Abstract

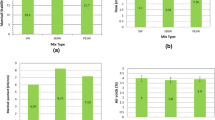

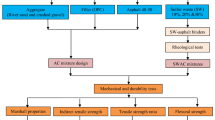

This study analyzes the possibility of using sulfur waste (SW), styrene–butadiene–styrene (SBS) and waste polypropylene (WPP) as sustainable materials in asphalt paving mixtures. Sulfur waste asphalt concrete (SWAC) combinations with virgin (V), SBS and WPP-asphalt binders were constructed for the study. The SW concentration in the asphalt concrete (AC) mixture was set at 5 percent (by weight of aggregate), while the weight of SBS and WPP polymers was set at 5 percent (by weight of asphalt). The tests performed to evaluate the performance and durability were the Marshall stability, Marshall quotient, indirect tension, tensile strength ratio, semi-circular bend and deformation strength in Kim tests. Based on these testing results, all V, SBS and WPP-SWAC combinations meet the minimal ASTM standards of 8kN stability, 2–4 mm flow, 3–5 percent air voids, and 14 percent VMA at the same optimal binder content, SBS and WPP increased the performance and durability of SWAC mixtures. SBS-SWAC mixture showed better performance and durability than the WPP-SWAC mix (i.e. lowering of deformation phenomenon, crack propagation, and moisture damage). In this study, it was determined that SW and WPP can be recycled and used as sustainable materials for paving applications where they available and the cost of transportation is lower than virgin materials.

Similar content being viewed by others

References

Boustead, 1993 Boustead I. Eco-profiles of the European polymer industry. Report 3. Polythene and polypropylene. Association of Plastics Manufacturers in Europe; 1993.

Al-Hadidy, A. I. (2022). Sustainable recycling of sulfur waste through utilization in asphalt paving applications. International Journal of Pavement Research and Technology. https://doi.org/10.1007/s42947-021-00143-w

Anurag, K., Xiao, F., & Amirkhanian, S. N. (2009). Laboratory investigation of indirect tensile strength using roofing polyester waste fibers in hot mix asphalt. Construction and Building Materials, 23(2009), 2035–2040.

Foo, K. Y., Hanson, D. I., & Lynn, T. A. (1999). Evaluation of roofing shingles in hot mixture asphalt. Journal of Materials in Civil Engineering, 11, 15–20.

Xiao, F. P., Amirkhanian, S. N., & Juang, C. H. (2007). Rutting resistance of rubberized asphalt concrete pavements containing reclaimed asphalt pavement mixtures. Journal of Materials in Civil Engineering, 19, 475–483.

Shaopeng, Wu., Zhu, J., Zhong, J., et al. (2011). Experimental investigation on related properties of asphalt mastic containing recycled red brick powder. Construction and Building Materials, 25, 2883–2887.

Huang, B., Ma, L., & Wenjuan, Xu. (2010). Research development of modified asphalt. Materials Reviews., 24(1), 137–141.

Zhiguo, C. (2010). Research on performance of volcanic ash asphalt mastic. Harbin: Harbin Institute of Technology.

Xiaokai, Y., Rui, X., Tianqi, F., Tao, Y., & Yanping, S. (2015). Laboratory investigation of the rheological property of activated coal gangue modified asphalt binder. Materials Reviews., 29(6), 135–139.

Gautam, P. K., et al. (2018). Sustainable use of waste in flexible pavement: A review. Construction and Building Materials, 180, 239–253.

Pouranian, M. R., & Shishehbor, M. (2019). Sustainability assessment of green asphalt mixtures: A review. Environments, 6(6), 73.

Lambert, S., & Wagner, M. (2017). Environmental performance of bio-based and biodegradable plastics: The road ahead. Chemical Society Reviews, 46(22), 6855–6871.

Wang, J., et al. (2018). Performance investigation and sustainability evaluation of multiple-polymer asphalt mixtures in airfield pavement. Journal of Cleaner Production, 189, 67–77.

RuiXiong, Lu., Wang, X. Y., Yang, Fa., Sheng, Y., Guan, B., & Chen, H. (2018). Experimental investigation on related properties of asphalt mastic with activated coal gangue as alternative filler. International Journal of Pavement Research and Technology, 11(2018), 725–732.

Punith, V. S., & Veeraragavan, A. (2007). Behavior of asphalt concrete mixtures with reclaimed polyethylene as additive. Journal of Materials in Civil Engineering, 19(6), 500–507.

Colagrande, S. (1997). Polyolefinic plastics taken from solid urban waste in bituminous concrete. In J. G. Cabrera (Ed.), Proceedings of the Second European Symposium on Performance and Durability of Bituminous Materials (pp. 85–100). Leeds: University of Leeds.

Little, D. N. (1993). Enhancement of Asphalt concrete mixtures to meet structural requirements through the addition of recycled polyethylene. In H. Fred Waller (Ed.), Use of waste materials in hot-mix asphalt, ASTM STP 1193 (pp. 210–230). Philadelphia: American Society for Testing and Materials.

Zoorob, S. E., & Suparma, L. B. (2000). Laboratory design and investigation of the properties of continuously graded Asphaltic concrete containing recycled plastics aggregate replacement (Plastiphalt). Cement & Concrete Composites, 22, 233–242.

Von Quintus, H. L., Mallela, J., & Buncher, M. (2007). Quantification of effect of polymer-modified asphalt on flexible pavement performance. Transportation Research Record, 2001(1), 141–154.

Arabani, M., Mirabdolazimi, S. M., & Sasani, A. R. (2010). The effect of waste tire thread mesh on the dynamic behaviour of asphalt mixtures. Construction and Building Materials, 24, 1060–1068.

Karasahin, M., & Terzi, S. (2007). Evaluation of marble waste dust in the mixture of asphaltic concrete. Construction and Building Materials, 21(2007), 616–620.

Taha, R., Al-Rawas, A., Al-Jabri, K., Al-Harthy, A., Hassan, H., & Al-Oraimi, S. (2004). An overview of waste materials recycling in the Sultanate of Oman. Resources, Conservation and Recycling, 41(2004), 293–306.

Putman, B. J., & Amirkhanian, S. N. (2004). Utilization of waste fibers in stone matrix asphalt mixtures. Resources, Conservation and Recycling, 42(2004), 265–274.

Ahmed et al. (1985) “Using sulfur waste as replacement of asphalt cement in paving constructions". NCCL, No. 28.

Al-Hadidy, A. I., & Yi-qiu, T. (2009). Effect of polyethylene on life of flexible pavements. Journal of Construction and Building Materials, 23, 1456–1464.

Al-Hadidy, A. I., & Yi-qiu, T. (2009). Mechanistic approach for polypropylene-modified flexible pavements. Journal of Materials and Design, 30, 1133–1140.

Waller HF. Use of waste materials in hot-mix asphalt. ASTM Publication No. 04–011930–08; 1992. p. 16–98.

Xiong, R., Fang, J., Anhua, X., et al. (2015). Laboratory investigation on the brucite fiber reinforced asphalt binder and asphalt concrete. Construction and Building Materials., 83, 44–52.

ASTM (American Society for Testing and Materials) (2015). Standard Test Method for Marshall Stability and Flow of Asphalt Mixtures, D6927.

SCRB (State cooperation of road and bridges). 2003. Hot mix asphaltic concrete pavement, Iraqi standard specification, Ministry of Housing and Construction, Department of Design and Study, Section R-9.

ASTM Standard Specifications, (2015). Part IB, Volume 04.03 Road and Paving Materials Vehicle Pavement Systems.

National Center for Construction Laboratories (NCCL), “Materials and Construction Works Specification”, Ministry of Housing and Construction and Public Works. Directorate of Research and Technical Affairs, January, 2018, Baghdad-Iraq.

Al-Hadidy, A. I. (2020). “Performance of SBS-HMA mixes made with sasobit and zeolite”. Journal of Materials in Civil Engineering, 32(10):06020017.

American society for Testing and Materials (ASTM), (2005), Standard Practice for Determining the Separation Tendency of Polymer from Polymer Modified Asphalt, Section 4, Vol. 04–03.

American society for Testing and Materials (ASTM), (2001), standard Specification for Hot-Mixed, Hot-Laid Bituminous Paving Mixtures, D 3515 – 76a, Section 4, Vol. 04–03.

British Standards Institution. Sampling and examination of bituminous mixture for road and other paved areas. Part 3: Method for design and physical testing. BS 598, 1990.

ASTM (American Society for Testing and Materials) (2012). Standard Test Method for Indirect Tensile (IDT) Strength of Bituminous Mixtures, D6931.

Yousefi, A., Behnood, A., Nowruzi, A., & Haghshenas, H. (2021). Performance evaluation of asphalt mixtures containing warm mix asphalt (WMA) additives and reclaimed asphalt pavement (RAP). Construction and Building Materials, 268, 121200.

G. Nsengiyumva, Development of Semi-Circular Bending (SCB), Fracture Test for Bituminous Mixtures (2015)

ASTM (American Society for Testing and Materials) (2016). Standard Test Method for Evaluation of Asphalt Mixture Cracking Resistance using the Semi-Circular Bend Test (SCB) at Intermediate Temperatures, D8044.

Kaseer, F., Yin, F., Arámbula-Mercado, E., Epps Martin, A., Daniel, J. S., & Salari, S. (2018). Development of an index to evaluate the cracking potential of asphalt mixtures using the semi-circular bending test. Construction and Building Materials., 167, 286–298.

Fakhri, M., Maleki, H., & Hosseini, S. A. (2017). Investigation of different test methods to quantify rutting resistance and moisture damage of GFM-WMA mixtures. Construction and Building Materials., 152, 1027–1040.

Doh, Y. S., Yun, K. K., Amirkhanian, S. N., & Kim, K. W. (2007). Framework for developing a static strength test for measuring deformation resistance of asphalt concrete mixtures. Construction and Building Materials, 21, 2047–2058.

Fakhri, M., Bahmai, B. B., & Javadi, S. (2020). An evaluation of the mechanical and self-healing properties of warm mix asphalt containing scrap metal additives. Journal of Cleaner Production, 253, 119963.

SPSS, (1999). Inc.version 10.0.5, Chicago IIIinois.

Mohammed, A.A, (1993). “Chemistry of polymers”.College of Education, Chemistry Department., University of Mosul,Mosul-Iraq,166.

Yu, Y., David, H., & Reynaldo, R. (2017). Fracture tolerance of asphalt binder at intermediate temperatures. Journal of Materials in Civil Engineering, 29(9), 4017108.

Yan, Y., Preti, F., Romeo, E., Lopp, G., Tebaldi, G., & Roque, R. (2018). Fracture energy density of interstitial component of asphalt mixtures. Materials and Structures, 51(5), 118.

Singh, D., Ashish, P. K., & Chitragar, S. F. (2018). Laboratory performance of recycled asphalt mixes containing wax and chemical based warm mix additives using semi circular bending and tensile strength ratio tests. Construction and Building Materials, 158, 1003–1014.

Mohammad, L. N., Elseifi, M. A., Cooper, S. B., Challa, H., & Naidoo, P. (2013). Laboratory evaluation of asphalt mixtures that contain biobinder technologies. Transportation Research Record, 2371(1), 58–65.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

There is no conflict of interest.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Al-Hadidy, A.I. Laboratory Evaluation of Sulfur Waste Asphalt Mixtures Containing SBS and Waste Polypropylene Polymers. Int. J. Pavement Res. Technol. 17, 503–517 (2024). https://doi.org/10.1007/s42947-022-00252-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42947-022-00252-0