Abstract

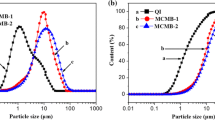

Two kinds of mesocarbon microbeads (MCMBs) with different chemical composition have been synthesized. The MCMBs were molded and heat treated at temperatures above 2000 °C to obtain graphite blocks. The effects of chemical composition of MCMBs on the pore morphology, carbon texture and thermal properties of the derived graphite blocks have been explored. The pore morphology was investigated by small angle X-ray scattering technique and a graphitization-induced morphology transition was observed. When the graphitic crystallite size exceeded a threshold value, the association of crystallites and migration of randomly distributed pores took place extensively. For the graphite blocks made of MCMBs which had light components with higher aromaticity value, the growth of crystallites caused a significant enhancement in thermal conductivity for the specimens. However, for the other kind of MCMBs, their light components tended to form solid porous carbon texture after graphitization, and the thermal conductivity coefficients of their graphite blocks could only increase slightly as crystallites grew. It was suggested that the thermal resistance at the granule’s boundary became noticeable in the latter case and thus the growth of thermal conductivity coefficients was prominently hindered.

Similar content being viewed by others

References

Lee SM, Kang DS, Roh JS (2015) Bulk graphite: materials and manufacturing process. Carbon Lett 16:135–146

Mochida I, Fujiura R, Kojima T, Sakamoto H, Yoshimura T (1995) Carbon disk of high density and strength prepared from heat-treated mesophase pitch grains. Carbon 33:265–274

Bhatia G, Aggarwal RK, Punjabi N, Bahl OP (1997) Effect of sintering temperature on the characteristics of carbons based on mesocarbon microbeads. J Mater Sci 32:135–139

Wang YG, Korai Y, Mochida I (1999) Carbon disc of high density and strength prepared from synthetic pitch-derived mesocarbon microbeads. Carbon 37:1049–1057

Hoffmann WR, Hüttinger KJ (1993) Demonstration of spontaneous liquid-phase sintering of mesophase powders. Carbon 31:259–262

Gao Y, Song H, Chen X (2003) Self-sinterability of mesocarbon microbeads (MCMB) for preparation of high-density isotropic carbon. J Mater Sci 38:2209–2213

Norfolk C, Mukasyan A, Hayes D, McGinn P, Varma A (2004) Processing of mesocarbon microbeads to high-performance materials: Part I. Studies towards the sintering mechanism. Carbon 42:11–19

Shen K, Huang ZH, Shen W, Yang J, Yang G, Yu S, Kang F (2015) Homogeneous and highly isotropic graphite produced from mesocarbon microbeads. Carbon 94:18–26

Martínez-Escandell M, Rodríguez-Valero MA, Coronado JS, Rodríguez-Reinoso F (2002) Modification of the sintering behavior of mesophase powder from a petroleum residue. Carbon 40:2843–2853

Llorca-Porcel J, Rodríguez-Valero MA, Martínez-Escandell M, Rodríguez-Reinoso F (2008) Sinterbility enhancement in semicokes obtained by controlled pyrolysis of petroleum residue. J Anal Appl Pyrolysis 85:163–169

Fernández JJ, Figueiras A, Granda M, Bermejo J, Menéndez R (1995) Modification of coal-tar pitch by air-blowing-I. variation of pitch composition and properties. Carbon 33:295–307

Taylor R, Gilchrist KE, Poston LJ (1968) Thermal conductivity of polycrystalline graphite. Carbon 6:537–544

Klemens PG, Pedraza DF (1994) Thermal conductivity of graphite in the basal plane. Carbon 32:735–741

Zhou Z, Bouwman WG, Schut H, Desert S, Jestin J, Hartmann S, Pappas C (2016) From nanopores to macropores: fractal morphology of graphite. Carbon 96:541–547

Mileeva Z, Ross DK, King SM (2013) A study of nuclear graphite using small-angle neutron scattering. Carbon 64:20–26

Murty HN, Bielderman DL, Heintz EA (1969) Kinetics of graphitization I- activation energies. Carbon 7:667–681

Marie J, Mering J (1970) Graphitization of soft carbon materials. In: Walker PL (ed) Chemistry and physics of carbon, vol 6. Decker, New York, pp 125–189

Jeng US, Su CH, Su CJ, Liao KF, Chuang WT, Lai YH, Chang JW, Chen YJ, Huang YS, Lee MT, Yu KL, Lin JM, Liu DG, Chang CF, Liu CY, Chang CH, Liang KS (2010) A small/wide-angle X-ray scattering instrument for structural characterization of air-liquid interfaces, thin films and bulk specimens. J Appl Crystallogr 43:110–121

Guillén MD, Iglesias MJ, Domínguez A, Blanco CG (1992) Semiquantitative FTIR analysis of a coal tar pitch and its extracts and residues in several organic solvents. Energy Fuels 6:518–525

Alcañiz-Monge D, Cazorla-Amorós D, Linares-Solano A (2001) Characterization of coal tar pitches by thermal analysis, infrared spectroscopy and solvent fractionation. Fuel 80:41–48

Russo C, Ciajolo A, Stanzione F, Tregrossi A, Oliano MM, Carpentieri A, Apicella B (2019) Investigation on chemical and structural properties of coal- and petroleum- derived pitches and implications on physico-chemical properties (solubility, softening and coking). Fuel 245:478–487

Blanco C, Santamaría R, Bermejo J, Menéndez R (2000) A comparative study of air-blowing and thermally treated coal-tar pitches. Carbon 38:517–523

Pérez M, Granda M, Santamaría R, Morgan T, Menéndez R (2004) A thermoanalytical study of the co-pyrolysis of coal-tar pitch and petroleum pitch. Fuel 83:1257–1265

Bai BC, Kim JG, Kim JH, Lee CW, Lee YS, Im JS (2018) Blending effect of pyrolyzed fuel oil and coal tar in pitch production for artificial graphite. Carbon Lett 25:78–83

Iwashita N, Park CR, Fujimoto H, Shiraishi M, Inagaki M (2004) Specification for a standard procedure of X-ray diffraction measurements on carbon materials. Carbon 42:701–714

Endo M, Kim C, Karaki T, Kasai T, Matthews MJ, Brown SDM, Dresselhaus MS, Tamaki T, Nishimura Y (1998) Structural characterization of milled mesophase pitch-based carbon fibers. Carbon 36:1633–1641

Pfeifer P, Ehrburger-Dolle F, Reiker TP, González MT, Hoffman WP, Molina-Sabio M, Rodríguez-Reinoso F, Schmidt PW, Voss DJ (2002) Nearly space-filling fractal networks of carbon nanopores. Phys Rev Lett 88:115502

Teixeira J (1988) Small angle scattering by fractal systems. J Appl Crystallogr 21:781–785

Reich MH, Russo SP, Snook IK, Wagenfeld HK (1990) The application of SAXS to determine the fractal properties of porous carbon-based materials. J Colloid Interface Sci 135:353–362

de Fonton S, Oberlin A, Inagaki M (1980) Characterization by electron microscopy of carbon phases (intermediate turbostratic phase and graphite) in hard carbons when heat-treated under pressure. J Mater Sci 15:909–917

Oberlin A, Villey M, Combaz A (1980) Influence of elemental composition on carbonization-pyrolysis of kerosene shale and kuckersite. Carbon 18:347–353

Monthioux M, Oberlin M, Bourrat X, Boulet R (1982) Heavy petroleum products: microstructure and ability to graphitize. Carbon 20:167–176

Acknowledgements

The authors are grateful to the China Steel Chemical Corporation, Taiwan for the supply of carbonaceous powder for this research. We also thank Dr. Hung Su (Department of Chemistry) and the Joint Center for High Valued Instruments at National Sun Yat-sen University for the support of LDI-TOFMS analysis.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Hsu, JY., Su, CJ., Yen, YL. et al. Effects of chemical composition of carbonaceous powder on morphology and thermal properties of graphite blocks. Carbon Lett. 32, 797–805 (2022). https://doi.org/10.1007/s42823-021-00312-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42823-021-00312-8