Abstract

Wheat (Triticum aestivum L.) breeding involves improvement of a wide range of traits. However, selection for these traits is only acceptable if the end use quality of the wheat is not compromised. In hard red spring wheat, the predominant end use of flour is bread. In this study, milling and baking quality characteristics were compared in the hard red spring wheat ‘Apogee’ and a near-isogenic line of Apogee (‘A30’) that contains a spontaneous segmental deletion of the long arm of chromosome arm 3DL that is associated with enhanced resistance to Fusarium head blight caused by the fungal pathogen Fusarium graminearum (Schwabe). Apogee and A30 were grown together in replicated greenhouse experiments, and the resultant grain was used to compare a diverse spectrum of grain characteristics and milling and baking properties of the grain in the two wheat genotypes. The major difference detected was a significant increase in protein content in A30, which had nearly 21% more flour protein than Apogee. This difference did not affect any of the flour properties or baking characteristics evaluated, suggesting that the increased protein concentrations in A30 are not associated with the principal seed storage properties associated with baking quality. These results indicate that despite the size of the deletion in A30, no key genes associated with end use quality are located on that chromosome segment. The deletion may therefore find use in efforts to enhance Fusarium head blight in hard red spring wheat.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Crop improvement involves improvement of a multitude of diverse traits within a crop species. In common wheat (Triticum aestivum L.) this includes resistance or tolerance to biotic stresses including bacterial, viral, and fungal pathogens and insect pests, and resistance/tolerance to abiotic stresses such as drought, salinity, and soil mineral toxicity and deficiency. As well, plant developmental and architectural traits such as vernalization response, stature, and resistance to lodging may be targets of selection (Gusta and Chen 1987; Worland and Snape 2000).

Yield serves as a proxy for how successfully a breeding program combines genes for these diverse traits over time. In the U.S., wheat yields have increased approximately 0.82% per year in recent decades (Graybosch et al. 2014). However, while yield is the most important trait, the end use quality of the product is also crucial. Thus, while it is critical to breed for improved biotic and abiotic stress tolerance as well as other traits to increase yield, this process must not cause an inadvertent erosion in end use quality properties required in wheat.

Wheat is the most widely grown crop on Earth and serves as a critical protein and energy source in human diets. (Shewry and Hey 2015). The geographic diversity of wheat production is mirrored in the cultural diversity of wheat products in human diets. The main component of wheat used in foods is flour, the milled grain endosperm. Wheat flour is used in a broad and diverse range of products including breads, noodles, tortillas, crackers, cookies, cakes, and, in the case of durum wheat (T. durum L.), pasta (Khan 2019). The end use properties required to make these diverse wheat products vary dramatically. Thus, different wheat breeding programs typically focus on improvement of a particular market class of wheat tailored to a particular end use. To retain end use quality, the germplasm pool from which breeders make crosses is typically restricted to those between genotypes of the same market class, where key end use quality parameters are generally fixed genetically, to avoid compromising end use quality.

Hard red spring wheat is a premium wheat grown in the Upper Midwest of the U.S. and represents a disproportionally high proportion of the U.S. wheat export market (USDA NASS 2019). Hard red spring wheat production is imperiled by the emergence of the fungal pathogen Fusarium graminearum, which causes Fusarium head blight (FHB). This disease not only causes yield losses, but also compromises quality and deposits the toxin deoxynivalenol on the grain (Snijders 1990). The disease is estimated to have caused several billions of dollars of economic losses to U.S. wheat production, with the hard red spring wheat region suffering the greatest losses (Nganje et al. 2004). Extensive breeding efforts over the last 25 years have improved FHB resistance but the disease is still damaging and greater levels of resistance are needed. Recently, a unique source of FHB resistance in hard red spring wheat was discovered. The resistance was found to be associated with the loss of a segment of the long arm of chromosome arm 3DL (Garvin et al. 2015), suggesting the possible loss of a disease susceptibility gene. This deletion may serve as a new tool to breeders for FHB improvement. However, its size suggests that large numbers of genes are lost due to the deletion. The objective of this study was to determine whether this deletion negatively impacts any key components of end use quality by examining its effect on a range of important kernel, milling, and baking characteristics that collectively impact end use quality.

Materials and methods

Plant genotypes

The wheat cultivar “Apogee” and a BC4-derived near-isoline of Apogee named “A30”, were grown for this study. Apogee is a full dwarf, rapid-maturing hard red spring wheat developed for growth under controlled conditions on long duration space missions (Bugbee et al. 1997). It was found to be highly susceptible to Fusarium head blight (FHB) caused by the fungal pathogen Fusarium graminearum (Mackintosh et al. 2006) and due to its developmental properties has been proposed as a model for investigations of this disease. A30 derives from an attempt to introduce a reported FHB resistance quantitative trait locus (QTL) on chromosome 2D from the soft red winter wheat cultivar ‘Freedom’ (Gupta 2002) into Apogee by marker-assisted backcrossing. A30 was found to possess significantly higher levels of FHB resistance than Apogee, but it was determined that the resistance derives not from the QTL but instead from a spontaneous deletion of a terminal segment of chromosome arm 3DL (Garvin et al. 2015).

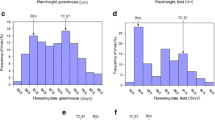

Plant growth

Seeds of Apogee and A30 were planted, five seeds to a pot (Magnum Square, Belden Plastics, Minnesota) containing soilless mix (Sungro VP, Sun Gro Horticulture, Massachusetts), in a greenhouse located on the St. Paul campus of the University of Minnesota. At the time of planting, each pot received one tablespoon of fertilizer (Osmocote 14–14–14 NPK) and one teaspoon of systemic insecticide (Marathon, OHP, South Carolina). The greenhouse was set to run at approximately 68F during the day, and 64F at night. The daylength was set to 16 h, which was accomplished with supplemental lighting to extend daylength in the morning and evening. Three biological replicates were grown between Spring 2018 and Fall 2019. In the first replicate, a total of 16 pots of each genotype were planted, while the second and third replicates had 20 pots per genotype. Pots were grown on a greenhouse bench with alternating rows of four, or in the case of the second and third reps, five pots of each genotype. At maturity spikes were harvested and threshed to obtain grain. Prior to evaluations, samples were cleaned to remove foreign material and broken kernels.

Grain physical characteristics

Physical characteristics of the grain including test weight (lb/bu), kernel size distribution (% large and small), 1000 kernel weight (g), protein (12% moisture basis), and ash (14% moisture basis). Test weight was determined according to AACCI (2010) Method 55-10.01. Kernel size distribution was determined using a Grain Sizer (Standard Industries, Inc., Fargo, ND) equipped with Tyler #7, #9, and #12 sieves. One thousand kernel weight was determined based on 10 g wheat samples counted by a Seedburo 801 Count-A-Pak seed counter (Seedburo Equipment Company, Des Plaines, IL). Single kernel hardness (HI, ≤ 10 = extra soft; ≥ 90 = extra hard), weight (mg), and diameter (mm) were determined according to AACCI (2010) Method 55-31.01 using a Single Kernel Characterization System 4100 (Perten Instruments, Springfield, IL). For whole grain protein, moisture, and ash content determination, wheat kernels (50 g) were first ground using a UDY Cyclone Sample Mill equipped with a 0.5 mm screen (UDY Corporation, Fort Collins, CO). Protein contents were determined by the combustion method (AACCI 2010 Method 46-30.01) using a Thermo Flash 2000 N/protein analyzer (Thermo Fisher Scientific, Waltham, MA). Ash and moisture contents were determined according to AACCI (2010) Methods 08-01.01 and AACCI (2010) 44-15.02, respectively.

Milling and flour characteristics

Grain samples (200 g) were conditioned to 16.5% moisture content and milled using Quadrumat Senior break and reduction grinding heads (C.W. Brabender Inc., South Hackensack, NJ). Bran, shorts, and flour fractions were collected and weighed separately. Flour extraction (%) was based on weight of total product. Flour ash and moisture contents were determined according to AACCI (2010) Methods 08-01.01 and AACCI (2010) 44-15.02, respectively. Flour protein contents were determined by the combustion method (AACCI 2010 Method 46-30.01) using a Thermo Flash 2000 N/protein analyzer (Thermo Fisher Scientific, Waltham, MA). Flour color was determined using a Minolta CR410 Colorimeter, and data were collected and processed using the SpectraMagic™ NX software (ver. 2.81, Konica Minolta Sensing Americas, Inc., Ramsey, NJ). Color values were expressed as Commission Internationale de l’Éclairage (CIE) L*, a, and b* (CIELAB 1986). The L*, a*, and b* values represent lightness (0 = black, 100 = white), redness ( − a* = greenness), and yellowness ( − b* = blueness), respectively.

Dough properties and baking characteristics

Dough properties were evaluated using a 10 g Mixograph (National Manufacturing Division, TMCO, Lincoln, NE) according to AACI Method (2010) 54-40.02. Optimum water absorption (%, 14% m.b.) was estimated by the following equation:

where is X is flour protein content (%, 14% m.b.). Mixograph parameters were collected and processed by the MixSmart software (Ver. 2.0.609, National Manufacturing Division, TMCO, Lincoln, NE). Parameters included midline peak time, height, width, left of peak slope (ascending slope), right of peak slope (descending slope), peak integral, and width at MPT + 2 min.

Bread-baking evaluations were completed by a straight-dough, 3-h fermentation method (AACCI 2010 Method 10-10.03) as described by Caffe-Treml et al. (2010) with the modification that ascorbic acid was included in the bread formulation. Loaves were prepared using 25 g of flour, sugar (5%, Domino Foods, Inc., Yonkers, NY), all-vegetable shortening (3%, Crisco, The J.M. Smucker Co., Orrville, OH), non-iodized salt, (1%, Morton Salt, Inc., Chicago, IL), Carnation instant non-fat dry milk (1%, Nestle U.S.A, Solon, OH), instant dry yeast (1%, Instaferm® RED, Lallemand, Montreal, Canada), fungal amylase Doh-Tone (0.003%, Caravan Ingredients, Lenexa, KS), and ascorbic acid (40 ppm, J.T. Baker, Center Valley, PA). Loaf volume (cm3) was measured by the rapeseed displacement method (AACCI 2010 10-05.01) using a pup volumeter (National Manufacturing Division, TMCO, Lincoln, NE).

Statistical analysis

Trait means for kernel characteristics, milling and flour characteristics, mixograph components, and baking characteristics were analyzed for statistically significant differences by Student’s t-tests.

Results

Kernel characteristics

Kernel characteristics between the two wheat genotypes were similar for most of the traits that were evaluated (Table 1), including test weight, kernel size, 1000 kernel weight, and ash content. However, a notable exception was protein content, which was significantly different between Apogee and A30. A30 possessed a protein content that was approximately 17% higher than Apogee (20.3% vs. 17.4%). Given that the genotypes do not differ in the above-mentioned characteristics, this difference cannot be attributed to a difference in morphological differences (e.g., smaller kernels in A30). Additionally, though statistical analysis was not completed due to data only being available for two of the three biological replicates, kernel hardness appeared different between the two genotypes as well, with Apogee possessing a hardness index approximately 15% higher than A30. Kernel plumpness, which also was only measured on two of the replicates, however, effectively appeared to be the same between the two genotypes (Apogee, 2.95 mm; A30, 3.03 mm). Thus, while the deletion in A30 does not appear to affect most of the kernel characteristics that were evaluated in this study, the elevated protein content in A30 appears to be associated with the deletion in a manner uncoupled from any alteration in grain morphology.

Milling and flour characteristics

Results of comparative milling of grain samples representing both genotypes are shown in Table 2. The flour mill stream represented the majority of the milled product as expected. The proportion of the milled product recovered for the genotypes was 55.4% and 56.8% of the mill streams for A30 and Apogee, respectively, a difference that was not significantly different. Likewise, the bran fraction as a percentage of the mill stream was not different between the two genotypes (29.5% versus 29.2% for Apogee and A30, respectively). In contrast, there was a statistical difference in the proportion of the mill stream associated with the shorts fraction. Milling of A30 resulted in 15.3% of the mill stream being in the shorts fraction. In contrast, the shorts fraction obtained from milling Apogee was approximately 10% lower than this (13.7% of the mill stream). The differences in the shorts fraction could be attributed to grain hardness since A30 had a lower hardness index value (71.1) than Apogee (81.6) (data not shown), and lower hardness can lead to more bran contamination in the flour.

The flour obtained from milling was evaluated for three quality characteristics: protein content, ash content, and color. As predicted from the results obtained from characterization of kernel parameters (Table 1), there was a significant difference between the two genotypes for protein content. A30 flour contained nearly 21% more protein than that extracted from Apogee (18.6% versus 15.4% respectively; p < 0.005%). This further supports the contention that the segmental deletion of the terminal region of chromosome arm 3DL that is present in A30 directly leads to increased protein levels. Flour ash content, however, was virtually identical between the two genotypes. Lastly, flour color was evaluated because bright unpigmented flour is an important quality characteristic in hard red spring wheat. The L* (lightness) and b* (yellowness) values are the most valuable color parameters in wheat flour. The L* and b* values for both Apogee and A30 were not significantly different (p > 0.05) and are typical for hard spring wheat flour (Talbert et al. 2013). The low b* values indicate minimal yellow pigment in the flour, which is desirable.

Flour functional properties

The final comparative evaluations of quality characteristics involved evaluations of multiple parameters related to dough properties associated with dough resistance and tolerance to mixing, measured via mixograph. Characteristics included peak time to measure dough development time, peak height which generally reflects protein content, peak width to assess dough strength, peak integral to assess the amount of work put into flour and water for dough development, and descending slope as a measure of mixing tolerance (Table 3). In no instance was there a significant difference between Apogee and A30 for any of these key parameters. This result appears to be discordant with the findings in both whole grain and flour analyses that A30 had significantly higher protein content, which might be predicted to lead to increased peak height in particular. It should be noted that peak time approached significance (p = 0.08) with A30 exhibiting the higher peak, so this may reflect its higher protein content.

The final evaluation of flour functional property was bread-baking analysis using pup-loaves containing 25 g of flour (Table 3). Standard measurements included baking water absorption, mix time, and finally loaf volume. None of these characteristics were significantly different between the two genotypes (Table 3). Mixograph characteristics did not differ significantly between the two genotypes, and these are predictive of various aspects of actual bread-baking outcomes. Thus, the finding that bread-baking evaluation did not identify any significant differences between the genotypes is expected. The overall results therefore suggest that the increased protein content in A30 flour is not associated with altered abundance of the major seed storage proteins associated with flour quality and loaf quality, because if so it might be predicted that one or more characteristics evaluated by mixograph and bread-baking would have differed between the two genotypes.

Discussion

In this study, we sought to examine whether a terminal deletion from the long arm of chromosome 3DL in wheat compromised end use quality through comparative evaluation of the wheat variety Apogee and a BC4 near-isoline of Apogee, termed A30, that possesses the deletion. The grain used for the evaluations was harvested from three biological replicates of the two genotypes grown under greenhouse conditions. Growing the material in the field would have provided a useful addition to this study. However, Apogee has features that make it unsuited to growth and harvest in the field. It is exceptionally short, matures rapidly, and is very susceptible to an array of diseases. Also, the rapid maturation and short stature make it particularly challenging to harvest, and it is also vulnerable to rodent predation. This was reported previously, although the authors speculated that it might be associated with volatiles attracting the rodents (Bugbee et al. 1999). Since the two genotypes are so similar genetically, we believe that the greenhouse evaluations provide a valid test of any relative differences in milling and baking quality between the two genotypes, and that any relative differences likely would be detected under field conditions as well, albeit based on different absolute values.

The impetus for this study was that while the deletion that A30 harbors enhances FHB resistance as well as reducing grain deoxynivalenol concentrations, it does represent the loss of approximately 20% of the long arm of chromosome arm 3BL based on the presence/absence of molecular markers previously mapped to “bins” that reflect different segments of the chromosome arm tethered to cytogenetic information that estimates the segments’ lengths (Sourdille et al. 2004). Since distal regions tend to be enriched in gene content relative to the more proximal region (closer to the centromere) of a chromosome arm (Sidhu and Gill 2004), elimination of this large of a chromosome segment is expected to eliminate a significant fraction of an arm’s genes. Chromosome arm 3DL possesses 5318 genes (IWGSC 2018), and the terminal 20% of arm 3DL possesses approximately 1160 of these genes. Given the multitude of characteristics that collectively contribute to end use quality (Finney et al. 1987) and their genetic complexity (e.g., Battenfield et al. 2016; Jernigan et al. 2018; Naraghi et al. 2019), there seemed to be some likelihood that one or more of the genes from chromosome arm 3DL in A30 may impact one or more aspects of end use quality in A30.

Our results indicated that very few of the characteristics and parameters evaluated differed between Apogee and A30. Protein content in whole kernels was significantly higher (~ 17%) in A30 compared to Apogee. This difference was also detected in the flour mill stream after grain milling though the difference approached 21% in the flour analysis. This result implies that the deletion of the particular region of chromosome arm 3DL may eliminate a gene or genes that play a role in negatively regulating protein accumulation in the endosperm and that in its/their absence, more protein accumulates. A large number of genes/loci/quantitative trait loci that influence grain protein content have been identified in wheat and found to be distributed throughout the wheat genome (Kumar et al. 2018). In only a few cases were such loci located on chromosome 3D, and these had very small effects (Bordes et al. 2011). However, it is important to note that mapping studies such as these rely upon existing genetic variation for a given gene to allow its detection and phenotypic effect. This is much different than the actual elimination of a gene entirely, which allows the detection of a gene in a manner similar to chemical mutagenesis, which can uncover important genes for which there may be no natural genetic variation.

It is worth highlighting the fact that although A30 had higher flour protein content than Apogee, this did not manifest itself any differences in the mixograph and bread-baking characteristics. In wheat, the glutenins and gliadins are the key seed storage proteins that collectively determine the viscoelastic properties of wheat dough (Hoseney and Rogers 1990). If the negative endosperm protein gene(s) that we postulate to exist on the chromosome segment deleted in A30 were involved in the accumulation of these protein families, it might be anticipated that this would result in one or more differences in the mixograph and/or baking characteristics. However, none of the traits evaluated in this study varied significantly between the genotypes. This implies that the increased protein accumulation in the endosperm of A30 is likely associated with the non-gluten proteins (i.e., albumins and globulins).

Lastly, while only two replicates for each genotype were evaluated for it, grain hardness was reduced in A30 compared to Apogee. While grain hardness in hard spring wheats is defined by well characterized genes on chromosome 5D (Morris 2002), it is unclear what may be the cause of the reduced hardness in A30. It should be noted that A30 was developed during a marker-assisted backcrossing program between Apogee and Freedom, a soft red winter wheat (Gooding et al. 1997), to attempt to shuttle a putative FHB resistance QTL from Freedom (Gupta 2002) to the Apogee background. Thus, it is possible that A30 has a background introgression of a gene from Freedom completely unassociated with the chromosome arm 3DL deletion that is reducing hardness. This reduced hardness in A30 may also explain why there was a small though significant increase in the shorts mill stream fraction.

In conclusion, the chromosome arm 3DL deletion present in A30 does not appear to exert significant negative deleterious effects on kernel, milling, mixograph and bread-baking characteristics. It therefore remains a potential new tool for improving FHB resistance in hard red spring wheat.

Availability of data and material

Not applicable.

Code availability

Not applicable.

References

AACC (2010) AACC method 08-01.01, Ash—basic method. In: AACC approved methods of analysis, 11th edn. Cereals & Grains Association, Minnesota. http://dx.doi.org/10.1094/AACCIntMethod-08-01.01

AACC (2010) AACC method 10-05.01, Guidelines for measurement of volume by rapeseed displacement. In: AACC approved methods of analysis, 11th edn. Cereals & Grains Association, Minnesota, http://dx.doi.org/10.1094/AACCIntMethod-10-05.01

AACC (2010) AACC method 10-10-03, Optimized straight-dough bread-making method. In: AACC approved methods of analysis, 11th edn. Cereals & Grains Association, Minnesota. http://dx.doi.org/10.1094/AACCIntMethod-10-10.03

AACC (2010) AACC method 44-15.02, Moisture—air-oven methods. In: AACC approved methods of analysis, 11th edn. Cereals & Grains Association, Minnesota. http://dx.doi.org/10.1094/AACCIntMethod-44-15.02

AACC (2010) AACC method 46-30.01, Crude protein – combustion method. In: AACC approved methods of analysis, 11th edn. Cereals & Grains Association, Minnesota. http://dx.doi.org/10.1094/AACCIntMethod-46-30.01

AACC (2010) AACC method 54-40.02, Mixograph method. In: AACC approved methods of analysis, 11th edn. Cereals & Grains Association, Minnesota. http://dx.doi.org/10.1094/AACCIntMethod-54-40.02

AACC (2010) AACC method 55-10.01, Test weight per bushel. In: AACC approved methods of analysis, 11th edn. Cereals & Grains Association, Minnesota. http://dx.doi.org/10.1094/AACCIntMethod-55-10.01

AACC (2010) AACC method 55-31.01, Single-kernel characterization system for wheat kernel texture. In: AACC approved methods of analysis, 11th edn. Cereals & Grains Association, Minnesota. http://dx.doi.org/10.1094/AACCIntMethod-55-31.01

Battenfield SD, Guzman C, Gaynor RC, Singh RP, Pena RJ, Dreisagacker S, Fritz A, Poland J (2016) Genomic selection for processing and end use quality traits in the CIMMYT spring wheat breeding program. Plant Genome. https://doi.org/10.3835/plantgenome2016.01.0005

Bordes J, Ravel C, Le Gouis J, Lapierre A, Charmet G, Balfourier F (2011) Use of a global wheat core collection for association analysis of flour and dough quality traits. J Cereal Sci 54:137–147

Bugbee B, Koerner G, Albrechtsen R, Dewey W, Clawson S (1997) Registration of ‘USU-Apogee’ wheat. Crop Sci 37:626

Bugbee B, Koerner G, Albrechtsen R, Dewey W, Clawson S (1999) "'USU-Apogee' Wheat—Registration". Dwarf Crops Paper 11

Caffe-Treml M, Glover KD, Krishnana PG, Hareland GA (2010) Variability and relationships among Mixolab, Mixograph, and baking parameters based on multienvironment spring wheat trials. Cereal Chem 87:574–580

CIE (1986) Colorimetry (Publication 15.2), 2nd ed. Commission Internationale de L’Éclairage, Vienna, Austria

Finney KF, Yamazaki WT, Youngs VL, Rubenthaler GL (1987) Quality of hard, soft, and durum wheats. In: Heyne EG (ed) Wheat and wheat improvement. ASA, Madison, WI, pp 677–747

Garvin DF, Porter H, Blankenheim ZJ, Chao S, Dill-Macky R (2015) A spontaneous segmental deletion from chromosome arm 3DL enhances Fusarium head blight resistance in wheat. Genome 58:479–488

Gooding RW, Lafever HN, Campbell KG, Herlad LD (1997) Registration of ‘Freedom’ wheat. Crop Sci 37:1007

Graybosch R, Bockelman HE, Garland-Campbell KA, Garvin DF, Regassa T (2014) Wheat. In: Ciers B, Specht J, Carver B (eds) Smith S. Yield gains in major U.S. field crops. ASA, Madison, WI, pp 459–487

Gupta A (2002) Host plant resistance genes to Fusarium head blight of wheat: sources, inheritance, and determination of genetic control. Dissertation, The Ohio State University

Gusta LV, Chen THH (1987) The physiology of water and temperature stress. In: Heyne EG (ed) Wheat and wheat improvement. ASA, Madison, WI, pp 115–150

Hoseney RC, Rogers DE (1990) The formation and properties of wheat flour doughs. Crit Rev Food Sci Nutr 29:73–93

International Wheat Genome Sequencing Consortium (IWGSC) (2018) Shifting the limits in wheat research and breeding using a fully annotated reference genome. Science. https://doi.org/10.1126/science.aar7191

Jernigan KJ, Godoy JV, Huang M, Zhou Y, Morris CF, Garland-Campbell KA, Zhang Z, Carter AH (2018) Genetic dissection of end use quality traits in adapted soft white winter wheat. Front Plant Sci 9:271. https://doi.org/10.3389/fpls.2018.00271

Khan H (2019) Genetic improvement for end use quality in wheat. In: Qureshi A, Dar Z, Wani S (eds) Quality breeding in field crops. Springer, Cham, Switzerland, pp 239–253

Kumar A, Jain S, Elias EM, Ibrahim M, Sharma LK (2018) An overview of QTL identification and marker-assisted selection for grain protein content in wheat. In: Sengar R, Singh A (eds) Eco-friendly agro-biological techniques for enhancing crop productivity. Springer, Singapore, pp 245–274

Mackintosh CA, Garvin DF, Radmer LE, Heinen SJ, Muehlbauer GJ (2006) A model wheat cultivar for transformation to improve resistance to Fusarium head blight. Plant Cell Rep 25:313–319

Morris CF (2002) Purindolines: the molecular genetic basis of wheat grain hardness. Plant Mol Biol 48:633–647

Naraghi SM, Simsek S, Kumar A, Al Rabbi H, Alamri MS, Elias EM, Mergoum M (2019) Deciphering the genetics of end use quality traits in wheat. G3 9:1405–1427

Nganje WE, Katiebie S, Wilson WW, Leistritz FL, Bangsund DA (2004) Economic impacts of Fusarium Head Blight in wheat and barley: 1993–2001. NDSU Agribus Appl Econ Rep 538

Sidhu D, Gill KS (2004) Distribution of genes and recombination in wheat and other eukaryotes. Plant Cell Tis Organ Cult 79:257–270

Snijders CHA (1990) Fusarium head blight and mycotoxin accumulation of wheat, a review. Neth J Plant Pathol 96:187–198

Shewry PR, Hey SJ (2015) The contribution of wheat to human diet and health. Food Energy Secur 4:178–202

Sourdille P, Singh S, Cadalen T, Brown-Guidera GL, Gay G, Qi L, Gill BS, Dufour P, Murigneux A, Bernard M (2004) Microsatellite-based deletion bin system for the establishment of genetic-physical map relationships in wheat (Triticum aestivum L.). Funct Integr Genomics 4:12–25

Talbert LE, Hofer P, Nash D, Marting JM, Lanning SP, Sherman JD, Giroux MJ (2013) Hard white versus hard red wheats: taste tests and milling and baking properties. Cereal Chem 90:249–255

USDA NASS (2019) Agricultural statistics 2019. U.S. Government Printing Office. Washington, https://www.nass.usda.gov/Publications/Ag_Statistics/2019/2019_complete_publication.pdf

Worland T, Snape JW (2000) Genetic basis of worldwide wheat varietal improvement. In: Bonjean AP, Angus WJ (eds) The world wheat book. Lavoisier, Paris, France, pp 59–100

Acknowledgements

We would like to thank Mary Valenzuela and Christopher Cossette for their technical assistance, and Rafael Della Coletta for assistance in wheat genome sequence data mining.

Funding

Supported by USDA ARS CRIS Projects 5062-21000-030-00D (DFG) and 3060-43440-015-00D (LD).

Author information

Authors and Affiliations

Contributions

DFG grew experimental materials, analyzed data and wrote the manuscript. LD completed research and wrote the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

Not applicable.

Ethical approval

Not applicable.

Consent to participate

Not applicable.

Additional information

The use of trade, firm, or corporation names in this publication is for the information and convenience of the reader. Such use does not constitute an official endorsement or approval by the United States Department of Agriculture or the Agricultural Research Service of any product or service to the exclusion of others that may be suitable. USDA is an equal opportunity provider and employer. The complete nondiscrimination policy can be found on the USDA website.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Garvin, D.F., Dykes, L. Evaluating milling and baking quality associated with a Fusarium head blight resistance-enhancing genome deletion in wheat. CEREAL RESEARCH COMMUNICATIONS 49, 413–419 (2021). https://doi.org/10.1007/s42976-020-00122-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42976-020-00122-0