Abstract

Vacuum-forming is a common manufacturing technique for constructing thin plastic shell products by pressing heated plastic sheets onto a mold using atmospheric pressure. Vacuum-forming is ubiquitous in packaging and casing products in the industry, spanning fast moving consumer goods to connected devices. Integrating advanced functionality, which may include sensing, computation and communication, within thin structures is desirable for various next-generation interactive devices. Hybrid additive manufacturing techniques like thermoforming are becoming popular for prototyping freeform surfaces owing to their design flexibility, speed and cost-effectiveness. This paper presents a new hybrid method for constructing thin, rigid and free-form interconnected surfaces via fused deposition modelling (FDM) 3D printing and vacuum-forming that builds on recent advances in thermoforming circuits. 3D printing the sheet material allows for the embedding of conductive traces within thin layers of the substrate, which can be vacuum-formed but remain conductive and insulated. This is an unexplored fabrication technique within the context of designing and manufacturing connected things. In addition to explaining the method, this paper characterizes the behavior of vacuum-formed 3D printed sheets, analyses the electrical performance of printed traces after vacuum-forming, and showcases a range of sample artefacts constructed using the technique. In addition, the paper describes a new design interface for designing conformal interconnects that allows designers to draw conductive patterns in 3D and export pre-distorted sheet models ready to be printed.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Thin, rigid 3D surfaces with integrated conductive interconnects may be desirable structures for the next generation of smart devices. Interconnected 3D printed devices open a range of new design opportunities for displays, wearables and interactions. The two most common industrial approaches for manufacturing such rigid interconnected devices are: (i) molded interconnect devices [1], which involves injection molding the 3D object, laser structuring the surface and electroless plating the activated traces with copper, nickel and gold, and (ii) in-mold electronics (IME), which involves 2D printing conductive silver patterns on polymer-film that is thermoformed and transferred onto the surface of the mold [2]. While these methods create highly accurate and functional electronic devices, they are best suited to mass-production because of the high cost of tooling, the molding requirement and the limited design flexibility inherent with multi-step manufacturing processes.

As a result, more flexible, personal, and smaller quantity-oriented fabrication approaches to constructing conformal circuits have been explored. These can be mainly categorized into three methods: (i) Translating separately prepared flat conductive patterns onto 3D surfaces, (ii) Constructing the conductive pattern directly onto the 3D surface, and (iii) Developing sheet material with integrated circuit into a free-form shapes.

In the first case, Saada et al. [3], Groeger et al. [4] and Ng et al. [5] use a hydroprinting technique to translate 2D inkjet-printed silver ink and graphene patterns onto 3D surfaces via water-soluble polyvinyl alcohol (PVA) film. Hodges et al. [6] and Zhu et al. [7] use conductive ink on inkjet printer and electrically conductive adhesive tape to transfer the 2D printed circuits onto conformal surfaces. Sim et al. [8] use a conformal additive stamping method to translate 2D prepared patterns onto various 3D surfaces. While these methods successfully construct conformal circuits on arbitrary surfaces, they require a separate construction of the substrate and the conductive patterns, which are impossible for constructing double-sided circuits.

In the second case, Aerosol Jet system by Optomec [9] uses droplet-based deposition of electronic ink on multi-axis systems to print complex conformal circuits on 3D substrates, and similarly Adams et al. in [10] use extrusion of conductive silver ink on a 3-axis positioning stage to construct electrically small antennas on hemispherical substrates. Hong et al. use conductive polylactic acid (PLA) and custom desktop 5-axis 3D printer to extrude conformal circuit onto hemispherical substrate [11]. In a more manual approach, Umetani et al. 3D prints cavities on freeform objects and mount conductive copper tape to form the circuit on surface [12]. Savage et al. [13] also use a similar method of attaching copper foil conformally onto a 3D object for fabricating various touch sensors. These methods of direct printing conductive patterns onto substrates require high-precision multi-axis stages, which in turn require complex toolpath preparation. Multi-axis equipment may also be inaccessible for many individual designers.

In the third case, several methods of thermoforming sheet materials to prototype 3D objects have been introduced in the HCI community [14, 15]. Since thermoforming enables constructing 3D geometries quickly and with minimal manufacturing steps, researchers have come up with various toolkits to explore this benefit in personal fabrication. For example, Schüller et al. [16] and Zhang et al. [17] showcased a design user-interface that converts a textured surface of a 3D digital model into a pre-distorted 2D image ready to be printed on the sheet prior to vacuum-forming with desktop size machines.

Furthermore, preparing both the substrate and the conductive pattern in planar sheets prior to forming them into 3D objects allows designers to embed the conductive patterns within the substrate, bypass the complex tooling required in conformal construction, and efficiently construct conformal interconnects for arbitrary concave and convex geometries. This method of thermoforming electronics relies on the ‘stretchability’ of the traces. A common method of constructing stretchable circuits is by adopting wavy patterns or using a stretchable conductive material. For instance, Markvicka et al. [18], Yang et al. [19], and Huang et al. [20] Use the meandering pattern to comply with distortions and stretches without breaking the trace. Alternatively, Nagels et al. [21] use stretchable liquid metal embedded inside the silicone substrate to construct various stretchable devices. Devaraj et al. [22] and Ting et al. [23] use conductive silver ink which remains connected after thermoforming. Hong et al. [24] 3D prints conductive PLA, which has low glass transition temperature and low tensile modulus that can be distorted and stretched into various shapes while remaining connected.

In our underpinning work, we introduced a novel technique of 3D printing both conductive PLA and substrate PLA in a single manufacturing step that is followed by heat bending. Since this method constructs both elements in a single print, it can conveniently fabricate double-sided circuits. As is inherent with folding flat material, however, the approach has limits with regard to form factor, and in terms of accuracy and repeatability because of fabrication elements `by hand'. The technique, namely Thermoformed Circuit Boards (TCB), also demonstrated copper electroplating of the printed traces for enhanced conductivity following recent works on electroplating conductive filaments [25, 26].

Building upon TCB, this paper presents a novel hybrid additive manufacturing technique of vacuum-forming 3D printed sheets to construct various conformal electronics. We first 3D print various sheet materials consisting of PLA and conductive PLA using a low-cost desktop 3D printer. Then, we employ a desktop vacuum-forming machine to vacuum-form 3D printed sheet material into a desired shape. Unlike heat-bending, vacuum-forming requires stretching and distorting the material, and can construct enclosed free-form hollow structures like domes, which may be preferable for enclosures for example. We therefore expand the manufacturable form-factors and application space for TCB, in addition to introducing the technique of vacuum-forming 3D printed sheets incorporating electronics for various shapes.

Although 3D printing of molds has been considered [27, 28], the approach of using 3D printed sheets with vacuum-forming remains largely unexplored. Eksi et al.'s analysis of deformation behavior of vacuum-formed 3D printed PLA sheets was the first and only to characterize the thermoforming behavior of the PLA sheet [29]. Key benefits of 3D printing the sheet materials and vacuum-forming include: (i) repeatability: the same object can be repetitively and accurately constructed using the same mold multiple times, (ii) speed: significantly less time to construct free-form geometries is required compared to traditional 3D printing, and (iii) design freedom: vacuum formed structures have a continuous layer structure with beneficial mechanical properties that can enhance the conductivity of printed traces and offer more flexibility to designers.

We also introduce a new user interface that integrates with a popular 3D CAD software to help users to design 3D interconnects in a parametric way with automated 3D to 2D distortion. Upon completion of a design, the user can export the sheet model for 3D printing. Integrated simulation allows designers to examine modifications and changes to layouts comfortably at design time without needing to export the 3D geometries between different platforms or unnecessarily manufacture suboptimal designs. Our contributions in this paper are summarized as follows:

-

We describe and demonstrate a new fabrication technique to construct thin, freeform smart surfaces from 3D printed sheets based on vacuum-forming; a simplification of thermoforming. This extends our recent work on 3D printing objects incorporating electronics using heat-bending [24]. Vacuum-forming employs stretching and distorting to construct closed free-form hollow surfaces, like domes, which is not possible with heat-bending. We expanded the fabrication technique introduced in our previous work by adding new form-factors, new software, enhanced accuracy, and repeatability, with demonstration for various applications.

-

We analyse the behavior of vacuum formed 3D printed sheets and evaluate electrical properties of vacuum-formed 3D printed conductive traces post stretching and distorting.

-

We provide an interactive GUI-based design editorFootnote 1 integrated within a 3D modelling environment to aid designers with modelling vacuum-formed interconnected surfaces with automated 3D to 2D mapping.

Materials and Methods

To vacuum-form 3D printed sheets, a low-cost desktop vacuum-forming machine (JT-18, JINTAI) was employed which has a maximum sheet dimension of 130 mm by 130 mm and fixed vacuum state with maximum pressure of 17 kPa provided by the manufacturer of the machine. However, the actual vacuum pressure exerted on a specific spot of the surface varies depending on the shape of the mold. We measured the vacuum-pressure of a single air hole (⌀2.5 mm) on the bed of the machine and found it to be 80 kPa. We used a desktop FDM 3D printer (Prusa i3 Mk3s) to construct 3D printed sheets with integrated conductive traces. We used conventional white PLA (GEETECH) and conductive PLA (Multi3D), all of which are commercially available online internationally.

We first evaluated the feasibility of vacuum-forming 3D printed sheet with embedded conductive traces. Then, we demonstrate a design interface integrated within a common CAD software namely Rhino3D (Version 6, SR35) and visual scripting language with physics extension called Grasshopper (Build 1.0.0007) and its included function called Kangaroo [30,31,32]. In our proposed method, the user can first design the 3D shape, simulate the vacuum-forming and draw the layout of the conformal circuit all within a single CAD environment. Once the design is confirmed the user can 3D print the mold and the sheet, and vacuum-form the sheet using the desktop forming machine. The overall workflow for simulation, designing interconnects and the vacuum-forming process can be found in the video Fig. 1.

Overview of a vacuum-formed smart surface. a Design editor enabling simulated vacuum-forming; b design tool for drawing interconnects on a vacuum-formed surface; c pre-distorted 3D printed sheet clamped to low-cost vacuum-forming machine; d vacuum-formed 3D printed sheet; e assembled and connected smart tray sensing the presence of an object

Temperature and Sheet Thickness

To evaluate the vacuum-forming characteristics of the 3D printed sheets, we 3D printed 9 plain square sheets sized 130 mm by 130 mm with varying thicknesses of 0.5 mm, 1.0 mm and 1.5 mm. The sheets were 3D printed at 0.25 mm layer height, 0.5 mm extrusion width and solid grid infill pattern with 0.4 mm brass nozzle at 205 °C and 55 °C heated bed temperature. We used 25% path overlap for infill and 1.1 extrusion multiplier. These 3D printing parameters allowed successful fabrication of the sheets with no void spaces between the paths. The sheet clamp has the same dimensions as the sheets and as such positioning the sheet against the mold is straightforward and precise. We then vacuum form the sheets at varying forming temperatures of 110 °C, 120 °C, and 130 °C. The temperature was measured using an infra-red thermometer mounted underneath the sheet (Fig. 2). Following the general guideline for vacuum-forming, we heated the 3D printed sheet until a visible sag was observed, indicating that the sheet is ready to be vacuum formed. In our experiments we found the 3D printed PLA sheet began to sag at 110 °C. While the forming temperature may differ depending on the filament manufacturer and tensile properties, we found that most commercial PLA started to sag at 110 °C, owing to the low glass transitional temperature of the PLA (Tg < 60 °C). The Young's modulus of the PLA, which measures the stiffness of the material, also drops significantly as the temperature rises (2296.1 MPa @ 30 °C to 229.6 MPa @ °C) [33], making the material highly compliant with stretching and distorting.

The white 3D printed sheets were vacuum formed against the 3D printed mold in pink PLA with a draft angle of 10 degrees and 15 mm height. We used Vaseline (i.e., petroleum jelly) as a releasing agent and the white PLA layer separates with ease. To examine the cross section of the vacuum-formed layer, we used a band saw to cut the samples into halves and measured the void area between the mold and the vacuum-formed layer via pixel counting.

Vacuum-Forming Conductive PLA

Next, we investigated the change in the resistance of the printed conductive PLA before and after vacuum-forming, and after electroplating. We first 3D printed the flat sheet consisting of white then conductive PLA. The conductive trace was printed in a cross-shape; 1.5 mm in width, 0.6 mm in height and 25 mm in length from the center of the cross to one end. The overall thickness of the sheet material was 0.9 mm printed in 0.3 mm layer height. We first measured the resistance of the trace before vacuum-forming, then we vacuum-formed the 3D printed sheet against three different mold with varying draft angles of 60 degrees, 30 degrees, and 4 degrees. The forming temperature for all 3D printed sheets was set to 120 °C. After vacuum forming, we measured the change in resistance before electroplating the traces. We measured resistance 4 times for each sample. Resistances were measured between the center of the cross to each end of the line. The samples shown in this results section have been electroplated for 90 min with varying constant voltage of 0.2– 0.4 V.

Design Interface with Vacuum-Forming Simulation

Simulation begins with importing a 3D mold into the CAD environment. The user can then define the resolution of the simulation by adjusting the size of the mesh grid and the number of vertices. Complex circuit designs will require smaller mesh faces and larger quantities of vertices for finer tessellation. Our design tool shows how many vertices there are in the sheet, which also influences the speed of the simulation.

The simulation consists of three stages: (i) heating the sheet; (ii) pressing the sheet against the mold, and iii) vacuuming the sheet to the mold. Our simulation approach relies on several assumptions that allow the software to run simulations quickly in exchange for a minor reduction in accuracy in comparison to industrial vacuum-forming simulators [34]. The assumptions made to increase execution time are: (i) the thickness of the sheet is not considered, and instead we only consider the overall weight to simulate the sagging of the sheet, (ii) heat is transferred onto the sheet evenly throughout the surface, although in reality the heat transfers more to the central area of the sheet than to the peripheries leading to uneven spread of the tensile strength within the sheet, and (iii) adhesion between the mold and the sheet is considered infinite, meaning that once the mesh collides with the mold, the vertices are fixed onto its position and no sliding occurs. The overall process of simulation is illustrated in Fig. 3.

Vacuum-forming stages: a preparing the vacuum-forming sheet by heating the sheet for initial sagging; b lowering the sheet to the mold whereupon the sheet is stretched against the mold and adhering points are set; c vacuum-forming the sheet against the mold, where the vertices are pulled toward the mold

This simulation allows users to design the interconnects with consideration for the distortion and stretching that occurs during the forming process. The design tool can draw and edit the conformal interconnects conveniently via graphical interface. It then exports the final layout in an STL format ready for 3D printing.

Heating (Fig. 3a): the process starts by setting the weight of the sheet, the Young's modulus of PLA at forming temperature, and the resolution of the grid. Kangaroo simulates the thermal relaxation of the sheet material by taking the edges of the quad mesh as an axial spring between each vertices. This means that the sheet material is considered as a net of rubber lines-like objects which together approximate the behavior of a continuous sheet material. Kangaroo uses the spring constant (k = EA/L) between each vertice, where E is the Young's modulus of the PLA in pascals at forming temperature, L is the length between the vertices, and A is the cross-sectional area. Since the line-like object between the vertices does not have thickness assigned to it, we assume the cross-section area to be the cross-sectional area of one mesh face perpendicular to the direction of the line like-object. The axial load from gravity is also exerted on every vertex in the negative Z direction. We also select the naked vertices at the edge of the sheet and anchor their position in their current XYZ with an infinite force which assumes that the clamping on vacuum-forming machine does not let the sheet slide at all during the entire process. In our design editor, the user can press the button for heating, which begins the simulation.

Pressing (Fig. 3b): in this process the sheet is lowered to the mold and the bed. During the iteration process, Kangaroo checks if the sheet's mesh vertices are in collision with the mold. If the vertices are in collision with the mold, those vertices are kept outside the input mold and its position remains fixed. In this simulation the mold is regarded as input only, which means that the mold is not impacted by the collision. In this process we anchor the XY position of the vertices at the edge of the mesh.

Vacuum (Fig. 3c): for the vacuum-forming process, we first anchor the vertices that are already in contact with the mold and the vertices at the edge of the mesh that are clamped. Then, we pull the vertices toward the mold. In this process no other external forces are considered.

To validate that the simulated digital 3D model matches the actual physical object, we compared the two models in various shapes including hemisphere, frustum, an arbitrary curved surface, and a rectangular concave. We 3D printed the sheet with a brown grid that is equally spaced as the digital mesh in the simulation. We noticed that our simulated model stretched more around the perimeter of the sheet in comparison to the actual vacuum-formed sheet. We find that this is due to our assumption that the heat is evenly spread during the heating process. To measure the accuracy of the simulation we measured the differences in the length of line segments at three locations on the surface of our concave model (red boxes in Fig. 7d).

Results and Discussion

Temperature and Sheet Thickness

As shown in Fig. 4, we noticed the reduction in the void area between the mold and the 3D printed sheet as the forming temperature increases. Shown in Table 1, we saw a sharp increase in the void area between 0.5 mm and 1.0 mm, but between 1.0 mm and 1.5 mm the change in area was small in comparison. We also noticed that by increasing the temperature to 130 °C the void can be almost entirely eradicated for all tested thicknesses. The low-cost desktop vacuum-forming machine was able to heat the 3D printed sheets to the desirable temperature within 1 min in the same manner as conventional vacuum-forming.

Vacuum-Forming Conductive PLA

Table 2 shows the average resistance of the vacuum-formed conductive PLA traces. The table shows that the resistance increases as the draft angle decreases. This is because the printed traces get more stretched as the draft angle decreases. The length of a single segment before vacuum forming was 25 mm and the measured length of the vacuum-formed traces were 28.5 mm, 30.9 mm, 32.2 mm respectively, but after electroplating the resistance dropped significantly. The thickness of the copper deposition after electroplating is expected to be below 100 μm according to Lazarus et al. [35]. In our own investigation, the thickness of electroplated copper was measured to be XX μm (Fig. 5).

The resistance of the Electrifi used in its dense 1.75 mm filament form (10 cm length) is 2.5 Ω [36]. Figure 6 shows the image of the 3 vacuum-formed samples pre and post electroplating. Through vacuum-forming the 3D printed sheet, it is possible to construct a doubly-curved, thin and rigid shell-like structure with integrated traces that would be difficult to achieve using conventional planar additive manufacturing. In planar construction the layer structure will be different at every angle, causing inconsistent mechanical properties of the substrate in addition to inconsistent resistance of the printed traces.

Design Interface with Vacuum-Forming Simulation

For simulation, the measured differences in the length of line segments at three locations on the surface of our concave model (red boxes in Fig. 7d) were 0.6 mm at the square outside the mold, 0.4 mm at the square on the surface of the draft, and 0.2 mm at inner concave surface. The amount of stretch may vary depending on PLA filament manufacturer, but a user can edit the value of the Young’s modulus to adjust the simulation. One issue regarding the simulation is that the mesh vertices may not align perfectly with the edge condition of the mold, and the constructed polygon may appear misaligned (Fig. 8). This can be resolved by increasing the amount of mesh faces but at the expense of reduced simulation speed.

Once the simulation is complete, a user can start designing the circuit on the surface using our design editor. A user can select the vertices on the surface of the vacuum-formed sheet to draw interconnects (Fig. 9a). A user can also select the mesh faces to create electrical contacts (Fig. 10b). A user can adjust the width of the interconnects by changing the value on slider at any point during the design process. The design editor uses colour coding to differentiate the interconnects for different layers (Fig. 9c). Since the design of the interconnects begins after vacuum-forming simulation is complete and the user design interconnect directly onto the vacuum-formed surface, designer can assess areas of high distortion and avoid such areas. Once all the interconnects are drawn on the conformal surface, the user can pre-distort the shape into a flat object (Fig. 10). Following this process, the user can still change the layer height and create vias that connect the interconnects between the layers. Upon completion, a user can then export the geometry in STL, which can be sliced for 3D printing.

Example Applications

To illustrate the unique characteristics of the vacuum-formed circuit boards, we fabricated four examples that incorporate sensing and actuation. Figure 11 shows an example of a 3D printed and vacuum-formed interconnect on a hemisphere (50 mm diameter) with LEDs mounted.

As previously highlighted, 3D printing the sheet materials and then vacuum-forming allows designers to customize the circuit by selectively positioning the contact areas and embedding the traces between PLA layers. The examples shown in this section overcome the limited form-factors shown in our previous work [24] by utilizing vacuum-forming. While heat-bending constructs freeform surfaces through folding in a manner similar to origami, vacuum-forming can perform more sophisticated plastic deformation through stretching and distorting, capable of constructing hollow shapes like domes. Vacuum-forming conforms to a more industrial approach to manufacturing which can accurately and repetitively construct replicas exploiting the use of a mold. The working video of the examples shown in this section can also be found in the video Fig. 1.

Smart Tray: Vacuum-formed trays and packages are extensively used in consumer goods owing to light weight and rigidness that makes them ideal for deliveries and storage. In this example, we show a smart tray with surface interactivity (Fig. 12). The smart tray has ex-posed conductive pads inside the concave surface of the tray which detect the presence of an object. At bottom face of the sheet there are electrical contacts for wiring. Beside the contacts that are needed to be exposed, all the printed traces are insulated between the PLA layers.

3D Buttons and Sliders: Embedding conductive interconnects within a thin and freeform surface is desirable for smart interactive surfaces. Embedded circuits allow miniaturization of electrical arrangements by eliminating unnecessary spaces for attaching separate PCBs and wires. Our vacuum-formed circuit approach can construct embedded traces for doubly curved surfaces, which increase freedom of design. In this example we show a doubly curved, shell-like sensing device consisting of discrete sliders and buttons (Fig. 13).

Modular Lamp: One of the key benefits of vacuum-forming is that since the same mold can be re-used multiple times, it can repetitively and accurately reproduce the same objects in a convenient way. Here we present a modular lamp (Fig. 14) controlled via a smartphone. For the modular lamp, we placed conductive traces to the bottom face of the sheet and electroplated it for minimum resistance.

Limitations and Future Work

In this section, we highlight some limitations of our vacuum-forming method and identify several interesting future directions.

Sensitive Print Settings: In our experiments we noticed that the quality of vacuum-formed 3D printed sheet is sensitive to the printer settings. For instance, if the PLA is under-extruded, the strands within the sheet can de-laminate and create holes during the vacuum-forming process. This is because small air gaps in 3D printed sheet widen during the forming process. For the 3D printed sheet, therefore, it is crucial that the optimal extrusion rate is used to ensure that there is sufficient overlapping between each printing path to avoid any air gaps. While we provide the successful parameters for 3D printing sheet with no void space on Prusa i3 Mk3s, the settings may need to be optimized if printing on different 3D printer.

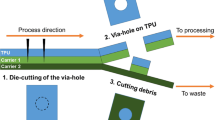

Limited Multi-Material Effectiveness: While exploring the possibility of mixing thermoplastic polyurethane (TPU) and PLA in a single 3D printed sheet, we noticed that due to their differences in the tensile properties de-lamination occurs during the vacuum-forming stage. Therefore, to successfully vacuum-form 3D printed sheet, it is advisable to maintain the same base materials that share similar glass transitional temperature and tensile properties. In future work, we aim to explore the vacuum-forming behavior of other 3D printing materials and their combinations.

Conductive PLA Constraints: Currently, the variety of commercially available conductive filaments for FDM 3D printers is limited. The resistance of available conductive filaments is too high. While Electrifi from Multi3D has significantly lower resistance in comparison to other competitors, it is very sensitive to heat. During the heating process of the sheet, the resistance of the 3D printed trace can increases significantly due to thermal annealing [37]. Although the exposed traces can be copper electroplated, the embedded traces cannot be plated and are thus most useful for sensing signals. The method of vacuum-forming 3D printed circuit and 3D printed electronics in general could benefit from having more diverse conductive filaments with improved thermal performance and conductivity. In addition, the conductivity of the printed PLA is very sensitive to the settings of the 3D printer, such as speed, extrusion rate and temperature. The conductivity of the printed trace hence varies at various areas of the single 3D printed sheet even before the vacuum-forming. This makes the software tool limited in terms of accurately predicting the change in conductivity of the vacuum-formed trace for arbitrary surfaces.

Conclusion

In this paper we presented a method of vacuum-forming 3D printed sheets to construct thin, rigid and freeform interactive surfaces with embedded interconnects that builds upon and significantly extends our previous work on heat-bending flat 3D printed circuits. We demonstrated the manufacturing technique using only low-cost and highly accessible equipment that individual designers can employ in a home environment. We first explored the ‘vacuum-form-ability’ of 3D printed sheets with embedded conductive traces and evaluated their electrical performance for different draft angles. We showcased a range of examples that are unique to our manufacturing technique. We also demonstrated a common 3D CAD environment with integrated physics engine to simulate the vacuum-forming for various mold shapes and provided a design editor for drawing interconnects onto conformal surfaces. Our design editor conveniently pre-distorts the design into the planar sheet ready for 3D printing. Hybrid manufacturing techniques are continuing to expand capabilities and opportunities for personal fabrication and manufacturing at the edge. Our work aims to contribute to the field of personal fabrication by exploring new manufacturing techniques for 3D printed electronics with unique form factors and characteristics.

References

Islam A, Hansen HN, Tang PT, Sun J. Process chains for the manufacturing of molded interconnect devices. Int J Adv Manuf Technol. 2009;42(2009):831–41. https://doi.org/10.1007/s00170-008-1660-9.

Beltrão M, Duarte FM, Viana JC, Paulo V. A review on in‐mold electronics technology. Polym Eng Sci. 2022;62(4):967. https://doi.org/10.1002/pen.25918.

Saada G, Layani M, Chernevousky A, Magdassi S. Hydroprinting conductive patterns onto 3D structures. Adv Mater Technol. 2017. https://doi.org/10.1002/admt.201600289.

Groeger D, Steimle J. Object skin: augmenting everyday objects with hydroprinted touch. Proc ACM Interact Mob Wearable Ubiquitous Technol. 2018;1(4):1–23. https://doi.org/10.1145/3161165.

Wei L, Ng T, Zhu X, Hu G, Macadam N, Um D, Wu TC, Le Moal F, Jones C, Hasan T. Conformal printing of graphene for single- and multilayered devices onto arbitrarily shaped 3D surfaces. Adv Funct Mater. 2019;29:36. https://doi.org/10.1002/adfm.201807933.

Hodges S, Villar N, Chen N, Chugh T, Qi J, Nowacka D, Kawahara Y. Circuit stickers: peel-and-stick construction of interactive electronic prototypes. Proc SIGCHI Conf Human Factors in Computing Systems (CHI 14). 2014. https://doi.org/10.1145/2556288.2557150.

Zhu J, Zhu Y, Cui J, Cheng L, Snowden J, Chounlakone M, Wessely M, Mueller S. MorphSensor: a 3D electronic design tool for reforming sensor modules. In: UIST’20 - Proceedings 25th Annual ACM Symposium User Interface Software Technology, 2020, pp. 541–553. https://doi.org/10.1145/3379337.3415898

Sim K, Chen S, Li Z, Rao Z, Liu J, Lu Y, Jang S, Ershad F, Chen J, Xiao J, Yu C. Three-dimensional curvy electronics created using conformal additive stamp printing. Nat Electr. 2019;2(10):471–9. https://doi.org/10.1038/s41928-019-0304-4.

Optomec Aerosol Jet printing technology effectively produces 3D printed electronics. 2020. https://optomec.com/printed-electronics/aerosol-jet-technology. Retrieved 01 July 2020.

Adams JJ, Duoss EB, Malkowski TF, Motala MJ, Ahn BY, Nuzzo RG, Bernhard JT, Lewis JA. Conformal printing of electrically small antennas on three-dimensional surfaces. Adv Mater. 2011;23(11):1335–40. https://doi.org/10.1002/adma.201003734.

Hong F, Hodges S, Myant C, Boyle D. Open5x: accessible 5-axis 3D printing and conformal slicing. CHI Conf Hum Factors Comput Syst Ext Abstr. 2022. https://doi.org/10.1145/3491101.3519782.

Umetani N, Schmidt R. SurfCuit: surface-mounted circuits on 3D prints. IEEE Comput Graph Appl. 2017;38(3):52–60. https://doi.org/10.1109/MCG.2017.40.

Savage V, Zhang X, Hartmann B. 2012. Midas: fabricating custom capacitive touch sensors to prototype interactive objects. In: UIST’12 - Proceedings 25th Annual ACM Symposium User Interface Software Technology, 2012, pp. 579–87. https://doi.org/10.1145/2380116.2380189

Yamaoka J, Kakehi Y. Draw forming: an interactive fabrication method for vacuum forming. Proc TEI. 2016. https://doi.org/10.1145/2839462.2856534.

Yamaoka J, Kakehi Y. ProtoMold: an interactive vacuum forming system for rapid prototyping. Proc CHI Conf Hum Factors Comput Syst. 2017. https://doi.org/10.1145/3025453.3025498.

Schüller C, Panozzo D, Grundhöfer A, Zimmer H, Sorkine E, Sorkine-Hornung O. Computational thermoforming. ACM Trans Graph. 2016;35(4):2–10. https://doi.org/10.1145/2897824.2925914.

Zhang Y, Tong Y, Zhou K. Coloring 3D printed surfaces by thermoforming. IEEE Trans Vis Comput Graph. 2017;23(8):1924–35. https://doi.org/10.1109/TVCG.2016.2598570.

Markvicka E, Wang G, Lee Y-C, Laput G, Majidi C, Yao L. ElectroDermis: fully untethered, stretchable, and highly-customizable electronic bandages. Proc CHI Conf Hum Factors Comput Syst (CHI 166). 2019. https://doi.org/10.1145/3290605.3300862.

Yang Y, Vervust T, Dunphy S, Van Put S, Vandecasteele B, Dhaenens K, Degrendele L, Mader L, De Vriese L, Martens T, Kaufmann M, Sekitani T, Vanfleteren J. 3D multifunctional composites based on large-area stretchable circuit with thermoforming technology. Adv Electron Mater. 2018;4(8):1–10. https://doi.org/10.1002/aelm.201800071.

Huang Z, Hao Y, Li Y, Hongjie H, Wang C, Nomoto A, Pan T, Yue G, Chen Y, Zhang T, Li W, Lei Y, Kim NH, Wang C, Zhang L, Ward JW, Maralani A, Li X, Durstock MF, Pisano A, Lin Y, Sheng X. Three-dimensional integrated stretchable electronics. Nat Electron. 2018;1(8):473–80. https://doi.org/10.1038/s41928-018-0116-y.

Nagels S, Ramakers R, Luyten K, Deferme W. Silicone devices: a scalable DIY approach for fabricating self-contained multi-layered soft circuits using microfluidics. Proc CHI Conf Hum Factors Comput Syst (CHI 18). 2018. https://doi.org/10.1145/3173574.3173762.

Devaraj H, Malhotra R. Scalable forming and flash light sintering of polymer-supported interconnects for surface-conformal electronics. J Manuf Sci Eng Trans ASME. 2019;141(4):1–10. https://doi.org/10.1115/1.4042610.

Ting J, Zhang Y, Yoon SH, Holbery JD, Ma S. IMold: enabling interactive design optimization for in-mold electronics. Conf Hum Factors Comput Sys. 2020. https://doi.org/10.1145/3334480.3382804.

Hong F, Myant C, Boyle D. Thermoformed circuit boards: fabrication of highly conductive freeform 3D printed circuit boards with heat bending. Proc CHI Conf Hum Factors Comput Syst. 2021. https://doi.org/10.1145/3411764.3445469.

Angel K, Tsang HH, Bedair SS, Smith GL, Lazarus N. Selective electroplating of 3D printed parts. Addit Manuf. 2018;20:164–72. https://doi.org/10.1016/j.addma.2018.01.006.

Kim MJ, Cruz MA, Ye S, Gray AL, Smith GL, Lazarus N, Walker CJ, Sigmarsson HH, Wiley BJ. One-step electrodeposition of copper on conductive 3D printed objects. Addit Manuf. 2019;27:318–26. https://doi.org/10.1016/j.addma.2019.03.016.

Formlab. Prototyping packaging with vacuum forming and 3D printed molds. 2021. https://formlabs.com/uk/blog/prototyping-vacuum-forming/. Retrieved 04 Mar 2021.

Cole Hartman. Benefits of 3D printing vacuum form molds. 2014. http://studiofathom.com/wp-content/uploads/Vacuum-Forming-White-Paper-F001-5-1-2014.pd. Accessed 04 May 2022

Eksi O, Karabeyoglu SS, Cinar K, Muhurcu A. Thermoforming behavior of 3D-printed PLA sheets. Mater Test. 2020;62(6):617–25. https://doi.org/10.3139/120.111522.

Rhinoceros 3D. 2020. https://www.rhino3d.com/. Retrieved 11 June 2020.

Grasshopper. 2021. https://www.grasshopper3d.com/. Retrieved 06 Apr 2021.

Kangaroo Physics. 2021. https://www.food4rhino.com/app/kangaroo-physics. Retrieved 18 Mar 2021.

Zhou C, Guo H, Li J, Huang S, Li H, Meng Y, Donghong Y, De Claville JCC, Jiang S. Temperature dependence of poly(lactic acid) mechanical properties. RSC Adv. 2016;6(114):113762–72. https://doi.org/10.1039/c6ra23610c.

Accuform. 2021. https://www.t-sim.com. Retrieved 06 Apr 2021.

Lazarus N, Bedair SS, Hawasli SH, Kim MJun, Wiley BJ, Smith GL. Selective electroplating for 3D-printed electronics. Adv Mater Technol. 2019;4(8):1–5. https://doi.org/10.1002/admt.201900126.

Electrifi specifications. 2020. https://www.multi3dllc.com/faqs/. Retrieved 10 June 2020.

Cardenas JA, Tsang H, Tong H, Abuzaid H, Price K, Cruz MA, Wiley BJ, Franklin AD, Lazarus N. Flash ablation metallization of conductive thermoplastics. Addit Manuf. 2020;36: 101409. https://doi.org/10.1016/j.addma.2020.101409.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Hong, F., Tendera, L., Myant, C. et al. Vacuum-Formed 3D Printed Electronics: Fabrication of Thin, Rigid and Free-Form Interactive Surfaces. SN COMPUT. SCI. 3, 275 (2022). https://doi.org/10.1007/s42979-022-01174-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42979-022-01174-1