2021). The emergence of new chemical and microbial contaminants in the aquatic environment is an issue of increasing concern (Chinoune et al. 2016; Joseph et al. 2020; Maleki et al. 2017). The wastewater generated from chemical industries carries a large number of deleterious pollutants such as synthetic dyes which have a serious environmental impact as toxicity, mutagenicity, and carcinogenicity (Kong et al. 2016; Krishnamoorthi et al. 2021). Therefore, removing of dyestuff from wastewater before discharging into a water body becomes a must (Kumar et al. 2019). Various techniques have been developed for the removal of dyes from wastewaters such as chemical precipitation, nanofiltration membrane, electro coagulation, adsorption, reverse osmosis, and biological treatment (Gopakumar, et al. 2019; Bhat et al. 2020; Deshpande et al. 2020; Yang et al. 2020). The adsorption process was regarded as superior as it is simple, economic, and most effective (Bazan-Wozniak and Pietrzak 2020; Raza et al. 2020).

Many studies elucidated that polyurethane is an efficient sorbent for various dyes which can be applied without any pretreatment, the effectiveness of this adsorbent can be enhanced by optimizing the experimental conditions (Sultan 2017; Fakhry et al. 2022).

Few reports were available on recycling PUFWs and remain for removal of synthetic dye from wastewater. This has inspired the authors to prepare new adsorbents by recycling of PUFWs with available materials. Among the various approaches, the chemical oxidation route is a robust and dependable method, low cost, and requires a short period of time to prepare. Thus, the aim of this work is to prepare a novel adsorbent from polyurethane foam wastes by a simple method and investigate the capability for industrial wastewater treatment. This can be achieved through: (i) Recycling of PUFWs by chemical oxidation process using potassium permanganate in 0.1 M H2SO4. (ii) Application of the produced (PUF-COO@MnO2) for the removal of methylene blue and trypan blue dyes (models for basic and acidic dyes) from wastewater. (iii) Examination the antibacterial effect of PUF-COO@MnO2 composite.

Experimental

Materials

All chemicals used throughout the work were of analytical reagent grade quality without further purification. Stock solutions (500 mg/L) of MB (Sigma Aldrich: CI 52015, CAS 122965-43-9, purity ≥ 82%) and TB (Sigma Aldrich: CI 23850, CAS 72-57-1, purity ≥ 75%) were prepared by dissolving 0.05 g of each dye in 100 mL distilled water. KMnO4, CuSO4, Fe2(SO4)3, K2Cr2O7, Na2S2O3 and Na2S2O8 were purchased from Sigma-Aldrich (Germany), HNO3, H2SO4 and HCl were brought from scientific office for laboratory supplies (Damietta, Egypt). Polyurethane foam remains were collected from upholstery stores and furniture factories from Damietta City, Egypt.

Synthesis of PUF-COO@MnO2 nanocomposite

The white and color industrial polyurethane foam remains and wastes (PUFWs) were collected from a scrap of household, upholstery stores, and furniture factories from Damietta City, Egypt. The two types of PUFWs were cut to similar small cubes, boiled for 3 h in HCl, squeezed, washed with distilled water and left to dry (Fig. 1).

PUF-COO@MnO2 nanocomposite was prepared as following: A 5 g of dried PUF remains were blended into small particles then refluxed with 5 g KMnO4 in round bottom flask with 200 mL H2SO4 (0.1 M) for 3 h with vigorous stirring. As the reaction progresses, the purple permanganate color was gradually changed to brown. The produced PUF-COO@MnO2 was washed with 0.1 M oxalic acid solution to remove excess KMnO4 followed by distilled water and then air dried (Fig. 2). The PUF-COO@MnO2 were finally blended, sieved, and stored in suitable container for use (Kiwaan et al. 2020).

In case of PUF scrap, PUF were washed with tap water to remove impurities, then with NaOH (0.1 M) for 1 h and HCl (0.1 M, 1 h), finally with distilled water and air dried then treated as similar as the industrial PUF remains.

Various oxidizing agents e.g. HNO3, CuSO4, Fe2(SO4)3, K2Cr2O7, Na2S2O3 and Na2S2O8 were examined for oxidation of PUF and treated as previously mentioned for preparation of PUF-COO@MnO2 composite. The oxidized PUFW cubs were blended in a food-processing blender and sieved. The particles (90 -250 μm size) were adopted for adsorption studies.

Adsorption experiments

To accomplish the optimum adsorption conditions, 0.2 ± 0.01 g of PUF-COO@MnO2 in 100 mL glass bottle was shaken for 2 h with 25 mL of MB and TB dyes aqueous solution individually at required pH adjusted by diluted HCl and/or NaOH. Blank solutions were run under the same experimental conditions. After phase separation, a 5 mL of the aliquot solution of each dye was assayed by direct spectrophotometry at 668, 607 nm for MB and TB, respectively. Effect of various parameters such as time, dye concentration and temperature on the removal efficiency of MB and TB was carefully investigated. The removal percentage (E) and capacity (Q, mg/g), were calculated according to the following equations (Fakhry et al. 2022):

where Ci and Ce are the initial and final dye concentration, \(V\) (mL) is the volume of solution and \(m\) is mass of the PUF-COO@MnO2.

Antibacterial activity of PUF@MnO2 composite

The antibacterial activity of the PUF-COO@MnO2 was examined employing the agar well diffusion method (Barry 2007) at concentration 150 μg/mL in DMSO. The nutrient agar medium was used against Gram-positive bacterial strains (Bacillus cereus and Staphylococcus aureus) and Gram-negative bacterial strain (Escherichia coli). About 200 μg/mL of PUF-COO@MnO2, Penicillin G (150 μg/mL); as a positive control and DMSO as a negative control were added separately into three wells (10 mm) that were made in the inoculated agar plates. The agar plates were incubated at 37 °C for 48 h. The antibacterial activities were assayed in terms of zones of inhibition (ZOI) diameters (mm ± SD).

Characterization of the prepared PUF-COO@MnO2 composite

All characterizations were conducted in Petroleum Research Institute (Cairo City, Egypt).

FTIR Spectrum

FTIR spectrum was performed using a JASCO-410 spectrometer (JASCO, Easton, MD) at a resolution of 4 cm−1 from 400–4000 cm−1. Disks made of a mixture of 0.6–1.0 mg of composite and 100 mg of KBr were vacuumed for 1 min, pressed at 350 MPa for 2 min, and oven-dried for 48 h at 110 °C before analysis.

SEM analysis

The morphological characteristics and elemental composition of the proposed composite surface was characterized using SEM, EDX (JEOL model JSM-6510LV, USA), at an accelerated voltage of 20 kV in the secondary electron mode. The sample was cut into 4 × 4 mm, dried in an oven at 40 ℃ for 10 h, and bent in liquid nitrogen. The fracture surface was vacuum coated with gold and examined at different magnifications.

Magnetic susceptibility

It was measured with a Johnson Matthey magnetic susceptibility balance (120 V power supply). The sample tube was placed in the balance and get an immediate digital read-out then 250 mg the sample was put in the tube and measured. The mass magnetic susceptibility was calculated using the following equation:

where L sample height (cm), m sample mass (g), C balance calibration constant, RO and R are the reading of empty tube and the tube plus sample, respectively.

UV/Vis spectra

A UV–Vis spectrophotometer (JASCO, V-630 UV–Vis Spectrophotometer, Japan) was employed for absorbance measurements of the dye solutions.

XRD patterns

The structure of PUF-COO@MnO2 nanocomposite was investigated by XRD patterns using an X-ray diffractometer (D8-Brucker Model) equipped with Cu Kα radiation (λ = 1.54 Å) at 40 mA and 40 kV in the 2θ range of 5–90°, using a step size of 0.02° and a counting time of 1 s. Samples were ground under ethanol to minimize loss during grinding and to mitigate structural damage.

TGA and DTA analysis

Thermo-gravimetric analysis was performed using Shimadzu (DTA/TGA-50, Japan) in a Pyrex furnace coupled to a Mettler balance. The sample (10 mg) was maintained in nitrogen atmosphere (20 cm3 min−1), from room temperature to 1000 °C with a heating rate of 10 °C min−1. Temperature and mass data were processed by a computer connected to the system.

BET data

The BET surface areas of the suggested adsorbent was determined by the liquid N2 adsorption–desorption approach (ASAP 2000, Micromeritics, France) at liquid nitrogen temperature (77 K). The sample was degassed at 80 °C for 12 h under vacuum prior to measurements. The surface area was calculated using the BET equation and the total pore volumes were estimated as the liquid volume of adsorbate adsorbed (N2) at a relative pressure of 0.99.

pH point of zero charge (pHPZC)

Determination the pH point of zero charge was performed by adding 0.2 gm of the prepared composite to 40.0 mL of 0.1 M NaNO3 in ten 120 ml bottle. The pH was adjusted to 2, 3, 4, 5, 6, 7, 8, 9, 10 and 11 by 0.1 M HCl and 0.1 M NaOH, then the solutions were shaken for 24 h to reach equilibrium. The final pH (pHf) was measured and the initial pH (pHo) vs. the difference between the pHo and pHf values (ΔpH) was plotted. The pzc was taken as the point (intercept with X axis) where pH = 0 (Fakhry et al. 2022).

Regeneration and reusability

To examine the stability of the synthesized composite, a cyclic test was performed. In each cycle, the adsorbent was separated from the dye solution, washed with distilled water, and dried at 50 °C for 2 h. The regenerated composite samples were used several times in dye adsorption experiment to determine the reusability of the samples (Fakhry et al. 2022).

Statistical analysis

The concentrations plot of MB (0.3–10 mg/L) and TB (0.05–10 mg/L) against absorbance was carried out to calculate the mean value, standard deviation and relative standard deviation. Thus, the final results were expressed as the mean ± relative standard deviation.

Application

The suggested PUF-COO@MnO2 composite was successfully tested for antibacterial activity. Moreover, the PUF-COO@MnO2 was assessed in batch mode for detection and removal of MB and TB from industrial wastewater in New Damietta and Ezbat EL-Borg cities. A 25 mL of industrial wastewater samples from different locations were individually spiked with 100 μg of MB and TB dyes, shaken for 30 min with 0.1 g of PUF-COO@MnO2, then the recovery percentage was calculated. The lower detection limits (LDL) of MB and TB dyes was established using preconcentration of 100 mL of different spiked wastewater samples then recovered with 5 mL of HCl (0.1 mol/L) under dark conditions.

Results and discussion

Chemical modification of PUFWs with different oxidizing agent

The white PUFWs before and after treatment with various oxidizing agents were displayed in Fig. 3. It is clear that the effect of HNO3, Fe2(SO4)3, and CuSO4 is non-significant on the PUFWs matrix. Both Na2S2O8 and K2Cr2O7 oxidized the PUFWs which is clear from color change. Moreover, the color of PUFWs was converted to brown-black after oxidation with KMnO4. Figure S1 represents the mixture of different color and densities PUFWs before and after treatment with the oxidizing agents. It is obvious that HNO3, Fe2(SO4)3, CuSO4, and Na2S2O8 had no effect on the color or matrix of PUFWs in contrast to K2Cr2O7. Finally, the color and matrix of PUFWs were completely changed on oxidizing with KMnO4.

Table 1 represents the FTIR spectra of PUFWs and the treated PUFWs using Na2S2O8, K2Cr2O7, HNO3, Fe2(SO4)3, and CuSO4. The data revealed that the PUFWs was slightly affected by Na2S2O8, HNO3, Fe2(SO4)3, and CuSO4 oxidizing agents as no significant changes in the peak position before and after treatment of PUFWs. FTIR spectrum of KMnO4treated PUFWs (PUF-COO@MnO2) was displayed in Fig. 4. The characteristic absorption peaks of PUFWs are observed at 3810–2996 cm–1 (OH, NH), 2935, 2850 cm–1 (C–H), 1654 cm–1 (C=O) and 1586 cm–1 for C=C (Fakhry et al. 2022). Comparing the spectrum of PUF and PUF-COO@MnO2 showed appearance of two broad bands of carboxylate and manganese oxide at 3656–1781 and 709–401 cm–1, respectively (Hatchett et al. 2005). In addition, the –NH, CHAr, and CHAlp were disappeared due to coupling in the broad band with OH group (Mahmood and Waisi 2021). This result indicates that the carbonyl group of PUF matrix was oxidized to carboxylic and then coupled with MnO2 which produced from the reduction of KMnO4 (Fig. 4).

Figures 5 and 2S show the examination of the treated PUFWs with different oxidizing agents for the removal of pollutants from wastewater. The removal percentages of MB and TB dyes from wastewater were displayed. The maximum removal percentages of MB and TB dyes (~ 97%) were obtained using the treated PUFWs with KMnO4. Thus, PUFWs treated with KMnO4 were better than other oxidizing agents and adopted in the subsequent work.

Characterization of PUF-COO@MnO2 nanocomposite

The novel PUF-COO@MnO2 adsorbent was characterized by various physical and chemical techniques to identify the surface morphology, structural properties and detect sorption efficiency.

Energy-dispersive X-ray spectrometry (EDX) was used to determine the elemental composition of the proposed adsorbent (Fig. 6) and evaluate the effect of KMnO4 on the PUFWs matrix. The weight percentages of PUF-COO@MnO2 were carbon (42%), oxygen (34%), manganese (19%) and potassium (1.7%). The calculated MnO2 in PUF-COO@MnO2 was 30.4%. The cross-sectional profile of C and O content in the PUF-COO@MnO2 EDX spectrum revealed that the matrix of PUFWs was partially oxidized. Besides, the presence of manganese and potassium elements in the PUF-COO@MnO2 increased surface activity. Thus, PUF-COO@MnO2 can be used as a powerful tool for the removal of pollutants from industrial wastewater. The weight percentages of Mn, K, and other metal in PUF-COO@MnO2 were also determined using gravimetric procedure. A 1 g of PUF-COO@MnO2 was ignited at 500 °C, cooled and weighed. It is found that the total weight percentages of metal oxide in composite were 34%.

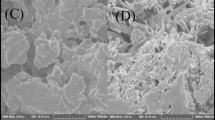

Surface morphology of PUF-COO@MnO2 was investigated using SEM at magnifications from 250 × to 25,000×. Figure 7A represents SEM image of PUF-COO@MnO2 matrix at magnifications of 250×. It is clear that the matrix contains many spaces, channels, and cells, which are irregular in size and shape. The particles of MnO2 were randomly distributed inside the spaces of the PUF matrix (Fig. 7B, 1000 ×). Higher SEM images magnification of PUF-COO@MnO2 nanocomposite (20,000 × and 25,000 ×) showed that the crystals of MnO2 were aggregated on the surface of PUF-COO@MnO2 (Fig. 7B–D) (Ma et al. 2021).

Magnetic susceptibility data of solid‐state MnO2 and PUF-COO@MnO2 composite (at 298 K) are summarized in Table 2. PUF-COO@MnO2 is found to be paramagnetic corresponding to an unpaired electron with positive value of R (+ 820). It is obvious that PUF-COOH@MnO2 \({X}_{\mathrm{g}}\) value (2.5 × 10–5 erg/G2 g) is higher than that of MnO2 value (8.5 × 10–6 erg/G2 g) due to the presence of trace elements e.g. Fe and Cu in PUF-COO@MnO2.

The electronic spectra of PUFWs and PUF-COO@MnO2 were tested using Nujol mulls method (Ghatge and Jadhav 1983). The PUFWs spectrum showed that the absorption peaks were appeared at 369, 337, 336, 218, and 209 nm due to π–π ∗ transition localized on the conjugated system. The spectrum of PUF-COO@MnO2 shows short peaks from 372 to 376 nm and higher band at 353–369 nm that may attributed to n–π ∗ transition which indicate successful addition of MnO2 into the PUFWs matrix (Moawed et al. 2019).

To probe surface crystallization of PUFWs and PUF-COO@MnO2, XRD analyses were performed; the results are displayed in Fig. 8. The XRD pattern of PUFWs was retrieved and a significant broad diffraction band at 2θ, 20.8°, which was identified as a characteristic peak of amorphous PUF; usually observed for the aromatic isocyanate-based PUF. In comparing PUFWs and PUF-COO@MnO2, the latter has lower band intensity, indicating the formation of the composite with a significant change of the amorphous phase; no obvious crystalline material was formed on the surface of PUFWS modified by KMnO4, and manganese oxide existed in an amorphous form (Wei et al. 2021).

The thermal stability of any polymer is essentially determined by the strength of the covalent bonds between the atoms forming the polymeric chains in addition to, the adhesion forces between different phases. The TGA curve of PUF-COO@MnO2 shows a smooth stepwise manner containing five steps (A, B, C, D, F) of thermal decomposition at temperature range 29–1000 °C as shown in Fig. 9 and Table 3. The total weight losses percentages at the detected temperatures was 66.6, the remaining weight percent (33.4%) represents the metal content in PUF-COO@MnO2. The weight loss of PUF-COO@MnO2 in the first step may be attributed to evaporation of adsorbed water molecules. The other decomposition steps have the major weight losses (45.2%) at temperature ranged between 103 and 403 °C due to the decomposition of PUF matrix. It was reported that the weight loss of (what is the adsorbent) was 99.8% at 27–400 °C (Bazan-Wozniak and Pietrzak 2020). The Differential Thermal Analysis (DTA) curve of PUF-COO@MnO2 showed two endothermic peaks at 52 and 126 °C while these peaks were appeared at 58 and 156 °C in Differential Scanning Calorimetry (DSC) curve (Fig. 3S).

Surface area, pore diameter and pore volume of PUF-COO@MnO2 were determined using BET and BJH techniques. The N2 adsorption/desorption isotherm of PUF-COO@MnO2 was nearly similar to III type of IUPAC classification which belong to mesopores dominated property (Fig. 10, S4). It is clear that the amount of adsorbed N2 gas increases gradually with increasing the relative pressure. In addition, the calculated surface area of PUF-COO@MnO2 was 14.3 m2/g which is higher than that obtained (2.8 m2/g) for PUF (Bazan-Wozniak and Pietrzak 2020); this indicated that the MnO2 was efficiently grafted with PUF matrix. The total mean pore volume and pore diameter at (P/Po = 0.990) were 0.07 cm3/g and 19.7 nm, respectively for PUF-COO@MnO2. (how can be interpreted and what is the significant).

Finally, the IR spectrum showed the appearance of two broad bands of carboxylate and manganese oxide at 3656–1781 and 709–401 cm–1, respectively. The SEM images magnification nanocomposite showed that the crystals of MnO2 were aggregated on its surface. Also, the remaining weight percent (33.4%) of TGA represents the metal content. Therefore, we suggested that the structure of the new composite was PUF-COO@MnO2.

Optimum conditions for removal of MB and TB dyes from aqueous solutions

The removal of MB and TB dyes from aqueous media were studied through batch modes in dark condition. The parameters included are pH, contact time, dye concentration, and solution temperature.

To depict the surface charge of the proposed sorbent, the zero-point charge (pHZPC) was determined. The estimated pHZPC values of PUFWs and PUF-COO@MnO2 were 7.4 and 7.9. At pH lower than pHZPC, the sorbents surface is positively charged and can attract anions from the solution where, at pH higher than pHZPC, the sorbents surface becomes negatively charged and attracts cations. The effect of pH (1–14) on the removal of MB and TB dyes using PUF-COO@MnO2 was investigated and the results showed that the maximum removal percentages of MB and TB were achieved at pH 3–13 and 1–3, respectively.

The removal of MB and TB dyes from aqueous solution increased with increasing contact time. The maximum removal percentages of MB and TB dyes (where are the removal percent’s) using PUF-COO@MnO2 were achieved at 5 and 60 min, respectively. It was noticed that the initial removal rate of MB dye is very rapid then slowed down with time till the equilibrium is established. This may be due to availability of a large number of active sites for occupation at the initial stages which were not easily accessible after a period of time as the solute molecules on the solid and bulk phases repel and the binding sites become saturated with dye molecules (Gagliano et al. 2020; Narkkun et al. 2019). These results indicate that the removal of tested dyes, at the early stages, would mainly depend on the porosity of PUF-COO@MnO2. Therefore, the fast removal of dyes and establishing equilibrium in a short period of time signifies the efficiency of the adsorbent for application in wastewater remediation. The removal of MB dye is higher percent and more rapid than that of TB dye due to the nature and molecular size of dyes. The obtained results are basically agreed with that recorded by Fakhry et al. (2022) who studied the removal of MB and methyl orange (MO) by polyacrylonitrile/polyvinylpyrrolidone coated polyurethane foam membrane and achieved removal percent of 97% and 95% for MB and MO, respectively. Similar data were recorded by Seddiki et al. (2020) who used nanocomposites hydrogels for removal of methylene blue and basic red 46 from water.

The data for plotting of the amount of dye per unit mass (capacity, Q) of PUF-COO@MnO2 against the concentrations of MB or TB was shown in Table 4. Linear curves with correlation coefficients (R2, 0.999 and 0.984) were obtained (Table 4, Fig. 11). Moreover, the capacities (Q) of PUF-COO@MnO2 for adsorption of MB and TB were 277 and 269 mg/g, respectively.

Temperature influences the adsorption rate by adjusting the molecular interactions and the solubility of adsorbate. The effect of temperature on the adsorption of MB and TB onto PUF-COO@MnO2, was investigated through batch experiments conducted in the range of 20–80 °C. The results showed that the removal percentage of MB increased slightly with increasing temperature due to the reduction in solution viscosity which led to a fact diffusion of adsorbate molecules toward adsorbent pores and increase removal process, whereas the removal percentage of TB reached to maximum value at room temperature (25 °C) and decreased with increasing temperature due to deformation of bonds between the TB dye molecules and the active site of PUF-COO@MnO2 and increasing solubility of the dye in aqueous solution, indicating exothermic adsorption process (Moawed et al. 2015). The Gibbs free energy (∆G° = −RTlnK) were −5.4 and −2.1 kJ/mol for the adsorption of MB and TM, respectively. The negative values of ΔG° demonstrated that the removal process of MB and TB was spontaneous.

The chemical stability of PUF-COOH@MnO2 composite was studied in different pHs (1–14) and various organic solvents e.g., methanol, ethanol, acetone, diethyl ether, petroleum ether, benzene, toluene, p-xylene, cyclohexanol, chloroform carbon tetrachloride, dimethylformamide, dimethyl sulfoxide, tetrahydrofuran, 2 methoxy ethanol, 1,4 dioxane and methylene chloride. A 0.5 g of the PUF-COOH@MnO2 was soaked in 25 mL of solutions with different pH or 25 mL organic solvent for 24 h then filtrated, dried, and weighted. The results showed that there is no significant change in the weights of PUF-COOH@MnO2. These results indicate that the PUF-COOH@MnO2 has good chemical stability in wide range of pH and organic solvents.

The stability of PUF-COO@MnO2 was also confirmed by examination after many times use in batch mode. A 1 g of PUF-COOH@MnO2 was shaken with 25 mL of methylene blue dye (MB) aqueous solution for 30 min. The average removal percentages of MB were 99–100%. Regeneration of PUF-COO@MnO2 was achieved by recovery of dye molecules from PUF-COO@MnO2 using hydrochloric acid (0.1 M). The obtained results indicated that the capacities of PUF-COO@MnO2 are nearly the same after ten-time recyclability.

Applications

The suggested PUF-COO@MnO2 composite was successfully tested for antibacterial activity. Moreover, the PUF-COO@MnO2 was assessed in batch mode for detection and removal of MB and TB from industrial wastewater in New Damietta and Ezbat EL-Borg cities.

Antibacterial activity test

The ZOI sizes of the PUF-COO@MnO2 against B. cereus, E. coli and S. aureus are shown in Fig. 12. B. cereus is a Gram-positive, rod-shaped, facultatively anaerobic and spore forming bacteria. It is responsible for a minority of foodborne illnesses (2–5%), causing severe nausea, vomiting, and diarrhea. Among the pathogenic bacteria, S. aureus which is a leading cause of gastroenteritis, Staphylococcal food poisoning and pneumonia. S. aureus is an important pathogen due to a combination of toxin-mediated virulence, invasiveness, and antibiotic resistance. In addition, the species E. coli causes enteric diseases, such as diarrhea or dysentery, and other pathotypes cause extra-intestinal infections. The PUF-COO@MnO2 showed a potent antibacterial action against B. cereus (8.8 mm) followed by S. aureus (7.5 mm) and E. coli (7.1 mm). The antibacterial effect of MnO2/single crystalline ZnO nanorod hybrids against E. coli and S. aureus were 14.4 and 10.29 mm, respectively. Also, Yu et al. (2016) reported that MnO2/ZnO nanorod hybrids had a good antibacterial activity against S. aureus and E. coli.

Detection of MB and TB dyes in industrial wastewater

The lowest concentrations of synthetic dyes in aquatic environment represents high risk for all living organisms so they should be detected and removed. The concentrations plot of MB and TB against absorbance give good straight lines with correlation coefficient of 0.998 and 0.997, respectively (Figure 1S). Calibration curve obeys Beer-Lambert law at that concentration range, with intercept value of 0.003 and 0.010. The lower detection limits (LDL) of MB and TB dyes was15.0 and 2.5 μg/L, respectively.

Removal of MB and TB dyes from industrial wastewater

The validity of the proposed method for removal of MB and TB dyes from wastewater samples was critically examined. A 25 mL of industrial wastewater samples from different locations were individually spiked with 100 μg of MB and TB dyes then the solutions were shaken for 30 min with 0.1 g of PUF-COO@MnO2. The Average removal percentages of MB and TB dyes were 97% and 89% with relative standard deviation (RSD%) of 0.92% and 3.27%, respectively.

Conclusion

Recycling of polyurethane foam wastes with KMnO4 in 0.1 M H2SO4 was achieved and reused for the removal of methylene blue and trypan blue dyes from wastewater. Also, the new product (composite) was used for antibacterial activity. The influence of pH, temperature, dye concentration, and time on the removal percentages of dyes from water using the batch technique. At pH ˃3 maximum removal of methylene blue dye (97.5–100%) was achieved, whereas the maximum removal percent of Trypan blue (85–87%) was in the pH range of 1–3. The experimental kinetic data were well-fitted to the pseudo-second-order supporting a chemisorption mechanism as evident by the shift of the FTIR bands of the functional groups of the PUF-COO@MnO2 after dye sorption. It was concluded that the synthesized PUF-COO@MnO2 composite is a promising material for environmental remediation.

References

Abdel-Rahman HA, Younes MM, Khattab MM (2019) Recycling of polyurethane foam waste in the production of lightweight cement pastes and its irradiated polymer impregnated composites. J Vinyl Addit Technol 25(4):328–338

Barry AL (2007) An overview of the Clinical and Laboratory Standards Institute (CLSI) and its impact on antimicrobial susceptibility tests. In: Schwalbe R et al (eds) Antimicrobial susceptibility testing protocol. CRC Press, Boca Raton, pp 1–6

Bazan-Wozniak A, Pietrzak R (2020) Adsorption of organic and inorganic pollutants on activated bio-carbons prepared by chemical activation of residues of supercritical extraction of raw plants. Chem Eng J 393:124785

Bergamonti L, Taurino R, Cattani L, Ferretti D, Bondioli F (2018) Lightweight hybrid organic-inorganic geopolymers obtained using polyurethane waste. Constr Build Mater 185:285–292

Bhat SA, Zafar F, Mondal AH, Mirza AU, Haq QMR, Nishat N (2020) Efficient removal of Congo red dye from aqueous solution by adsorbent films of polyvinyl alcohol/melamine-formaldehyde composite and bactericidal effects. J Clean Prod 255:120062

Chinoune K, Bentaleb K, Bouberka Z, Nadim A, Maschke U (2016) Adsorption of reactive dyes from aqueous solution by dirty bentonite. Appl Clay Sci 123:64–75

Deshpande BD, Agrawal PS, Yenkie MKN, Dhoble SJ (2020) Prospective of nanotechnology in degradation of waste water: a new Challenges. Nano-Struct Nano-Objects 22:100442

Dou ZJ, Cheng M, Qin YF, Chen L, Qin ZY (2014) Simultaneous improvement of mechanical properties and thermal stability of polyurethane by polyethylene glycol grafted cellulose nanocrystals. Adv Mater Res 1052:249–253

Fakhry H, El-Sonbati M, Omar B, El-Henawy R, Zhang Y, EL-Kady M (2022) Novel fabricated low-cost hybrid polyacrylonitrile/polyvinylpyrrolidone coated polyurethane foam (PAN/PVP@PUF) membrane for the decolorization of cationic and anionic dyes. J Environ Manage 315:115128. https://doi.org/10.1016/j.jenvman.2022.115128

Gagliano E, Sgroi M, Falciglia PP, Vagliasindi FGA, Roccaro P (2020) Removal of poly-and perfluoroalkyl substances (PFAS) from water by adsorption: role of PFAS chain length, effect of organic matter and challenges in adsorbent regeneration. Water Res 171:115381

Ghatge ND, Jadhav JY (1983) Synthesis, characterization, and properties of novel poly (ether urethanes). J Polym Sci Polym Chem Ed 21(7):1941–1950

Gómez-Rojo R, Alameda L, Rodríguez Á, Calderón V, Gutiérrez-González S (2019) Characterization of polyurethane foam waste for reuse in eco-efficient building materials. Polymers (Basel) 11(2):359

Gopakumar DA, Arumukhan V, Gelamo RV, Pasquini D, Morais LC, Hermawan SRD, Nzihou A, Abdul Khalil HPS (2019) Carbon dioxide plasma treated PVDF electrospun membrane for the removal of crystal violet dyes and iron oxide nanoparticles from water. Nano-Struct Nano-Objects 18:100268

Graca CAL, Lima RB, Pereira MFR, Silva AMT, Ferreira A (2020) Intensification of the ozone-water mass transfer in an oscillatory flow reactor with innovative design of periodic constrictions: optimization and application in ozonation water treatment. Chem Eng J 389:124412

Hasanpour M, Hatami M (2020) Photocatalytic performance of aerogels for organic dyes removal from wastewaters: review study. J Mol Liq 309:113094

Hatchett DW, Kodippili G, Kinyanjui JM, Benincasa F, Sapochak L (2005) FTIR analysis of thermally processed PU foam. Polym Degrad Stab 87(3):555–561

Joseph J, Radhakrishnan RC, Johnson JK, Joy SP, Thomas J (2020) Ion-exchange mediated removal of cationic dye-stuffs from water using ammonium phosphomolybdate. Mater Chem Phys 242:122488

Kemona A, Piotrowska M (2020) Polyurethane recycling and disposal: methods and prospects. Polymers (Basel) 12(8):1752. https://doi.org/10.3390/POLYM12081752

Kiwaan HA, Elsonbati MA, Elzakzouk SK, Elghamaz NA, Moawed EA (2020) Equilibrium studies of the removal of trypan blue using modifier polyurethane foam. Int J Sci Eng Res 11(6):558–562

Kong L, Qiu F, Zhao Z, Zhang X, Zhang T, Pan J, Yang D (2016) Removal of brilliant green from aqueous solutions based on polyurethane foam adsorbent modified with coal. J Clean Prod 137:51–59

Krishnamoorthi R, Anbazhagan R, Tsai H-C, Wang C-F, Lai J-Y (2021) Preparation of caffeic acid-polyethyleneimine modified sponge for emulsion separation and dye adsorption. J Taiwan Inst Chem Eng 118:325–333

Kumar P, Gihar S, Kumar B, Kumar D (2019) Synthesis and characterization of crosslinked chitosan for effective dye removal antibacterial activity. Int J Biol Macromol 139:752–759

Lei W, Zhou X, Fang C, Li Y, Song Y, Wang C, Huang Z (2019) New approach to recycle office waste paper: reinforcement for polyurethane with nano cellulose crystals extracted from waste paper. Waste Manage 95:59–69

Ma J, Wang C, Xi W, Zhao Q, Wang S, Qiu M, Wang J, Wang X (2021) Removal of radionuclides from aqueous solution by manganese dioxide-based nanomaterials and mechanism research: a review. ACS ES&T Eng 1(4):685–705

Mahmood OAA-Q, Waisi BI (2021) Crystal violet dye removal from aqueous water using polyacrylonitrile precursor beads. Mater Today Proc 42:2185–2192

Maleki A, Hamesadeghi U, Daraei H, Hayati B, Najafi F, McKay G, Rezaee R (2017) Amine functionalized multi-walled carbon nanotubes: single and binary systems for high capacity dye removal. Chem Eng J 313:826–835

Moawed EA, El-Shahat MF (2016) Equilibrium, kinetic and thermodynamic studies of the removal of triphenyl methane dyes from wastewater using iodopolyurethane powder. J Taibah Univ Sci 10(1):46–55

Moawed EA, Abulkibash AB, El-Shahat MF (2015) Synthesis and characterization of iodo polyurethane foam and its application in removing of aniline blue and crystal violet from laundry wastewater. J Taibah Univ Sci 9(1):80–88

Moawed E, Elhagrasy M, Kamal M (2019) Detection and removing of lead from wastewater using chemical treatment of polyurethane foam waste: batch and column experiments. Desalin Water Treat 159:338–345

Moon J, Kwak SB, Lee JY, Kim D, Ha JU, Oh JS (2020) Recycling of bio-polyurethane foam using high power ultrasound. Polymer (guildf) 186:122072

Narkkun T, Boonying P, Yuenyao C, Amnuaypanich S (2019) Green synthesis of porous polyvinyl alcohol membranes functionalized with l-arginine and their application in the removal of 4-nitrophenol from aqueous solution. J Appl Polym Sci 136(31):47835

Nikje MMA, Garmarudi AB, Idris AB (2011) Polyurethane waste reduction and recycling: from bench to pilot scales. Des Monomers Polym 14(5):395–421

Raza N, Raza W, Gul H, Azam M, Lee J, Vikrant K, Kim K-H (2020) Solar-light-active silver phosphate/titanium dioxide/silica heterostructures for photocatalytic removal of organic dye. J Clean Prod 254:120031

Schmidt PJ, Anderson WB, Emelko MB (2020) Describing water treatment process performance: why average log-reduction can be a misleading statistic. Water Res 176:115702

Seddiki N, Aliouche D, Boudhene I (2020) Preparation of nanocomposite hydrogels with nanoclay: Characterization, swelling properties and dye adsorption behavior. Rev Roum Chim 65(2):119–133. https://doi.org/10.33224/rrch.2020.65.2.01

Simón D, Borreguero AM, De Lucas A, Rodríguez JF (2018) Recycling of polyurethanes from laboratory to industry, a journey towards the sustainability. Waste Manage 76:147–171

Sultan M (2017) Polyurethane for removal of organic dyes from textile wastewater. Environ Chem Lett 15(2):347–366. https://doi.org/10.1007/s10311-016-0597-8

Wei Z, Liu Z, Fu X, Wang Y, Yuan A, Lei J (2021) Effect of crystalline structure on water resistance of waterborne polyurethane. Eur Polym J 157:110647

Yang C, Xu W, Nan Y, Wang Y, Chen X (2020) Novel negatively charged nanofiltration membrane based on 4, 4′-diaminodiphenylmethane for dye removal. Sep Purif Technol 248:117089

Yu W, Liu T, Cao S, Wang C, Chen C (2016) Constructing MnO2/single crystalline ZnO nanorod hybrids with enhanced photocatalytic and antibacterial activity. J Solid State Chem 239:131–138

Zheng J, Du L, Gao P, Chen K, Ma L, Liu Y, You S (2021) Mino-modified biomass for highly efficient removal of anionic dyes from aqueous solutions. J Taiwan Inst Chem Eng 119:136–145

Zhou M, Zhao S, Zhou K, Mei F, Qian X, Shi C (2022) Flexible polyurethane foams surface-modified with FeOOH for improved oil-water separation and flame retardancy. Mater Chem Phys 276:125408

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Moawed, E.A., Kiwaan, H.A., El-Zakzouk, S.K. et al. Chemical recycling of polyurethane foam waste and application for antibacterial and removal of anionic and cationic dyes. Braz. J. Chem. Eng. 40, 389–401 (2023). https://doi.org/10.1007/s43153-022-00258-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s43153-022-00258-y