Abstract

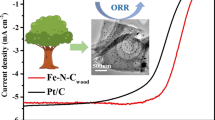

As promising energy-storage devices, zinc–air batteries (ZABs) exhibit slow reaction kinetics for oxygen reduction reaction (ORR) and oxygen evolution reaction (OER) occurring at their electrodes. High-performance bifunctional catalysts must thus be synthesized to accelerate the reversible conversion of oxygen and improve the rate and overall performance of ZABs. Herein, we reported the promising prospects of self-supported composite electrodes composed of wood-derived carbon (WDC) and bimetallic cobalt-iron alloys/oxides (CoFe-CoFe2O4@WDC) as efficient electrocatalysts for alkaline ORR/OER. WDC provided a favorable three-phase interface for heterogeneous reactions owing to its layered porous structure and genetic stability, thereby enabling mass diffusion and improving reaction kinetics. The CoFe2O4 spinel surface was reduced to bimetallic CoFe alloy to form abundant heterostructure interfaces that promote electron transfer. Under alkaline conditions, the optimized composite electrode exhibited a remarkable high half-wave potential of 0.85 V and an exceptionally low overpotential of 1.49 V. It also exhibited stable performance over an impressive 2340 cycles in a ZAB. Theoretical calculations also confirmed that the heterointerface addresses the issue of proton scarcity throughout the reaction and actively facilitates the creation of O–O bonds during the reversible transformation of oxygen. This study introduces a new concept for developing bifunctional and efficient electrocatalysts based on charcoal and encourages the sustainable and high-value use of forest biomass resources.

Graphical Abstract

Highlights

-

Water dissociation was regulated to provide proton for smooth response under alkaline conditions and accelerate the conversion of *O2 to *OOH.

-

The alloy surface formed CoFe oxyhydroxide in the OER voltage range, and the adsorption capacity of intermediates was adjusted to facilitate O–O bond formation.

-

The d-band center moved downward due to interface electron interaction, modifying the binding ability of intermediates.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Increasing fossil fuel consumption and related environmental issues have necessitated the urgent exploration and development of safe, clean renewable energy systems (Suen et al. 2017; Wang et al. 2020; Zhang et al. 2023). Hydrogen–oxygen fuel cells, metal–air batteries, and ion batteries have garnered extensive research attention owing to their environmental benefits, high conversion rates, easy operation, and long cycling stability (Bates et al. 2022; Rehman et al. 2023; Xiao et al. 2021). Among them, zinc–air batteries (ZABs) have several advantages such as green synthesis, environmental friendliness, cost-effectiveness, high energy density, enhanced safety and stability, and zero carbon emissions (Balaji et al. 2023; Hu and Zhu 2023b; Zhao et al. 2023). ZABs are widely applied for powering electronic devices and large-scale long-distance power supply (Hu et al. 2024). However, the kinetics of reversible oxygen reactions during charging and discharging at the air electrode were sluggish. This issue must therefore be addressed to improve the energy efficiency of ZABs caused by increased overpotential (Hu and Zhu 2023a; Liu et al. 2023). Multielectron transfer processes involved in oxygen reduction reaction/oxygen evolution reaction (ORR/OER) require catalytically active sites at the gas–solid–liquid interface. Therefore, an ideal electrode material must contain abundant electrically active sites and exhibit high intrinsic activity (Chandrasekaran et al. 2023; Liu et al. 2019; Xu et al. 2023; Zhao et al. 2020). Furthermore, a meticulous electrode structural design can simultaneously enhance electron transfer and facilitate mass transport during reversible oxygen conversion. Although noble metal catalysts such as platinum, iridium, and ruthenium have excellent catalytic performance, their scarcity and low stability hinder their practical applications (Guo et al. 2023b; Jiang et al. 2019; Li et al. 2023)

Transition metals, including oxides, hydroxides, sulfides, phosphides, and alloys, have therefore been widely studied as alternatives to such metal catalysts. They exhibit impressive electrocatalytic behavior in ORR/OER in alkaline media. Among them, spinel oxide (AB2O4) has flexible and adjustable A and B sites. Half of the Fe3+ in CoFe2O4 was located in a tetrahedral (Td) coordination environment, whereas the remaining Fe3+ and Co2+ occupy an octahedral (Oh) coordination arrangement. The metal substitution of Co-based spinel can optimize its electronic configuration, resulting in charge separation, carrier migration, and changes in its energy band structure (Avcı et al. 2022; Shao et al. 2022; Sun et al. 2018; Wierzbicki et al. 2023). An imprecisely designed spinel cannot exhibit bifunctional activity. Co-based spinel has insufficient electroactive sites or poor accessibility of active sites; therefore, their adsorption capacity for oxygen intermediates is too strong or too weak (Xie et al. 2022). To address this issue, it is combined with other materials. Alloys have been extensively studied for their use in OER. At standard potential, transition metal-based catalysts can easily form hydroxides or oxyhydroxides as active materials for effective OER (Kim et al. 2019; Xie et al. 2020; Xu et al. 2024; Zheng et al. 2020). The adsorption and desorption behaviors of intermediates is adjusted via electronic interactions or multiactivity site effects to achieve superior catalytic activity; however, they have poor structural stability (Seh et al. 2017; Song et al. 2020). Metals and their derivatives are prone to agglomeration during the catalytic process, affecting their catalytic activity. Therefore, appropriate supports must be introduced during such reactions to effectively disperse and stabilize the active sites. Biomass is widely used in energy and conversion devices because it has abundant sources and sustainable resource supply (Jin et al. 2022; Qiu et al. 2021, 2022). Wood-derived carbon (WDC) is cross-linked by complex polymers and contains rich functional groups, which provides it with flexible control potential (Peng et al. 2019; Tu et al. 2020). After dehydration, condensation, and carbonization, WDC yields a material with a three-dimensional layered porous structure (Hu et al. 2021). The enhanced mechanical properties and porosity can considerably promote oxygen migration and ion diffusion, providing ideal mass transfer interconnection channels and dispersion medium for catalytic active sites (Lin et al. 2023; Shen et al. 2022). As these materials cannot be effectively integrated due to lack of methods, their bifunctional performance cannot be assessed.

This paper reports on a self-supporting nanoporous bimetallic CoFe alloy/spinel interface monolithic composite electrode as an efficient ORR/OER electrocatalyst material. WDC was effectively bound to the active sites using heteroatoms for modifying the electron density. The neatly arranged porous channels of WDC provide a stable structure for the active sites, with excellent mass transfer effect (Ha et al. 2020; Tao et al. 2020). The interface of the alloy precipitated on the spinel surface accelerates the charge transfer, alleviating insufficient proton sources in the alkaline environment and accelerating the conversion of *O2 to *OOH. Moreover, the irreversibly formed CoFeOOH on the alloy surface moderately enhances the adsorption ability of the intermediates and facilitates the conversion of OH− to O2. Relying on the three-dimensional continuous nanoporous structure, CoFe-CoFe2O4@WDC exhibits excellent bifunctional activity. The ZABs based on the CoFe-CoFe2O4@WDC catalyst exhibited enhanced performance with high power density and long cycling stability. This study essentially optimizes molecule transport to improve catalytic activity by designing pore structures and active centers, providing novel insights into the optimization of energy devices and the engineering of carbon-based catalysts for energy conversion.

2 Results and discussion

2.1 Catalyst preparation and characterization

Uniform CoFe2O4 nanospheres were prepared on activated WDC via the typical hydrothermal treatment. Further, CoFe precipitated from CoFe2O4 via surface reduction to obtain CoFe-CoFe2O4@WDC (Fig. 1). The carbon treated with ammonium chloride had evenly distributed pores, as observed via scanning electron microscopy (SEM; Fig. 2a). The natural pores in modified wood were not destroyed, and the genetic characteristics of its physical structure were maintained. The stem-cut surface in Fig. S1 shows a mesoporous structure on the side of the channel. Owing to its hierarchical porous structure, high specific surface area, and low cost, WDC is beneficial for mass transfer processes. The neatly arranged pores confirm the ability of WDC for inherent mass transfer (Zhong et al. 2021). Uniformly distributed nanoparticles and spinel nanostructures were observed after hydrothermal treatment (Fig. S2). After Ar/H2 reduction, the nanoparticle size did not change considerably (Fig. 2b, c). Abundant nanoparticles were thus successfully loaded on the WDC surface, forming a gas–solid–liquid interface in a system conducive to the reaction.

The microstructure and morphology of CoFe-CoFe2O4@WDC were determined via transmission electron microscopy (TEM). Uniformly arranged nanoparticles were observed on the radial channels of wood, indicating the growth of metal on the support (Fig. 2d). The high-resolution TEM (HRTEM) image of CoFe-CoFe2O4@WDC showed that the synthesized composite samples are firmly integrated with a distinct interface between the CoFe alloy and CoFe2O4 (Fig. 2e). The three selected areas represented these mixed crystal structures in composite materials. Two lattice fringes (0.247 and 0.197 nm) were observed in the typical TEM image of CoFe-CoFe2O4@WDC; this finding corresponded well with the (311) crystal face of CoFe in alloy composition and (110) crystal face of CoFe2O4 in spinel composition. Different crystal structures and clear heterogeneous interfaces could be observed between CoFe and CoFe2O4. The selected area electron diffraction (SAED) patterns of the (311) and (440) planes of CoFe2O4 and (110) plane of CoFe confirmed the polycrystalline nature of CoFe-CoFe2O4@WDC (Fig. 2f; Chen et al. 2019). The EDX mapping in Fig. 2g well reflected the even dispersion of C, N, O, Fe, and Co in the CoFe-CoFe2O4@WDC structure. Electron microscopy confirmed the successful synthesis of CoFe-CoFe2O4@WDC catalyst, highlighting the effective dispersion of metal components on the multilayer carbon structure.

X-ray diffraction (XRD) analysis was performed to elucidate the structural composition of the sample. The prominent peaks at 35.4°, 57.1°, and 62.7° corresponded well with the (311), (511), and (440) crystal planes of CoFe2O4, respectively (PDF#03-0864; Fig. 3a). A CoFe2O4 inverse spinel structure was thus successfully synthesized. After surface reduction, CoFe-CoFe2O4@WDC showed two additional diffraction peaked at 44.8° and 65.3° that corresponded to the (110) and (200) crystal planes of the CoFe alloy (PDF#49–1567); no obvious changes were noted for other peaks. These results were consistent with the TEM results, thereby indicating the formation of an alloy structure after surface reduction. Moreover, the separated or new phases were not observed for CoFe-CoFe2O4@WDC, and its crystal structure was not affected by the partial reduction of spinel during which the alloy was modified on the spinel surface.

Raman spectra reflect the information on the carbon skeleton of the samples. The Raman spectra of WDC, CoFe2O4@WDC, and CoFe-CoFe2O4@WDC showed a D peak at 1340 cm−1 and G peak at 1590 cm−1 (Fig. 3b). The D peak indicated the degree of sp3-hybridized carbon within the carbon material, indicative of amorphous or defective structures. In contrast, the G peak represented the level of sp2-hybridized carbon, revealing the presence of ordered or typical graphitic structures in carbon materials. The ordered and disordered structure of carbon-based samples were determined based on the ID/IG ratio. The larger the ratio, the more significant the contribution of amorphous or defective structures (Tan et al. 2021). CoFe-CoFe2O4@WDC had the lowest ID/IG ratio, indicating that transition metal loading improved its graphitization degree. Transition metals can catalyze the conversion of amorphous carbon to graphitized carbon (Tao et al. 2020) and improve the electrical conductivity of spinel. Nitrogen (N2) adsorption/desorption isotherm showed that when the relative pressure (P/P0) was 0.1, the isotherm increased and CoFe-CoFe2O4@WDC had the highest surface area (835 m2 g−1) (Fig. 3c). Moreover, micropores and mesopores coexisted in the pore size distribution (Fig. S3). This hierarchical pore structure facilitated the penetration of electrolyte and provided a larger surface area for highly loaded active electrode materials (Gan et al. 2021). Thus, a reasonable structural design enabled CoFe-CoFe2O4@WDC to expose abundant active sites and exhibit fast mass transfer paths and high conductivity, thereby promoting rapid electrolyte penetration/diffusion and accelerating the transport of ions/reaction intermediates. It also ensured excellent electron conduction and allowed the generated O2 to diffuse freely (Chen et al. 2020b).

X-ray photoelectron spectroscopy (XPS) was used to characterize CoFe-CoFe2O4@WDC for obtaining insights into its surface valence state and chemical composition (Table S1). The XPS spectra of CoFe-CoFe2O4@WDC showed Co, Fe, O, N, and C (Fig. 3d). In the Co 2p spectrum, the three sub-peaks arising from spin–orbit splitting indicated distinct valence states of Co: Co3+ (780.4 eV, 795.7 eV), Co2+ (798.1 eV, 782.6 eV), and Co0 (793.2 eV, 776.6 eV). Co alloy was partially reduced on the catalyst surface (Fig. 3e). The Fe 2p spectrum also showed similar characteristic peaks: Fe3+ (725.6 eV, 712.6 eV), Fe2+ (723.9 eV, 710.2 eV) and Fe0 (721.2 eV, 705.1 eV) (Fig. 3f). These results revealed the coexistence of the CoFe alloy and CoFe2O4 spinel in the CoFe-CoFe2O4@WDC catalyst (Go et al. 2022). XPS spectra were obtained before and after loading metal in WDC to analyze changes in surface composition (Fig. S4). The C 1 s spectrum (Fig. 3g) showed peaks at 284.8, 285.6, and 289.2 eV corresponding to C=C/C–C, C–N, and C–O, respectively. Thus, wood was successfully carbonized, which is the carbon and nitrogen source for N-doped carbon formation (Zhang et al. 2021). N 1s spectra had several peaks corresponding to various nitrogen dopants such as pyridine-N (398.7 eV), pyrrole-N (400.1 eV), graphite-N (401.4 eV), and oxide-N (403.3 eV) (Fig. 3h). The local electronic structure of C could be adjusted because pyridine-N is an electron-withdrawing group. The high pyridinic-N content with lone pairs of electrons in CoFe-CoFe2O4@WDC can provide effective coordination sites with adjacent metal species, which are effective electrocatalytic active sites for ORR and OER (Balamurugan et al. 2023). At 529.9 eV, an obvious binding peak corresponding to the metal-bound oxygen atom (O1) could be observed. Typically, the peak at 532.7 eV is associated with hydroxyl species adsorbed on the water-exposed surface (O2), whereas that at 531.5 eV indicates the presence of defective sites with low-coordinated oxygen (O3) (Fig. 3i). Notably, the O 1s spectra of CoFe-CoFe2O4@WDC showed evident peak shifts to lower binding energies than those of WDC. Heterostructure formation indicated the existence of a strong electronic coupling between Co, Fe and O, which further promoted the rapid transfer of interface electrons (Qiu et al. 2019).

2.2 Oxygen electrocatalytic performance evaluation

The electrocatalytic capabilities, such as efficiency and reactivity within the electrochemical environment, of catalysts were thoroughly evaluated using a conventional three-electrode system. First, cyclic voltammetry (CV) was performed on CoFe-CoFe2O4@WDC under O2 and N2 atmospheres (Fig. S5). The reduction peaks of all samples were considerably enhanced in O2-saturated electrolytes than N2-saturated solutions. As the oxygen molecules in the O2-saturated electrolyte directly participated in the ORR reaction, their activity and adsorption characteristics considerably enhanced the reduction peak. These catalysts exhibited different catalytic activities (Yan et al. 2021). Under O2 atmosphere, CoFe-CoFe2O4@WDC showed an obvious reduction peak at 0.8–1.0 V, contrary to that under N2 atmosphere. This was indicative of the enhanced oxygen catalytic activity of CoFe-CoFe2O4@WDC.

Linear sweep voltammetry (LSV) curves of WDC, CoFe2O4@WDC, CoFe-CoFe2O4@WDC, and 20% Pt/C catalysts are shown in Fig. 4a. CoFe-CoFe2O4@WDC catalysts with different surface reduction times were also tested. WDC and CoFe-CoFe2O4@WDC exhibited half-wave potential (E1/2) at 0.79 and 0.81 V, respectively. The performance of the unregulated spinel structure needs to be improved. When the surface of the catalyst was reduced for different times, 2-CoFe-CoFe2O4@WDC performed outstandingly with a E1/2 (0.85 V) higher than other catalysts with similar reduction times. Due to surface reduction, the spinel is partly reduced to the alloy, and multicomponent coordination together improves the oxygen electrocatalytic performance. The Tafel value for 2-CoFe-CoFe2O4@WDC was notably lower at 97 mV dec−1 than those for WDC (152 mV dec−1), CoFe2O4@WDC (149 mV dec−1), 1-CoFe-CoFe2O4@ WDC (144 mV dec−1), and 3-CoFe-CoFe2O4@WDC (110 mV dec−1) and was comparable to that of the 20% Pt/C catalyst (100 mV dec−1) (Fig. 4b). A lower Tafel slope indicates faster electron transfer on the catalyst and excellent catalytic kinetics. As the current density increases, the overpotential decreases only slightly. This implies that the catalyst can achieve efficient ORR with lower energy consumption (Tan et al. 2021). When the rotational speed of the electrode increased uniformly from 400 to 2025 rpm, the limiting current increases consistently (Fig. 4c). The excellent mass transfer efficiency of the catalyst was confirmed due to the mass transfer acceleration caused by increasing rotational speed.

a LSV curves. b Tafel plots of WDC, 20% Pt/C, CoFe2O4@WDC, 1-CoFe-CoFe2O4@WDC, 2-CoFe-CoFe2O4@WDC and 3-CoFe-CoFe2O4@WDC in ORR. c LSV curves of CoFe-CoFe2O4@WDC@NCF at 400–2025 rpm. d LSV curves in OER voltage range. e Calculated converted Tafel plots. f ΔE of different catalysts. g Comparison of ΔE and E1/2 values in existing related reports. h Calculated electron transfer numbers and determined peroxide yield of CoFe-CoFe2O4@WDC. i Methanol tolerance of CoFe-CoFe2O4@WDC and 20% Pt/C

Furthermore, the OER performance of the catalyst was assessed in a 0.1 M KOH solution. The activity curve of the 2-CoFe-CoFe2O4@WDC indicated its superior performance as it achieved a potential of 260 mV at 10 mA cm−2 (Fig. 4d). The overpotential of commercial RuO2 as a comparative material is 180 mV. The overpotentials of WDC, CoFe2O4@WDC, 1-CoFe-CoFe2O4@WDC, and 3-CoFe-CoFe2O4@WDC were 420, 380, 280, and 300 mV, respectively. The Tafel slopes for WDC, CoFe2O4@WDC, 1-CoFe-CoFe2O4@WDC, 3-CoFe-CoFe2O4@WDC, and RuO2 were 263, 241, 156, 174, and 89 mV dec−1, respectively. 2-CoFe-CoFe2O4@WDC exhibited relatively low Tafel slope (134 mV dec−1) closest to RuO2 (Fig. 4e). 2-CoFe-CoFe2O4@WDC exhibited excellent OER performance due to the stable structure of oxyhydroxide (OOH-CoFe) that was easily generated at the interface. Within the OER voltage range, the in situ generated OOH-CoFe at the interface was confirmed to be a true catalytically active site (Feng et al. 2016).

To further verify the bifunctional properties of the 2-CoFe-CoFe2O4@WDC catalyst, the ΔE of several samples was measured continuously, where ΔE = Ej = 10 − E1/2. A smaller ΔE indicates higher activity for the bifunctional catalyst. The 2-CoFe-CoFe2O4@WDC catalyst showed the lowest ΔE (0.64 V; Fig. 4f). The 2-CoFe-CoFe2O4@WDC catalyst had a higher half-wave potential and excellent bifunctional catalytic activity (Fig. 4g and Table S2). The electrochemical active surface area (ECSA) was determined by varying the CV scan speed to study the double-layer capacitance (Cdl). The Cdl value for 2-CoFe-CoFe2O4@WDC was determined to be 9.76 mF cm−2, considerably surpassing those of 1-CoFe-CoFe2O4@WDC (6.07 mF cm−2), 3-CoFe-CoFe2O4@WDC (2.49 mF cm−2), CoFe2O4@WDC (5.26 mF cm−2), and WDC (7.70 mF cm−2) (Fig. S6). The elevated ECSA of 2-CoFe-CoFe2O4@WDC exposes a larger number of active sites, facilitating enhanced contact between reactants and metal sites. The rotating ring-disk electrode test was performed to determine the electron transfer number (n) during ORR and quantify hydrogen peroxide production. The value of n for the catalyst within the voltage range of 0.2–0.8 V was ~ 3.85 (close to 4); thus, ORR is a typical 4e− transfer path (Guo et al. 2023a). The production yield of hydrogen peroxide was below 14% (Fig. 4h), indicating that the CoFe-CoFe2O4@WDC catalyst could effectively suppress the release of hydrogen peroxide.

The performance of ZAB will be affected due to methanol poisoning in the active sites during the reaction. Therefore, methanol tolerance test was used for evaluating the stability of the electrode material. The resistance of CoFe-CoFe2O4@WDC and 20% Pt/C to methanol poisoning was tested (Fig. 4i). The current flowing through CoFe-CoFe2O4@WDC changed slightly after the addition of methanol and then returns to normal, indicating its excellent durability against methanol. In contrast, the current flowing through 20% Pt/C showed a sharp decay state, retaining only 45% after 0.5 h, upon adding methanol. This confirms that CoFe-CoFe2O4@WDC has enhanced electrochemical activity, methanol resistance, and stability than 20% Pt/C. The stability of catalysts during catalysis was evaluated via chronoamperometry and accelerated durability (ADT) tests. The performance difference between CoFe-CoFe2O4@WDC and 20% Pt/C can be seen in the chronoamperometry test (Fig. S7). After continuous testing for 20 h, the performance of CoFe-CoFe2O4@WDC decayed by 15%, whereas that of 20% Pt/C deteriorated to 35%. Moreover, the LSV curves of CoFe-CoFe2O4@WDC only shifted to the left by ~ 13 mV after ADT testing (Fig. S8). These findings showed that CoFe-CoFe2O4@WDC had excellent stability, benefiting from the rational construction of nonprecious metals, thereby reducing the usage of precious metals.

2.3 Application evaluation of ZABs

Given the notable ORR and OER activities of CoFe-CoFe2O4@WDC, it was used as a cathode material in liquid ZABs and integrated into the battery setup (Fig. 5a). To compare the performance of different catalysts, ZABs were constructed using 20% Pt/C and RuO2, and their efficiencies were assessed under identical conditions. The open-circuit voltage (OCV) of ZAB containing CoFe-CoFe2O4@WDC was 1.52 V, which surpassed that of ZAB containing 20% Pt/C + RuO2 (1.47 V) (Fig. 5b). The operational dynamics of the battery, as depicted by the voltage–current relation, can be inferred by estimating the power density from the discharge polarization curve. Notably, the ZAB assembled with CoFe-CoFe2O4@WDC exhibited a substantially higher peak power density (185 mW cm−2) than those assembled with 20% Pt/C + RuO2 (80 mW cm−2) (Fig. 5c).

a Schematic of a liquid ZAB. b Open-circuit voltage comparison between ZABs using CoFe-CoFe2O4@WDC and 20% Pt/C + RuO2. c Power density curves illustrating the performance of ZABs with CoFe-CoFe2O4@WDC and 20% Pt/C + RuO2. d Galvanostatic discharge–charge cycling curves of CoFe-CoFe2O4@WDC and 20% Pt/C + RuO2. e Rate capability test of the ZAB with CoFe-CoFe2O4@WDC. f Specific capacities. g and h Lamp beads powered by CoFe-CoFe2O4@WDC based ZABs

Batteries that meet commercial standards must be tested for cycling charge and discharge tests (Tang et al. 2023). Experimental results show that ZAB assembled with CoFe-CoFe2O4@WDC exhibited long-term cycling stability lasting for 780 h (2340 cycles) at 10 mA cm−2. After 500 h of charge–discharge cycle, the voltage gap remained at a mere 0.91 V. In contrast, ZAB assembled with 20% Pt/C + RuO2 exhibited a large voltage gap of over 2 V after 230 cycles (Fig. 5d). The curves of the ZAB assembled based on CoFe-CoFe2O4@WDC show only slight deformation after 800 h of charge–discharge cycles. Due to long-term operation, the negative zinc sheet electrode exhibited a certain degree of irregular loss, with uneven zinc deposition. CoFe-CoFe2O4@WDC exhibited excellent rate capability at different discharge current densities (Fig. 5e). In addition, the measured specific capacity of the battery reached 809 mA h gZn−1 at a current density of 10 mA cm−2, which was higher than that for ZAB based on 20% Pt/C + RuO2 (Fig. 5f). A comprehensive analysis shows that ZAB composed of CoFe-CoFe2O4@WDC have excellent stability and broad application prospects such as power sources (Fig. S9). Two ZABs connected in series can be used to power lamp beads of different colors (rated voltage 2.0–2.5 V) (Fig. 5g, h) and power an LED panel (rated voltage 3.0 V) (Fig. S10). The application of ZABs shows that CoFe-CoFe2O4@WDC serves as a multifunctional electrocatalyst, providing insights into the high-value utilization of carbon-based materials.

Quasi-solid ZAB are designed as a sandwich structure. The monolithic CoFe-CoFe2O4@WDC, prepared as an air electrode, was combined with a PVA gel serving as a solid electrolyte. These components were assembled together with a zinc foil to construct a ZAB featuring a sandwich structure (Fig. 6a). The quasi-solid ZAB composed of monolithic CoFe-CoFe2O4@WDC were tested using a multimeter together with an electrochemical workstation; they exhibited an OCV of 1.453 V (Fig. 6b). As observed from the discharge curve, the quasi-solid ZAB has a remarkable peak power density of 82 mW cm−2 (Fig. 6c).

a Schematic of a quasi-solid ZAB. b Open-circuit voltage of ZAB with CoFe-CoFe2O4@WDC catalyst. c Power density curves for ZABs composed of CoFe-CoFe2O4@WDC. d Cycling curves measured at 2 mA cm−2 for CoFe-CoFe2O4@WDC and 20% Pt/C + RuO2. e Specific capacities recorded at 2 mA cm−2 for CoFe-CoFe2O4@WDC. f LED lights powered by ZABs composed of CoFe-CoFe2O4@WDC

The enduring cyclic performance of ZAB composed of CoFe-CoFe2O4@WDC was explored to assess their long-term rechargeability. The quasi-solid ZAB demonstrated stable cycling over 300 cycles (Fig. 6d). At 2 mA cm−2, they exhibited a minimal voltage gap of only 0.8 V. Furthermore, they exhibited excellent specific capacity of 759 mAh gZn−1 at 2 mA cm−2 (Fig. 6e). Moreover, they can be conveniently connected in series to power lamp beads (Fig. 6f). Thus, using CoFe-CoFe2O4@WDC as an integral catalyst in micro energy-storage devices has commercial potential.

2.4 Catalytic mechanism analysis

Understanding the reversible conversion process of oxygen at the atomic and molecular level is crucial for revealing the catalytic mechanism. To this end, two models were constructed using density functional theory calculations: CoFe2O4@WDC and CoFe-CoFe2O4@WDC (Fig. S11). The free energy barriers of the adsorption intermediates (*, *OH, *O, and *OOH) were independently calculated as their stable structures change. When U = 0 V in ORR, oxidative reduction was exothermic and the reaction proceeded spontaneously from a thermodynamic point of view (Fig. S12). When U = 1.23 V, *O2 → *OOH and *O → *OH processes were endothermic and higher energy barriers were required to overcome. When CoFe-CoFe2O4@WDC generated *OOH from *O2, the corresponding Gibbs free energy (ΔG) was 0.32 eV; this value was lower than that for CoFe2O4@WDC (0.64 eV). *O2 → *OOH was the rate-determining step (RDS) of the reaction (Fig. 7a). When U = 0.85 V, *O2 → *OOH was the RDS of the ORR and CoFe-CoFe2O4@WDC exhibited better catalytic activity (Fig. S13) because large number of protons were donated (Chen et al. 2020a). In addition, differential charge calculations were performed for different catalysts, which indicated electron transfer between different atoms. The electron transfer on CoFe-CoFe2O4@WDC proceeded rapidly than that on CoFe2O4@WDC, and the charge transfer (Δq) occurring at the interface between CoFe alloy and oxide was the largest (1.524|e|; Fig. 7b). Substantial electronic structural changes at the interface also confirmed the promoting effect of O2 to OH− conversion. As the ORR is proton-deficient in an alkali medium, the protons produced by water dissociation replenished and promoted the formation of *OOH. The free energy barriers of CoFe2O4@WDC and CoFe-CoFe2O4@WDC during water dissociation were then determined. CoFe-CoFe2O4@WDC only needed to overcome a lower energy barrier; therefore, it provided higher number of protons to facilitate the rapid conversion of *OOH (Fig. S14).

a Gibbs free energy change diagram of CoFe2O4@WDC and CoFe-CoFe2O4@WDC during the ORR process. b Calculated differential charge density of CoFe2O4@WDC and CoFe-CoFe2O4@WDC. c The d-band centers of CoFe2O4@WDC and CoFe-CoFe2O4@WDC. d Gibbs free energy change diagram of OOH-CoFe2O4@WDC and OOH-CoFe-CoFe2O4@WDC during the OER process. e Interface configuration of OOH-CoFe-CoFe2O4@WDC at four different stages during the OER

During OER, the active site adsorbed OH− ions and underwent deprotonation, forming *O; O–O bonds couple to generate *OOH. Then, O2 was desorbed on the catalyst surface via secondary deprotonation; thus, the adsorption between oxygen intermediates and active sites was moderate (Wang et al. 2022). When used as an alkaline OER catalyst, CoFe-CoFe2O4@WDC is easily surface reconstituted into (oxy)hydroxide in a strong oxidizing environment. The surface is irreversibly oxidized on the CoFe component to form oxyhydroxide (OOH-CoFe) (Zeng et al. 2023; Zhang et al. 2018). The density of states determined for these catalysts showed that the d-band center of OOH-CoFe-CoFe2O4@WDC moved downward than that of OOH-CoFe2O4@WDC (Fig. 7c and Fig. S15). The adsorption energy of O species on OOH-CoFe-CoFe2O4@WDC was also weakened, and considerably high adsorption energy was not conducive to the evolution of intermediates (Gao et al. 2021). As O species have different adsorption capabilities, they have different RDSs in the OH− → O2 reaction. On OOH-CoFe-CoFe2O4@WDC, the RDS of OER was *O → *OOH and ΔGRDS was as low as 0.414 eV. O–O coupling occurred via the nucleophilic attack of OH−, yielding the *OOH intermediate. On OOH-CoFe2O4@WDC, the RDS was OH− desorption (Fig. 7d). After experiencing different intermediate configurations in OER (Fig. 7e), the OOH-CoFe-CoFe2O4@WDC interface with the lowest energy barrier was used as an electroactive site to obtain appropriate intermediate adsorption and desorption capabilities and considerably improve the OER kinetics.

3 Conclusions

In conclusion, a carbon-based nanoporous alloy/oxide composite electrode was fabricated herein for ORR/OER by constructing a heterojunction interface. The interface between the alloy and oxide effectively promoted the dissociation of water and facilitated the conversion of O2 to *OOH. The alloy surface was converted to CoFeOOH and the d-band center moved downward during OER, thereby optimizing the adsorption energies of *OH, *O, and *OOH intermediates. Electrochemical test results showed an impressive ΔE value of 0.64 V for CoFe-CoFe2O4@WDC. CoFe-CoFe2O4@WDC assembled in liquid ZABs achieved a high peak power density of 185 mW cm−2. This study provides guidance on key catalytic steps for optimizing potential energy conversion and the performance of energy-storage applications.

Data availability

Data of this work will be made available for reasonable reason.

References

Avcı ÖN, Sementa L, Fortunelli A (2022) Mechanisms of the oxygen evolution reaction on NiFe2O4 and CoFe2O4 inverse-spinel oxides. ACS Catal 12(15):9058–9073. https://doi.org/10.1021/acscatal.2c01534

Balaji R, Nguyen TT, Austeria PM, Kim DH, Lee JH, Kim NH (2023) Electronic coupling coordinated vanadium nitride/magnesium oxide hetero-junction for accelerating oxygen reaction and long-life flexible zinc-air batteries. Appl Catal B Environ Energy 335:122895. https://doi.org/10.1016/j.apcatb.2023.122895

Balamurugan J, Austeria PM, Kim JB, Jeong E-S, Huang H-H, Kim DH, Koratkar N, Kim SO (2023) Electrocatalysts for zinc–air batteries featuring single molybdenum atoms in a nitrogen-doped carbon framework. Adv Mater 35(35):2302625. https://doi.org/10.1002/adma.202302625

Bates AM, Preger Y, Torres-Castro L, Harrison KL, Harris SJ, Hewson J (2022) Are solid-state batteries safer than lithium-ion batteries? Joule 6(4):742–755. https://doi.org/10.1016/j.joule.2022.02.007

Chandrasekaran S, Hu R, Yao L, Sui L, Liu Y, Abdelkader A, Li Y, Ren X, Deng L (2023) Mutual self-regulation of d-electrons of single atoms and adjacent nanoparticles for bifunctional oxygen electrocatalysis and rechargeable zinc-air batteries. Nano-Micro Lett 15(1):48. https://doi.org/10.1007/s40820-023-01022-8

Chen J, Liu J, Xie J-Q, Ye H, Fu X-Z, Sun R, Wong C-P (2019) Co-Fe-P nanotubes electrocatalysts derived from metal-organic frameworks for efficient hydrogen evolution reaction under wide pH range. Nano Energy 56:225–233. https://doi.org/10.1016/j.nanoen.2018.11.051

Chen G, Wang T, Liu P, Liao Z, Zhong H, Wang G, Zhang P, Yu M, Zschech E, Chen M, Zhang J, Feng X (2020a) Promoted oxygen reduction kinetics on nitrogen-doped hierarchically porous carbon by engineering proton-feeding centers. Energy Environ Sci 13(9):2849–2855. https://doi.org/10.1039/d0ee01613f

Chen Z, Zhuo H, Hu Y, Lai H, Liu L, Zhong L, Peng X (2020b) Wood-derived lightweight and elastic carbon aerogel for pressure sensing and energy storage. Adv Funct Mater 30(17):1910292. https://doi.org/10.1002/adfm.201910292

Feng J-X, Ye S-H, Xu H, Tong Y-X, Li G-R (2016) Design and synthesis of FeOOH/CeO2 heterolayered nanotube electrocatalysts for the oxygen evolution reaction. Adv Mater 28(23):4698–4703. https://doi.org/10.1002/adma.201600054

Gan W, Wu L, Wang Y, Gao H, Gao L, Xiao S, Liu J, Xie Y, Li T, Li J (2021) Carbonized wood decorated with cobalt-nickel boinary nanoparticles as a low-cost and efficient electrode for water splitting. Adv Funct Mater 31(29):2010951. https://doi.org/10.1002/adfm.202010951

Gao L, Cui X, Sewell CD, Li J, Lin Z (2021) Recent advances in activating surface reconstruction for the high-efficiency oxygen evolution reaction. Chem Soc Rev 50(15):8428–8469. https://doi.org/10.1039/D0CS00962H

Go Y, Min K, An H, Kim K, Shim SE, Baeck S-H (2022) Oxygen-vacancy-rich CoFe/CoFe2O4 embedded in N-doped hollow carbon spheres as a highly efficient bifunctional electrocatalyst for Zn–air batteries. Chem Eng J 448:137665. https://doi.org/10.1016/j.cej.2022.137665

Guo W, Gao X, Zhu M, Xu C, Zhu X, Zhao X, Sun R, Xue Z, Song J, Tian L, Xu J, Chen W, Lin Y, Li Y, Zhou H, Wu Y (2023a) A closely packed Pt1.5Ni1−x/Ni–N–C hybrid for relay catalysis towards oxygen reduction. Energy Environ Sci 16(1):148–156. https://doi.org/10.1039/d2ee02381d

Guo X, Zhang S, Kou L, Yam C-Y, Frauenheim T, Chen Z, Huang S (2023b) Data-driven pursuit of electrochemically stable 2D materials with basal plane activity toward oxygen electrocatalysis. Energy Environ Sci 16(11):5003–5018. https://doi.org/10.1039/D3EE01723K

Ha Y, Fei B, Yan X, Xu H, Chen Z, Shi L, Fu M, Xu W, Wu R (2020) Atomically dispersed Co-pyridinic N–C for superior oxygen reduction reaction. Adv Energy Mater 10(46):2002592. https://doi.org/10.1002/aenm.202002592

Hu S, Zhu M (2023a) Recent advances in carbon-based non-noble single-atom catalysts for rechargeable zinc–air batteries. Curr Opin Chem Eng 41:100926. https://doi.org/10.1016/j.coche.2023.100926

Hu S, Zhu M (2023b) Semiconductor for oxygen electrocatalysis in photo-assisted rechargeable zinc-air batteries: principles, advances, and opportunities. Energy Storage Mater 61:102866. https://doi.org/10.1016/j.ensm.2023.102866

Hu B, Wang H, Liu R, Qiu M (2021) Highly efficient U(VI) capture by amidoxime/carbon nitride composites: evidence of EXAFS and modeling. Chemosphere 274:129743. https://doi.org/10.1016/j.chemosphere.2021.129743

Hu S, Shi J, Yan R, Pang S, Zhang Z, Wang J, Zhu M (2024) Flexible rechargeable photo-assisted zinc-air batteries based on photo-active pTTh bifunctional oxygen electrocatalyst. Energy Storage Mater 65:103139. https://doi.org/10.1016/j.ensm.2023.103139

Jiang H, Gu J, Zheng X, Liu M, Qiu X, Wang L, Li W, Chen Z, Ji X, Li J (2019) Defect-rich and ultrathin N doped carbon nanosheets as advanced trifunctional metal-free electrocatalysts for the ORR, OER and HER. Energy Environ Sci 12(1):322–333. https://doi.org/10.1039/c8ee03276a

Jin X, Liu R, Wang H, Han L, Qiu M, Hu B (2022) Functionalized porous nanoscale Fe3O4 particles supported biochar from peanut shell for Pb(II) ions removal from landscape wastewater. Environ Sci Pollut Res 29(25):37159–37169. https://doi.org/10.1007/s11356-021-18432-z

Kim C, Dionigi F, Beermann V, Wang X, Möller T, Strasser P (2019) Alloy nanocatalysts for the electrochemical oxygen reduction (ORR) and the direct electrochemical carbon dioxide reduction reaction (CO2RR). Adv Mater 31(31):1805617. https://doi.org/10.1002/adma.201805617

Li Z, Ji S, Wang C, Liu H, Leng L, Du L, Gao J, Qiao M, Horton JH, Wang Y (2023) Geometric and electronic engineering of atomically dispersed copper-cobalt diatomic sites for synergistic promotion of bifunctional oxygen electrocatalysis in zinc–air batteries. Adv Mater 35(25):2300905. https://doi.org/10.1002/adma.202300905

Lin X, Liu J, Qiu X, Liu B, Wang X, Chen L, Qin Y (2023) Ru-FeNi alloy heterojunctions on lignin-derived carbon as bifunctional electrocatalysts for efficient overall water splitting. Angew Chem Int Ed 62:e202306333. https://doi.org/10.1002/anie.202306333

Liu M, Zhao Z, Duan X, Huang Y (2019) Nanoscale structure design for high-performance Pt-based ORR catalysts. Adv Mater 31(6):1802234. https://doi.org/10.1002/adma.201802234

Liu Z-Q, Liang X, Ma F-X, Xiong Y-X, Zhang G, Chen G, Zhen L, Xu C-Y (2023) Decoration of NiFe-LDH nanodots endows lower Fe-d band center of Fe1-N-C hollow nanorods as bifunctional oxygen electrocatalysts with small overpotential gap. Adv Energy Mater 13(13):2203609. https://doi.org/10.1002/aenm.202203609

Peng X, Zhang L, Chen Z, Zhong L, Zhao D, Chi X, Zhao X, Li L, Lu X, Leng K, Liu C, Liu W, Tang W, Loh KP (2019) Hierarchically porous carbon plates derived from wood as bifunctional ORR/OER electrodes. Adv Mater 31(16):e1900341. https://doi.org/10.1002/adma.201900341

Qiu B, Wang C, Zhang N, Cai L, Xiong Y, Chai Y (2019) CeO2-induced interfacial Co2+ octahedral sites and oxygen vacancies for water oxidation. ACS Catal 9(7):6484–6490. https://doi.org/10.1021/acscatal.9b01819

Qiu M, Hu B, Chen Z, Yang H, Zhuang L, Wang X (2021) Challenges of organic pollutant photocatalysis by biochar-based catalysts. Biochar 3(2):117–123. https://doi.org/10.1007/s42773-021-00098-y

Qiu M, Liu L, Ling Q, Cai Y, Yu S, Wang S, Fu D, Hu B, Wang X (2022) Biochar for the removal of contaminants from soil and water: a review. Biochar 4(1):19. https://doi.org/10.1007/s42773-022-00146-1

Rehman SU, Hassan MH, Kim H-S, Song R-H, Lim T-H, Hong J-E, Joh D-W, Park S-J, Lee J-W, Lee S-B (2023) Designing the nano-scale architecture of the air electrode for high-performance and robust reversible solid oxide cells. Appl Catal B Environ Energy 333:122784. https://doi.org/10.1016/j.apcatb.2023.122784

Seh ZW, Kibsgaard J, Dickens CF, Chorkendorff I, Nørskov JK, Jaramillo TF (2017) Combining theory and experiment in electrocatalysis: insights into materials design. Science 355(6321):eaad4998. https://doi.org/10.1126/science.aad4998

Shao Z, Zhu Q, Sun Y, Zhang Y, Jiang Y, Deng S, Zhang W, Huang K, Feng S (2022) Phase-reconfiguration-induced NiS/NiFe2O4 composite for performance-enhanced zinc-air batteries. Adv Mater 34(15):2110172. https://doi.org/10.1002/adma.202110172

Shen X, Zhang C, Han B, Wang F (2022) Catalytic self-transfer hydrogenolysis of lignin with endogenous hydrogen: road to the carbon-neutral future. Chem Soc Rev 51(5):1608–1628. https://doi.org/10.1039/d1cs00908g

Song J, Wei C, Huang Z-F, Liu C, Zeng L, Wang X, Xu ZJ (2020) A review on fundamentals for designing oxygen evolution electrocatalysts. Chem Soc Rev 49(7):2196–2214. https://doi.org/10.1039/C9CS00607A

Suen N-T, Hung S-F, Quan Q, Zhang N, Xu Y-J, Chen HM (2017) Electrocatalysis for the oxygen evolution reaction: recent development and future perspectives. Chem Soc Rev 46(2):337–365. https://doi.org/10.1039/c6cs00328a

Sun J, Guo N, Shao Z, Huang K, Li Y, He F, Wang Q (2018) A facile strategy to construct amorphous spinel-based electrocatalysts with massive oxygen vacancies using ionic liquid dopant. Adv Energy Mater 8(27):1800980. https://doi.org/10.1002/aenm.201800980

Tan Y, Zhu W, Zhang Z, Wu W, Chen R, Mu S, Lv H, Cheng N (2021) Electronic tuning of confined sub-nanometer cobalt oxide clusters boosting oxygen catalysis and rechargeable Zn–air batteries. Nano Energy 83:105813. https://doi.org/10.1016/j.nanoen.2021.105813

Tang W, Tang J, Liao K, Shao Z (2023) Self-reconstruction of highly active NiCo2O4 with triple-continuous transfer of electrons, ions, and oxygen for Zn–air batteries. Chem Eng J 455:140855. https://doi.org/10.1016/j.cej.2022.140855

Tao X, Xu H, Luo S, Wu Y, Tian C, Lu X, Qing Y (2020) Construction of N-doped carbon nanotube encapsulated active nanoparticles in hierarchically porous carbonized wood frameworks to boost the oxygen evolution reaction. Appl Catal B Environ Energy 279:119367. https://doi.org/10.1016/j.apcatb.2020.119367

Tu K, Puertolas B, Adobes-Vidal M, Wang Y, Sun J, Traber J, Burgert I, Perez-Ramirez J, Keplinger T (2020) Green synthesis of hierarchical metal-organic framework/wood functional composites with superior mechanical properties. Adv Sci 7(7):1902897. https://doi.org/10.1002/advs.201902897

Wang H-F, Chen L, Pang H, Kaskel S, Xu Q (2020) MOF-derived electrocatalysts for oxygen reduction, oxygen evolution and hydrogen evolution reactions. Chem Soc Rev 49(5):1414–1448. https://doi.org/10.1039/C9CS00906J

Wang X, Xi S, Huang P, Du Y, Zhong H, Wang Q, Borgna A, Zhang YW, Wang Z, Wang H, Yu ZG, Lee WSV, Xue J (2022) Pivotal role of reversible NiO6 geometric conversion in oxygen evolution. Nature 611:702–708. https://doi.org/10.1038/s41586-022-05296-7

Wierzbicki S, Darvishzad T, Grybos J, Stelmachowski P, Sojka Z, Kruczala K (2023) Switching the locus of oxygen reduction and evolution reactions between spinel active phase and carbon carrier upon heteroatoms doping. Catal Today 418:114043. https://doi.org/10.1016/j.cattod.2023.114043

Xiao F, Wang Y-C, Wu Z-P, Chen G, Yang F, Zhu S, Siddharth K, Kong Z, Lu A, Li J-C, Zhong C-J, Zhou Z-Y, Shao M (2021) Recent advances in electrocatalysts for proton exchange membrane fuel cells and alkaline membrane fuel cells. Adv Mater 33(50):2006292. https://doi.org/10.1002/adma.202006292

Xie C, Niu Z, Kim D, Li M, Yang P (2020) Surface and interface control in nanoparticle catalysis. Chem Rev 120(2):1184–1249. https://doi.org/10.1021/acs.chemrev.9b00220

Xie X, Wang B, Wang Y, Ni C, Sun X, Du W (2022) Spinel structured MFe2O4 (M = Fe Co, Ni, Mn, Zn) and their composites for microwave absorption: a review. Chem Eng J 428:131160. https://doi.org/10.1016/j.cej.2021.131160

Xu F, Liu X, Zhang L, Guo M, Li M, Ding X, Zhang L (2023) Revealing and optimizing the dialectical relationship between NOR and OER: cation vacancy engineering enables RuO2 with unanticipated high electrochemical nitrogen oxidation performance. Adv Energy Mate 13(22):2300615. https://doi.org/10.1002/aenm.202300615

Xu X, Wang X, Huo S, Liu X, Ma X, Liu M, Zou J (2024) Modulation of phase transition in cobalt selenide with simultaneous construction of heterojunctions for highly-efficient oxygen electrocatalysis in zinc-air battery. Adv Mater 36:2306844. https://doi.org/10.1002/adma.202306844

Yan J, Huang Y, Zhang Y, Peng W, Xia S, Yu J, Ding B (2021) Facile synthesis of bimetallic fluoride heterojunctions on defect-enriched porous carbon nanofibers for efficient ORR catalysts. Nano Lett 21(6):2618–2624. https://doi.org/10.1021/acs.nanolett.1c00242

Zeng S-P, Shi H, Dai T-Y, Liu Y, Wen Z, Han G-F, Wang T-H, Zhang W, Lang X-Y, Zheng W-T, Jiang Q (2023) Lamella-heterostructured nanoporous bimetallic iron-cobalt alloy/oxyhydroxide and cerium oxynitride electrodes as stable catalysts for oxygen evolution. Nat Commun 14(1):1811. https://doi.org/10.1038/s41467-023-37597-4

Zhang B, Wang L, Zhang Y, Ding Y, Bi Y (2018) Ultrathin FeOOH nanolayers with abundant oxygen vacancies on BiVO4 photoanodes for efficient water oxidation. Angew Chem Int Ed 57(8):2248–2252. https://doi.org/10.1002/anie.201712499

Zhang J, Zhang J, He F, Chen Y, Zhu J, Wang D, Mu S, Yang HY (2021) Defect and doping Co-engineered non-metal nanocarbon ORR electrocatalyst. Nano-Micro Lett 13(1):65. https://doi.org/10.1007/s40820-020-00579-y

Zhang H, Liu Y, Zhou L, Wei H, Wen H, Wang Z, Yue X, Wu X, Zhang Y, Liu B, Fan Y, Cao H, Jiang J, Li B (2023) Refined alteration of active sites via O modification on CoP/Co2P@carbon hetero-structural catalyst for hydrogen generation. Appl Catal B Environ Energy 325:122324. https://doi.org/10.1016/j.apcatb.2022.122324

Zhao ZL, Wang Q, Huang X, Feng Q, Gu S, Zhang Z, Xu H, Zeng L, Gu M, Li H (2020) Boosting the oxygen evolution reaction using defect-rich ultra-thin ruthenium oxide nanosheets in acidic media. Energy Environ Sci 13(12):5143–5151. https://doi.org/10.1039/D0EE01960G

Zhao Y, Adiyeri Saseendran DP, Huang C, Triana CA, Marks WR, Chen H, Zhao H, Patzke GR (2023) Oxygen evolution/reduction reaction catalysts: from in situ monitoring and reaction mechanisms to rational design. Chem Rev 123(9):6257–6358. https://doi.org/10.1021/acs.chemrev.2c00515

Zheng Y, Zhao C, Li Y, Zhang W, Wu T, Wang Z, Li Z, Chen J, Wang J, Yu B, Zhang J (2020) Directly visualizing and exploring local heterointerface with high electro-catalytic activity. Nano Energy 78:105236. https://doi.org/10.1016/j.nanoen.2020.105236

Zhong L, Jiang C, Zheng M, Peng X, Liu T, Xi S, Chi X, Zhang Q, Gu L, Zhang S, Shi G, Zhang L, Wu K, Chen Z, Li T, Dahbi M, Alami J, Amine K, Lu J (2021) Wood carbon based single-atom catalyst for rechargeable Zn–air batteries. ACS Energy Lett 6(10):3624–3633. https://doi.org/10.1021/acsenergylett.1c01678

Acknowledgements

This work was supported by the Tianchi Talent Training Program (No. 2023000061), the Jiangsu Key Lab of Biomass Energy and Material (JSBEM-S-202101), the Young Top Talent Program of Zhongyuan-Yingcai-Jihua (No. 30602674), and the National Natural Science Foundation of China (No. 31901272).

Funding

This research was funded by the Tianchi Talent Training Program (No. 2023000061), the Jiangsu Key Lab of Biomass Energy and Material (No. JSBEM-S-202101), the Young Top Talent Program of Zhongyuan-Yingcai-Jihua (No. 30602674), and the National Natural Science Foundation of China (No. 31901272).

Author information

Authors and Affiliations

Contributions

Limin Zhou: Investigation, Visualization, Writing—review and editing. Junxiao Li: Methodology, Investigation, Formal analysis. Jiao Yin: Methodology, Investigation, Formal analysis. Gaoyue Zhang: Design, Formal analysis, Investigation. Pengxiang Zhang: Investigation, Visualization, Formal analysis. Jingjing Zhou: Investigation, Writing—review and editing. Anqi Zhang: Investigation, Visualization, Formal analysis. Ao Wang: Investigation, Formal analysis, Conceptualization. Baojun Li: Formal analysis, Supervision, Conceptualization. Yanyan Liu: Formal analysis, Supervision, Investigation Visualization. Kang Sun: Design, Formal analysis, Supervision, Visualization.

Corresponding authors

Ethics declarations

Competing interests

The authors have no relevant financial or non-financial interests to disclose.

Additional information

Handling editor: Xiangke Wang.

Supplementary Information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Zhou, L., Li, J., Yin, J. et al. Heterostructure catalyst coupled wood-derived carbon and cobalt-iron alloy/oxide for reversible oxygen conversion. Biochar 6, 54 (2024). https://doi.org/10.1007/s42773-024-00348-9

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42773-024-00348-9