Abstract

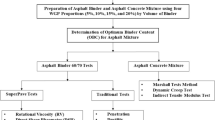

The vast quantity of sulfur waste (SW) materials accumulating in Iraq is creating costly disposal and gas emission problem. Application of SW as an asphalt binder performance extender is an economical solution to decrease virgin binder usage, as well as toxic gas emission. The present study investigates the potential use of SW as a partial substitution for sustainable pavement construction. Asphalt cement binder was partially substituted with different percentages of SW (10%, 20%, and 30% by weight). The resultant binders were subjected to penetration, ductility, softening point, absolute viscosity, elastic modulus, durability, and cracking index tests. Furthermore, a total of three sulfur waste-asphalt concrete (SWAC) mixtures and one asphalt concrete (AC) reference mixture were designed for the study. Three SWAC mixtures were designed with 10%, 20%, and 30% SW content, respectively. Mechanical and durability tests including Marshall stability, Marshall quotient, static indirect tensile strength at 25 and 60 °C, tensile strength ratio, and flexural strength at 0 and 15 °C were conducted on AC and SWAC mixtures. Results indicate that 10% SW-substituted binder show lower softening point and durability and keep the ductility value at a minimum range of ASTM specification of 100+ cm and temperature susceptibility in the preferable range. The SWAC mixtures show lower Marshall stability and moisture susceptibility. The values of stability and tensile strength ratio are still greater than the minimum values of ASTM specification limit up to 20% SW. Although flexural strain values of 10% SWAC mixtures is lower than those of control mixtures, these strain values considered to be acceptable. Overall, 10% of SW by weight of asphalt can be recycled and used as sustainable materials for paving applications to that found in this study.

Similar content being viewed by others

References

Federal Highway Administration. (2016). Strategies for improving sustainability of asphalt pavements. In US department of Transportation, Office of Pavement Technology, FHWA-HIF-16-012.

Al-Hadidy, A.I. (2001). Influence of polyethylene and sulfur waste on characteristics of asphalt paving materials, M.Sc. thesis, college of Engg. University of Al-Mustansiriyah, Baghdad-Iraq.

Cocurullo, A., Grenfell, J., Yusoff, N. I. M., & Airey, G. (January). Effect of moisture conditioning on fatigue properties of sulphur modified asphalt mixtures. In 7th RILEM International Conference on Cracking in Pavements (pp. 793–803). Springer

Kentucky Product Evaluation List. (2010). Shell Thiopave. http://www.ktc.uky.edu (2010).

Kennedy, T. W., Haas, R., Smith, P., Kennepohl, G. A., & Hignell, E. T. (1977). “Engineering evaluation of sulphur-asphalt mixtures.” Transportation Research Record 659, Transportation Research Record, Washington, DC, 12–17.

Bencowitz, I., & Boe, E. S. (1938). Effect of Sulphur upon some of the Properties of Asphalts. In Proc. ASTM (Vol. 38, No. Part II, p. 539).

Kennepohl, G. J. A., Logan, A., & Bean, D. C. (1975). Conventional Paving Mixes with Sulphur-Asphalt Binders. In Proceedings of the Association of Asphalt Paving Technologists (Vol. 44, pp. 485–518).

Beatty, T. L., Dunn, K., Harrigan, E. T., Stuart, K., & Weber, H. (1987). Field evaluation of sulfur-extended asphalt pavements. Transportation research record, 1115, Asphalt Materials and Mixtures, p. 161–170.

Deme, I., & Kennedy, B. (2004). Use of sulfur in asphalt pavements. In: SURF 2004: 5th Int. Symp. on Pavement Surface Characteristics, Roads and Airfields, Toronto.

Taylor, A., Tran, N., May, R., Timm, D., Robbins, M., & Powell, B. (2010). Laboratory evaluation of sulfur-modified warm mix. Journal of the Association of Asphalt Paving Technologists, 79, 403–442.

Safaei, F., Lee, J. S., Nascimento, L. A. H. D., Hintz, C., & Kim, Y. R. (2014). Implications of warm-mix asphalt on long-term oxidative ageing and fatigue performance of asphalt binders and mixtures. Road Materials and Pavement Design, 15(sup1), 45–61. https://doi.org/10.1080/14680629.2014.927050

Cooper, S. B., III., Mohammad, L. N., & Elseifi, M. A. (2011). Laboratory performance characteristics of sulfur-modified warm-mix asphalt. Journal of Materials in Civil Engineering, 23(9), 1338–1345.

Croteau, J., & Tessier, B. (2008). Warm mix asphalt paving technologies: A road builder’s perspective, de annual conference and exhibition of the Transportation Association of Canada—Transportation: A key to a sustaintable future, 2008.

Pérez-Martínez, M., Moreno-Navarro, F., Martín-Marín, J., Ríos-Losada, C., & Rubio-Gámez, M. C. (2014). Analysis of cleaner technologies based on waxes and surfactant additives in road construction. Journal of Cleaner Production, 65, 374–379.

Lee, W., Chao, W., Shih, M., Tsai, C., Chen, T., & Tsai, P. (2004). Emissions of polycyclic aromatic hydrocarbons from batch hot mix asphalt plants. Environmental Science & Technology, 38(20), 5274–5280.

Strickland, D., Colange, J., Martin, M., & Deme, I. (2009). Performance properties of sulphur extended asphalt mixtures with modified sulphur pellets. In Proceedings of the International Society for Asphalt Pavements.

Timm, D., Tran, N., Taylor, A., Robbins, M., & Powell, B. (2009). Evaluation of mixture performance and structural capacity of pavements using Shell Thiopave. Phase I: Mix design, laboratory performance evaluation and structural pavement analysis and design. NCAT Rep. 09–05, National Center for Asphalt Technology, Auburn, AL.

Strickland, D., Colange, J., Shaw, P., & Pugh, N. (2008). A study of the low-temperature properties of sulphur extended asphalt mixtures. In Canadian Technical Asphalt Association.

Cooper, S. B., III., Elseifi, M., Mohammad, L. N., & Hassan, M. (2012). Performance and cost-effectiveness of sustainable technologies in flexible pavements using the mechanistic-empirical pavement design guide. Journal of Materials in Civil Engineering, 24(2), 239–247.

Sarsam, S. I., & Lafta, I. M. (2014). Assessment of modified—asphalt cement properties. The Journal of Engineering, 20(6), 1–14.

Rezvani, V., & Saghi, H. (2015). Characteristics and preparation method of sulfur extended asphalt mixtures. American Journal of Civil Engineering, 3(2–2), 69–74.

Elkholy, S. A., Abd El-Rahman, A. M. M., El-Shafie, M., & Abo-Shanab, Z. L. (2018). Physical and rheological properties of modified sulfur asphalt binder. International Journal of Pavement Research and Technology, 11, 838–845.

Ahmed et al., (1985). Using sulfur waste as replacement of asphalt cement in paving constructions. NCCL, No. 28.

Nguyen, V. H., & Le, V. P. (2019). Performance evaluation of sulfur as alternative binder additive for asphalt mixtures. International Journal of Pavement Research and Technology, 12, 380–387.

Federal Highway Administration. (2012). An alternative asphalt binder, sulfur-extended asphalt (SEA). In US department of Transportation, Office of Pavement Technology, FHWA-HIF-12-037.

ASTM Standard Specifications. (2015). Part IB, Volume 04.03 Road and Paving Materials Vehicle Pavement Systems.

ASTM Standard Specifications. (2015). Part IB, Volume 04–02, Concrete and Aggregates.

State cooperation of road and bridges (SCRB) (2003). Hot mix asphaltic concrete pavements. In Iraqi standard specification. Ministry of Housing and construction. Department of Design and Study, section R9.

American association of state highway and transportation officials (AASHTO). (2010). Standard specifications for transportation materials and methods of sampling and testing, 30th edition, part 2A.

Yousefi, A., Behnood, A., Nowruzi, A., & Haghshenas, H. (2021). Performance evaluation of asphalt mixtures containing warm mix asphalt (WMA) additives and reclaimed asphalt pavement (RAP). Construction and Building Materials, 268, 121200.

Yousefi, A. A., Sobhi, S., Aliha, M. R. M., Pirmohammad, S., & Haghshenas, H. F. (2021). Cracking properties of warm mix asphalts containing reclaimed asphalt pavement and recycling agents under different loading modes. Construction and Building Materials, 300, 124130.

Al-Hadidy. A.I. (2020). Performance of SBS-HMA mixes made with sasobit and zeolite. Journal of Materials in Civil Engineering, © ASCE, ISSN 0899–1561 (Article in press)

SPSS, (1999). Inc. version 10.0.5, Chicago IIIinois.

Yoder, E. J., & Witczak, M. W. (1975). Principles of pavement design (2d ed.). Wiley.

Brown, S. F., & Brunton, J. M. (1992). An introduction to the analytical design of bituminous pavements (3rd edition). University of Nottingham.

Anon. (1992). Residential course on bituminous pavements: materials, design and evaluation. University of Nottingham.

Yang, H. H. (1993). Pavement analysis and design (pp. 336–410). Prentice-Hall, Inc., A Paramount Communications Company.

Lu, X., & Isacsson, U. (1997). Characterization of SBS polymer modified bitumen comparison of conventional methods and DMA. Journal of Testing and Evaluation, 25(1997), 383–390.

Al-Hadidy, A. I. (2018). Engineering behavior of aged polypropylene-modified asphalt pavements. Journal of Construction and Building Materials, 191, 187–192.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that there is no conflict of interest.

Rights and permissions

About this article

Cite this article

Al-Hadidy, A.I. Sustainable Recycling of Sulfur Waste Through Utilization in Asphalt Paving Applications. Int. J. Pavement Res. Technol. 16, 474–486 (2023). https://doi.org/10.1007/s42947-021-00143-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42947-021-00143-w