Abstract

A fast and convenient technique for Asphalt Binders was proposed in this paper, which was based on air-jet pressurized and laser to detect the transient deformation and creep recovery of asphalt. Taking five kinds of asphalt and modified asphalt commonly used in China as the research objects, the performance of asphalt were tested and analyzed by adopting the Penetration Test, Dynamic Shear Rheological (DSR) Test, Multiple Stress Creep and Recovery (MSCR) Test and the proposed test technology. The results verified the feasibility of the proposed test technology and the correlation between the traditional tests and the proposed test technology. The results demonstrated that the proposed test technology had good discrimination ability for different kinds of asphalt and could effectively reflect the performance differences. The new test protocol was similar to the Penetration Test. There was a significant correlation between the maximum deformation index and penetration index. The correlation coefficient was above 0.8, and the p value was much less than 0.01. It could be used as a possible alternative to the Penetration Test. The proposed new test was relatively convenient and fast compared with the dynamic shear test. There was a linear correlation between the maximum deflection index and the complex shear modulus G*, and the correlation coefficient between the recovery index and the phase angle is above 0.8, which indicated that the proposed new test and the DSR test had a significant correlation. There was also a good correlation between the creep recovery index of MSCR test and the recovery data of the proposed new test method. The research results provided a new solution for the performance test and evaluation of asphalt in China.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The performance of asphalt material is one of the key factors affecting the performance of asphalt pavement. The research and the evaluation of asphalt material run through the whole research of asphalt pavement. At present, the performance evaluation methods of asphalt in China are mainly based on experience-based needle penetration grading evaluation system and performance grading (PG) evaluation system based on rheological properties of asphalt [1, 2]. Penetration test is an empirical method, simple and convenient, and is widely used in asphalt performance evaluation. The instruments of penetration test are cheap and simple to operate, which can basically meet the needs of road engineering in China [3, 4]. However, penetration test has certain limitations. It is a semi-empirical evaluation test method, and has no direct relationship with the road performance of asphalt mixture [5, 6]. The results of asphalt penetration test can only reflect the material reaction of asphalt material within a certain loading time, but cannot obtain the deformation recovery information of asphalt under unloading condition. For example, the penetration test cannot distinguish two asphalt materials with the same penetration value but obviously different deformation resilience [7]. Performance grade (PG) test is a major research result proposed by SHRP program in the United States, which is scientific and advanced by characterizing rheological properties and pavement properties of asphalt [8,9,10,11,12]. However, PG test has certain limitations. It is difficult to detect asphalt samples quickly and in real time due to complexity and long time of the test. The test equipment is expensive and the operation is complicated. It is not suitable for testing on the construction site and difficult to promote. The test results of this method are relatively applicable to the asphalt, while the high discreteness for the modified asphalt, and some indexes are not applicable to the modified asphalt [13,14,15].

This study proposed a test method of asphalt material performance based on air jet pressurized and laser to detect the transient deformation and creep recovery of asphalt. The main technical principle is as follows: the surface of the asphalt sample is stressed for a period of time by air jet pressurization at the selected temperature. The asphalt sample deforms under the action of pressure and the deformation recovers after loading. In this process, the instantaneous deformation and the recovery deformation of the asphalt sample are measured by the laser measuring device. The deformation and the recovery data obtained by the laser measurement are used to draw the deformation curve of the asphalt sample during the whole process from the initial deformation under stress loading to the final partial deformation, which can be used to analyze and verify the quality of the asphalt sample. A schematic of the operation principle of the test device is shown in Fig. 1. Figure 2 shows indentations produced in asphalt samples during a test. A first article version of the testing device was developed by Laser Technology Inc. (LTI). Further testing was conducted at Dongre Laboratory Services Inc. (DLSI) and FHWA using the working prototype to further evaluate the technology [16].

The purpose of this study is to verify the feasibility of the new technology through the test analysis of asphalt and modified asphalt commonly used in China. The correlation of several test methods was analyzed through the needle Penetration Test, Dynamic Shear Rheology (DSR) Test, and Multi-Stress Repeated Creep Recovery (MSCR) Test. The research results provide a new solution for asphalt performance evaluation and contribute to the popularization and application of this test technology in China.

2 Experimental Approach

Five kinds of asphalt and modified asphalt commonly used in China were tested and analyzed by adopting the Penetration Test, Dynamic Shear Rheological (DSR) Test, MSCR Test, and the proposed new test technology. These binders are listed in Table 1.

2.1 The introduction of the Air-jet Laser Detection Test for Asphalt Binders

The asphalt sample (about 85 g) was poured into the asphalt sample dish, and the temperature of the sample was kept at 25 ± 0.1 °C for 1 h ± 10 min to make the internal temperature of the sample balanced. The surface of the asphalt sample was pressurized by air jet, the loading pressure was selected as 0.05 MPa, the loading time was 20 s, and the recovery time was 10 s. The maximum creep deformation and the creep recovery rate of asphalt samples were obtained by laser measurement. The same sample was tested in parallel for 5 times. Figure 3 shows the typical deformation recovery curve of asphalt samples.

2.2 The Asphalt Penetration Test

The penetration test of asphalt was carried out according to the Chinese standard “Test Procedures for Asphalt and Asphalt Mixture of Highway Engineering” T0604-2011. The test temperature was selected at 25 °C, and the same sample was tested parallel for at least 3 times.

2.3 Dynamic Shear Rheological (DSR) Test

According to the test method of AASHTO T315-10 [8], the test temperature range was 56–88 °C, the angular frequency was 10 rad/s, and complex shear modulus G* and phase angle were recorded.

2.4 Multi-Stress Repeated Creep Recovery Test (MSCR)

The MSCR test protocol (AASHTO T 350) was used to test the asphalt. The MSCR test standard requires that the asphalt be pre-aged using the Rolling Thin-Film Oven (RTFO) aging method (AASHTO T 240) and the test temperature is based on the climate [17]. The MSCR tests were carried out under 0.1 kPa and 3.2 kPa creep stresses respectively, and the recovery rate test results were recorded.

3 Results and Discussion

3.1 Evaluation of the Air-Jet Laser Detection Test for Asphalt Binders

Figure 4 shows the curves of deformation recovery under pressure loading for five kinds of asphalt. As shown, there is a wide range of responses of the listed binders in terms of both depth of indentation as well as in the level of recovery data obtained by the Air-jet Laser Detection Test. For different types of asphalt binders, the Air-jet Laser Detection Test technology can directly reflect the difference of deformation recovery ability among different types of asphalt binders.

The experimental method of Air-jet Laser Detection Technology is essentially a creep recovery test. Table 2 shows the expression of pressure loading deformation recovery function of 5 kinds of asphalt. It can be seen that the entire deformation stage of asphalt can be expressed by piecewise function. In the loading stage, when the loading stress is constant, the strain of asphalt gradually increases with time, which is the strain creep stage. The strain rate of the unmodified asphalt follows a linear distribution, and the strain increases linearly with time. The unmodified asphalt is in the steady creep stage under the test conditions (25 °C, 0.05 MPa). The strain rate of modified asphalt follows the inverse function distribution, and the strain rate decreases gradually. The modified asphalt is in the initial creep or transition creep stage under the test conditions (25 °C, 0.05 MPa). In the unloading stage, the asphalt is in the recovery stage and the strain gradually decreases. The deformation function follows exponential distribution, reflecting the recovery ability of different asphalt materials. The deformation recovery ability of modified asphalt is obviously better than that of unmodified asphalt (Table 3).

5# asphalt was a high viscosity modified asphalt prepared by adding 12% high viscosity modifier on the 2# asphalt. By comparing the test results of asphalt 2# and asphalt 5#, it is verified whether the new test technology will have a clear response to the addition of asphalt modifier. The test results are shown in Table 1. The test results show the difference between unmodified asphalt and high viscosity modified asphalt. The Air-jet Laser Detection Test for Asphalt Binders can effectively discriminate the asphalt properties of different modifier content. After the addition of high viscosity modifier, the deformation recovery ability of 2# unmodified asphalt has been significantly improved, which greatly improves the deformation resistance of asphalt. It is verifies the relevant research results that high viscosity modifier can effectively improve the high-temperature deformation resistance of asphalt [18, 19].

To determine the repeatability of the Air-jet Laser Detection Test, several asphalt binders were tested in replicate. Five replicate measurements were made as shown in Table 4. The repeatability was found to be in the range of 2–4 percent for maximum deflection and between 2 and 6% in the case of percent-recovery values.

3.2 Correlation Between Air-Jet Laser Detection Test and Asphalt Penetration Test

It can be seen from the second section that the test processes of air-jet laser detection test and asphalt penetration test are roughly similar. Table 5 shows the test results of asphalt penetration test and air-jet laser detection test for the selected asphalt binders. Both tests were conducted at 25 °C. Regression analysis was performed on the test result data, and the least square method was used for parameter estimation. The correlation between the penetration values and the maximum deflection data is shown in Fig. 5. The \({R}^{2}\) value equals 0.8069. The \({R}^{2}\) means coefficient of determination, which reflects the proportion of the total variation of the dependent variable that can be explained by the independent variable through the regression relation. It is between 0 and 1, and the closer it is to 1, the better the regression fitting and the stronger the correlation. It is generally believed that models above 0.8 have higher goodness of fit. It is suggested that there is a good correlation between asphalt penetration values and maximum deflection data.

Penetration values data and maximum deflection values data obey normal distribution and the measured core variable is depth. P value test is adopted to analyze the penetration values data and maximum deflection values data, and to further verify the correlation between them. The analysis results are shown in Table 6.

According to the statistical significance test method, P values are generally considered significant if P < 0.05, and very significant if P < 0.01. The analysis results showed that the two-tailed P value of maximum deformation values and the penetration values was 9.25E−18, which was much less than 0.01, indicating that the correlation level was very significant, and it could be determined that there was a strong correlation between the penetration data and the maximum creep deformation data.

The penetration test is an empirical test. Penetration needles often encounter polymer-rich and asphalt-rich phases in asphalt binders, resulting in inconsistent test results. The air-jet laser detection test produces an indentation using air pressure which engages the bulk of the asphalt binders. Thus, it generates repeatable measurements that better distinguish binders. For two asphalt binders (such as 1# and 4# asphalt) with the same penetration value but obviously different deformation and rebound ability, the air-jet laser detection test is a better solution. The air-jet laser detection test may be used as a possible alternative to the penetration test and need to be further research.

3.3 Correlation Between Air-Jet Laser Detection Test and Dynamic Shear Rheological (DSR) Test

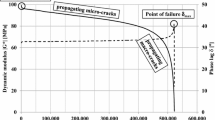

Several binders listed in Table 1 were tested by adopting Dynamic Shear Rheological (DSR) Test and Air-jet Laser Detection Test. The DSR test temperature is 76 °C. The Air-jet Laser Detection test data, however, were generated on the same asphalt at 25 °C. Figure 6 shows the correlation between the complex modulus (G*) obtained by the DSR test and the maximum deflection obtained by the Air-jet Laser Detection Test. There is a linear correlation between the maximum deflection index and the complex shear modulus (G*), and the correlation value is 0.9483, indicating that there is a good correlation between them. Figure 7 shows good correlation with the high-temperature phase angle and recovery data obtained by the Air-jet Laser Detection Test. The \({R}^{2}\) value equals 0.8456. Figure 7 also clearly shows that the Air-jet Laser Detection Test can correctly identify the binder with low-phase angle and the performance difference of two different asphalt with the same phase angle, which is the advantage of the Air-jet Laser Detection Test.

3.4 Correlation Between Air-Jet Laser Detection Test and Multi-stress Repeated Creep Recovery Test (MSCR)

The MSCR test standard requires that the asphalt be pre-aged using the RTFO aging method and the test temperature is based on the climate. The Air-jet Laser Detection test data, however, were generated on the same asphalt at 25 °C in an unaged condition. Figure 8 shows the correlation between the MSCR recovery rate and the recovery rate of the Air-jet Laser Detection Test. The MSCR multiple stress creep recovery tests were carried out at 64 °C under creep stresses of 0.1 kPa and 3.2 kPa, the loading time was 1 s, and the recovery time was 9 s. The air-jet laser detection test was carried out under 25 °C and 0.05 MPa pressure, and the loading time of the test is 20 s, and the recovery time is 10 s. Although the temperature and the loading conditions of the two tests are different, the recovery rate data of MSCR multiple stress creep recovery test obtained by DSR shear rheometer, no matter corresponding to the creep stress condition of 0.1 kPa or the creep stress condition of 3.2 kPa, have a better linear regression fitting effect with the recovery rate data obtained by the air-jet laser detection test. Figure 9 shows relationship between Jnr indicator data from MSCR and the creep and recovery data of the Air-jet Laser Detection Test. The filled circles and the solid line in Fig. 9 represent the Jnr value measured by the MSCR test at climate temperature and RTFO condition. The filled triangle symbols show the measured data from the air-jet laser detection test at 25 °C and the unaged condition. The rheological behavior represented by the slope of the two curves is the same (− 0.83). The constant multiplier for the creep and recovery data of the Air-jet Laser Detection Test is 5.8068, whereas that for the Jnr indicator data for the MSCR test is 21.142. This is explained by the difference in compliance expected due to difference in aging (RTFO versus unaged) as well as the difference in test temperatures (25 °C versus climate temperature). This implies that it may be possible to successfully predict the MSCR behavior in RTFO aged condition at climate temperatures from the recovery rate data measured at 25 °C in unaged condition of the Air-jet Laser Detection Test.

4 Conclusions

A new performance evaluation technique of asphalt was proposed in this paper, which was based on air-jet pressurized and laser to detect the transient deformation and creep recovery of asphalt. The application of the air-jet laser detection technology for asphalt binders was analyzed through the performance tests of five kinds asphalt commonly used in China, with the following main findings:

-

1.

The new test method adopts air-jet to produce creep and recovery loading and laser to detect the transient deformation and creep recovery deformation of asphalt, which can accurately identify different types of asphalt and directly reflect the performance differences between various asphalt binders. It was found to be easy to use and produced repeatable data quickly. The proposed test provides a new solution for asphalt performance testing and evaluation.

-

2.

The proposed test is similar to the asphalt penetration test process. The maximum creep depth index has a significant correlation with the needle penetration index, the correlation coefficient is above 0.8, and the P value is much less than 0.01. It may be used as a possible alternative to the penetration test and need to be further research.

-

3.

Compared with traditional more time consuming test method of asphalt, such as DSR test and MSCR test, the proposed test method is relatively convenient and produced repeatable data quickly. The maximum creep depth index of the proposed test has a logarithmic correlation with the complex shear modulus (G*) index in DSR test, and the correlation coefficient between recovery rate index and high-temperature phase angle is above 0.8. There is also a good correlation between the recovery rate index of the proposed test and the creep recovery rate index of the MSCR test. It is necessary to further study the rheological properties of asphalt based on the proposed test.

References

JTG E20. (2011). Standard test methods of bitumen and bituminous mixtures for highway engineering. Ministry of Communications.

JTG F40. (2004). Technical specification for construction of highway asphalt pavements. Ministry of Communications.

Hu, X. Q. (2015). Overview of road petroleum asphalt evaluation system. Architectural Engineering Technology and Design, 7, 878.

Zhang, Y. Z., & Wang, C. H. (2003). Classification of petroleum bitumen product standard. Petroleum Bitumen, 17(1), 44–47.

Huang, W. D., Sun, L. J., Zhang, Z. Q., et al. (2005). Study on penetration index of asphalt. Journal of Tongji University (Natural Science), 33(3), 306–310.

Li, F. J. (2013). Experimental study on asphalt penetration index. Road Construction and Machinery, 30(6), 57–63.

Gao, R. (2012). Study on key technical parameters and test methods of SBS modified asphalt. Changan: Chang’an University. in Chinese.

American Association of State Highway and Transportation Officials (AASHTO) T315-10. (2010). Standard method of test for determining the rheological properties of asphalt binder using a dynamic shear rheometer. In Standard specifications for transportation materials and methods of sampling and testing, Part 2B, 30th Edn.

Zhou, Q. H., & Jia, Y. (2008). Evaluation of high temperature performance test method of asphalt binder. Journal of Chang ’an University (Natural Science Edition), 28(2), 9–12.

The Multiple Stress Creep Recovery (MSCR) Procedure[R]. (2011). U.S. Department of Transportation, Federal Highway Administration, Office of Pavement Technology, FHWA-HIF-11-038.

Bahia, H. U., Hanson, D. I., Zeng, M. et al. (2001). Characterization of modified asphalt binders in superpave mix design[R]. NCHRP Report 459, Transportation Research Board, National Research Council.

Al-Adham, K., & Al-Abdul Wahhab, H. (2018). Influence of temperature on Jnr values of polymer modified asphalt binders. International Journal of Pavement Research and Technology, 11(6), 603–610.

Xu, S. F., Zhou, Z. H., Qian, P. Z., et al. (2003). Effectiveness analysis of modified asphalt in superpave specification. Journal of Highway and Transportation Science and Technology, 20(1), 41–44.

Liu, Z. Y., Zhang, M., & Shao, L. G. (2009). Effect of DSR on PG classification of modified asphalt. Journal of China and Foreign Highway, 29(6), 241–244.

Saboo, N., & Kumar, P. (2016). Use of flow properties for rheological modeling of bitumen. International Journal of Pavement Research and Technology, 9(1), 63–72.

Dongre, R., Youtcheff, J., Newman, J. (2015). Development of a Quality Assurance Test (QAT) for Asphalt Binders. In Proceedings of the Canadian technical asphalt association (CTAA), Winnipeg, Manitoba, Canada.

American Association of State Highway and Transportation Officials (AASHTO) T350. (2013). Multiple Stress Creep And Recovery Test. Standard specifications for transportation materials and methods of sampling and testing, Part 2B, 2013 Edition, Washington, D.C., T350-1:5.

Zhou, P. Y., Cheng, Z. H., Li, X., et al. (2015). Study on the effect of high viscosity modifier on asphalt performance. Journal of Highway and Transportation Research and Development (Applied Technology Edition), 11, 56–58.

Chen, J. S., & Lin, K. Y. (2005). Mechanism and behavior of bitumen strength reinforcement using fibers. Journal of Materials Science, 40(1), 87–95.

Acknowledgements

This research was funded by the Special Fund of Chinese Central Government for Basic Scientific Research Operations in Commonweal Research Institutes (no. 2018-9006).

Funding

The Special Fund of Chinese Central Government for Basic Scientific Research Operations in Commonweal Research Institutes (no. 2018-9006).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interest regarding the publication of this research paper.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Wang, Z., Huang, X. & Ma, R. Application of the Air-Jet Laser Detection Technology for Asphalt Binders. Int. J. Pavement Res. Technol. (2023). https://doi.org/10.1007/s42947-023-00387-8

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42947-023-00387-8