Abstract

The extensive use of neonicotinoids on food crops for pest management has resulted in substantial environmental contamination. It is imperative to develop an effective remediation material and technique as well as to determine the evolution pathways of products. Here, novel ball-milled nitrogen-doped biochar (NBC)-modified zero-valent iron (ZVI) composites (named MNBC-ZVI) were fabricated and applied to degrading neonicotinoids. Based on the characterization results, NBC incorporation introduced N-doped sites and new allying heterojunctions and achieved surface charge redistribution, rapid electron transfer, and higher hydrophobicity of ZVI particles. As a result, the interaction between ZVI particles and thiamethoxam (a typical neonicotinoid) was improved, and the adsorption–desorption and reductive degradation of thiamethoxam and ·H generation steps were optimized. MNBC-ZVI could rapidly degrade 100% of 10 mg·L−1 thiamethoxam within 360 min, its reduction rate constant was 12.1-fold greater than that of pristine ZVI, and the electron efficiency increased from 29.7% to 57.8%. This improved reactivity and selectivity resulted from increased electron transfer, enhanced hydrophobicity, and reduced accumulation of iron mud. Moreover, the degradation of neonicotinoids occurred mainly via nitrate reduction and dichlorination, and toxicity tests with degradation intermediates revealed that neonicotinoids undergo rapid detoxification. Remarkably, MNBC-ZVI also presented favorable tolerance to various anions, humic acid, wastewater and contaminated soil, as well as high reusability. This work offers an efficient and economic biochar-ZVI remediation technology for the rapid degradation and detoxification of neonicotinoids, significantly contributes to knowledge on the relevant removal mechanism and further advances the synthesis of highly reactive and environmentally friendly materials.

Graphical Abstract

Highlights

-

N-doped BC (NBC) incorporation induced charge redistribution and hydrophobicity of ZVI.

-

NBC incorporation optimized reductive degradation of thiamethoxam and ·H generation.

-

NBC enhanced thiamethoxam adsorption and weakened atomic H adsorption.

-

Neonicotinoids undergo rapid detoxification.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Neonicotinoids have been extensively applied to hundreds of crops in agriculture, horticulture, and forestry for pest control due to their broad insecticidal spectrum, high insecticidal activity, and long persistence (Jeschke et al. 2011; Matsuda et al. 2020). However, these neonicotinoids have been excessively used in recent decades and have become a major source of organic pollution in global agricultural soil and groundwater, with concentrations of parts per billion/million in soil and parts per trillion/billion in water (Morrissey et al. 2015; Alsafran et al. 2022; Gu et al. 2023). Furthermore, numerous studies have shown that neonicotinoids have serious negative effects on nontarget organisms, including aquatic creatures, honey bees, and birds, and affect biodiversity (Yamamuro et al. 2019; Li et al. 2020; Annoscia et al. 2020); this abysmal phenomenon has aroused great interest and attention from scholars worldwide. Neonicotinoids were also included in the Watch List of Contaminants of Emerging Concerns (CECs) of 2018/840 for the European Union (EC/2018/840). Hence, it is imperative to develop an efficient and eco-friendly technique for remediating neonicotinoid-contaminated water and soil environments.

Several techniques have been reported for neonicotinoid pollution remediation, including physical adsorption and biological and chemical degradation (Zhang et al. 2018, 2020; Yin et al. 2018; Duan et al. 2020; Mori et al. 2021). In particular, the electron transfer-mediated reductive degradation pathway is among the most effective methods for rapidly degrading neonicotinoids (Yin et al. 2018). Zero-valent iron (ZVI) has been demonstrated to act as an electron donor, and ZVI application has been suggested as a new strategy for removing hard-to-biodegrade organic pollutants; this method results in the elimination of functional groups on organic pollutants, reduces toxicity and improves biodegradability (Fu et al. 2014; Liu et al. 2018). However, ZVI technology has several limitations when applied to the remediation of contaminated environments, including diminished reactivity caused by the accumulation of iron hydroxides and insufficient reactivity due to the spontaneous aggregation, oxidation, and hydrogen evolution reaction (HER) of ZVI (Fu et al. 2014; Sun et al. 2016). Although a large number of studies have investigated the modification of ZVI (e.g., sulfidation, metal doping and integration with functional bacteria) to improve its reactivity, selectivity, and durability in pollution remediation (Han and Yan 2014; Gu et al. 2017; Dong et al. 2019), it remains challenging to develop inexpensive and environmentally friendly techniques for generating ZVI-based materials with the above improvements.

Recently, biochar (BC), an environmentally friendly carbon-based catalyst, has received extensive attention due to its high specific surface area (SSA), conductive aromatic structure, and strong acid or alkali resistance (He et al. 2022; Shaheen et al. 2022; Swaren et al. 2022). Numerous studies have investigated BC-based modifications of ZVI, including loading, support, and ball milling modifications (Wang et al. 2019, 2020, 2023). Among these modification methods, ball milling is more desirable because of its simplicity, efficiency, and affordability. It has been reported that ball milling can reduce the size of ZVI and accelerate electron transfer. In particular, adding BC further improved the catalytic ability because an iron carbide phase and graphitic carbon structure formed during the process (Wang et al. 2020). Despite the above efforts, the HER and passivation side reactions at the interface between ZVI particles and water consume a significant quantity of electrons and hinder the application of ZVI to contaminant degradation. As a result, the surface chemical composition and structure of ZVI must be further optimized to achieve efficient degradation of target pollutants and to mitigate the interaction with water. Recently, some studies have shown that N doping could lead to an uneven distribution of charges within the carbon framework and influence itinerant electrons at the ZVI interface, thus favoring the adsorption of reactants, decreasing the HER, and improving electron efficiency (Gong et al. 2021b, c). Consequently, it is expected that the innovative design of C/N-incorporated ZVI (with NBC as a source of C and N) with optimal chemistry will further enhance ZVI’s reactivity, selectivity toward contaminants, and longevity for successful application in the remediation of contaminated sites.

As mentioned previously, the interface components strongly mediate the HER of ZVI particles and their catalytic ability to degrade contaminants. It has been well established that nitridation of ZVI can decrease the HER and eventually promote the efficient reduction of trichloroethylene and that the carbonization of ZVI can accelerate electron transfer from ZVI to pollutants by enhancing adsorption (Gao et al. 2015; Guan et al. 2020; Gong et al. 2021c). However, the interface reactions between NBC-modified ZVI and neonicotinoids remain poorly understood for various surface compositions; the release of the Fe(II) ion and subsequent formation of hydroxy-iron oxides is not the focus of most studies (Huang and Zhang 2006; Tang et al. 2014). Indeed, the interfacial distribution of dissolved Fe(II) (e.g., dissolved Fe(II) adsorbed on the surface of the material) is a crucial factor for the improvement in reactivity and longevity of ZVI under anaerobic conditions (Noubactep 2012; Bae and Hanna 2015). However, a generalized conclusion cannot be made to date regarding the distribution of dissolved Fe(II) at the interface of modified ZVI in solution and its catalytic activity on target pollutants. Additionally, there are still research gaps in the degradation pathway of neonicotinoids and the biotoxicity of degradation products of modified ZVI particles due to the uncertainty of neonicotinoid degradation throughout the reaction process.

Hence, in this work, novel ball-milled N-doped biochar-ZVI composites (MNBC-ZVI) were synthesized by ball milling mixtures of micron-sized ZVI and NBC powder. These materials were then used to degrade neonicotinoids and explore the evolution of toxicity to nontarget organisms. The specific objectives of this study were to (1) develop a method for synthesizing MNBC-ZVI with multiple heteroatoms (C and N) on its surface by ball milling ZVI particles with NBC as a precursor; (2) examine whether the MNBC-ZVI materials produced are effective for the degradation of neonicotinoids under ambient conditions and assess the effects of these materials on the HER and the distribution of Fe(II)/Fe(III) species; and (3) evaluate the toxicity of degradation products and the stability of the prepared materials to verify the potential of the materials for the remediation of neonicotinoid-contaminated water and soil. This work is the first systematic investigation on the neonicotinoid degradation mechanism and variations in the toxicity of neonicotinoids in the MNBC-ZVI system, and the obtained results will contribute to knowledge related to biochar-ZVI remediation technologies for the degradation of organic pollutants in the environment.

2 Materials and methods

2.1 Chemicals and biomass

Micron-sized ZVI (20–100 μm) and urea were purchased from Meryer (Shanghai, China). Thiamethoxam (99%), imidacloprid (98%) and clothianidin (98%) were provided by Rainbow Chemical Co., Ltd. (Shandong, China), and their physicochemical properties are summarized in Additional file 1: Table S1 of the Supporting Information (SI). Other chemicals, including nitrilotriacetic acid (NTA), tert-butyl alcohol (TBA), NaOH, HCl, KCl, NH4F, NaCl, NaNO3, NaHCO3, Na2SO4, and humic acid (HA), were all purchased from Macklin (Shanghai, China). Analytical or chromatographic-grade chemicals were used in this study. Dried rice straw (elemental composition: C: 40%, O: 41%, H: 5%, N: 1%) was utilized as the source material for doped or undoped biochar production and was collected from rice farmland (Zengchen District, Guangzhou, China).

2.2 Preparation and characterization of MNBC-ZVI composites

N-doped biochar (NBC) was synthesized based on our previous impregnation‒pyrolysis method, and the detailed process is presented in Additional file 1: Text S1 (Huang et al. 2022). The MNBC-ZVI composites were prepared by a mechanochemical method, and the flowchart is shown in Fig. 1a. Briefly, 25.0 g as-purchased micron-sized ZVI and 2.5 g NBC powder were mixed evenly and placed in a planetary ball mill (Mitr, China) with 200 g agate beads as the grinding medium. The ball milling speed was 300 rpm, and nitrogen was used as a protective gas. After 10 h of ball milling, the composites were collected and stored in a brown glass bottle in an anoxic atmosphere. The obtained composites were marked as MNmBCn-ZVI, in which m (0.5, 1, 2) indicates the additive mass ratio of urea to rice straw in the precursor and n (500, 700, 900) indicates the pyrolysis temperature. Undoped biochar (BC) was also prepared as a control based on the above steps without the addition of urea, and the products were marked as MBCn-ZVI (where n has the same meaning as above). For convenience of describing the synthetic materials in this paper, MNBC-ZVI indicates the ball-milled NBC-ZVI composite in which the mass ratio of urea to rice straw was 1.0, the pyrolysis temperature was 900 °C, and the mass ratio of NBC to ZVI was 0.1.

The prepared materials were then subjected to morphology, crystal structure, chemical composition, SSA, contact angle, surface functional groups and electrochemical property (e.g., cyclic voltammetry (CV) and chronoamperometry (i-t curve)) characterizations; the methods included scanning electron microscopy (SEM), X-ray diffraction (XRD), transmission electron microscopy (TEM), bulk elemental analysis, Brunauer‒Emmett‒Teller (BET) analysis, contact angle testing, Fourier transform infrared spectrometry (FITR), X-ray photoelectron spectroscopy (XPS), Raman spectroscopy and analysis on an electrochemical workstation with a standard three-electrode system. More detailed characterization information is provided in Additional file 1: Text S2.

2.3 Degradation experiments

Batch experiments of thiamethoxam degradation by various ZVI-based materials were carried out in 40 mL brown glass vials with 40 mL deionized water (anoxic, no pH adjustment), 0.75 g·L−1 composite material, and 10 mg·L−1 thiamethoxam. After being sealed with caps, the vials were horizontally shaken on a shaker at 150 rpm and 25 ± 2 °C. At specific times (0–360 min), 0.5 mL of the suspension was mixed with 1.0 mL acetonitrile and 0.3 g NaCl in a 2.0 mL centrifuge tube. The mixtures were then vortexed for 2 min and centrifuged for 5 min at 10,000 rpm. Finally, the supernatant was filtered through a 0.22 μm nylon membrane and stored in a refrigerator at 4 ℃ for concentration and product analysis. At the end of the reaction, the used composites were collected through extraction–filtration and freeze-dried in preparation for the subsequent cycling experiment. All experiments were performed in triplicate.

Additional file 1: Text S3 contains the detailed measurements of the thiamethoxam concentration distribution in the aqueous and solid phases of the catalytic system; hydrogen (H2) accumulation in catalytic systems with or without thiamethoxam; the contribution of atomic hydrogen (·H) to thiamethoxam degradation; and data on different Fe species (e.g., Feaq, dissolved iron in aqueous solution; Fead, dissolved iron adsorbed on the surface of material; Fecry, iron-containing crystals on the ZVI surface; and Fedep, deposited iron (oxyhydr)oxide not in contact with ZVI) in the reaction system. In addition, the influences of coexisting substances and real water on thiamethoxam degradation by the prepared materials were studied by setting up experiments with different ions (e.g., Cl−, NO3−, SO42−, HCO3−), HA, contaminated soil and different water matrices (e.g., wastewater, river water, and seawater). The physicochemical properties and composition of the contaminated water and soil samples are shown in Additional file 1: Text S6 and Table S2.

2.4 Toxicity evaluation experiments

The ECOSAR model was utilized to calculate the acute and chronic toxicity of neonicotinoids (including thiamethoxam, imidacloprid, and clothianidin) and their intermediate products to the aquatic plant green algae. In addition, bioassay experiments were performed for neonicotinoids and their intermediate products at different reaction stages (0, 60, 180, and 360 min) to evaluate the toxicity changes and effects on the learning ability of honey bees. Specifically, during the bioassay experiment, honey bees (Apis cerana) in storage cages were first starved for 2 h, frozen, anesthetized, and then randomly assigned to cages in an artificial climate chamber (temperature: 25 ± 2 °C, humidity: 70 ± 2%). Next, 100 µL of sucrose solution with neonicotinoids was added to a 2.0 mL centrifuge tube, and when the solution was consumed, it was replaced with sucrose water for feeding. Poisoning symptoms and the number of deaths of test honey bees were recorded at 24 h and 48 h after treatment. Furthermore, a learning ability test was performed with honey bees that survived the above bioassay experiments according to a reported method (Zhang et al. 2022), and the detailed process is described in Additional file 1: Text S4. Three replicates of 10 honey bees per treatment were used in all experiments.

2.5 Data analysis

The concentrations of thiamethoxam, imidacloprid and clothianidin were determined by high-performance liquid chromatography (HPLC), and the degradation products were analyzed by high-performance liquid chromatography‒mass spectrometry (HPLC‒MS/MS). The detailed method is given in Additional file 1: Text S5. The kinetic degradation curves of the neonicotinoids were fitted as follows (Eq. 1):

where Ct (mg·L−1) and C0 (mg·L−1) represent the concentrations of neonicotinoids at the initial time 0 (min) and reaction time t (min), respectively, and kobs (min−1) is the degradation rate constant obtained by the kinetic model for neonicotinoid degradation.

3 Results and discussion

3.1 Morphological structure and chemical composition of materials

SEM images of the pristine ZVI and synthesized ZVI-based particles are presented in Fig. 1b–e and Additional file 1: Fig. S1. The ball-milling process decreased the particle size of pristine ZVI from 20–100 μm to 1–10 μm (M-ZVI) (Fig. 1c), and obvious agglomeration of M-ZVI particles was observed. However, the presence of biochar decreased the particle size to the submicron scale for MBC-ZVI and MNBC-ZVI (50–500 nm). Furthermore, the MNBC-ZVI particles appeared as blocks with rough surfaces, were well distributed and showed no obvious clustering. Chemical mapping was used to further explore the distribution of NBC with ZVI (Fig. 1e). As expected, C, N, and Fe appeared uniformly distributed and superimposed, indicating that C and N were adjacent to each other (Fig. 1e) and potentially suggesting the presence of an Fe–C coordination structure, in line with previous works (Gao et al. 2015; Wang et al. 2020). Further observation by TEM (Fig. 1f, g) indicated that MNBC-ZVI had anomalous particles, including abundant outer particles, and revealed the tightly bound state of NBC and ZVI. Based on these findings, we speculated that ZVI and NBC closely combine to form a new ZVI-carbon heterojunction structure by continuous mechanical fracturing and welding during ball milling. Additionally, the SSA of the ZVI-based particles increased progressively from 0.29 to 18.33 m2·g−1 with BC or NBC incorporation (Additional file 1: Table S3). The particle size distribution at 50% (D50) of the ZVI-based particles exhibited an opposite trend to that of SSA (Additional file 1: Fig. S2), and the corresponding changes demonstrate that BC or NBC contributed to the greater breakdown of the ZVI structure during ball milling; this result corresponds with a previous study in which BC modification was shown to decrease the particle size of ZVI (Wang et al. 2020).

In the XRD patterns (Fig. 2a), two diffraction peaks occurred at 2θ = 44.7° and 65.0° for the pristine ZVI, M-ZVI, MBC-ZVI and MNBC-ZVI particles and are attributed to the (110) and (200) planes of cubic ZVI (Xu et al. 2019). However, after ball milling with biochar, MBC-ZVI and MNBC-ZVI displayed a new broad peak at 2θ = 19–26°, corresponding to graphite-like stacks of biochar. A greater intensity of this peak was observed in MNBC-ZVI than in MBC-ZVI, likely caused by the doping of N into the carbon network of biochar, which graphitizes part of the carbon and decreases the carbon crystallinity (Ismagilov et al. 2009). The peak at the same location (2θ = 19–26°) was flatter for MNBC-ZVI than for MN0.5,1BC-ZVI (Additional file 1: Fig. S3), further verifying the above result. Furthermore, an obvious small peak at 2θ = 42.8° was found for the iron carbide phase (attributed to martensite), implying that NBC was incorporated into ZVI (Gao et al. 2015); this result directly confirmed the presence of the ZVI-carbon heterojunction structure in MNBC-ZVI.

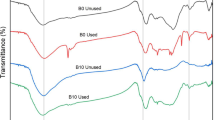

Generally, incorporating NBC into ZVI by ball milling could change the surface chemical composition, which was investigated by FTIR, Raman spectroscopy and XPS. The FTIR spectra clearly showed that two new peaks at 1536 and 1561 cm−1, indexed to C–N and N–H stretching vibrations, appeared in MNBC-ZVI in contrast to MBC-ZVI (Fig. 2b). This illustrates that N was successfully embedded into the carbon network of the biochar (Ren et al. 2020), consistent with the bulk elemental analysis results of this study (Additional file 1: Table S4). Additionally, a peak at 540–650 cm−1 corresponding to Fe–O stretching vibrations was observed for pristine ZVI, M-ZVI and MBC-ZVI (Hussain et al. 2017); however, the peak disappeared in the FTIR spectrum of MNBC-ZVI, verifying that NBC incorporation could prevent iron oxides from forming and replace the iron oxide films (e.g., magnetite, hematite) on the surface of ZVI. The Raman spectra further confirmed the formation of new Fe–N bonds (218 and 284 cm−1) by NBC incorporation (Fig. 2c) (Smit et al. 2001; Gong et al. 2021c), which may be another reason for the reduction of the iron oxide films on the surface of MNBC-ZVI. Moreover, all four ZVI-based materials showed the characteristic Raman peaks of C atoms, including the D-band at 1350 cm−1 and the G-band at 1580 cm−1. Further calculation revealed that the area ratio of the D-band to the G-band (ID/IG) decreased from 2.25 (MBC-ZVI) to 0.89 (MNBC-ZVI), indicating that the coupling of N doping and ZVI could reduce the amount of disordered carbon in MNBC-ZVI, consistent with its higher degree of graphitization, which is in line with the XRD results (Fig. 2a).

The changes in the surface chemical elements of the two biochar-ZVI materials were further analyzed using XPS. C–C/C=C/C–N, C=O, and C–O structures (corresponding to 288.78, 286.48, 284.88 eV) were found on the surface of MBC-ZVI and MNBC-ZVI (Fig. 2d), indicating that N-doped or undoped biochar was embedded on the ZVI surface. Furthermore, the XPS spectra of N 1 s exhibited three distinct fitted peaks at 398.2, 399.5, and 400.6 eV (Fig. 2e), which are attributed to pyridine-N, pyrrole-N, and graphite-N, respectively (Chen et al. 2017; Huang et al. 2022). However, compared to MBC-ZVI, MNBC-ZVI showed a greater N content and higher graphitic-N and pyridine-N percentages. Moreover, MNBC-ZVI samples with different nitrogen contents (e.g., MN0.5BC-ZVI and MN2BC-ZVI) also showed similar results (Additional file 1: Fig. S4). It has been well documented that additional energy input (e.g., a higher N content or temperature) can convert pyrrolic-N to graphitic-N (Liu et al. 2010). Therefore, the higher content of graphitic-N in MNBC-ZVI resulted from the addition of NBC for ball milling. Interestingly, it has been demonstrated that graphitic-N plays a crucial role in Fe–C-driven redox reactions as an electron transfer mediator (Lin et al. 2014; Huang et al. 2022). In addition, due to its lone pair of electrons, pyridine-N could serve as a coordination site to transfer electrons from MNBC-ZVI to pollutants (Lin et al. 2014). The XPS spectra of Fe 2p (Fig. 2f) were fitted with four peaks (711.5, 712.8, 725.0 and 726.5 eV), which were attributed to Fe(II)2p3/2, Fe(III)2p3/2, Fe(II)2p1/2, and Fe(III)2p1/2, respectively (Sun et al. 2019); the presence of Fe(II) and Fe(III) on the surface of the materials is attributable to the oxidation of ZVI (Stefaniuk et al. 2016). In addition, the characteristic peak of ZVI at 707.6 eV was detected. However, MNBC-ZVI had lower Fe(II) and Fe(III) contents and a greater ZVI proportion than MBC-ZVI, which further verified that the NBC on MNBC-ZVI replaced the oxide layer and reduced the exposure of ZVI. This finding was also confirmed by the XRD, FTIR and Raman analysis results (Fig. 2a–c).

3.2 Efficient reductive degradation of thiamethoxam catalyzed by MNBC-ZVI

Thiamethoxam (10 mg·L−1) was used to evaluate the activity of diverse ZVI-based materials. Figure 3a and Additional file 1: Fig. S5a show that thiamethoxam could be degraded by 30.8% within 180 min by M-ZVI, which was a slightly higher degradation rate than that of pristine ZVI (22.3%); thus, ball milling could improve the activity of ZVI. However, with the presence of NBC, MNBC-ZVI could degrade thiamethoxam by 94.7% within 180 min, and the degradation rate reached 100% after 360 min, which was much better than that of the as-purchased ZVI, M-ZVI, and MBC-ZVI (all were less than 59.4%). Correspondingly, the reduction rate constant (kobs) of thiamethoxam catalyzed by MNBC-ZVI (0.0169 min−1) was 12.1-fold, 8.0-fold, and 4.8-fold that of pristine ZVI (0.0014 min−1), M-ZVI (0.0021 min−1), and MBC-ZVI (0.0035 min−1), respectively. This result suggests that MNBC-ZVI exhibited higher activity for thiamethoxam degradation. A mixed control group was also prepared by mixing M-ZVI and M-NBC (M-ZVI + M-NBC, mass ratio = 10:1) without ball milling (Additional file 1: Fig. S5b), which degraded only 52.7% of thiamethoxam within 360 min; compared to that of MNBC-ZVI (100%), this percentage was significantly lower. This result reconfirmed the necessity for NBC incorporation to improve the reaction activity of ZVI and achieve the efficient degradation of thiamethoxam.

Degradation kinetics of thiamethoxam obtained using different reaction systems with ZVI-based materials: a material type; b mass ratio of urea to rice straw in MNBC-ZVI; c temperature of MNBC-ZVI; and d mass ratio of NBC to ZVI in MNBC-ZVI (Reaction conditions: material concentration = 0.75 g·L−1, thiamethoxam concentration = 10 mg·L−1, no adjustment of pH, anoxic, T = 25 °C)

Different synthesis parameters, including the mass ratio of urea to rice straw (urea/straw), the pyrolysis temperature of NBC, and the percentage of NBC in MNBC-ZVI, were investigated by performing batch degradation experiments with thiamethoxam. As depicted in Fig. 3b, the degradation rate of thiamethoxam catalyzed by MNBC-ZVI increased with increasing urea/straw ratio from 0 to 1.0. However, when the urea/straw ratio increased to 2.0, the degradation rate declined to 76.8% within 360 min, likely because the increased N concentration increased the defectiveness of the graphite structure in MNBC-ZVI (Ismagilov et al. 2009). Regarding the effect of the pyrolysis temperature of NBC on MNBC-ZVI, we found that MNBC-ZVI prepared at 900 °C exhibited the best catalytic performance for thiamethoxam degradation. A similar trend was also observed for MBC-ZVI (Additional file 1: Fig. S5c). It was reported that a higher pyrolysis temperature can cause carbon graphitization and promote the conversion of pyrrolic-N to graphitic-N. The formation of these structures (graphite-N or graphite-C) is favorable for the electron transfer of MNBC-ZVI (Huang et al. 2022). Furthermore, the effect of the NBC content in MNBC-ZVI on thiamethoxam degradation was determined; the degradation rate of thiamethoxam was 63.8% at 2% NBC in MNBC-ZVI and 87.5% at 20% NBC in MNBC-ZVI (Fig. 3d), both of which were lower than that at a 10% NBC content (100%). This result could be because at higher contents, NBC plugs and masks the reaction sites of MNC-ZVI in solution. In conclusion, the optimal conditions of the MNBC-ZVI system (urea/straw ratio of 1.0, NBC pyrolyzed at 900 °C, 10% NBC) were selected for subsequent thiamethoxam degradation experiments.

3.3 Mechanistic insights into thiamethoxam degradation by MNBC-ZVI

3.3.1 Evidence of direct electron transfer and ·H

Due to the low standard electrode potential of ZVI-based materials, direct electron transfer between these materials and thiamethoxam is possible, which in turn degrades thiamethoxam (Stefaniuk et al. 2016). In this study, the reaction systems containing the materials were subjected to a series of electrochemical tests to verify this hypothesis. The CV curves of the four materials are shown in Fig. 4a. In comparison to the control group with a bare glassy carbon electrode (GCE), the redox peaks and current densities of pristine ZVI, M-ZVI, MBC-ZVI, and MNBC-ZVI all increased, and the variations in charge potential and cycle reversibility were more pronounced for MNBC-ZVI. This result confirms the presence of NBC as an efficient electron transfer and catalyst reaction carrier. A possible reason may be the formation of N-doped sites and a heterogeneous structure in MNBC-ZVI, improving its electron transfer and reactivity (Gong et al. 2021c; Huang et al. 2022). Subsequently, an i-t curve was further applied to examine the current output with MNBC-ZVI and thiamethoxam. When thiamethoxam was injected into the reaction system at 200 s, a significant current peak was observed (Fig. 4b), which directly demonstrates a substantial electron transfer process between thiamethoxam and MNBC-ZVI.

Electrochemical analysis results: a CV and b i-t curves [obtained at 0.0 V vs. Ag/AgCl (50 mM Na2SO4)]; c thiamethoxam degradation with or without TBA; d rate of the HER; e electron efficiency and H2 accumulation; f adsorption kinetics of thiamethoxam by BC and NBC; g dissolved Fe(II) (Feaq and Fead) concentration; h biochar adsorption of dissolved Fe(II); and i ratio of Fedep to Fecry in the pristine ZVI, M-ZVI, MBC-ZVI and MNBC-ZVI systems (Reaction conditions: material concentration = 0.75 g·L−1, thiamethoxam concentration = 10 mg·L−1, no adjustment of pH, anoxic, T = 25 °C)

In addition to direct electron transfer, which provides electrons to degrade thiamethoxam, protons can accept electrons and form ·H, which degrades thiamethoxam by hydrolysis (Eq. 2). Adequate TBA (5.0 M) was used as a scavenger of ·H to investigate the contribution of ·H to the reduction of thiamethoxam (Eq. 3) (Lymar and Schwarz 2012). As shown in Fig. 4c, TBA dramatically inhibited the degradation of thiamethoxam with an inhibition ratio of 6.6% for pristine ZVI, 9.2% for M-ZVI, 10.6% for MBC-ZVI, and 16.3% for MNBC-ZVI. This result provided direct evidence that ·H was partially involved in the reductive degradation of thiamethoxam. Notably, the contribution of ·H to the reductive degradation of thiamethoxam showed the following trend: MNBC-ZVI (16.8%) < MBC-ZVI (27.9%) < M-ZVI (41.8%) < pristine ZVI (42.3%). This phenomenon could be explained by the high hydrophobicity of NBC (Additional file 1: Fig. S6a), resulting in a weaker affinity of MNBC-ZVI to water molecules and a lower amount of ·H; as a result, the contribution of •H to thiamethoxam degradation decreased (Xu et al. 2020).

3.3.2 HER and electron utilization efficiency

Time series data of the HER were measured during thiamethoxam degradation in the ZVI-based material systems, and the HER activity (kSA,H2) was defined as the molar quantity of produced H2 at 6 h divided by the time, the particle mass concentration, and the SSA (Gu et al. 2017). Under similar ZVI contents in the materials (Additional file 1: Table S5), the kSA,H2 value and H2 accumulation for the ZVI-based materials generally followed the order of MNBC-ZVI < MBC-ZVI < M-ZVI < pristine ZVI (Fig. 4d, e), which is consistent with previous studies in which biochar incorporation was shown to reduce the HER of ZVI (Gong et al. 2021c). In particular, the kSA,H2 for MNBC-ZVI further decreased with NBC incorporation, likely due to the increase in hydrophobicity of NBC, as it led to a decrease in the interaction of MNBC-ZVI with water and inhibited the HER. In addition, the electron efficiencies (εe) for thiamethoxam by the ZVI-based materials were obtained based on a previous calculation method (Gu et al. 2017), and the results are listed in Fig. 4e and Additional file 1: Table S6. The εe for thiamethoxam degradation by the ZVI-based materials increased from 29.7% to 57.8% with BC and NBC incorporation. NBC incorporation led to the greatest εe (57.8%), implying that carbonization and nitridation exhibited synergistic effects and improve the εe for MNBC-ZVI particles compared to MBC-ZVI (45.1%). This is possibly because the strong interaction of MNBC-ZVI with thiamethoxam promoted thiamethoxam degradation, which will be discussed below, while the HER was inhibited in contrast to that in MBC-ZVI, M-ZVI and ZVI (Fig. 4d).

The strong interaction between thiamethoxam and MNBC-ZVI was investigated by performing contact angle tests and batch desorption/adsorption experiments. Additional file 1: Fig. S6a shows contact angles of 147.92° for NBC, 121.46° for BC and 0° for ZVI, suggesting that BC (NBC) and ZVI exhibited strong hydrophobicity and hydrophilicity, respectively, and that N-doping enhanced the hydrophobicity of BC. Notably, the high hydrophobicity of MNBC-ZVI is conducive to the mass transfer of thiamethoxam (a typical hydrophobic organic pollutant) from the aqueous phase to the surface of the material by hydrophobic interactions (Li et al. 2021; Liu et al. 2022). Furthermore, the thiamethoxam desorption results for the composites showed that MNBC-ZVI induced a mass transfer of 29.7% for thiamethoxam within 60 min, which was 2.9-fold that of MBC-ZVI, 30.7-fold that of M-ZVI, and 50.3-fold that of pristine ZVI (Additional file 1: Fig. S6b); this result was consistent with the NBC-induced enhancement in the adsorption of thiamethoxam relative to BC (Fig. 4f). This indicates that NBC incorporation improved the mass transfer of thiamethoxam by MNBC-ZVI and acted synergistically with the reductive degradation process. This is due to the presence of hydrophobic N-doped sites, especially graphitic-N and pyridine-N (Fig. 2 and Additional file 1: Fig. S6), which can promote the binding of MNBC-ZVI and thiamethoxam by hydrophobic partitioning and electrostatic interactions (Cheng et al. 2022). Overall, the stronger adsorption effect of MNBC-ZVI on thiamethoxam accelerated thiamethoxam degradation while inhibiting the HER; this could provide a significant advantage for MNBC-ZVI over conventional forms of ZVI in contamination remediation.

3.3.3 Role of dissolved Fe(II) in interfacial electron transfer

The concentrations of dissolved Fe(II), including Fe(II)aq and Fe(II)ad, were obtained during thiamethoxam degradation and compared for MNBC-ZVI, MBC-ZVI, M-ZVI and pristine ZVI (Fig. 4g). The dissolved Fe(II) concentration was highest for MNBC-ZVI during thiamethoxam degradation, which was attributable to the higher reactivity of MNBC-ZVI than the other materials. In particular, the Fe(II)ad concentration for MNBC-ZVI was 0.37 mg·L−1 at 60 min, which was 2.3-fold, 6.2-fold, and 9.3-fold greater than that of MBC-ZVI, M-ZVI, and pristine ZVI, respectively. Further calculations revealed that the ratio of Fe(II)ad to Fe(II)aq of MNBC-ZVI was 1.8-fold higher than that of MBC-ZVI, and similar results were found for the values at 180 min (1.7-fold) and 360 min (1.9-fold). This confirms that MNBC-ZVI exhibited stronger adsorption than the other materials for dissolved Fe(II), which is corroborated by the phenomenon that NBC enhanced the adsorption of dissolved Fe(II) relative to BC (Fig. 4h). It has been reported that Fe(II)aq or Fe(II)ad can decrease the redox potential, promote interfacial electron transfer, and accelerate the reductive transformation of contaminants (Liu et al. 2008; Noubactep 2012). Therefore, the greater distribution of dissolved Fe(II) on the surface of MNBC-ZVI provides favorable conditions for electron transfer to degrade thiamethoxam by changing the local chemical environment of the solid–liquid interface in the MNBC-ZVI system.

In addition to Fe(II)ad, secondary solid Fe species (e.g., Fecry and Fedep) are formed at the interface of ZVI. As shown in Fig. 4i and Additional file 1: Table S7, the relative contents of Fecry and Fedep were examined at different times (0, 60, 180, 360 min). The ratio of Fedep to Fecry was lowest for MNBC-ZVI (2.9) at 360 min relative to ZVI (6.0), M-ZVI (7.7), and MBC-ZVI (19.2), while the ratio of Fedep to Fecry for MNBC-ZVI decreased with time (from 9.0 to 2.5). Therefore, MNBC-ZVI could promote the conversion of Fedep to Fecry. XRD analysis of MNBC-ZVI was performed at different times (60, 180, 360 min) (Additional file 1: Fig. S7 and Table S8), and the content of magnetite increased as the reaction proceeded, which is consistent with the trend in Fecry concentration at 60–360 min (from 5.8 to 9.5 mg·L−1, Table S7). This further verifies that MNBC-ZVI promoted the conversion of Fedep to Fecry. This observation can be explained by some studies in which Fedep on surfaces with large positive charges tended to migrate to the surface of MNBC-ZVI; in addition, dissolved Fe(II) (e.g., Fe(II)ad) can accelerate the transformation of Fedep (e.g., Fe mud (iron hydroxides), Fe(OH)3 or FeOOH) to form magnetite (Eqs. 4–5) (Tamaura et al. 1984; Tronc et al. 1992; Pedersen et al. 2005; Hansel et al. 2005; Yang et al. 2010; Tang et al. 2014). Intriguingly, magnetite has been demonstrated to be an electronic carrier on the ZVI particle surface and is less likely than other forms of Fe to negatively affect degradation (Mercier-Bion et al. 2018; Gong et al. 2021a). Furthermore, Fedep transformation can alleviate the inhibition of the reaction by the attachment of iron hydroxides to the MNBC-ZVI surface. This observation may also explain why MNBC-ZVI maintained an efficient catalytic capacity for thiamethoxam degradation. However, the specific behavior of dissolved Fe(II) under circumneutral conditions cannot be assessed in the same manner because secondary iron species inevitably form and adsorb on the MNBC-ZVI surface once the reaction begins.

Based on the comprehensive results of the MNBC-ZVI performance assessment, electrochemical and quenching tests, HER analysis, and Fe species identification, the possible catalytic mechanism of MNBC-ZVI for thiamethoxam degradation is described in Fig. 5. Briefly, electron transfer and the ·H reaction were the primary mechanisms of thiamethoxam degradation catalyzed by MNBC-ZVI. This process was strengthened by the addition of NBC to ZVI for ball milling. Specifically, NBC incorporation formed a linked heterojunction and N-doped sites, which resulted in a decrease in particle size, surface charge redistribution, and an increase in the hydrophobicity of ZVI particles in MNBC-ZVI. Thus, the thiamethoxam adsorption, electron transfer ability and ·H generation steps were improved while inhibiting the HER. In addition, adsorbed Fe(II) on the MNBC-ZVI surface further optimized the reductive environment of MNBC-ZVI with thiamethoxam while transforming iron hydroxides into magnetite to ensure the catalytic reactivity of MNBC-ZVI.

3.4 Degradation pathway and product toxicity assessment of neonicotinoids

The degradation products of thiamethoxam catalyzed by MNBC-ZVI were detected using HPLC‒MS/MS, and two possible degradation pathways for thiamethoxam were proposed (Fig. 6a and Additional file 1: Fig. S8). First, –NO2 is eliminated and converted into –NH2 to form primary hydrazone (P1) by a reaction in which the O atom of –NO2 in the thiamethoxam molecule is attacked by the electron in MNBC-ZVI. This degradation step is followed by the further reductive degradation of –NH3 to produce imine (P2) (Kanne et al. 2005; Mir et al. 2013; Patil et al. 2021). Finally, a stable carbocation is formed, possibly by delocalization of the negative charge of the thiazole ring; then, the –NO2 group’s electrophilic N undergoes nucleophilic attack, and water is lost to produce P3 (Mir et al. 2013). The same degradation pathway occurred for clothianidin catalyzed by MNBC-ZVI (Additional file 1: Figs. S9-11). In contrast, another insecticide, imidacloprid, underwent denitrification, and a chlorine atom was removed from its pyridine ring (Additional file 1: Fig. S11a). This may have occurred because the five-membered thiazole ring in thiamethoxam is rich in electrons, and its C–Cl bond possesses a higher electron density (the higher the electron density is, the more stable the C–Cl bond) than that of the six-membered pyridine ring in imidacloprid. Therefore, the Cl groups of thiamethoxam and clothianidin are difficult to remove through reduction by MNBC-ZVI.

a Proposed transformation pathways involved in thiamethoxam degradation by MNBC-ZVI; b acute toxicity and c chronic toxicity estimates of thiamethoxam and its intermediate products to green algae via ECOSAR; d toxicity and e influence on learning ability of the reaction solution in the MNBC-ZVI system to honey bees (P < 0.05)

For on-site application of any remediation technologies, possible secondary risks caused by the degradation products of pollutants after remediation must be carefully investigated. In this work, the ECOSAR model was used to predict the phytotoxicity of the degradation intermediates of thiamethoxam, imidacloprid and clothianidin (Thomaidi et al. 2015), and it was found that the toxicity of the intermediates to green algae decreased compared to that of their parent chemicals (Fig. 6b, c and Additional file 1: Fig. S12). Furthermore, solution samples from different stages (0, 60, 180, 360 min) of the degradation reaction were obtained and fed to honey bees in equal proportions after dilution according to the LD50 measured in the preexperiment; this was performed to determine the changes in toxicity to honey bees during the reaction (Additional file 1: Table S9). The results showed that the mortality of the honey bees gradually decreased as the reaction proceeded and reached almost 0% at the end of the reaction (Fig. 6d). In addition, the learning ability of honey bees that received the reaction solution after 360 min was not significantly different from that of normal honey bees (Fig. 6e, p > 0.05), which further indicated that the toxicity of the neonicotinoids to the honey bees was completely eliminated after the nitro group was removed via the reduction reaction. In summary, the effective denitrification of neonicotinoids using MNBC-ZVI via the reduction reaction is ecologically important for reducing insecticide selection pressure.

3.5 Practical application potential of MNBC-ZVI

It is necessary to clarify the effect of solution conditions on the activity of MNBC-ZVI for organic pollutant degradation for practical applications. For this purpose, the effects of MNBC-ZVI on degrading thiamethoxam under different inorganic anions, in the presence HA, and in four natural water samples were examined. The degradation of thiamethoxam was slightly inhibited by NO3− and HCO3−, and the inhibition effect was positively correlated with their concentrations (Fig. 7a and Additional file 1: Fig. S13). Previous studies have shown that NO3− can react with ZVI and compete with organic pollutants (Sun et al. 2016), which may be responsible for the decreased degradation rate of thiamethoxam (Eqs. 6–7). The strong inhibition of thiamethoxam degradation by HCO3− may be due to the partial passivation of the material surface caused by the increase in solution pH. In contrast, the addition of SO42− and Cl− promoted thiamethoxam degradation (Fig. 7a and Additional file 1: Fig. S13); this is because the two anions increased the dissolution of the iron oxide layer on the ZVI surface, which led to the local corrosion of ZVI and thus accelerated the electron transfer and mass transfer of the reactant (Eqs. 8–9) (Su and Puls 2004; Katsenovich et al. 2023). HA also promoted thiamethoxam degradation, which is likely caused by the complexation of HA with ZVI, resulting in ZVI exposure and rapid corrosion (Fig. 7b) (He et al. 2020).

Effects of (a) various types of anions and (b) HA on thiamethoxam degradation by MNBC-ZVI; (c) degradation kinetics of thiamethoxam by MNBC-ZVI in real water matrices; (d) cyclic experiment (Reaction conditions: material concentration = 0.75 g·L−1, thiamethoxam concentration = 10 mg·L−1, no adjustment of pH, anoxic, T = 25 °C)

A batch experiment was conducted to further explore the potential application of MNBC-ZVI in various water matrices. As shown in Fig. 7c, the degradation rates of thiamethoxam in seawater, wastewater, and river water after 180 min of reaction were 98.0%, 53.6%, and 78.6%, respectively. The decrease in thiamethoxam degradation in wastewater and river water may be due to the interference of a large amount of organic and inorganic substances (e.g., NO3−, Hg2+). Natural seawater promoted the degradation of thiamethoxam in the MNBC-ZVI catalytic system, possibly because of the low redox potential of seawater with high concentrations of Cl− and SO42− (Additional file 1: Table S2); this was consistent with the result that SO42− and Cl− could promote thiamethoxam degradation in the MNBC-ZVI system (Wei et al. 2010). Moreover, historically pesticide-contaminated water and soil samples were adopted to verify the activity of MNBC-ZVI. The water and soil samples contained more than nine pesticides, e.g., imidacloprid, thiamethoxam, acetochlor, chlorothalonil, nitrobenzene, with total concentrations of 0.3–24.7 mg·L−1 (mg·kg−1). As shown in Additional file 1: Figs. S14a-b, the degradation rates of the 9 pesticides in the MNBC-ZVI system were greater than 88.2%. The above results further suggest that MNBC-ZVI presented a great advantage for the degradation of different pollutants in actual contaminated water and soil. Furthermore, the stability and activity of MNBC-ZVI in the catalytic degradation of thiamethoxam was tested by recoverability. As shown in Fig. 7d, MNBC-ZVI presented a reductive degradation rate of thiamethoxam of 90.2% after four cycles. The decline in thiamethoxam degradation mainly occurred because the electron donor (ZVI) participating in the process steadily discharged and intermediates accumulated on the surface of MNBC-ZVI. In addition, the Fe 2p XPS analysis and examination of dissolved Fe content of MNBC-ZVI after the first reaction showed that the surface iron hydroxides of MNBC-ZVI and the amount of leached Fe remained at a low level of < 0.32% total Fe, suggesting that the Fe in MNBC-ZVI was relatively stable (Fig. 4g and Additional file 1: Fig. S15). These results also explained why MNBC-ZVI could continuously degrade thiamethoxam even after four cycles (degradation rate: > 90%).

4 Conclusions

In this work, a novel MNBC-ZVI material was successfully synthesized by ball milling and applied to degrade neonicotinoids in aqueous solution. The obtained MNBC-ZVI exhibited a 100% degradation rate for thiamethoxam (10 mg·L−1) within 360 min with a degradation rate constant (0.0169 min−1) approximately 12.1 times higher than that of pristine ZVI. NBC incorporation also dramatically increased the electron efficiency from 29.7% to 57.8%. The excellent catalytic performance and high electron efficiency of MNBC-ZVI could result from the following factors: (i) ball milling decreased the particle size of pristine ZVI and allowed it to achieve a high degree of dispersion with NBC, preventing the aggregation and oxidation of ZVI; (ii) NBC incorporation introduced new linked heterojunctions and N-doped sites, inducing the charge redistribution of MNBC-ZVI, rapid electron transfer, and high hydrophobicity; and (iii) MNBC-ZVI improved the adsorption of thiamethoxam and dissolved Fe(II) in solution, optimizing the adsorption–desorption and reductive degradation of thiamethoxam and •H generation steps. Moreover, the low toxicity of the denitrification products of neonicotinoids to green algae and honey bees during the reaction; the favorable tolerance of MNBC-ZVI to various anions, HA, different water matrices, and contaminated soil; and the high reusability of MNBC-ZVI indicate the promise of MNBC-ZVI for practical applications. As a whole, the results obtained in this study offer a new strategy for the remediation of neonicotinoid-contaminated water, which could guide the development of more efficient and friendly technologies to remediate organic contaminants in the environment. Moreover, the evolution of passivation byproducts formed by ZVI-based materials during the reaction and their effects on pollutant degradation have not been accurately elucidated. Further studies should investigate the relation between the evolution of specific properties (structural properties, morphological properties, and composition) of materials and pollutant degradation, especially in complex aquatic and soil environments (e.g., paddy fields contaminated with organic pesticides), to engineer specific designs for pollution remediation.

Availability of data and materials

The data that support the findings of this study are available from the corresponding author upon request.

Change history

07 December 2023

A Correction to this paper has been published: https://doi.org/10.1007/s42773-023-00292-0

References

Alsafran M, Rizwan M, Usman K, Saleem MH, Jabri HA (2022) Neonicotinoid insecticides in the environment: a critical review of their distribution, transport, fate, and toxic effects. J Environ Chem Eng 10:108485. https://doi.org/10.1016/j.jece.2022.108485

Annoscia D, Di Prisco G, Becchimanzi A, Caprio E, Frizzera D, Linguadoca A, Nazzi F, Pennacchio F (2020) Neonicotinoid Clothianidin reduces honey bee immune response and contributes to Varroa mite proliferation. Nat Commun 11:5887. https://doi.org/10.1038/s41467-020-19715-8

Bae S, Hanna K (2015) Reactivity of nanoscale zero-valent iron in unbuffered systems: effect of pH and Fe(II) dissolution. Environ Sci Technol 49:10536–10543. https://doi.org/10.1021/acs.est.5b01298

Chen P, Zhou T, Xing L, Xu K, Tong Y, Xie H, Zhang L, Yan W, Chu W, Wu C, Xie Y (2017) Atomically dispersed iron-nitrogen species as electrocatalysts for bifunctional oxygen evolution and reduction reactions. Angew Chem Int Ed 56:610–614. https://doi.org/10.1002/anie.201610119

Cheng Y, Wang B, Shen J, Yan P, Kang J, Wang W, Bi L, Zhu X, Li Y, Wang S, Shen L, Chen Z (2022) Preparation of novel N-doped biochar and its high adsorption capacity for atrazine based on π–π electron donor-acceptor interaction. J Hazard Mater 432:128757. https://doi.org/10.1016/j.jhazmat.2022.128757

Dong H, Li L, Lu Y, Cheng Y, Wang Y, Ning Q, Wang B, Zhang L, Zeng G (2019) Integration of nanoscale zero-valent iron and functional anaerobic bacteria for groundwater remediation: a review. Environ Int 124:265–277. https://doi.org/10.1016/j.envint.2019.01.030

Duan P, Qi Y, Feng S, Peng X, Wang W, Yue Y, Shang Y, Li Y, Gao B, Xu X (2020) Enhanced degradation of clothianidin in peroxymonosulfate/catalyst system via core-shell FeMn @ N-C and phosphate surrounding. Appl Catal B Environ 267:118717. https://doi.org/10.1016/j.apcatb.2020.118717

EC/2018/840 (2018) Commission implementing decision (EU) 2018/840 of 5 June 2018 establishing a watch list of substances for union-wide monitoring in the field of water policy pursuant to Directive 2008/105/EC of the European Parliament and of the Council and repealing Comm. Official Journal of the European Commission, Brussels. http://data.europa.eu/eli/decimpl/2018/840/oj

Fu F, Dionysiou DD, Liu H (2014) The use of zero-valent iron for groundwater remediation and wastewater treatment: a review. J Hazard Mater 267:194–205. https://doi.org/10.1016/j.jhazmat.2013.12.062

Gao J, Wang W, Rondinone AJ, He F, Liang L (2015) Degradation of trichloroethene with a novel ball milled Fe–C nanocomposite. J Hazard Mater 300:443–450. https://doi.org/10.1016/j.jhazmat.2015.07.038

Gong L, Qi J, Lv N, Qiu X, Gu Y, Zhao J, He F (2021a) Mechanistic role of nitrate anion in TCE dechlorination by ball milled ZVI and sulfidated ZVI: experimental investigation and theoretical analysis. J Hazard Mater 403:123844. https://doi.org/10.1016/j.jhazmat.2020.123844

Gong L, Qiu X, Cheng D, Hu Y, Zhang Z, Yuan Q, Yang D, Liu C, Liang L, He F (2021b) Coincorporation of N and S into zero-valent iron to enhance TCE dechlorination: kinetics, electron efficiency, and dechlorination capacity. Environ Sci Technol 55:16088–16098. https://doi.org/10.1021/acs.est.1c03784

Gong L, Qiu X, Tratnyek PG, Liu C, He F (2021c) FeNX(C)-coated microscale zero-valent iron for fast and stable trichloroethylene dechlorination in both acidic and basic pH conditions. Environ Sci Technol 55:5393–5402. https://doi.org/10.1021/acs.est.0c08176

Gu Y, Wang B, He F, Bradley MJ, Tratnyek PG (2017) Mechanochemically sulfidated microscale zero valent iron: pathways, kinetics, mechanism, and efficiency of trichloroethylene dechlorination. Environ Sci Technol 51:12653–12662. https://doi.org/10.1021/acs.est.7b03604

Gu S, Li Z, Yang L, Bao X, Ying C, Zhang Q (2023) The distribution and human health risk assessment of eight neonicotinoid residues in agricultural soils from four provinces, south China. Chemosphere 322:138143. https://doi.org/10.1016/j.chemosphere.2023.138143

Guan X, Du X, Liu M, Qin H, Qiao J, Sun Y (2020) Enhanced trichloroethylene dechlorination by carbon-modified zero-valent iron: revisiting the role of carbon additives. J Hazard Mater 394:122564. https://doi.org/10.1016/j.jhazmat.2020.122564

Han Y, Yan W (2014) Bimetallic nickel–iron nanoparticles for groundwater decontamination: effect of groundwater constituents on surface deactivation. Water Res 66:149–159. https://doi.org/10.1016/j.watres.2014.08.001

Hansel CM, Benner SG, Fendorf S (2005) Competing Fe(II)-induced mineralization pathways of ferrihydrite. Environ Sci Technol 39:7147–7153. https://doi.org/10.1021/es050666z

He C, Ding R, Zhou G, He D, Fan P, Guan X, Mu Y (2020) Coexistence of humic acid enhances the reductive removal of diatrizoate via depassivating zero-valent iron under aerobic conditions. J Mater Chem A 8:14634–14643. https://doi.org/10.1039/D0TA04276E

He M, Xu Z, Hou D, Gao B, Ok YS, Rinklebe J, Bolan NS, Tsang DCW (2022) Waste-derived biochar for water pollution control and sustainable development. Nat Rev Earth Environ 3:444–460. https://doi.org/10.1038/s43017-022-00306-8

Huang Y, Zhang T (2006) Enhanced trichloroethylene dechlorination by carbon-modified zero-valent iron. Water Res 40:3075–3082. https://doi.org/10.1016/j.watres.2006.06.016

Huang P, Zhang P, Wang C, Tang J, Sun H (2022) Enhancement of persulfate activation by Fe-biochar composites: synergism of Fe and N-doped biochar. Appl Catal B Environ 303:120926. https://doi.org/10.1016/j.apcatb.2021.120926

Hussain I, Li M, Zhang Y, Li Y, Huang S, Du X, Liu G, Hayat W, Anwar N (2017) Insights into the mechanism of persulfate activation with nZVI/BC nanocomposite for the degradation of nonylphenol. Chem Eng J 311:163–172. https://doi.org/10.1016/j.cej.2016.11.085

Ismagilov ZR, Shalagina AE, Podyacheva OY, Ischenko AV, Kibis LS, Boronin AI, Chesalov YA, Kochubey DI, Romanenko AI, Anikeeva OB, Buryakov TI, Tkachev EN (2009) Structure and electrical conductivity of nitrogen-doped carbon nanofibers. Carbon 47:1922–1929. https://doi.org/10.1016/j.carbon.2009.02.034

Jeschke P, Nauen R, Schindler M, Elbert A (2011) Overview of the status and global strategy for neonicotinoids. J Agric Food Chem 59:2897–2908. https://doi.org/10.1021/jf101303g

Kanne DB, Dick RA, Tomizawa M, Casida JE (2005) Neonicotinoid nitroguanidine insecticide metabolites: synthesis and nicotinic receptor potency of guanidines, aminoguanidines, and their derivatives. Chem Res Toxicol 18:1479–1484. https://doi.org/10.1021/tx050160u

Katsenovich YP, Maria AA, Williams J, Kandel S, Boglaienko D, Emerson HP, Levitskaia TG (2023) Reductive removal of pertechnetate and chromate by zero valent iron under variable ionic strength conditions. J Hazard Mater 445:130546. https://doi.org/10.1016/j.jhazmat.2022.130546

Li Y, Miao R, Khanna M (2020) Neonicotinoids and decline in bird biodiversity in the United States. Nat Sustain 3:1027–1035. https://doi.org/10.1038/s41893-020-0582-x

Li D, Zhong Y, Zhu X, Wang H, Yang W, Deng Y, Huang W, Peng P (2021) Reductive degradation of chlorinated organophosphate esters by nanoscale zerovalent iron/cetyltrimethylammonium bromide composites: reactivity, mechanism and new pathways. Water Res 188:116447. https://doi.org/10.1016/j.watres.2020.116447

Lin L, Zhu Q, Xu A (2014) Noble-metal-free Fe–N/C catalyst for highly efficient oxygen reduction reaction under both alkaline and acidic conditions. J Am Chem Soc 136:11027–11033. https://doi.org/10.1021/ja504696r

Liu L, Yin J, Zhao Y, Zhang L (2008) Effects of ferrous ions on nitrobenzene reduction in zero-valent iron system. In: 2008 2nd International Conference on Bioinformatics and Biomedical Engineering. IEEE, Shanghai, pp 3356–3359

Liu R, Wu D, Feng X, Müllen K (2010) Nitrogen-doped ordered mesoporous graphitic arrays with high electrocatalytic activity for oxygen reduction. Angew Chem Int Ed 49:2565–2569. https://doi.org/10.1002/anie.200907289

Liu X, Cao Z, Yuan Z, Zhang J, Guo X, Yang Y, He F, Zhao Y, Xu J (2018) Insight into the kinetics and mechanism of removal of aqueous chlorinated nitroaromatic antibiotic chloramphenicol by nanoscale zero-valent iron. Chem Eng J 334:508–518. https://doi.org/10.1016/j.cej.2017.10.060

Liu X, Liu Y, Qin H, Ye Z, Wei X, Miao W, Yang D, Mao S (2022) Selective removal of phenolic compounds by peroxydisulfate activation: inherent role of hydrophobicity and interface ROS. Environ Sci Technol 56:2665–2676. https://doi.org/10.1021/acs.est.1c07469

Lymar SV, Schwarz HA (2012) Hydrogen atom reactivity toward aqueous tert -butyl alcohol. J Phys Chem A 116:1383–1389. https://doi.org/10.1021/jp2116593

Matsuda K, Ihara M, Sattelle DB (2020) Neonicotinoid insecticides: molecular targets, resistance, and toxicity. Annu Rev Pharmacol Toxicol 60:241–255. https://doi.org/10.1146/annurev-pharmtox-010818-021747

Mercier-Bion F, Li J, Lotz H, Tortech L, Neff D, Dillmann P (2018) Electrical properties of iron corrosion layers formed in anoxic environments at the nanometer scale. Corros Sci 137:98–110. https://doi.org/10.1016/j.corsci.2018.03.028

Mir NA, Khan A, Muneer M, Vijayalakhsmi S (2013) Photocatalytic degradation of a widely used insecticide Thiamethoxam in aqueous suspension of TiO2: adsorption, kinetics, product analysis and toxicity assessment. Sci Total Environ 458–460:388–398. https://doi.org/10.1016/j.scitotenv.2013.04.041

Mori T, Ohno H, Ichinose H, Kawagishi H, Hirai H (2021) White-rot fungus Phanerochaete chrysosporium metabolizes chloropyridinyl-type neonicotinoid insecticides by an N-dealkylation reaction catalyzed by two cytochrome P450s. J Hazard Mater 402:123831. https://doi.org/10.1016/j.jhazmat.2020.123831

Morrissey CA, Mineau P, Devries JH, Sanchez-Bayo F, Liess M, Cavallaro M, Liber K (2015) Neonicotinoid contamination of global surface waters and associated risk to aquatic invertebrates: a review. Environ Int 74:291–303. https://doi.org/10.1016/j.envint.2014.10.024

Noubactep C (2012) Comment on “Reductive dechlorination of γ-hexachloro-cyclohexane using Fe–Pd bimetallic nanoparticles” by Nagpal et al. [J. Hazard. Mater. 175 (2010) 680–687]. J Hazard Mater 235–236:388–391. https://doi.org/10.1016/j.jhazmat.2011.03.081

Patil PB, Raut-Jadhav S, Pandit AB (2021) Effect of intensifying additives on the degradation of thiamethoxam using ultrasound cavitation. Ultrason Sonochem 70:105310. https://doi.org/10.1016/j.ultsonch.2020.105310

Pedersen HD, Postma D, Jakobsen R, Larsen O (2005) Fast transformation of iron oxyhydroxides by the catalytic action of aqueous Fe(II). Geochim Cosmochim Acta 69:3967–3977. https://doi.org/10.1016/j.gca.2005.03.016

Ren W, Nie G, Zhou P, Zhang H, Duan X, Wang S (2020) The intrinsic nature of persulfate activation and N-doping in carbocatalysis. Environ Sci Technol 54:6438–6447. https://doi.org/10.1021/acs.est.0c01161

Shaheen SM, Mosa A, Natasha AH, Niazi NK, Antoniadis V, Shahid M, Song H, Kwon EE, Rinklebe J (2022) Removal of toxic elements from aqueous environments using nano zero-valent iron- and iron oxide-modified biochar: a review. Biochar 4:24. https://doi.org/10.1007/s42773-022-00149-y

Smit E, Manoun B, Waal DD (2001) Low-wavenumber Raman spectra of the spin-transition complexes [Fe(NH2 trz)3](ClO4)2 and [Fe(Htrz)3](ClO4)2. J Raman Spectrosc 32:339–344. https://doi.org/10.1002/jrs.696

Stefaniuk M, Oleszczuk P, Ok YS (2016) Review on nano zerovalent iron (nZVI): from synthesis to environmental applications. Chem Eng J 287:618–632. https://doi.org/10.1016/j.cej.2015.11.046

Su C, Puls RW (2004) Nitrate reduction by zerovalent iron: effects of formate, oxalate, citrate, chloride, sulfate, borate, and phosphate. Environ Sci Technol 38:2715–2720. https://doi.org/10.1021/es034650p

Sun Y, Li J, Huang T, Guan X (2016) The influences of iron characteristics, operating conditions and solution chemistry on contaminants removal by zero-valent iron: a review. Water Res 100:277–295. https://doi.org/10.1016/j.watres.2016.05.031

Sun Y, Yang Z, Tian P, Sheng Y, Xu J, Han Y (2019) Oxidative degradation of nitrobenzene by a Fenton-like reaction with Fe-Cu bimetallic catalysts. Appl Catal B Environ 244:1–10. https://doi.org/10.1016/j.apcatb.2018.11.009

Swaren L, Safari S, Konhauser KO, Alessi DS (2022) Pyrolyzed biomass-derived nanoparticles: a review of surface chemistry, contaminant mobility, and future research avenues to fill the gaps. Biochar 4:33. https://doi.org/10.1007/s42773-022-00152-3

Tamaura Y, Saturno M, Yamada K, Katsura T (1984) The transformation of γ-FeO(OH) to Fe3O4 and green rust II in an aqueous solution. Bull Chem Soc Jpn 57:2417–2421. https://doi.org/10.1246/bcsj.57.2417

Tang C, Huang Y, Zeng H, Zhang Z (2014) Reductive removal of selenate by zero-valent iron: the roles of aqueous Fe2+ and corrosion products, and selenate removal mechanisms. Water Res 67:166–174. https://doi.org/10.1016/j.watres.2014.09.016

Thomaidi VS, Stasinakis AS, Borova VL, Thomaidis NS (2015) Is there a risk for the aquatic environment due to the existence of emerging organic contaminants in treated domestic wastewater? Greece as a case-study. J Hazard Mater 283:740–747. https://doi.org/10.1016/j.jhazmat.2014.10.023

Tronc E, Belleville P, Jolivet JP, Livage J (1992) Transformation of ferric hydroxide into spinel by Fe(II) adsorption. Langmuir 8:313–319. https://doi.org/10.1021/la00037a057

Wang S, Zhao M, Zhou M, Li Y, Wang J, Gao B, Sato S, Feng K, Yin W, Igalavithana AD, Oleszczuk P, Wang X, Ok YS (2019) Biochar-supported nZVI (nZVI/BC) for contaminant removal from soil and water: a critical review. J Hazard Mater 373:820–834. https://doi.org/10.1016/j.jhazmat.2019.03.080

Wang K, Sun Y, Tang J, He J, Sun H (2020) Aqueous Cr(VI) removal by a novel ball milled Fe0-biochar composite: role of biochar electron transfer capacity under high pyrolysis temperature. Chemosphere 241:125044. https://doi.org/10.1016/j.chemosphere.2019.125044

Wang P, Hu J, Liu T, Han G, Ma W, Li J (2023) New insights into ball-milled zero-valent iron composites for pollution remediation: an overview. J Clean Prod 385:135513. https://doi.org/10.1016/j.jclepro.2022.135513

Wei Y, Wu S, Chou C, Che C, Tsai S, Lien H (2010) Influence of nanoscale zero-valent iron on geochemical properties of groundwater and vinyl chloride degradation: a field case study. Water Res 44:131–140. https://doi.org/10.1016/j.watres.2009.09.012

Xu J, Cao Z, Zhou H, Lou Z, Wang Y, Xu X, Lowry GV (2019) Sulfur dose and sulfidation time affect reactivity and selectivity of post-sulfidized nanoscale zerovalent iron. Environ Sci Technol 53:13344–13352. https://doi.org/10.1021/acs.est.9b04210

Xu J, Avellan A, Li H, Liu X, Noël V, Lou Z, Wang Y, Kaegi R, Henkelman G, Lowry GV (2020) Sulfur loading and speciation control the hydrophobicity, electron transfer, reactivity, and selectivity of sulfidized nanoscale zerovalent iron. Adv Mater 32:1906910. https://doi.org/10.1002/adma.201906910

Yamamuro M, Komuro T, Kamiya H, Kato T, Hasegawa H, Kameda Y (2019) Neonicotinoids disrupt aquatic food webs and decrease fishery yields. Science 366:620–623. https://doi.org/10.1126/science.aax3442

Yang L, Steefel CI, Marcus MA, Bargar JR (2010) Kinetics of Fe(II)-catalyzed transformation of 6-line ferrihydrite under anaerobic flow conditions. Environ Sci Technol 44:5469–5475. https://doi.org/10.1021/es1007565

Yin K, Deng Y, Liu C, He Q, Wei Y, Chen S, Liu T, Luo S (2018) Kinetics, pathways and toxicity evaluation of neonicotinoid insecticides degradation via UV/chlorine process. Chem Eng J 346:298–306. https://doi.org/10.1016/j.cej.2018.03.168

Zhang P, Sun H, Ren C, Min L, Zhang H (2018) Sorption mechanisms of neonicotinoids on biochars and the impact of deashing treatments on biochar structure and neonicotinoids sorption. Environ Pollut 234:812–820. https://doi.org/10.1016/j.envpol.2017.12.013

Zhang P, Min L, Tang J, Rafiq M, Sun H (2020) Sorption and degradation of imidacloprid and clothianidin in Chinese paddy soil and red soil amended with biochars. Biochar 2:329–341. https://doi.org/10.1007/s42773-020-00060-4

Zhang Z, Mu X, Cao Q, Shi Y, Hu X, Zheng H (2022) Honeybee gut Lactobacillus modulates host learning and memory behaviors via regulating tryptophan metabolism. Nat Commun 13:2037. https://doi.org/10.1038/s41467-022-29760-0

Acknowledgements

We would like to thank Editage (www.editage.cn) for English language editing.

Funding

This work was supported by the National Natural Science Foundation of China (Nos. U21A20291, 42377384), the National Key R & D Program of China (No. 2021YFD1000500) and the Major Research Plan of the Shandong Science Foundation (No. ZR2020ZD19).

Author information

Authors and Affiliations

Contributions

XL and XZ: methodology, investigation and writing (original draft). XW, HS, YL and CL: writing (review and editing). PZ, LJ, HS and CL: conceptualization, writing (review and editing) and funding acquisition. All authors participated in discussions of the study results.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Additional information

Xiangying Li and Xiangyu Zhang contributed equally to the work.

The original version of this article was revised: The Funding information has been corrected.

Supplementary Information

Additional file 1.

Supplementary Text S1–S6, Tables S1–S9 and Figures S1–S15.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Li, X., Zhang, X., Zhang, P. et al. Incorporation of N-doped biochar into zero-valent iron for efficient reductive degradation of neonicotinoids: mechanism and performance. Biochar 5, 78 (2023). https://doi.org/10.1007/s42773-023-00280-4

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42773-023-00280-4