Abstract

One key challenge for the development of fusion energy is plasma-facing materials. Tungsten-based materials are promising candidates for plasma-facing components (PFCs) in the magnetic confinement nuclear fusion reactors because of their high melt temperature, high-thermal conductivity, high-thermal load resistance, low tritium retention, and low sputtering yield. In fusion reactors, PFCs are exposed to high-thermal flux, because there are some transient events such as plasma disruptions, edge-localized modes, and vertical displacement events (VDEs). Especially, in VDEs, a heat flux of 10–100 MW m−2 with duration of milliseconds-to-several seconds can induce recrystallization and then change the microstructure of tungsten-based plasma-facing materials, leading to instability of microstructures. Then, a significant degradation of material properties is caused such as a reduction of mechanical strength and fracture toughness, a rise in the ductile-to-brittle-transition temperature well, and decrease of irradiation/high-thermal load resistance. Therefore, many efforts were devoted to improve the thermal stability of tungsten-based materials as high as possible, such as oxide dispersion strengthening, carbide dispersion strengthening, and K bubbles dispersion strengthening. Here, the thermal stabilities of various dispersion-strengthened tungsten materials are reviewed by evaluating their recrystallization temperature and the corresponding hardness evolutions. In addition, the possible development trends are proposed.

Similar content being viewed by others

Change history

21 August 2021

A Correction to this paper has been published: https://doi.org/10.1007/s42864-021-00115-4

References

Norajitra P, Boccaccini LV, Gervash A, Giniyatulin R, Holstein N, Ihli T, Janeschitz G, Krauss W, Kruessmann R, Kuznetsov V, Makhankov A, Mazul I, Moeslang A, Ovchinnikov I, Rieth M, Zeep B. Development of a helium-cooled divertor: material choice and technological studies. J Nucl Mater. 2007;367–370:1416.

Philipps V. Tungsten as material for plasma-facing components in fusion devices. J Nucl Mater. 2011;415(1):S2.

Neu R, Dux R, Kallenbach A, Putterich T, Balden M, Fuchs JC, Herrmann A, Maggi CF, O’Mullane M, Pugno R, Radivojevic I, Rohde V, Sips ACC, Suttrop W, Whiteford A, The ASDEX Upgrade Team. Tungsten: an option for divertor and main chamber plasma facing components in future fusion devices. Nucl Fusion. 2005;45(3):209.

Rupp D, Mönig R, Gruber PA, Weygand SM. Fracture toughness and microstructural characterization of polycrystalline rolled tungsten. Int J Refract Met Hard Mater. 2010;28(6):669.

Wurster S, Gludovatz B, Hoffmann A, Pippan R. Fracture behaviour of tungsten–vanadium and tungsten–tantalum alloys and composites. J Nucl Mater. 2011;413(3):166.

Xia M, Yan Q, Xu L, Guo H, Zhu L, Ge C. Bulk tungsten with uniformly dispersed La2O3 nanoparticles sintered from co-precipitated La2O3/W nanoparticles. J Nucl Mater. 2013;434(1–3):85.

Ueda Y, Schmid K, Balden M, Coenen JW, Loewenhoff TH, Ito A, Hasegawa A, Hardie C, Porton M, Gilbert MR. Baseline high heat flux and plasma facing materials for fusion. Nucl Fusion. 2017;57(9):092006.

El-Guebaly L, Kurtz R, Rieth M, Kurishita H, Robinson A, ARIES Team. W-based alloys for advanced divertor designs: options and environmental impact of state-of-the-art alloys. Fusion Sci Technol. 2011;60(1):185.

Miki N, Verrecchia M, Barabaschi P, Belov A, Chiocchio S, Elio F, Ioki K, Kikuchi S, Kokotkov V, Ohmori J, Roccella M, Sonato P, Testoni P, Utin Y. Vertical displacement event/disruption electromagnetic analysis for the ITER-FEAT vacuum vessel and in-vessel components. Fusion Eng Des. 2001;58–59:555.

Abdullaev SS, Finken KH, Wongrach K, Tokar M, Koslowski HR, Willi O, Zeng L. Mechanisms of plasma disruption and runaway electron losses in the TEXTOR tokmak. J Plasma Phys. 2015;81(5):475810501.

Bolt H, Barabash V, Federici G, Linke J, Loarte A, Roth J, Sato K. Plasma facing and high heat flux materials–needs for ITER and beyond. J Nucl Mater. 2002;307–311(Part 1):43.

Maddaluno G, Maruccia G, Merola M, Rollet S. Energy deposition and thermal effects of runaway electrons in ITER-FEAT plasma facing components. J Nucl Mater. 2003;313–316:651.

Romaner L, Ambrosch-Draxl C, Pippan R. Effect of rhenium on the dislocation core structure in tungsten. Phys Rev Lett. 2010;104(19):195503.

Kurishita H, Arakawa H, Matsuo S, Sakamoto T, Kobayashi S, Nakai K, Pintsuk G, Linke J, Tsurekawa S, Yardley V, Tokunaga K, Takida T, Katoh M, Ikegaya A, Ueda Y, Kawai M, Yoshida N. Development of nanostructured tungsten based materials resistant to recrystallization and/or radiation induced embrittlement. Mater Trans. 2013;54(4):456.

Rieth M, Dudarev SL, de Vicente GSM, Aktaa J, Ahlgren T, Antusch S, Armstrong DEJ, Balden M, Baluc N, Barthe MF, Basuki WW, Battabyal M, Becquart CS, Blagoeva D, Boldyryeva H, Brinkmann J, Celino M, Ciupinski L, Correia JB, De Backer A, Domain C, Gaganidze E, García-Rosales C, Gibson J, Gilbert MR, Giusepponi S, Gludovatz B, Greuner H, Heinola K, Höschen T, Hoffmann A, Holstein N, Koch F, Krauss W, Li H, Lindig S, Linke J, Linsmeier CH, López-Ruiz P, Maier H, Matejicek J, Mishra TP, Muhammed M, Muñoz A, Muzyk M, Nordlund K, Nguyen-Manh D, Opschoor J, Ordás N, Palacios T, Pintsuk G, Pippan R, Reiser J, Riesch J, Roberts SG, Romaner L, Rosiński M, Sanchez M, Schulmeyer W, Traxler H, Ureña A, van der Laan JG, Veleva L, Wahlberg S, Walter M, Weber T, Weitkamp T, Wurster S, Yar MA, You JH, Zivelonghi A. Recent progress in research on tungsten materials for nuclear fusion applications in Europe. J Nucl Mater. 2013;432(1–3):482.

Huang B, Tang J, Chen L, Yang X, Lian Y, Chen L, Liu X, Cui X, Gu L, Liu CT. Design of highly thermal-shock resistant tungsten alloys with nanoscaled intra- and inter-type K bubbles. J Alloy Compd. 2019;782:149.

Liu R, Xie ZM, Hao T, Zhou Y, Wang XP, Fang QF, Liu CS. Fabricating high performance tungsten alloys through zirconium micro-alloying and nano-sized yttria dispersion strengthening. J Nucl Mater. 2014;451(1–3):35.

Wu Y. Manufacturing of tungsten and tungsten composites for fusion application via different routes. Tungsten. 2019;1:80.

Deng H, Xie Z, Wang YK, Liu R, Zhang T, Hao T, Wang XP, Fang QF, Liu CS. Mechanical properties and thermal stability of pure W and W–0.5 wt% ZrC alloy manufactured with the same technology. Mater Sci Eng A. 2018;715:117.

Kurishita H, Matsuo S, Arakawa H, Sakamoto T, Kobayashi S, Nakai K, Takida T, Kato M, Kawai M, Yoshida N. Development of re-crystallized W–1.1% TiC with enhanced room-temperature ductility and radiation performance. J Nucl Mater. 2010;398(1–3):87.

Zhang T, Yan W, Xie Z, Miao S, Yang J, Wang X, Fang Q, Liu C. Recent progress of oxide/carbide dispersion strengthened W-based materials. Acta Metall Sin. 2018;54:831.

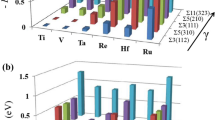

Wang YK, Miao S, Xie ZM, Liu R, Zhang T, Fang QF, Hao T, Wang XP, Liu CS, Liu X, Cai LH. Thermal stability and mechanical properties of HfC dispersion strengthened W alloys as plasma-facing components in fusion devices. J Nucl Mater. 2017;492:260.

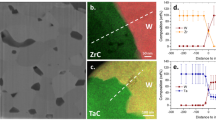

Xie ZM, Miao S, Liu R, Zeng LF, Zhang T, Fang QF, Liu CS, Wang XP, Lian YY, Liu X, Cai LH. Recrystallization and thermal shock fatigue resistance of nanoscale ZrC dispersion strengthened W alloys as plasma-facing components in fusion devices. J Nucl Mater. 2017;496:41.

Dong Z, Liu N, Ma Z, Liu C, Guo Q, Yamauchi Y, Alamri HR, Alothman ZA, Hossain MSA, Liu Y. Synthesis of nanosized composite powders via a wet chemical process for sintering high performance W–Y2O3 alloy. Int J Refract Met Hard Mater. 2017;69:266.

Fan J, Han Y, Li P, Sun Z, Zhou Q. Micro/nano composited tungsten materials and its high thermal loading behavior. J Nucl Mater. 2014;455(1–3):717.

Lian Y, Liu X, Feng F, Song J, Yan B, Wang Y, Wang J, Chen Z. Mechanical properties and thermal shock performance of W–Y2O3 composite prepared by high-energy-rate forging. Phys Scr. 2017;T170:014044.

Battabyal M, Schäublin R, Spätig P, Baluc N. W–2 wt% Y2O3 composite: microstructure and mechanical properties. Mater Sci Eng A. 2012;538:53.

Zhang J, Ma S, Zhu J, Kang K, Luo G, Wu C, Shen Q, Zhang L. Microstructure and compression strength of W/HfC composites synthesized by plasma activated sintering. Met Mater Int. 2019;25:416.

Xie ZM, Liu R, Miao S, Zhang T, Wang XP, Fang QF, Liu CS, Luo GN. Effect of high temperature swaging and annealing on the mechanical properties and thermal conductivity of W–Y2O3. J Nucl Mater. 2015;464:193.

Zhao M, Zhou Z, Zhong M, Tan J. Effect of hot rolling on the microstructure and fracture behavior of a bulk fine-grained W–Y2O3 alloy. Mater Sci Eng A. 2015;646:19.

Luo LM, Tan XY, Chen HY, Luo GN, Zhu XY, Cheng JG, Wu YC. Preparation and characteristics of W–1 wt% TiC alloy via a novel chemical method and spark plasma sintering. Powder Technol. 2015;273:8.

Feng F, Lian Y, Liu X, Wang J, Xu Y. Effect of high-energy-rate forging on microstructure and properties of W–TaC alloys. IEEE Trans Plasma Sci. 2017;46:2314.

Kang K, Zhang L, Luo G, Zhang J, Tu R, Wu C, Shen Q. Microstructural evolution and mechanical behavior of W–Si–C multi-phase composite prepared by arc-melting. Mater Sci Eng A. 2018;712:28.

Xie ZM, Zhang T, Liu R, Fang QF, Miao S, Wang XP, Liu CS. Grain growth behavior and mechanical properties of zirconium micro-alloyed and nano-size zirconium carbide dispersion strengthened tungsten alloys. Int J Refract Met Hard Mater. 2015;51:180.

Liu R, Xie ZM, Yang JF, Zhang T, Hao T, Wang XP, Fang QF, Liu CS. Recent progress on the R&D of W–ZrC alloys for plasma facing components in fusion devices. Nucl Mater Energy. 2018;16:191.

Tsuchida K, Miyazawa T, Hasegawa A, Nogami S, Fukuda M. Recrystallization behavior of hot-rolled pure tungsten and its alloy plates during high-temperature annealing. Nucl Mater Energy. 2018;15:158.

Ren C, Fang Z, Xu L, Ligda JP, Paramore JD, Butler BG. An investigation of the microstructure and ductility of annealed cold-rolled tungsten. Acta Mater. 2019;162:202.

Xie ZM, Liu R, Zhang T, Fang QF, Liu CS, Liu X, Luo GN. Achieving high strength/ductility in bulk W–Zr–Y2O3 alloy plate with hybrid microstructure. Mater Des. 2016;107:144.

Zan X, Gu M, Wang K, Luo L, Zhu X, Wu Y. Recrystallization kinetics of 50% hot-rolled 2% Y2O3 dispersed tungsten. Fusion Eng Des. 2019;144:1.

Miao S, Xie ZM, Zhang T, Wang XP, Fang QF, Liu CS, Luo GN, Liu X, Lian YY. Mechanical properties and thermal stability of rolled W–0.5 wt% TiC alloys. Mater Sci Eng A. 2016;671:87.

Liu X, Chen J, Lian Y, Wu J, Xu Z, Zhang N, Wang Q, Duan X, Wang Z, Zhong J. Vacuum hot-pressed beryllium and TiC dispersion strengthened tungsten alloy developments for ITER and future fusion reactors. J Nucl Mater. 2013;442(1–3):S309.

Xie ZM, Miao S, Zhang T, Liu R, Wang XP, Fang QF, Hao T, Zhuang Z, Liu CS, Lian YY, Liu X, Cai LH. Recrystallization behavior and thermal shock resistance of the W–1.0 wt% TaC alloy. J Nucl Mater. 2018;501:282.

Wang YK, Xie ZM, Wang MM, Deng HW, Yang JF, Jiang Y, Zhang T, Wang XP, Fang QF, Liu CS. The superior thermal stability and tensile properties of hot rolled W–HfC alloys. J Refract Metals Hard Mater. 2019;81:42.

Yang XD, Xie ZM, Miao S, Liu R, Jiang WB, Zhang T, Wang XP, Fang QF, Liu CS, Luo GN, Liu X. Tungsten-zirconium carbide-rhenium alloys with extraordinary thermal stability. Fusion Eng Des. 2016;106:56.

Guo W, Cheng L, De Temmerman G, Yuan Y, Lu GH. Retarded recrystallization of helium-exposed tungsten. Nucl Fusion. 2018;58:106011.

Shi K, Huang B, He B, Xiao Y, Chen L, Lian Y, Liu X, Tang J. Recrystallization behavior after annealing and thermal shock tests of W–K–TiC alloy. Fusion Eng Des. 2017;122:223.

Briant CL, Horacsek O, Horacsek K. The effect of wire history on the coarsened substructure and secondary recrystallization of doped tungsten. Metall Trans A. 1993;24(4):843.

Nikolić V, Riesch J, Pippan R. The effect of heat treatments on pure and potassium doped drawn tungsten wires: part I-microstructural characterization. Mater Sci Eng A. 2018;737:422.

Schade P. Potassium bubble growth in doped tungsten. Int J Refract Met Hard Mater. 1998;16(1):77.

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (Grant Nos. 51771184, 11735015, 11575241, 51801203 and 11575231), the Natural Science Foundation of Anhui Province (Grant No. 1808085QE132) and the Open Project of State Key Laboratory of Environment Friendly Energy Materials(Grant No. 18kfhg02).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, T., Xie, Z., Yang, J. et al. The thermal stability of dispersion-strengthened tungsten as plasma-facing materials: a short review. Tungsten 1, 187–197 (2019). https://doi.org/10.1007/s42864-019-00022-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42864-019-00022-9