Abstract

Microalgae technology is a viable solution for environmental conservation (carbon capture and wastewater treatment) and energy production. However, the nutrient cost, slow-kinetics, and low biosorption capacity of microalgae hindered its application. To overcome them, algal-biochar (BC) can be integrated with microalgae to treat textile wastewater (TWW) due to its low cost, its ability to rapidly adsorb pollutants, and its ability to serve as a nutrient source for microalgal-growth to capture CO2 and biodiesel production. Chlorella vulgaris (CV) and algal-BC were combined in this work to assess microalgal growth, carbon capture, TWW bioremediation, and biodiesel production. Results showed the highest optical density (3.70 ± 0.07 OD680), biomass productivity (42.31 ± 0.50 mg L−1 d−1), and dry weight biomass production (255.11 ± 6.01 mg L−1) in an integrated system of CV-BC-TWW by capturing atmospheric CO2 (77.57 ± 2.52 mg L−1 d−1). More than 99% bioremediation (removal of MB-pollutant, COD, nitrates, and phosphates) of TWW was achieved in CV-BC-TWW system due to biosorption and biodegradation processes. The addition of algal-BC and CV microalgae to TWW not only enhanced the algal growth but also increased the bioremediation of TWW and biodiesel content. The highest fatty acid methylesters (biodiesel) were also produced, up to 76.79 ± 2.01 mg g−1 from CV-BC-TWW cultivated-biomass. Biodiesel’s oxidative stability and low-temperature characteristics are enhanced by the presence of palmitoleic (C16:1) and linolenic (C18:3) acids. Hence, this study revealed that the integration of algal-biochar, as a biosorbent and source of nutrients, with living-microalgae offers an efficient, economical, and sustainable approach for microalgae growth, CO2 fixation, TWW treatment, and biodiesel production.

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

As a consequences of rapid growth in urbanization and industrialization, the atmospheric and aqueous environments received a huge amount of greenhouse gases and pollutant-laden wastewater, respectively (Abdelfattah et al. 2023; Fazal et al. 2021a). Fossil fuels are burned to meet the energy needs of domestic and industrial purposes, which contributes to climate change by releasing greenhouse gases, especially CO2 up to 419 ppm, in atmosphere (Tarafdar et al. 2023). The industrial sectors, including pharmaceuticals, paper printing, color photography, food, textile dyeing, and cosmetics industries, utilize a huge amount of freshwater and synthetic chemicals during their industrial processes (Leonardo et al. 2022). Among them, textile industry consumes freshwater every day and releases a large volume of textile wastewater (TWW) (Javed et al. 2022; Christian et al. 2023). This wastewater, containing excessive levels of auxiliary chemicals (synthetic dyes (i.e. methylene blue), nitrates, phosphates, and heavy metals), poses a great threat to receiving ecosystems (Fazal et al. 2018), as they are responsible to create aesthetic, eutrophication, carcinogenic, mutagenic, and teratogenic problems to the aquatic life and human health due to their direct disposal into water bodies (Motitswe et al. 2022). Therefore, it is a need of hour to control climate change and remove pollutants from wastewater streams for the sustainability of our ecosystem.

Several conventional (physical and chemical) technologies have been used for the carbon capture (Rodas-Zuluaga et al. 2021) and wastewater treatment (Abdelfattah et al. 2023; Mushtaq et al. 2022, 2019). However, none of these technologies are able to remove all the aforementioned pollutants/chemicals from environment single-handedly due to their high operation and maintenance costs, slow kinetics, lower efficiencies, extensive use of chemicals, and sludge production (Rafique et al. 2022; Satya et al. 2023). Microalga technology is considered as a promising approach due to its green, effective, and environment-friendly nature for the removal of CO2 and pollutants from wastewater during photosynthesis process (Devi et al. 2023). Microalgae technology consists of two processes including microalgae cultivation/bioconversion (living algae) and biosorption (dead algae) (Onen et al. 2023). The living microalgae cultivation has been proven an efficient process for the carbon capture and bioremediation of wastewater (Debeni Devi et al. 2023). Microalgae, as low-spore crypto-sporous plants with chlorophyll, have an ability to perform photosynthesis process under source of light, freshwater, and nutrients (carbon, nitrates, phosphates, and minerals) for its cultivation (Ahmad and Ashraf 2023). However, the costs of freshwater and nutrients-supply mark this process expensive and create a challenge to its commercial application.

To overcome them, Chlorella vulgaris was cultivated (1.7 g L−1) to treat industrial textile wastewater by removing COD (91.12%), nitrate (98.03%), and phosphate (95.83%), where TWW was used as a nutrient source for microalgae growth along with CO2 supply through air bubbling (Javed et al. 2023a). In addition, the real textile wastewater was diluted with other industrial (juice) wastewater to minimize the freshwater requirement for microalgae-mediated bioremediation process and it resulted in an increase in biomass yield up to 2.83 g L−1 in 75% diluted TWW with juicy wastewater (25%) (Javed et al. 2023b). Meanwhile, the dead-algae derived biosorption process has also been used to remove organic dyes and heavy metal pollutants from wastewaters (Georgin et al. 2019). However, the limited biosorption capacity of algae biomass, slow kinetics, and high energy constraint for the regeneration of biosorbent make this process less efficient for the treatment of TWW (Ord et al. 2023). The synthesis of algal-derived biochar can provide high removal efficiency and fast biosorption rate to remove dyes from TWW. For instance, macroalgae-derived biochar was synthesized to remove MB dye. More than 90% MB removal (48 mg g−1) was achieved in only 10 min as compared to simple algal biomass (74% and 37 mg g−1) due to the large surface area and electrostatic attractions to bind/adsorb dye molecules on the surface of BC (Fazal et al. 2019). Therefore, a microalgae-mediated technology can be useful for the development of sustainable approach to CO2 capture and bioremediation of TWW.

The integration of microalgae cultivation and dead algal-biosorption processes along with TWW provide a viable solution to removing atmospheric carbon (CO2) and all toxic pollutants from TWW. The utilization of pollutants-laden TWW can make the microalgae cultivation process more efficient, cost-effective, and sustainable due to the supply of organic carbon (dyes), nitrates, phosphates, and heavy metals (Jiang et al. 2023). On the contrary, algal biomass-derived biochar, as a biosorbent, can be used due to its high adsorption capacity, large surface area with higher binding (functional groups) sites, and fast adsorption rate to remove dyes from TWW (Nguyen et al. 2023). Biochar (BC) can also be used as a source of nutrients to grow microalgae due to the presence of micronutrients (i.e. Na, K, Ca, Mg, Cu, Zn, and Mn metals) in stable and available forms (Law et al. 2022). Depending on these properties (as biosorbent and nutrient source), BC can be integrated along with microalgae for the removal of organic dyes, nitrates, and phosphates from TWW and the microalgae growth during the bioremediation process (Khan et al. 2022). The obtained microalgal biomass (containing lipids, carbohydrates, and proteins) can be served as a feedstock for the production of biodiesel, biofertilizer, and animal feed, which makes this technology more economical and sustainable for the implementation on an industrial scale for CO2 capture and wastewater treatment (Chettri et al. 2023). Thus, microalgae-mediated wastewater treatment technique (microalgae cultivation and biosorption) can be integrated to exploit the advantages of both technologies for the CO2 capture, nutrients recovery, and biodiesel production and the addition of algae-derived biochar improved the rate of adsorption and acted as nutrient source for microalgae growth by providing minerals.

The aim of this study was to evaluate the potential of microalgae cultivation in TWW and the use of biochar as an active green biosorbent for the removal of pollutants and as a nutrient source for the growth of microalgae in TWW. The integrated processes of microalgae cultivation and biochar-based biosorption were investigated under four experimental set-ups: (PBR-1) microalgae (Chlorella vulgaris, CV) cultivation in BG-11 as a control (CV-BG-11); (PBR-2) CV cultivation in TWW (CV-TWW); (PBR-3) biochar based biosorption of TWW (BC-TWW); and (PBR-4) hybrid system of CV microalgae and BC in TWW (CV-BC-TWW) for the capturing of CO2, bioremediation of TWW, and bioenergy production. The microalgae growth, carbon capturing, and removal of dye, COD, N–NO3−1, and P–PO4−3 from TWW were evaluated in all set-ups. The collected biomass was used to produce biodiesel through a transesterification process, prior to the determination of their fatty acid profiles. The experimental results showed that microalgae can efficiently capture CO2 during cultivation in an integrated system of CV-BC-TWW and produce biodiesel; meanwhile, biochar can also act as a good biosorbent and nutrient source for bioremediation process and microalgae cultivation, respectively.

2 Material and methods

2.1 Raw materials

The stored (at 4 °C) inoculum of Chlorella vulgaris was obtained from COMSATS University Islamabad, Lahore Campus Pakistan. BG-11 media chemicals were bought from PENTA Chemicals, Singapore. Methylene Blue (MB) dye was procured from Sigma Aldrich (Germany). Distilled water was obtained from Double Water Distilling Apparatus (WD-AD5, Biobase, China). This distilled water was passed through a filter paper using filtration assembly for further use.

2.2 Pre-culture growth

Microalgae pre-culture was cultivated in BG-11 media to obtain fresh culture of Chlorella vulgaris. BG-11 media was composed using two stock solutions. The stock solution A consisted of NaNO3 (1.5 g−1 L), K2HPO4 (0.04 g L−1), MgSO4⋅7H2O (0.075 g L−1), CaCl2⋅2H2O (0.036 g L−1), Na2–EDTA (0.001 g L−1), Na2CO3 (0.02 g L−1), citric acid (0.006 g L−1), and ferric alum citrate (0.006 g L−1). The composition of stock solution B (trace metal solution) was comprised of MnCl⋅4H2O (181 mg L−1), ZnSO4⋅7H2O (222 mg L−1), NaMoO4⋅2H2O (390 mg L−1), CuSO4⋅5H2O (79 mg L−1), Co(NO3)2⋅6H2O (49.4 mg L−1), and boric acid (2.86 g L−1) (Fazal et al. 2021a). The only one ml of solution B was mixed with solution A to obtain the BG-11 media. The BG-11 media was autoclaved (BKQ-B50 II, Biobase, China 2019) at 121 °C for 20 min, and then cooled down under UV light in a biosafety cabinet (JSCB-1200SB, JSR, Korea). Then, an inoculum of CV was added in a BG-11 media for fresh-culture preparation under the illumination of two LED lights (5W for each) at 25 °C in a shaking incubator (Jeio Tech ISS-3075).

2.3 Photobioreactor design

The microalgae cells were cultivated in an assembly of four photobioreactors (PBRs), as shown in Fig. 1. The circular-shaped plexiglass chambers (H-32.5 cm × D-14 cm, 5 L) were used as PBR. An air pump-line was connected with the air filters to provide the ambient air (200 mL min−1) through diffuser (for CO2 supply), which was placed at the bottom of PBRs. Each PBR was tightly closed with the silicon cork, containing three transparent lines of pipes for air supply, emission of extra gases, and the collection of samples. All PBRs were placed in a biological safety cabinet at 27–30 °C under the illumination of two LED lights (50 W) having luminous intensity of 4000–4200 lx. All required accessories of PBR including air filters, sampling syringes, pipes, diffusers, and all glass wares were sterilized in an autoclave at 121 °C for 20 min before use. The microalgae growth (optical density) was observed at 680 nm wavelength on daily basis using UV-Spectrophotometry (BK D560, BIOBASE China).

2.4 Preparation of simulated textile wastewater

The synthetic textile wastewater with the similar composition of real TWW [Methylene Blue (10 mg L−1), NaNO3 (247 mg L−1), K2HPO4 (22 mg L−1), and glucose (1000 mg L−1)] was prepared for the experiments. The composition of textile wastewater was kept similar to the real textile wastewater, as reported in literature (Wu et al. 2017; Fazal et al. 2021a). The as-prepared TWW was sterilized in an autoclave at 121 °C for 20 min. After cooling, TWW media was immediately placed in a biological safety cabinet under UV light before use.

2.5 Preparation of biochar

Macroalgae biomass was used for the preparation of biochar (BC) using pyrolysis method (Fazal et al. 2019; Sufiana et al. 2023). Macroalgae mix culture biomass was obtained from a freshwater pond prior to washing with distilled water. The washed biomass was dried under sunlight. Then, it was crushed into fine particles using pestle and mortar and stored for further use. The fine powder of macroalgae biomass was placed into muffle furnace (Power = 2.5 KW, with the dimensions (Depth = 200 mm, Width = 150 mm, and Height = 150 mm) of heating chamber) to prepare biochar through pyrolysis process at 650 °C for 2 h in the absence of oxygen with a continuous supply of nitrogen (2000 ml min−1) to avoid combustion (Fazal et al. 2020). The pyrolysis temperature of 650 °C was selected to produce high porosity in biochar, which can provide high adsorption ability to dyes as compared to low temperature-pyrolyzed biochar (i.e., 450 and 550 °C), as reported in literature (Fazal et al. 2019). The obtained BC was grinded before passing through the sieves (120 US standard mesh size) to obtain fine particles (> 125 μm). Before using BC in PBRs, algal-BC was kept under UV light to kill the microbes and/or to avoid microbial contamination in PBR. The functional groups, morphology, surface area, and elemental characteristics of algal-BC at 650 °C were reported in previous studies (Fazal et al. 2020, 2019). See supplementary data.

2.6 Experimental design

For experiments, four set-ups of photobioreactors (PBR) were installed to cultivate microalgae, as shown in Fig. 1. In PBR-1 set-up, pure BG-11 media along with Chlorella vulgaris microalgae (CV-BG-11) was employed as a controlled media for microalgae growth. In PBR-2, CV microalgae in TWW (denoted as CV-TWW) was used to check the potential of microalgae growth and bioremediation of TWW. In PBR-3 set-up, biochar biosorbent was used in TWW (denoted as BC-TWW) to determine the biosorption effect of biochar. In PBR-4, both CV microalgae and biochar were employed in TWW (denoted as CV-BC-TWW) to observe the combined effect of both on microalgae growth and bioremediation/biosorption of TWW. A fixed volume (2 L) of media (BG-11 or TWW) was used in each PBR along with Chlorella vulgaris inoculum (20 mL L−1) and biochar (1 g L−1) in their respective PBRs. The air, as a source of CO2 (0.04%), was provided by air pump (20 L min−1), which is connected with diffuser to generate air bubbles for mixing. All PBRs were illuminated under two LED lights (50 W each and 4000–4200 lx intensity).

Light is the source of energy for the photosynthesis process to maximize algal growth and lipid production. It was reported that light intensity has a significant effect on the growth of biomass, specific growth rate, and lipid productivity (Montoya-Vallejo et al. 2023). Temperature is also considered as one of the physical parameters that regulates the growth of microalgae and affects metabolism through the facilitation of enzymatic processes. The denaturation of metabolic and life-sustaining enzymes would occur at high temperatures (Devi et al. 2023; Min Woon et al. 2023). The pH of the solution has an impact on the biosorbent (biochar) surface charge and/or degree of ionization. The positively and negatively charged accessible sites increase and decrease in response to any change in pH in the solution. Therefore, moderate temperature (27–30 °C) and light intensity (4000–4200 Lux) in a light: dark (16:8) ratio were selected to cultivate microalgae at natural pH (6.9) of TWW (Chin et al. 2023). The position of each PBR was shuffled on daily basis to provide uniform light illumination/exposure. Each PBR was shaken manually for three to four times on daily basis to avoid the attachment of microalgae cells with PBR walls. The attachment of cells to the PBR walls can lead to biofilm formation, inadequate supply of light, clogging, algal-fouling, and nutrient uptake challenge, which can affect the cell growth and harvesting challenges. All PBRs were installed in duplicates and placed in a biological safety cabinet to maintain the temperature. The biological safety cabinet was cleaned with 70% ethanol on daily basis to avoid any contamination. The cultivation experiment work was carried out for 14 days to examine the microalgae growth and bioremediation of TWW using C. vulgaris and BC in TWW.

2.7 Microalgae growth analysis

To observe microalgae growth, 10 mL of sample was withdrawn from each PBRs and stored in a test tube on daily basis until 14 days. The microalgae growth in the presence of nutrient mediums (BG-11 or TWW and BC) was examined by measuring of OD at 680 nm wavelength (Wu et al. 2017) using UV–Vis spectrophotometer (Biobase, China). The OD680 of BC was subtracted to examine the OD680 of microalgae in PBR-4 (CV-BC-TWW). Then, a rearranged calibration equation (Eq. 1) was used to determine biomass concentration (X, mg L−1) prior to measuring the specific growth rate (day−1) and biomass productivity (P, mg L−1 d−1) according to the Eq. 2 and Eq. 3, respectively (Behl et al. 2019). Where, X1 and X2 present the biomass concentrations at time t1 and t2 (day), respectively. The CO2 fixation rate (mg L−1 d−1) was calculated using Eq. 4; whereas Cc is carbon content (as considered 50%) in microalgae biomass, MCO2 and MC are molecular mass of CO2 and carbon (Leflay et al. 2021).

After 14 days of experiment, cultivated biomass was filtered from each PBR to determine dry weight biomass (DWB, g L−1). To collect biomass, remaining culture from each PBR was filtered through the 0.22 μm filter paper using vacuum filtration assembly. Then, the collected biomass was placed in an oven (BOV-V65F Biobase, China) at 90 °C for overnight drying. The DWB from each PBR was calculated using gravimetrical method prior to the storage in air-tight tube for further use in biodiesel production. The mass of BC was neglected to measure the DWB in PBR-4.

2.8 Bioremediation analysis

In this study, different physiochemical analyses have been performed to investigate the effect of microalgae cultivation on bioremediation of TWW. The change in pH of solution during algal growth was determined on daily basis using a pH meter (pH meter, WA-2015). The removal rates (%) of MB dye, COD, nitrates, and phosphates were measured to observe the bioremediation and biosorption potential of Chlorella vulgaris and BC from TWW. All collected solution samples were centrifuged (CE202-Orto Alresa, Spain) at 8000 rpm for 5 min. The supernatant of each sample was used to determine the initial and final absorbance of MB at 664 nm wavelength using a UV–Vis spectrophotometer prior to measuring MB removal (%) according to the Eq. 5. The COD analyses of samples were performed at 150 °C for 2 h using a Photometer apparatus (Aqualytic-AL200, Germany). The initial and final values of COD were calculated on selective days (0, 4, 8, 12, and 14th day) from each PBR. The nitrates (NO3−, Hach, NI-11, USA) and phosphates (PO43−, Hach, PO-23, USA) test kits were utilized to examine their initial and final values. The removal rates (%) of COD, NO3−, and PO43− were measured using Eq. 6 (Nezbrytska et al. 2022). All of these values were taken in duplicates and then their average values were presented with standard deviation. The statistical analysis using ANOVA T-Test was carried out to observe the significant difference (p < 0.05) between all systems.

2.9 Lipid extraction and biodiesel analysis

Dried biomass of microalgae was used to extract algal oil/lipids using a modified Folch method, as reported in a previous study (Fazal et al. 2021a). An amount of 10 mg biomass was mixed at 200 rpm in the solution of methanol and chloroform (15 mL, 1:2 v/v) (Vasistha et al. 2023). Under acidic transesterification process, extracted algal oil was processed to produce fatty acid methyl esters (FAME, known as biodiesel) in the presence of sulfuric acid catalyst and methanol. The FAME sample was centrifuged and washed with distilled water to remove unreacted methanol and sulfuric acid before drying. Afterwards, the qualitative analysis and characterization of FAME were carried out using a Shimadzu-gas chromatograph coupled with flame ionization detector (FID) at 140 °C (held for 2 min) to 250 °C with the heating rate of 2.3 °C min−1 and injector temperature (240 °C). An EN14103-capillary column (0.25 μm × 30 m × 0.32 mm) with nitrogen carrier gas (1.5 mL min−1) was used to determine FAMEs yield.

3 Results and discussions

3.1 Microalgae growth analysis

Microalgae specie i.e. Chlorella vulgaris (CV) is widely used for the treatment of wastewater because it has a high tolerance and survival in the presence of toxic pollutants (Abdelfattah et al. 2023). It also has higher biomass and oil content than other algal species (Heredia-arroyo et al. 2011). Therefore, this green microalgae (CV) specie was selected in this experiment for the bioremediation of TWW and energy production during cultivation. The growth or cultivation of microalgae in TWW was observed using optical density, biomass concentration, specific growth rate, biomass productivity, and dry weight biomass.

3.1.1 Optical density and cell concentration

The optical density (OD680) of cultures was measured at 680 nm to investigate the growth of microalgae in PBR-1 (CV-BG-11), PBR-2 (CV-TWW), and PBR-4 (CV-BC-TWW), except PBR-3 (BC-TWW) due to unavailability of CV inoculum in culture. The highest OD680 was achieved in a PBR-4 having CV-BC-TWW culture as compared to other PBR cultures (CV-BG-11 and CV-TWW), as shown in Fig. 2a. The value of OD680 in CV-BC-TWW culture was gradually increased from 0.17 ± 0.04 to 3.70 ± 0.07 with the cultivation time (0–9th day) because of the higher availability of nutrients in TWW (glucose, nitrates, phosphates, and MB dye) and BC (minerals) (Oyebamiji et al. 2019). The nutrients of BC and TWW are responsible to grow more microalgae in this system. Meanwhile, the lowest OD680 was observed in a PBR-2 having CV-TWW culture, as it was raised from 0.12 ± 0.02 to 2.34 ± 0.05 during the cultivation period (0–12th day). In a PBR-4 having CV-BC-TWW culture, the algal growth entered the exponential stage just after the second day of lag phase as compared to the CV-TWW (entered the exponential phase after three days of lag phase). In lag phases of both cultures (CV-TWW and CV-BCC-TWW), microalgae growth might be slower due to the slow uptake of inorganic (CO2) and organic (glucose and dye) carbon in initial stages of mixotrophic cultivation mode. Afterwards, the utilization of inorganic carbon and organic carbon under photosynthetic (Calvin cycle and tricarboxylic acid cycle, TCA) and dark reaction (catabolism) processes is increased during exponential phase of cultivation (Shan et al. 2023). Meanwhile, the controlled PBR-1 of BG-11 culture showed higher OD680 than CV-TWW but lower than CV-BC-TWW culture, as it was increased from 0.18 ± 0.01 to 3.32 ± 0.07 during cultivation phase from 0–10th day. The growth rate in BG-11 culture was initially higher than that in other cultures and entered the exponential phase just after one day of lag phase because microalgae are more capable or faster to convert the inorganic carbon (CO2) into essential substrates (HCO3− ↔ CO3−2) under photoautotrophic cultivation mode rather than mixotrophic mode in other PBR cultures, which indicates that essential substances are more suitable to enhancing a Calvin-Benson-Bassham (CBB) cycle to accumulate higher biomass (Castillo et al. 2021) in BG-11 culture. The microalgal growth in CV-BC-TWW and CV-TWW cultures slowed down after the 9th and 12th days, respectively, and entered the stationary phase, followed a decline or death of cells until the 14th day, which might be due to the unavailability of nutrients (which had been already consumed) in the culture. Meanwhile, stationary growth phase in BG-11 culture started after the 10th day, followed by a decline in microalgae growth due to the nitrogen starvation conditions, which facilitated the conversion of the accumulated carbon (carbohydrates) into lipids during stationary/decline phase of microalgae growth (Vasistha et al. 2023). However, the overall growth rate in CV-BC-TWW was higher because of nitrates, phosphates, and carbon fixation by assimilating inorganic (CO2)-organic carbon and BC minerals as compared to the other two systems (CV-BG-11 and CV-TWW).

To investigate the biomass production, the concentration of microalgae cells (X, mg L−1) was measured using value of OD680 in Eq. 1 for all PBRs. Similar to OD680 results, it can be seen that the highest biomass cell concentration was also observed in CV-BC-TWW around 262.26 ± 3.02 mg L−1, followed by BG-11 with 235.13 ± 3.01 mg L−1 and CV-TWW with 165.62 ± 1.01 mg L−1 during exponential growth, as shown in Fig. 2b. The higher cell concentration in CV-BC-TWW culture might be obtained in the presence of two nutrient sources such as TWW and BC, which improves the growth of microalgae cells due to the assimilation of nitrates, phosphates, and glucose from TWW as well as micronutrients (minerals/metals) from BC into essential substances like NADPH, ATP, phosphoglycerate (i.e. glyceraldehyde-3-phosphate), pigments, and lipids (triglycerides) through CBB cycle, TCA cycle, glycolysis, and pentose phosphate processes, respectively (Castillo et al. 2021). As mentioned above, CV-TWW culture only contains organic and inorganic substrates or pollutants in the absence of BC, which was attributed to lower growth and lower concentration of cells as compared to CV-BC-TWW and controlled CV-BG-11 cultures. The composition of BG-11 media, having essential nutrients (inorganic CO2, nitrates and phosphates), is more suitable for microalgae growth under photoautotrophic cultivation, which enables Chlorella vulgaris to uptake these nutrients and increase the biomass cell concentration during cultivation period (Javed et al. 2023b). The highest dry weight biomass (DWB) was also measured in an integrated CV-BC-TWW culture up to 255.11 ± 6.01 mg L−1, followed by BG-11 (234.12 ± 3.77 mg L−1) and CV-TWW (164.36 ± 4.02 mg L−1), see Fig. 2c. The values of DWB were close enough to the highest wet biomass cell concentrations of all PBRs, which represent that microalgae is growing properly in all PBR cultures. Hence, both algal-BC and TWW can be used to provide essential nutrients (organic-carbon, nitrates, phosphates, and mineral-metals) for microalgae-growth due to its ability to carbon capture, biosorption, and biodegradation processes.

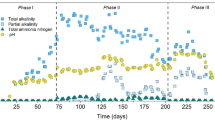

3.1.2 Biomass productivity and specific growth rate

The biomass productivity and specific growth rates of microalgae were determined to observe the kinetics rate of microalgae growth during 14 days of cultivation experiment (Tambat et al. 2023). In CV-BC-TWW, biomass productivity gradually increased from 5.11 ± 0.03 to 42.31 ± 0.50 mg L−1 d−1 in the exponential phase of cultivation (0–4th days), as shown in the Fig. 3a. The highest productivity of hybrid system was achieved due to the presence of nutrients in excess amount compared to other systems as biochar continuously supplied crucial metals with TWW nutrients for good microalgae growth (Ashour and Omran 2022). The CV-BG-11 system showed second highest biomass productivity, as it was increased from 7.94 ± 0.84 to 32.63 ± 0.71 mg L−1 d−1 on the 5th day of cultivation. The lowest productivity in comparison with other two PBRs (CV-BC-TWW and BG-11) was observed in CV-TWW system, as it was increased from 3.62 ± 0.03 to 21.92 ± 0.07 mg L−1 d−1 during exponential growth phase of cultivation (0–7th day). Afterwards, biomass productivities in all PBR cultures were decreased, showing that the growth of microalgae slowed down even in the exponential phases due to the limitation of nutrients in the surrounding environment. Meanwhile, the values of OD680 or cell concentrations (see Fig. 2a, b) increased during exponential phase of cultivation, because microalgae were still consuming available nutrients at a slower rate, before going into stationary and decline phases. Similar results can be seen in terms of specific growth rates (see Fig. 3b), where the specific growth rates were higher at initial stages of exponential phase during all PBR cultures. The highest specific growth rate was found up to 0.76 ± 0.02 day−1 on the 2nd day of cultivation in CV-BC-TWW as compared to CV-BG-11 (0.64 ± 0.01 day−1 on the 2nd day of cultivation) and CV-TWW (0.44 ± 0.05 day−1 on the 4th day of cultivation) prior to decline due to the consumption (lower concentration) of nutrients during growth, as shown in Fig. 3b. Hence, it can be assumed that microalgae productivity and growth rates are higher in the presence of higher concentration of nutrients. In addition, the lower concentration or limitation of essential substances can hinder the growth rate of microalgae. On the basis of biomass productivity, the highest CO2 fixation was also determined in an integrated system, and CV-BC-TWW system was able to fix 77.57 ± 2.52 mg L−1 CO2 per day as compared to CV-TWW (59.82 ± 1.03 mg L−1 d−1) and CV-BG-11 (37 ± 1.34 mg L−1 d−1) systems. See Fig. 3c.

3.1.3 pH variations during microalgae cultivation

The pH of solution/culture plays a vital role in the microalgae growth and vice versa, because microalgae growth is hindered in a very high acidic or basic pH mediums. Most of microalgae strains like C. vulgaris preferred to grow in the the pH range of 5–9 (Wang et al. 2023; Zhang et al. 2023). In this study, a significant variation in solution pH was observed on a daily basis during the cultivation of C. vulgaris, varying from weakly acidic to basic (6–9), as seen in Fig. 3d. The pH slightly increased from acidic (6.89 pH on zero day) to basic region (8.49 pH on the 11th day) during cultivation of microalgae in CV-BC-TWW culture as compare to CV-TWW (6.95–8.26 pH), which represents that microalgae cells are adjusting the solution pH to enhance the growth by consuming bicarbonates/carbonates and other nutrients during different metabolic reactions (Zaini and Kasmuri 2023). In CV-BG-11 culture, pH increased from 7.79 towards the basic region (9.73 on the 5th day) at initial stages of growth. During cultivation, microalgae cells are responsible to convert the inorganic CO2 into essential substrates (HCO3− ↔ CO32−) under the phototrophic process and enhance the pH of culture to basic region (Kupriyanova et al. 2023). After the 6th day, microalgae cells again maintained the pH towards neutral or slightly basic (7–8 pH range) to support microalgae cells growth during metabolic reactions. Hence, it can be conclude that microalgae cells have an ability to adjust their surroundings pH to support or improve the growth. Meanwhile, a change in pH directly affects the surface charge of microalgae cells and adsorbent like BC, which can be helpful to adsorb cationic MB dye molecules through electrostatic attraction forces (Sireesha et al. 2022), (see 3.2.1 section).

3.2 Bioremediation of textile wastewater

3.2.1 Removal of dye and COD

Microalgae biomass has an ability to break down the azo bonds of dye molecules and remove its color from TWW via biosorption followed by bioaccumulation/biodegradation processes (Sriphirom et al. 2019). In this study, C. vulgaris and algal biochar were used to biodegrade and adsorb dye molecules from TWW, respectively, during cultivation period. The highest dye removal (%) of about 99.90 ± 0.71% was achieved on the 14th day of cultivation in a hybrid culture of CV-BC-TWW, which indicates that biochar and microalgal cells undergo biosorption and bioaccumulation processes, respectively. On the contrary, CV-TWW and BC-TWW systems also showed a significant dye removal up to 88.61 ± 0.31% and 43.5 ± 0.04% respectively, as shown in Fig. 4a. In CV-TWW system, dye removal was slower in the beginning as microalgae cells were adjusting themselves into a surrounding environment, as shown in Fig. 2. The dye molecules were removed due to bioaccumulation or biodegradation in CV-TWW system during exponential growth phase of microalgae. However, the dye removal rate is slower in CV-TWW than hybrid CV-BC-TWW system because it only causes biodegradation rather than biosorption-biodegradation processes of hybrid systems due to the presence of microalgae cells and algal biochar active sites (which provide pores and functional groups such as carboxyl and hydroxyl at biochar surface to adsorb dye molecules) (Jagaba et al. 2022). Meanwhile in BC-TWW culture, the dye removal (due to biosorption only) was rapidly increased in initial days due to the availability of active sites on BC surface. It can be seen that the dye removal significantly slowed down after the 5th day due to the saturation of all active sites or pores with MB molecules (Danouche et al. 2022). The biosorption of dye molecules using algal BC might occur due to electrostatic force of attraction, hydrogen bonding, π–π stacking, diffusion, and chemisorption between dye molecules and BC (Qiu et al. 2022). Thus, it can be concluded that algal BC has an ability to adsorb organic dye molecules on the surface of BC and C. vulgaris microalgae cells uptake dye molecules for bioaccumulation/biodegradation due to the metabolic reactions of extracellular polymeric substances and/or enzymatic catalysis process (Fazal et al. 2018). Therefore, the integration of algal BC with C. vulgaris improves the bioremediation rate of dyes from TWW as compared to individual systems.

As mentioned above, the bioremediation of TWW using microalgae involves different mechanisms such as biosorption, bioaccumulation, and/or biodegradation, as shown Fig. 5. The biosorption process is considered a passive process, where pollutants can bind on the surface or transfer to the pores of biosorbent. Methylene blue, as a cationic dye, has a positive charge and microalgae C. vulgaris has a net negative charge on the surface of its cell membrane. Firstly, microalgae cells attract MB molecules towards their negatively charged surface. The membrane of microalgal cells possesses anionic functional groups (–OH, –PO4, and –COOH, etc.), which act as active sites to attract positively charged methylene blue molecules on its surface by electrostatic attraction (Chin et al. 2020). Secondly, microalgae cells are responsible for bioaccumulation or biodegradation of dye molecules into algal biomass by metabolic reactions. The adsorbed dye molecules, due to their hydrophobic nature, are penetrated or bioaccumulated inside the cell membrane through passive diffusion, passive-facilitated diffusion, and energy-dependent/active uptake (Hernández-zamora et al. 2015). Then, microalgae cell degrades these dye molecules extracellularly or intracellularly or in a combination of both through the excretion of extracellular polymeric substances and specific enzymes (such as azo-dye reductase) and converts them into simple and nontoxic compounds (i.e. CO2, H2O, and NH2) during metabolic reactions. These nontoxic compounds, along with other contaminants like nitrates and phosphates, are bioconverted into ATP, ADP, NADPH, and phosphoglycerate metabolites by nitrate reductase and glutamine synthetase. Then, these metabolic substances are used to produce carbohydrates, proteins, pigments, and lipid compounds through Calvin-Benson cycle, TCA cycle, and TAG synthesis processes. These energy compounds are stored into microalgae cells as algal biomass (Abdelfattah et al. 2023). For instance, microalgae C. vulgaris cultivation shows a significant dye removal efficiency from 76.3 to 99.0% from TWW due to biosorption and bioaccumulation/biodegradation processes (Chin et al. 2020; Khan et al. 2023).

The COD analyses of samples were also conducted to confirm the degradation or removal of MB from TWW at specific time intervals (0, 8, 12, and 14 days). The highest COD removal on the 14th day was found in CV-BC-TWW around 99.9 ± 1.14% as compared to the CV-TWW (92.2 ± 1.45%), BC-TWW (16.2 ± 1.53%), and CV-BG-11 (89.1 ± 1.28%), as shown in Fig. 4b. The COD removal pattern in all PBRs indicates that COD removal was higher during exponential phase of growth. As microalgae cultivation entered their exponential growth phase (4–12 days), the consumption/bioconversion of organic carbon (MB dye and glucose) increased due to the photosynthesis-Calvin-Benson processes of microalgae cells, which resulted in an increase in COD removal from 29.0 ± 2.12 to 99.8 ± 2.01% in CV-BC-TWW, 17.6 ± 1.28 to 86.9 ± 1.85% in CV-TWW, and 20.76 ± 1.55 to 87.37 ± 1.54% in CV-BG-11 culture. This high COD removal during exponential growth phases indicates that microalgae cells are responsible to breakdown or bioconversion of MB molecules into metabolites during bioaccumulation process/metabolic reactions (Fazal et al. 2021a; Hashmi et al. 2023). Meanwhile, the lowest COD removal was observed in BC-TWW system due to the presence of organic carbon (glucose) in TWW, as only BC is not able to breakdown glucose into simple substances through biosorption process, unlike microalgae processes of bioaccumulation or biodegradation (Jagaba et al. 2022).

3.2.2 Removal of nitrates and phosphates

During microalgae growth, the source of nitrogen and phosphorus plays a key role in increasing the cell growth of C. vulgaris. Therefore, these nutrients can be reduced from TWW effluents by C. vulgaris cultivation. The results of this study showed that the uptake of nitrogen (nitrates, NO3−) and phosphorus (phosphates, PO43−) increased slowly during lag phase of growth prior to going into exponential growth phase (the 4th to 12th day), where the removal of both NO3− and PO43− increased exponentially from 40.28 ± 0.70 to 96.76 ± 1.41% and 43.75 ± 1.98 to 96.25 ± 1.71%, respectively, in CV-BC-TWW system. See Fig. 6. Afterwards, the removal of NO3− and PO43− did not increase significantly due to stationary/decline phases of microalgae growth with the highest removal of NO3− and PO43− reaching up to 99.62 ± 0.17% and 99.27 ± 1.01%, respectively, on the 14th day of cultivation in CV-BC-TWW system, followed by CV-BG-11 system (93.39 ± 1.41% and 93.75 ± 1.42%) and CV-TWW (89.47 ± 1.42% and 78.75 ± 1.01%). The lowest removal of NO3− and PO43− content was observed in BC-TWW system up to 10.32 ± 0.71% and 13.74 ± 1.07%, respectively. It can be seen from Figs. 4b, and 6a, b that the removal of these nutrients is directly proportional to the COD removal efficiency, as microalgae cells consume organic carbon (MB/glucose), NO3−, and PO43− nutrients during their metabolic reactions to form chlorophyll, phycocyanin, amino acids, nucleic acids (DNA, RNA), and triglycerides (Castillo et al. 2021; Hsieh-Lo et al. 2019). The formation of these substances is attributed to the bioremediation of COD, nitrates, and phosphates from TWW during microalgae cultivation (Kumar et al. 2020). Hence, it can be concluded that integration of algal BC with C. vulgaris is a more efficient way to reduce/consume the NO3− and PO43− from TWW effluents and convert them into value added products during cultivation process.

3.3 Biodiesel production

The biodiesel production is associated with the presence of free fatty acids, which help to enhance the quantity and quality of biodiesel during transesterification process (Ahmad et al. 2019). The quantity and quality of microalgae-derived biodiesel are influenced by the nutrients availability. For this purpose, C. vulgaris derived algal oil/lipids from different cultures were used to produce biodiesel (fatty acids methyl ester, FAMEs) before the assessment of FAME yield and FAME profiles. The total FAME yields were found 43.32 ± 1.77, 38.86 ± 1.02, and 76.79 ± 2.01 mg g−1 in CV-BG-11, CV-TWW, and CV-BC-TWW cultures, respectively, as shown in Fig. 7a. The highest FAME yield was achieved in an integrated system (CV-BC-TWW) due to the early starvation of nutrients, as microalgae growth reached stationary phase after the 9th day as compared to other CV-BG-11 (the 10th day) and CV-TWW (the 12th day) cultures. Mostly, microalgae cells switch their metabolic reactions from biomass generation to cell maintenance and lipid-based energy storage under nutrient starvation conditions (Peng et al. 2020; Angelaalincy et al. 2023). A significant FAME was yielded from extracted lipids of CV-BC-TWW microalgae biomass due to the deficiency/starvation of nitrogen (nitrates) content during stationary-decline phases (9–14th day), as shown in Fig. 7. On the contrary, microalgae cells in CV-TWW culture were engaged in growing phase until the 12th day and produced low lipids content during stationary-decline phases (only two days), which lead them to produce low FAME yield. It can be concluded that fast/rapid microalgae growth is responsible to create nutrient starvation conditions, which led the cells to change their growth processes (protein production) to cell maintenance, lipid production/aggregation, and the conversion of excess carbon buildup through the photosynthetic system into triglycerides (Vasistha et al. 2023; Mulgund 2022).

FAME profiles showed that different FAME compounds, with C16:0, C16:1, C18:0, C18:2, C18:3, C22:0, and C22:1 chain lengths, were present in biodiesel in different concentrations, as shown in Fig. 7b. Similar composition of C. vulgaris derived FAME compounds was reported in literature (Fazal et al. 2021a; Vasistha et al. 2023). In CV-BC-TWW cultivated C. vulgaris, the total FAMEs were composed of 15.66 mg g−1 saturated fatty acids (SFAs), 34.82 mg g−1 monounsaturated fatty acids (MUFAs), and 26.31 mg g−1 polyunsaturated fatty acids (PUFAs), as shown in Table 1. Meanwhile, FAME profiles of microalgal-derived biodiesel in CV-BG-11 and CV-TWW cultures indicated that different FAME compounds were also present in biodiesel in terms of SFAs (6.92 and 7.84 mg g−1), MUFAs (16.94 and 15.05 mg g−1), and PUFAs up to 19.46 mg g−1 and 15.97 mg g−1, respectively. The dominant fatty acid compounds such as palmitoleic acid (C16:1, MUFA) and linolenic acid (C18:3, PUFA) improve the oxidative stability of biodiesel, reduce its freezing point, and intensify its low temperature properties (Fazal et al. 2021a). The lower components of SFAs in biodiesel are responsible to provide a stability and higher cetane number and/or better fuel quality (Mulgund 2022). On the other aspect, the FAME components of linoleic acid (C18:2) and linolenic acid (C18:3) also play an important role in making membrane structures of microalgae cells (Russell and Rodriguez 2023). The characteristics of algal biodiesel derived from CV-BC-TWW biomass such as relative density, kinematic viscosity, cloud point, flash point, and pour point were also measured up to 0.856 g mL−1, 3.994 mm2 s−1 at 70 °C, 4.983 °C, 98.626 °C, and − 4.994 °C, respectively.

4 Conclusion

In this study, the addition of algal-BC and TWW provides essential nutrients such as organic carbon, dyes, nitrates, phosphates, and minerals for microalgae cultivation. Therefore, the integrated system of CV-BC-TWW showed highest microalgae biomass production (255.11 ± 6.01 mg g−1), CO2 fixation rate (77.57 ± 2.52 mg L−1 d−1), bioremediation of TWW (> 99%), and biodiesel production (76.79 mg g−1) as compare to individual systems. The algal growth, bioremediation of TWW in terms of MB and COD removal, and biodiesel content were increased up to 1.55, 1.15, and 1.97 fold in CV-BC-TWW system as compare to CV-TWW system. It indicated that the addition of algal-BC in integrated system not only enhanced the algal-growth but also increased the bioremediation of TWW (due to biosorption and biodegradation) and biodiesel content (i.e. C16:1, C18:3, and C22:0), as they improve the oxidative stability and low temperature properties of biodiesel. Hence, this study demonstrated that microalgae Chlorella vulgaris and algal-BC can be integrated to develop a fast, green, efficient, economical, and sustainable approach for the microalgae-growth, carbon capture, bioremediation of TWW, and biodiesel production.

Data availability

Data will be made available on request.

References

Abdelfattah A, Ali SS, Ramadan H, El-Aswar EI, Eltawab R, Ho SH, Elsamahy T, Li S, El-Sheekh MM, Schagerl M, Kornaros M, Sun J (2023) Microalgae-based wastewater treatment: Mechanisms, challenges, recent advances, and future prospects. Environ Sci Ecotechnol 13:100205. https://doi.org/10.1016/j.ese.2022.100205

Ahmad A, Ashraf SS (2023) Sustainable food and feed sources from microalgae: Food security and the circular bioeconomy. Algal Res 74:103185. https://doi.org/10.1016/j.algal.2023.103185

Ahmad N, Javed F, Awan JA, Ali S, Fazal T, Hafeez A, Aslam R, Rashid N, Rehman MSU, Zimmerman WB, Rehman F (2019) Biodiesel production intensification through microbubble mediated esterification. Fuel 253:25–31. https://doi.org/10.1016/j.fuel.2019.04.173

Angelaalincy M, Nishtha P, Ajithkumar V, Ashokkumar B, Muthu Ganesh Moorthy I, Brindhadevi K, Thuy Lan Chi N, Pugazhendhi A, Varalakshmi P (2023) Phycoremediation of Arsenic and biodiesel production using green microalgae Coelastrella sp. M60—an integrated approach. Fuel 333:126427. https://doi.org/10.1016/j.fuel.2022.126427

Ashour M, Omran AMM (2022) Recent advances in marine microalgae production: highlighting human health products from microalgae in view of the coronavirus pandemic (COVID-19). Fermentation. https://doi.org/10.3390/fermentation8090466

Behl K, Sinha S, Sharma M, Singh R, Joshi M, Bhatnagar A, Nigam S (2019) One-time cultivation of Chlorella pyrenoidosa in aqueous dye solution supplemented with biochar for microalgal growth, dye decolorization and lipid production. Chem Eng J 364:552–561. https://doi.org/10.1016/j.cej.2019.01.180

Castillo T, Ramos D, García-Beltrán T, Brito-Bazan M, Galindo E (2021) Mixotrophic cultivation of microalgae: an alternative to produce high-value metabolites. Biochem Eng J. https://doi.org/10.1016/j.bej.2021.108183

Chettri D, Verma AK, Verma AK (2023) Exploring the potential of microalgae cell factories for generation of biofuels. Biofuels. https://doi.org/10.1080/17597269.2023.2233805

Chin JY, Chng LM, Leong SS, Yeap SP, Hidayah N, Yasin M, Toh PY (2020) Removal of Synthetic dye by chlorella vulgaris microalgae as natural adsorbent. Arab J Sci Eng 45:7385–7395. https://doi.org/10.1007/s13369-020-04557-9

Chin GJWL, Andrew AR, Abdul-Sani ER, Yong WTL, Misson M, Anton A (2023) The effects of light intensity and nitrogen concentration to enhance lipid production in four tropical microalgae. Biocatal Agric Biotechnol 48:102660. https://doi.org/10.1016/j.bcab.2023.102660

Christian D, Gaekwad A, Dani H, Shabiimam MA, Kandya A (2023) Recent techniques of textile industrial wastewater treatment: a review. Mater Today Proc 77:277–285. https://doi.org/10.1016/j.matpr.2022.11.301

Danouche M, El Arroussi H, El Ghachtouli N (2022) Bioremoval of Acid Red 14 dye by Wickerhamomyces anomalus biomass: kinetic and thermodynamic study, characterization of physicochemical interactions, and statistical optimization of the biosorption process. Biomass Convers Bioref 14:2829–2848. https://doi.org/10.1007/s13399-022-02711-x

Debeni Devi N, Sun X, Hu B, Goud VV (2023) Bioremediation of domestic wastewater with microalgae-cyanobacteria co-culture by nutritional balance approach and its feasibility for biodiesel and animal feed production. Chem Eng J. https://doi.org/10.1016/j.cej.2022.140197

Devi A, Verma M, Saratale GD, Saratale RG, Ferreira LFR, Mulla SI, Bharagava RN (2023) Microalgae: a green eco-friendly agents for bioremediation of tannery wastewater with simultaneous production of value-added products. Chemosphere 336:139192. https://doi.org/10.1016/j.chemosphere.2023.139192

Fazal T, Mushtaq A, Rehman F, Ullah A, Rashid N (2018) Bioremediation of textile wastewater and successive biodiesel production using microalgae. Renew Sustain Energy Rev 82:3107–3126. https://doi.org/10.1016/j.rser.2017.10.029

Fazal T, Faisal A, Mushtaq A, Hafeez A, Javed F, Alaud Din A, Rashid N, Aslam M, Rehman MSU, Rehman F (2019) Macroalgae and coal-based biochar as a sustainable bioresource reuse for treatment of textile wastewater. Biomass Convers Bioref 11:1491–1506. https://doi.org/10.1007/s13399-019-00555-6

Fazal T, Razzaq A, Javed F, Hafeez A, Rashid N, Amjad US, Rehman MSU, Faisal A, Rehman F (2020) Integrating adsorption and photocatalysis: a cost effective strategy for textile wastewater treatment using hybrid biochar-TiO2 composite. J Hazard Mater 390:121623. https://doi.org/10.1016/j.jhazmat.2019.121623

Fazal T, Rehman MSU, Javed F, Akhtar M, Mushtaq A, Hafeez A, Alaud Din A, Iqbal J, Rashid N, Rehman F (2021) Integrating bioremediation of textile wastewater with biodiesel production using microalgae ( Chlorella vulgaris ). Chemosphere 281:130758. https://doi.org/10.1016/j.chemosphere.2021.130758

Georgin J, Franco DSP, Netto MS, Manzar MS, Zubair M, Meili L, Piccilli DGA, Silva LFO (2022) Adsorption of the first-line covid treatment analgesic onto activated carbon from residual pods of Erythrina speciosa. Environ Manage. https://doi.org/10.1007/s00267-022-01716-6

Hashmi Z, Bilad MR, Fahrurrozi, Zaini J, Lim JW, Wibisono Y (2023) Recent progress in microalgae-based technologies for industrial wastewater treatment. Fermentation 9:1–25. https://doi.org/10.3390/fermentation9030311

Heredia-arroyo T, Wei W, Ruan R, Hu B (2011) Mixotrophic cultivation of Chlorella vulgaris and its potential application for the oil accumulation from non-sugar materials. Biomass Bioenerg 5:2245–2253. https://doi.org/10.1016/j.biombioe.2011.02.036

Hernández-zamora M, Cristiani-urbina E, Martínez-jerónimo F, Perales-vela HV, Ponce-noyola T, Montes-horcasitas MC, Cañizares-villanueva RO (2015) Bioremoval of the azo dye Congo Red by the microalga Chlorella vulgaris. Env Sci Pollut Res 15:4277. https://doi.org/10.1007/s11356-015-4277-1

Hsieh-Lo M, Castillo G, Ochoa-Becerra MA, Mojica L (2019) Phycocyanin and phycoerythrin: strategies to improve production yield and chemical stability. Algal Res 42:101600. https://doi.org/10.1016/j.algal.2019.101600

Jagaba AH, Kutty SRM, Abubakar S, Birniwa AH, Lawal IM, Umaru I, Usman AK, Yaro NSA, Al-Zaqri N, Al-Maswari BM, Ibrahim MNM, Hussain F (2022) Synthesis, characterization, and performance evaluation of hybrid waste sludge biochar for COD and color removal from agro-industrial effluent. Separations 9:1–21. https://doi.org/10.3390/separations9090258

Javed F, Rehman F, Khan AU, Fazal T, Hafeez A, Rashid N (2022) Real textile industrial wastewater treatment and biodiesel production using microalgae. Biomass Bioenerg 165:106559. https://doi.org/10.1016/j.biombioe.2022.106559

Javed F, Zimmerman WB, Fazal T, Hafeez A, Mustafa M, Rashid N, Rehman F (2023a) Green synthesis of biodiesel from microalgae cultivated in industrial wastewater via microbubble induced esterification using bio-MOF-based heterogeneous catalyst. Chem Eng Res Des 189:707–720. https://doi.org/10.1016/j.cherd.2022.12.004

Javed F, Rashid N, Fazal T, Hafeez A, Rehman F (2023b) Integration of real industrial wastewater streams to enhance chlorella vulgaris growth: nutrient sequestration and biomass production. Water Air Soil Pollut 234:164. https://doi.org/10.1007/s11270-023-06066-5

Jiang X, Liu Y, Yin X, Deng Z, Zhang S, Ma C, Wang L (2023) Efficient removal of chromium by a novel biochar-microalga complex: mechanism and performance. Environ Technol Innov 31:103156. https://doi.org/10.1016/j.eti.2023.103156

Khan AA, Gul J, Naqvi SR, Ali I, Farooq W, Liaqat R, AlMohamadi H, Štěpanec L, Juchelková D (2022) Recent progress in microalgae-derived biochar for the treatment of textile industry wastewater. Chemosphere. https://doi.org/10.1016/j.chemosphere.2022.135565

Khan MD, Singh A, Khan MZ, Tabraiz S, Sheikh J (2023) Current perspectives, recent advancements, and efficiencies of various dye-containing wastewater treatment technologies. J Water Process Eng 53:103579. https://doi.org/10.1016/j.jwpe.2023.103579

Kumar V, Nanda M, Pruthi V, Sharma N, Vlaskin MS, Tomar MS (2020) Integration of wastewater valorization with microalgae for biofuel production. Elsevier Inc.

Kupriyanova EV, Pronina NA, Los DA (2023) Adapting from low to high: an update to CO2-concentrating mechanisms of cyanobacteria and microalgae. Plants. https://doi.org/10.3390/plants12071569

Law XN, Cheah WY, Chew KW, Ibrahim MF, Park YK, Ho SH, Show PL (2022) Microalgal-based biochar in wastewater remediation: its synthesis, characterization and applications. Environ Res 204:111966. https://doi.org/10.1016/j.envres.2021.111966

Leflay H, Pandhal J, Brown S (2021) Direct measurements of CO2 capture are essential to assess the technical and economic potential of algal-CCUS. J CO2 Util 52:101657. https://doi.org/10.1016/j.jcou.2021.101657

Leonardo W, Cristine P, Muraro L, Pavoski G, Crocce D, Espinosa R (2022) Preparation and characterization of biochar from cement waste for removal of rhodamine B dye. J Mater Cycles Waste Manag. https://doi.org/10.1007/s10163-022-01416-7

Min Woon J, Shiong Khoo K, Akermi M, Alanazi MM, Wei Lim J, Jing Chan Y, Sean Goh P, Silas Chidi B, Kee Lam M, Zaini J, Roil Bilad M, Zhou Y, Tasnim Sahrin N, Musa AF (2023) Reviewing biohydrogen production from microalgal cells through fundamental mechanisms, enzymes and factors that engendering new challenges and prospects. Fuel 346:128312. https://doi.org/10.1016/j.fuel.2023.128312

Montoya-Vallejo C, Guzmán Duque FL, Quintero Díaz JC (2023) Biomass and lipid production by the native green microalgae Chlorella sorokiniana in response to nutrients, light intensity, and carbon dioxide: experimental and modeling approach. Front Bioeng Biotechnol 11:1–16. https://doi.org/10.3389/fbioe.2023.1149762

Motitswe MG, Badmus KO, Khotseng L (2022) Development of adsorptive materials for selective removal of toxic metals in wastewater: a review. Catalysts 12:1–23. https://doi.org/10.3390/catal12091057

Mulgund A (2022) Increasing lipid accumulation in microalgae through environmental manipulation, metabolic and genetic engineering: a review in the energy NEXUS framework. Energy Nexus 5:100054. https://doi.org/10.1016/j.nexus.2022.100054

Mushtaq A, Cho H, Ahmed MA, Rehman MSU, Han JI (2019) A novel method for the fabrication of silver nanowires-based highly electro-conductive membrane with antifouling property for efficient microalgae harvesting. J Memb Sci 590:117258. https://doi.org/10.1016/j.memsci.2019.117258

Mushtaq A, Cho H, Ryu H, Ahmed MA, Saif Ur Rehman M, Han JI (2022) Novel metallic stainless-steel mesh-supported conductive membrane and its performance in the electro-filtration process. Chemosphere 308:136160. https://doi.org/10.1016/j.chemosphere.2022.136160

Nezbrytska I, Shamanskyi S, Pavliukh L, Kharchenko G (2022) Assessment of inorganic nitrogen and phosphorus compounds removal efficiency from different types of wastewater using microalgae cultures. Oceanol Hydrobiol Stud 51:45–52. https://doi.org/10.26881/oahs.2022.1.05

Nguyen TB, Nguyen VT, Hoang HG, Cao NDT, Nguyen TT, Vo TDH, Nguyen NKQ, Pham MDT, Nghiem DL, Vo TKQ, Di Dong C, Bui XT (2023) Recent development of algal biochar for contaminant remediation and energy application: a state-of-the art review. Curr Pollut Reports 9:73–89. https://doi.org/10.1007/s40726-022-00243-6

Onen N, Elwardany A, Fujii M (2023) Biosorption of Congo Red dye from aqueous solutions using pristine biochar and ZnO biochar from green pea peels. Chem Eng Res Des 189:636–651. https://doi.org/10.1016/j.cherd.2022.12.003

Ord JI, Cort S, Maluenda P (2023) Biosorption of heavy metals with algae: critical review of its application in real effluents. Sustainability. https://doi.org/10.3390/su15065521

Oyebamiji OO, Boeing WJ, Holguin FO, Ilori O (2019) Green microalgae cultured in textile wastewater for biomass generation and biodetoxi fi cation of heavy metals and chromogenic substances. Bioresour Technol Reports 7:100247. https://doi.org/10.1016/j.biteb.2019.100247

Peng H, de Bashan LE, Bashan Y, Higgins BT (2020) Indole-3-acetic acid from Azosprillum brasilense promotes growth in green algae at the expense of energy storage products. Algal Res 47:101845. https://doi.org/10.1016/j.algal.2020.101845

Qiu B, Shao Q, Shi J, Yang C, Chu H (2022) Application of biochar for the adsorption of organic pollutants from wastewater: modification strategies, mechanisms and challenges. Sep Purif Technol 300:121925. https://doi.org/10.1016/j.seppur.2022.121925

Rafique M, Hajra S, Tahir MB, Gillani SSA, Irshad M (2022) A review on sources of heavy metals, their toxicity and removal technique using physico-chemical processes from wastewater. Environ Sci Pollut Res 29:16772–16781. https://doi.org/10.1007/s11356-022-18638-9

Rodas-Zuluaga LI, Castañeda-Hernández L, Castillo-Vacas EI, Gradiz-Menjivar A, López-Pacheco IY, Castillo-Zacarías C, Boully L, Iqbal HMN, Parra-Saldívar R (2021) Bio-capture and influence of CO2 on the growth rate and biomass composition of the microalgae Botryococcus braunii and Scenedesmus sp. J CO2 Util. https://doi.org/10.1016/j.jcou.2020.101371

Russell C, Rodriguez C (2023) Lipid extraction from Chlorella vulgaris & Haematococcus pluvialis using the switchable solvent DMCHA for biofuel production. Energy 278:127983. https://doi.org/10.1016/j.energy.2023.127983

Satya ADM, Cheah WY, Yazdi SK, Cheng YS, Khoo KS, Vo DVN, Bui XD, Vithanage M, Show PL (2023) Progress on microalgae cultivation in wastewater for bioremediation and circular bioeconomy. Environ Res 218:114948. https://doi.org/10.1016/j.envres.2022.114948

Shan S, Yurevich A, Wang C, Ge B, Han J, Zhang X, Zhou C, Yan X, Ruan R, Cheng P (2023) Mixotrophy, a more promising culture mode: multi-faceted elaboration of carbon and energy metabolism mechanisms to optimize microalgae culture. Bioresour Technol 386:129512. https://doi.org/10.1016/j.biortech.2023.129512

Sireesha S, Agarwal A, Santosh K, Sreedhar SI (2022) Modified coal fly ash as a low—cost, efficient, green, and stable adsorbent for heavy metal removal from aqueous solution. Biomass Convers Bioref. https://doi.org/10.1007/s13399-022-02695-8

Sriphirom P, Chidthaisong A, Yagi K, Tripetchkul S, Towprayoon S (2019) Evaluation of biochar applications combined with alternate wetting and drying (AWD) water management in rice field as a methane mitigation option for farmers’ adoption. Soil Sci Plant Nutr 66:235–246. https://doi.org/10.1080/00380768.2019.1706431

Sufiana F, Marchelli J, Fiori L (2023) Algal biomass, biochar and hydrochar from Chlorella vulgaris for cadmium removal from aqueous streams. Res Sq. https://doi.org/10.21203/rs.3.rs-2943751/v1

Tambat VS, Sheng Tseng Y, Kumar P, Chen CW, Singhania RR, Chang JS, Di Dong C, Patel AK (2023) Effective and sustainable bioremediation of molybdenum pollutants from wastewaters by potential microalgae. Environ Technol Innov 30:103091. https://doi.org/10.1016/j.eti.2023.103091

Tarafdar A, Sowmya G, Yogeshwari K, Rattu G, Negi T, Awasthi MK, Hoang AT, Sirohi R (2023) Environmental pollution mitigation through utilization of carbon dioxide by microalgae. Environ Pollut. https://doi.org/10.1016/j.envpol.2023.121623

Vasistha S, Balakrishnan D, Manivannan A, Rai MP (2023) Microalgae on distillery wastewater treatment for improved biodiesel production and cellulose nanofiber synthesis: a sustainable biorefinery approach. Chemosphere 315:137666. https://doi.org/10.1016/j.chemosphere.2022.137666

Wang J, Tian Q, Zeng W, Qiu G, Shen L (2023) Insights about fungus-microalgae symbiotic system in microalgae harvesting and wastewater treatment: a review. Renew Sustain Energy Rev 182:113408. https://doi.org/10.1016/j.rser.2023.113408

Wu J, Lay C, Chen C, Wu S (2017) Lipid accumulating microalgae cultivation in textile wastewater: environmental parameters optimization. J Taiwan Inst Chem Eng. https://doi.org/10.1016/j.jtice.2017.02.017

Zaini N, Kasmuri N (2023) The growth and development of Chlorella vulgaris in the batch culture system. IOP Conf Ser Earth Environ Sci. https://doi.org/10.1088/1755-1315/1140/1/012009

Zhang C, Laipan M, Zhang L, Yu S, Li Y, Guo J (2023) Capturing effects of filamentous fungi Aspergillus flavus ZJ-1 on microalgae Chlorella vulgaris WZ-1 and the application of their co-integrated fungi-algae pellets for Cu ( II ) adsorption. J Hazard Mater 442:130105. https://doi.org/10.1016/j.jhazmat.2022.130105

Acknowledgements

The authors have expressed gratitude to Khwaja Fareed University of Engineering and Information Technology, Rahim Yar Khan, Pakistan, for its lab facilities. This work was also made possible by QNRF grant No. MME03-1101-210007 from the Qatar National Research Fund. Open Access funding provided by the Qatar National Library. The statements made herein are solely the responsibility of the authors.

Funding

Open Access funding provided by the Qatar National Library (MME03-1101-210007).

Author information

Authors and Affiliations

Contributions

Rabia Rehman: Methodology, Investigation, Writing-Original Draft. Javed Iqbal and Muhammad Saif Ur Rehman: Supervision, Conceptualization, Project Administration. Shanawar Hamid: Formal Analysis, Writing-Review and Editing. Yuze Wang: Validation, Visualization, Resources, Kashif Rasool: Writing-Review and Editing, Funding acquisition. Tahir Fazal: Methodology, Writing-Original Draft, Visualization, Supervision. The author(s) read and approved the final manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Handling editor: Ondrej Masek

Supplementary Information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Rehman, R., Iqbal, J., Ur Rehman, M.S. et al. Algal-biochar and Chlorella vulgaris microalgae: a sustainable approach for textile wastewater treatment and biodiesel production. Biochar 6, 65 (2024). https://doi.org/10.1007/s42773-024-00358-7

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42773-024-00358-7