Abstract

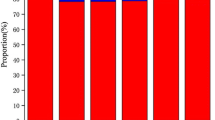

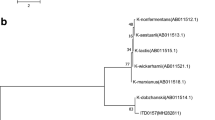

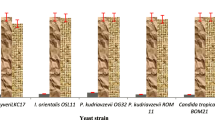

The aim of this study was to evaluate the biosynthesis of flavor compounds from rice bran by fermentation facilitated by Kluyveromyces marxianus and Debaryomyces hansenii. The growth of both yeasts was assessed by specific growth rates and doubling time. The biosynthesis of flavor compounds was evaluated by gas chromatography–olfactometry (GC-O), gas chromatography-mass spectrometry (GC–MS), and Spectrum™ sensory analysis. The specific growth rate (µ) and doubling time (td) of K. marxianus was calculated as 0.16/h and 4.21h, respectively, whereas that of D. hansenii was determined as 0.13/h and 5.33h, respectively. K. marxianus and D. hansenii produced significant levels of higher alcohols and acetate esters from rice bran. Results showed that K. marxianus can produce 827.27 µg/kg of isoamyl alcohol, 169.77 µg/kg of phenyl ethyl alcohol, and 216.08 µg/kg of phenyl ethyl acetate after 24-h batch fermentation. A significant amount of isovaleric acid was also synthesized by K. marxianus (4013 µg/kg) after the batch fermentation of 96 h. 415.64 µg/kg of isoamyl alcohol and 135.77 µg/kg of phenyl ethyl acetate was determined in rice bran fermented by D. hansenii after 24-h fermentation. Fermented cereals and rose were the characteristic flavor descriptors of the fermented rice bran samples. Rose flavor in fermented rice bran samples was found to be associated with phenyl ethyl alcohol, phenyl ethyl acetate, isoamyl acetate, and guaiacol. Thus, the findings of this study demonstrate that the valorization of rice bran can be achieved with the production of natural flavor compounds by yeast metabolism.

Similar content being viewed by others

Data availability

Research data are not shared. The data generated during the present study are available from the corresponding author upon reasonable request.

References

Hosoglu MI, Guneser O, Yuceer YK (2018) Different bioengineering approaches on production of bioflavor compounds. In: Grumezescu AM, Holban AM (eds) The role of materials science in food bioengineering Volume 19, 1st edn. Academic Press, Cambridge, pp 37–71. https://doi.org/10.1016/B978-0-12-811448-3.00002-4

Scragg AH (2007) The production of flavours by plant cell cultures. In: Berger RG (ed) Flavours and fragrances: chemistry, bioprocessing and sustainability, 1st edn. Springer, Berlin-Heidelberg, pp 599–614. https://doi.org/10.1007/978-3-540-49339-6_25

Ziegler H (2007) Introduction. In: Ziegler H (ed) Flavourings: production, composition, applications regulations, 2nd edn. Wiley-VCH Verlag GmbH&Co. KGaA, Weinheim, pp 1–13. https://doi.org/10.1002/9783527611454.ch1

Bettio G, Zardo LC, Rosa CA, Záchia Ayub MA (2021) Bioconversion of ferulic acid into aroma compounds by newly isolated yeast strains of the Latin American biodiversity. Biotechnol Prog 37 e3067. 10.1002/btpr.3067

Ben Akacha N, Gargouri M (2015) Microbial and enzymatic technologies used for the production of natural aroma compounds: synthesis, recovery modeling, and bioprocesses. Food Bioprod Process 94:675–706. https://doi.org/10.1016/j.fbp.2014.09.011

Coimbra JM, Cristina dos Reis K, Schwan RF, Silva CF (2021) Effect of the strategy of molasses supplementation in vinasse to high SCP production and rose flavor compound. Waste Biomass Valori 12:359–369. https://doi.org/10.1007/s12649-020-00961-2

Yilmaztekin M, Erten H, Cabaroglu T (2009) Enhanced production of isoamyl acetate from beet molasses with addition of fusel oil by Williopsis saturnus var. saturnus. Food Chem 112:290–294. https://doi.org/10.1016/j.foodchem.2008.05.079

Rossi SC, Vandenberghe LPS, Pereira BMP, Gago FD, Rizzolo JA, Pandey A, Soccol CR, Medeiros ABP (2009) Improving fruity aroma production by fungi in SSF using citric pulp. Food Res Int 42:484–486. https://doi.org/10.1016/j.foodres.2009.01.016

Chakraborty D, Kaur B, Obulisamy K, Selvam A, Wong JWC (2017) Agrowaste to vanillin conversion by a natural Pediococcus acidilactici strain BD16. Environ Technol 38:1823–1834. https://doi.org/10.1080/09593330.2016.1237556

Fadel HHM, Mahmoud MG, Asker MMS, Lotfy SN (2015) Characterization and evaluation of coconut aroma produced by Trichoderma viride EMCC-107 in solid state fermentation on sugarcane bagasse. Electron J Biotechnol 18:5–9. https://doi.org/10.1016/j.ejbt.2014.10.006

Güneşer O, Demirkol A, Karagül Yüceer Y, Özmen Toğay S, İşleten Hoşoğlu M, Elibol M (2015) Bioflavour production from tomato and pepper pomaces by Kluyveromyces marxianus and Debaryomyces hansenii. Bioprocess Biosyst Eng 38:1143–1155. https://doi.org/10.1007/s00449-015-1356-0

Güneşer O, Yüceer YK (2017) Biosynthesis of eight-carbon volatiles from tomato and pepper pomaces by fungi: Trichoderma atroviride and Aspergillus sojae. J Biosci Bioeng 123:451–459. https://doi.org/10.1016/j.jbiosc.2016.11.013

Wang M, Lei M, Samina N, Chen L, Liu C, Yin T, Yan X, Wu C, He H, Yi C (2020) Impact of Lactobacillus plantarum 423 fermentation on the antioxidant activity and flavor properties of rice bran and wheat bran. Food Chem 330:127–156. https://doi.org/10.1016/j.foodchem.2020.127156

Yılmaz Tuncel N, Yılmaz Korkmaz F (2021) Comparison of lipid degradation in raw and infrared stabilized rice bran and rice bran oil matrix effect. J Food Meas Charact 15:1057–1067. https://doi.org/10.1007/s11694-020-00709-5

Sharif MK, Butt MS, Anjum FM, Khan SH (2014) Rice bran: a novel functional ingredient. Crit Rev Food Sci Nutr 54:807–816. https://doi.org/10.1080/10408398.2011.608586

Gul K, Yousuf B, Singh AK, Singh P, Wani AA (2015) Rice bran: nutritional values and its emerging potential for development of functional food - A review. Bioact Carbohydrates Diet Fibre 6:24–30. https://doi.org/10.1016/j.bcdf.2015.06.002

Malekian F, Rao RM, Prinyawiwatkul W, Marshall WE, Windhauser M, Ahmedna M (2000) Lipase, and lipoxygenase activity, functionality, and nutrient losses in rice bran during storage. Bull La Agric Exp Stn LSU Agric Cent 870:1–68

Zheng L, Zheng P, Sun Z, Bai Y, Wang J, Guo X (2007) Production of vanillin from waste residue of rice bran oil by Aspergillus niger and Pycnoporus cinnabarinus. Bioresour Technol 98:1115–1119. https://doi.org/10.1016/j.biortech.2006.03.028

Morrissey J, Etschmann M, Jens S, de Billerbeck GM (2015) Cell factory applications of the yeast Kluyveromyces marxianus for the biotechnological production of natural flavour and fragrance molecules. Yeast 32:3–16. https://doi.org/10.1002/yea.3054

Fonseca GG, Heinzle E, Wittmann C, Gombert AK (2008) The yeast Kluyveromyces marxianus and its biotechnological potential. Appl Microbiol Biotechnol 79:339–354. https://doi.org/10.1007/s00253-008-1458-6

Breuer U, Harms H (2006) Debaryomyces hansenii - an extremophilic yeast with biotechnological potential. Yeast 23:415–437. https://doi.org/10.1002/yea.1374

Atlas RM (2004) Handbook of microbiological media. CRC Press, Boca Raton https://doi.org/10.1201/9781420039726

Ray B, Bhunia A (2013) Fundamental food microbiology CRC Press, Boca Raton https://doi.org/10.1201/b16078

Avsar YK, Karagul-Yuceer Y, Drake MA, Singh TK, Yoon Y, Cadwallader KR (2004) Characterization of nutty flavor in Cheddar cheese. J Dairy Sci 87:1999–2010. https://doi.org/10.3168/jds.S0022-0302(04)70017-X

Meilgaard M, Civille G, Carr B (1999) Sensory evaluation techniques, 3rd edn. CRC Press LLC, Boca Raton, Florida, USA

Sheskin D (2004) Handbook of parametric and nonparametric statistical procedures. Chapman and Hall ⁄CRC press, New York

Wilkowska A, Kregiel D, Guneser O, Karagul Yuceer Y (2015) Growth and byproduct profiles of Kluyveromyces marxianus cells immobilized in foamed alginate. Yeast 32:217–225. https://doi.org/10.1002/yea.3044

Zafar S, Owais M (2006) Ethanol production from crude whey by Kluyveromyces marxianus. Biochem Eng J 27:295–298. https://doi.org/10.1016/j.bej.2005.05.009

Goshima T, Tsuji M, Inoue H, Yano S, Hoshino T, Matsushika A (2013) Bioethanol production from lignocellulosic biomass by a novel Kluyveromyces marxianus strain. Biosci Biotechnol Biochem 77:1505–1510. https://doi.org/10.1271/bbb.130173

Mardawati E, Andoyo R, Muhaemin M, Nurjanah S, Natawigena D, Herwanto T, Handarto H, Utama GL, Rosalinda S, Poppy L, Kramadibrata AM (2019) Fermentation process of glycerol to arabitol from byproducts of reutalis trisperma biodiesel using yeast of Debaryomyces hansenii. IOP Conf Ser Earth Environ Sci 347:012232. https://doi.org/10.1088/1755-1315/347/1/012132

Sharma NK, Behera S, Arora R, Kumar S (2017) Evolutionary adaptation of Kluyveromyces marxianus NIRE-K3 for enhanced xylose utilization. Front Energy Res 5:1–8. https://doi.org/10.3389/fenrg.2017.00032

Maurya DP, Singla A, Negi S (2015) An overview of key pretreatment processes for biological conversion of lignocellulosic biomass to bioethanol. 3 Biotech 5:597–609. https://doi.org/10.1007/s13205-015-0279-4

Singh nee’ Nigam P, Gupta A, Anthwal N (2009) Pre-treatment of agro-industrial residues. In: Singh nee’ Nigam P, Pandey A, (eds) Biotechnology for agro-industrial residues utilisation, 1st edn. Springer, Heidelberg, pp 13–33. https://doi.org/10.1007/978-1-4020-9942-7_2

Drake MA, Civille GV (2003) Flavor lexicons. Compr Rev Food Sci Food Saf 2:33–40. https://doi.org/10.1111/j.1541-4337.2003.tb00013.x

Czerny M, Christlbauer M, Christlbauer M, Fischer A, Granvogl M, Hammer M, Hartl C, Hernandez NM, Schieberle P (2008) Re-investigation on odour thresholds of key food aroma compounds and development of an aroma language based on odour qualities of defined aqueous odorant solutions. Eur Food Res Technol 228:265–273. https://doi.org/10.1007/s00217-008-0931-x

Koehler PE, Mason ME, Odell GV (1971) Odor threshold levels of pyrazine compounds and assessment of their role in the flavor of roasted foods. J Food Sci 36:816–818. https://doi.org/10.1111/j.1365-2621.1971.tb03314.x

Belitz H-D, Grosch W, Schieberle P (2009) Food chemistry, 3rd edn. Springer, Heidelberg

Saerens SMG, Delvaux FR, Verstrepen KJ, Thevelein JM (2010) Production and biological function of volatile esters in Saccharomyces cerevisiae. Microb Biotechnol 23:165–177. https://doi.org/10.1111/j.1751-7915.2009.00106.x

Bartowsky EJ, Pretorius IS (2009) Microbial formation and modification of flavor and off-flavor compounds in wine. In: König H, Unden G, Fröhlich JH (eds) Biology of microorganisms on grapes, in must and in wine. Springer, Heidelberg, pp. 209–231. https://doi.org/10.1007/978-3-540-85463-0_11

Hazelwood LA, Daran JM, Van Maris AJA, Pronk JT, Dickinson JR (2008) The Ehrlich pathway for fusel alcohol production: a century of research on Saccharomyces cerevisiae metabolism. Appl Environ Microbiol 74:2259–2266. https://doi.org/10.1128/AEM.02625-07

Etschmann M, Bluemke W, Sell D, Schrader J (2002) Biotechnological production of 2-phenylethanol. Appl Microbiol Biotechnol 59:1–8. https://doi.org/10.1007/s00253-002-0992-x

Martínez-Avila O, Sánchez A, Font X, Barrena R (2018) Bioprocesses for 2-phenylethanol and 2-phenylethyl acetate production: current state and perspectives. Appl Microbiol Biotechnol 2102:9991–10004. https://doi.org/10.1007/s00253-018-9384-8

Varela JA, Gethins L, Stanton C, Ross P, Morrissey JP (2017) Applications of Kluyveromyces marxianus in biotechnology In: Satyanarayana T, Kunze G (eds) Yeast diversity in human welfare. 1st edn. Springer, Heidelberg, pp 439–453. https://doi.org/10.1007/978-981-10-2621-8_17

Lee CW, Richard J (1984) Catabolism of L phenylalanine by some microorganisms of cheese origin. J Dairy Res 51:461–469. https://doi.org/10.1017/S0022029900023761

Gethins L, Guneser O, Demirkol A, Demirkol A, Rea MC, Stanton C, Ross RP, Yuceer Y, Morrissey JP (2015) Influence of carbon and nitrogen source on production of volatile fragrance and flavour metabolites by the yeast Kluyveromyces marxianus. Yeast 32:67–76. https://doi.org/10.1002/yea.3047

Van Der Sluis C, Rahardjo YSP, Smit BA, Kroon PJ, Hartmans S, Ter Schure EG, Tramper J, Wijffels R (2002) Concomitant extracellular accumulation of alpha-keto acids and higher alcohols by Zygosaccharomyces rouxii. J Biosci Bioeng 93:117–124. https://doi.org/10.1016/S1389-1723(02)80002-0

Chatonnet P, Dubourdieu D, Boidron JN, Lavigne V (1993) Synthesis of volatile phenols by Saccharomyces cerevisiae in wines. J Sci Food Agric 62:191–202. https://doi.org/10.1002/jsfa.2740620213

Shinohara T, Kubodera S, Yanagida F (2000) Distribution of phenolic yeasts and production of phenolic off-flavors in wine fermentation. J Biosci Bioeng 90:90–97. https://doi.org/10.1016/S1389-1723(00)80040-7

Hübschmann HJ (2015) Handbook of GC-MS fundamentals and applications Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim

Yilmaztekin M, Erten H, Cabaroglu T (2008) Production of isoamyl acetate from sugar beet molasses by Williopsis saturnus var. saturnus. J Inst Brew 114:34–38. https://doi.org/10.1002/j.2050-0416.2008.tb00303.x

Kılmanoğlu H, Hoşoğlu Isleten M, Güneşer O, Yüceer YK (2021) Optimization of pretreatment and enzymatic hydrolysis conditions of tomato pomace for production of alcohols and esters by Kluyveromycesmarxianus. LWT 138:110728. https://doi.org/10.1016/j.lwt.2020.110728

Vong WC, Liu SQ (2017) Changes in volatile profile of soybean residue (okara) upon solid-state fermentation by yeasts. J Sci Food Agric 97:135–143. https://doi.org/10.1002/jsfa.7700

Lalou S, Mantzouridou F, Paraskevopoulou A, Bugarski B, Levic S, Nedovic V (2013) Bioflavour production from orange peel hydrolysate using immobilized Saccharomyces cerevisiae. Appl Microbiol Biotechnol 97:9397–9407. https://doi.org/10.1007/s00253-013-5181-6

Mantzouridou F, Paraskevopoulou A (2013) Volatile Bio-ester production from orange pulp-containing medium using Saccharomyces cerevisiae. Food Bioprocess Technol 6:3326–3334. https://doi.org/10.1007/s11947-012-1009-0

Martínez O, Sánchez A, Font X, Barrena R (2017) Valorization of sugarcane bagasse and sugar beet molasses using Kluyveromyces marxianus for producing value-added aroma compounds via solid-state fermentation. J Clean Prod 158:8–17. https://doi.org/10.1016/j.jclepro.2017.04.155

Urit T, Löser C, Wunderlich M, Bley T (2011) Formation of ethyl acetate by Kluyveromyces marxianus on whey: studies of the ester stripping. Bioprocess Biosyst Eng 34:547–559. https://doi.org/10.1007/s00449-010-0504-9

Medeiros ABP, Pandey A, Christen P, Fontoura PSG, de Freitas RJS, Soccol CR (2001) Aroma compounds produced by Kluyveromyces marxianus in solid state fermentation on a packed bed column bioreactor. World J Microbiol Biotechnol 17:767–771. https://doi.org/10.1023/A:1013596330389

Lukin I, Merz J, Schembecker G (2018) Techniques for the recovery of volatile aroma compounds from biochemical broth: a review. Flavour Fragr J 33:203–216. https://doi.org/10.1002/ffj.3447

Try S, Voilley A, Chunhieng T, De-Coninck J, Waché Y (2018) Aroma compounds production by solid state fermentation, importance of in situ gas-phase recovery systems. Appl Microbiol Biotechnol 102:7239–7255. https://doi.org/10.1007/s00253-018-9157-4

Tay S (2013) Using the method of “in situ product removal” while producing natural banana flavor through bioconversion. Master Thesis, University of İnönü, Turkey.

İşleten-Hoşoğlu M (2018) Study of increasing the production of volatile flavor compounds by the yeast Kluyveromyces marxianus through optimization of carbon and nitrogen sources. Food Heal 4:112–123. https://doi.org/10.3153/fh18011

Cano-García L, Flores M, Belloch C (2013) Molecular characterization and aromatic potential of Debaryomyces hansenii strains isolated from naturally fermented sausages. Food Res Int 52:42–49. https://doi.org/10.1016/j.foodres.2013.02.047

Sørensen LM, Gori K, Petersen MA, Jespersen L, Arneborg N (2011) Flavour compound production by Yarrowia lipolytica, Saccharomyces cerevisiae and Debaryomyces hansenii in a cheese-surface model. Int Dairy J 21:970–978. https://doi.org/10.1016/j.idairyj.2011.06.005

Leclercq-Perlat MN, Corrieu G, Spinnler HE (2004) Comparison of volatile compounds produced in model cheese medium deacidified by Debaryomyces hansenii or Kluyveromyces marxianus. J Dairy Sci 87:1545–1550. https://doi.org/10.3168/jds.S0022-0302(04)73306-8

Acknowledgements

The authors would like to thank Bioflavor COST Action FA0907 for supporting this scientific work. The authors would also like to thank the panelists for their participation and contribution during sensory panels.

Funding

This study was supported by The Scientific and Technological Council of Turkey (TUBITAK, Ankara Turkey; Project No. 110O903).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Ethics approval was not required for this research.

Consent for publication

All authors are in agreement with publication.

Conflict of interest

The authors declare no competing interests.

Additional information

Responsible Editor: Rosane Freitas Schwan

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Guneser, O., Yuceer, Y.K., Hosoglu, M.I. et al. Production of flavor compounds from rice bran by yeasts metabolisms of Kluyveromyces marxianus and Debaryomyces hansenii. Braz J Microbiol 53, 1533–1547 (2022). https://doi.org/10.1007/s42770-022-00766-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42770-022-00766-6