Abstract

All-solid-state Li-SeS2 batteries (ASSLSs) are more attractive than traditional liquid Li-ion batteries due to superior thermal stability and higher energy density. However, various factors limit the practical application of all-solid-state Li-SeS2 batteries, such as the low ionic conductivity of the solid-state electrolyte and the poor kinetic property of the cathode composite, resulting in unsatisfactory rate capability. Here, we employed a traditional ball milling method to design a Li7P2.9W0.05S10.85 glass–ceramic electrolyte with high conductivity of 2.0 mS cm− 1 at room temperature. In order to improve the kinetic property, an interpenetrating network strategy is proposed for rational cathode composite design. Significantly, the disordered cathode composite with an interpenetrating network could promote electronic and ionic conduction and intimate contacts between the electrolyte–electrode particles. Moreover, the tortuosity factor of the carrier transport channel is considerably reduced in electrode architectures, leading to superior kinetic performance. Thus, assembled ASSLS exhibited higher capacity and better rate capability than its counterpart. This work demonstrates that an interpenetrating network is essential for improving carrier transport in cathode composite for high rate all-solid-state Li-SeS2 batteries.

Graphical abstract

Similar content being viewed by others

References

Yang CP, Xin S, Yin YX, Ye H, Zhang J, Guo YG. An advanced selenium-carbon cathode for rechargeable lithium-selenium batteries. Angew Chem Int Ed 2013;52:8363.

Armand M, Tarascon J-M. Building better batteries. Nature 2008;451:652.

Li X, Liang J, Li X, Wang C, Luo J, Li R, Sun X. High-performance all-solid-state Li-Se batteries induced by sulfide electrolytes. Energy Environ Sci 2018;11:2828.

Cai W, Yao Y-X, Zhu G-L, Yan C, Jiang L-L, He C, Huang J-Q, Zhang Q. A review on energy chemistry of fast-charging anodes. Chem Soc Rev 2020;49:3806.

Eftekhari A. The rise of lithium-selenium batteries. Sustain Energy Fuels 2017;1:14.

Zeng L-C, Li W-H, Jiang Y, Yu Y. Recent progress in Li-S and Li-Se batteries. Rare Met 2017;36:339.

Abouimrane A, Dambournet D, Chapman KW, Chupas PJ, Weng W, Amine K. A new class of lithium and sodium rechargeable batteries based on selenium and selenium-sulfur as a positive electrode. J Am Chem Soc 2012;134:4505.

Lee JT, Kim H, Oschatz M, Lee DC, Wu F, Lin HT, Zdyrko B, Cho WI, Kaskel S, Yushin G. Micro-and mesoporous carbide-derived carbon-selenium cathodes for high-performance lithium selenium batteries. Adv Energy Mater 2015;5:1400981.

Wang WP, Zhang J, Yin YX, Duan H, Chou J, Li SY, Yan M, Xin S, Guo YG. A rational reconfiguration of electrolyte for high-energy and long-life lithium-chalcogen batteries. Adv Mater 2020;32:2000302.

Liu F, Wang L, Zhang Z, Shi P, Feng Y, Yao Y, Ye S, Wang H, Wu X, Yu Y. A mixed lithium-ion conductive Li2S/Li2Se protection layer for stable lithium metal anode. Adv Func Mater 2020;30:2001607.

Yi Z, Yuan L, Sun D, Li Z, Wu C, Yang W, Wen Y, Shan B, Huang Y. High-performance lithium-selenium batteries promoted by heteroatom-doped microporous carbon. J Mater Chem A 2015;3:3059.

Yang X, Luo J, Sun X. Towards high-performance solid-state Li-S batteries: from fundamental understanding to engineering design. Chem Soc Rev 2020;49:2140.

Chen S, Xie D, Liu G, Mwizerwa JP, Zhang Q, Zhao Y, Xu X, Yao X. Sulfide solid electrolytes for all-solid-state lithium batteries: structure, conductivity, stability and application. Energy Storage Mater 2018;14:58.

Zheng F, Kotobuki M, Song S, Lai M, Lu L. Review on solid electrolytes for all-solid-state lithium-ion batteries. J Power Sources 2018;389:198.

Sun C, Liu J, Gong Y, Wilkinson DP, Zhang J. Recent advances in all-solid-state rechargeable lithium batteries. Nano Energy 2017;33:363.

Manthiram A, Yu X, Wang S. Lithium battery chemistries enabled by solid-state electrolytes. Nat Rev Mater 2017;2:1.

Ren H-T, Zhang Z-Q, Zhang J-Z, Peng L-F, He Z-Y, Yu M, Yu C, Zhang L, Xie J, Cheng S-J. Improvement of stability and solid-state battery performances of annealed 70Li2S-30P2S5 electrolytes by additives. Rare Met 2022;41:106.

Wu J, Liu S, Han F, Yao X, Wang C. Lithium/sulfide all-solid-state batteries using sulfide electrolytes. Adv Mater 2021;33:2000751.

Deng Z, Zhang Z, Lai Y, Liu J, Liu Y, Li J. A sulfur-carbon composite for lithium/sulfur battery based on activated vapor-grown carbon fiber. Solid State Ionics 2013;238:44.

Yoon K, Kim J-J, Seong WM, Lee MH, Kang K. Investigation on the interface between Li10GeP2S12 electrolyte and carbon conductive agents in all-solid-state lithium battery. Sci Rep 2018;8:1.

Zheng H, Yang R, Liu G, Song X, Battaglia VS. Cooperation between active material, polymeric binder and conductive carbon additive in lithium ion battery cathode. J Phys Chem C 2012;116:4875.

Sun D, Tan Z, Tian X, Ke F, Wu Y, Zhang J. Graphene: A promising candidate for charge regulation in high-performance lithium-ion batteries. Nano Res 2021;14:1.

Zhang W, Leichtweiß T, Culver SP, Koerver R, Das D, Weber DA, Zeier WG, Janek J. The detrimental effects of carbon additives in Li10GeP2S12-based solid-state batteries. ACS Appl Mater Interfaces 2017;9:35888.

Hu Y, Zhong Y, Qi L, Wang H. Inorganic/polymer hybrid layer stabilizing anode/electrolyte interfaces in solid-state Li metal batteries. Nano Res 2020;13:3230.

Deng S, Sun Y, Li X, Ren Z, Liang J, Doyle-Davis K, Liang J, Li W, Norouzi Banis M, Sun Q. Eliminating the detrimental effects of conductive agents in sulfide-based solid-state batteries. ACS Energy Lett 2020;5:1243.

Xu R, Xia X, Li S, Zhang S, Wang X, Tu J. All-solid-state lithium–sulfur batteries based on a newly designed Li7P2.9Mn0.1S10.7I0.3 superionic conductor. J Mater Chem A 2017;5:6310.

Zhang Y, Chen R, Liu T, Shen Y, Lin Y, Nan C-W. High capacity, superior cyclic performances in all-solid-state lithium-ion batteries based on 78Li2S-22P2S5 glass-ceramic electrolytes prepared via simple heat treatment. ACS Appl Mater Interfaces 2017;9:28542.

Busche MR, Weber DA, Schneider Y, Dietrich C, Wenzel S, Leichtweiss T, Schröder D, Zhang W, Weigand H, Walter D. In situ monitoring of fast Li-ion conductor Li7P3S11 crystallization inside a hot-press setup. Chem Mater 2016;28:6152.

Park M, Jung H-G, Jung WD, Cho SY, Yun B-N, Lee YS, Choi S, Ahn J, Lim J, Sung JY. Chemically evolved composite lithium-ion conductors with lithium thiophosphates and nickel sulfides. ACS Energy Lett 2017;2:1740.

Wenzel S, Weber DA, Leichtweiss T, Busche MR, Sann J, Janek J. Interphase formation and degradation of charge transfer kinetics between a lithium metal anode and highly crystalline Li7P3S11 solid electrolyte. Solid State Ionics 2016;286:24.

Altavilla C, Sarno M, Ciambelli P. A novel wet chemistry approach for the synthesis of hybrid 2D free-floating single or multilayer nanosheets of MS2@ oleylamine (M=Mo, W). Chem Mater 2011;23:3879.

Rajagopal R, Ryu K-S. Evaluation of Li6P2S8I solid electrolyte for all solid-state lithium battery applications. Chem Eng J 2020;402:126179.

Wang Z, Jiang Y, Wu J, Jiang Y, Huang S, Zhao B, Chen Z, Zhang J. Reaction mechanism of Li2S-P2S5 system in acetonitrile based on wet chemical synthesis of Li7P3S11 solid electrolyte. Chem Eng J 2020;393:124706.

Wu Z, Xie Z, Yoshida A, An X, Wang Z, Hao X, Abudula A, Guan G. Novel SeS2 doped Li2S-P2S5 solid electrolyte with high ionic conductivity for all-solid-state lithium sulfur batteries. Chem Eng J 2020;380:122419.

Ge Q, Zhou L, Lian Y-m, Zhang X, Chen R, Yang W. Metal-phosphide-doped Li7P3S11 glass-ceramic electrolyte with high ionic conductivity for all-solid-state lithium-sulfur batteries. Electrochem Commun 2018;97:100.

Kaus M, Stöffler H, Yavuz M, Zinkevich T, Knapp M, Ehrenberg H, Indris S. Local structures and Li ion dynamics in a Li10SnP2S12-based composite observed by multinuclear solid-state nmr spectroscopy. J Phys Chem C 2017;121:23370.

Hirai K, Tatsumisago M, Takahashi M, Minami T. 29Si and 31P MAS-NMR spectra of Li2S-SiS2-Li3PO4 rapidly quenched glasses. J Am Ceram Soc 1996;79:349.

Ahmad N, Zhou L, Faheem M, Tufail MK, Yang L, Chen R, Zhou Y, Yang W. Enhanced air stability and high Li-Ion conductivity of Li6.988P2.994Nb0.2S10.934O0.6 glass-ceramic electrolyte for all-solid-state lithium-sulfur batteries. ACS Appl Mater Interfaces 2020;12:21548.

Zhou L, Tufail MK, Yang L, Ahmad N, Chen R, Yang W. Cathode-doped sulfide electrolyte strategy for boosting all-solid-state lithium batteries. Chem Eng J 2020;391:123529.

Tufail MK, Zhou L, Ahmad N, Chen R, Faheem M, Yang L, Yang W. A novel air-stable Li7Sb0.05P2.95S10.5I0.5 superionic conductor glass-ceramics electrolyte for all-solid-state lithium-sulfur batteries. Chem Eng J 2021;407:127149.

Eckert H, Zhang Z, Kennedy JH. Structural transformation of non-oxide chalcogenide glasses. The short-range order of lithium sulfide (Li2S)-phosphorus pentasulfide (P2S5) glasses studied by quantitative phosphorus-31, lithium-6, and lithium-7 high-resolution solid-state NMR. Chem Mater 1990;2:273.

Seino Y, Nakagawa M, Senga M, Higuchi H, Takada K, Sasaki T. Analysis of the structure and degree of crystallisation of 70Li2S-30P2S5 glass ceramic. J Mater Chem A 2015;3:2756.

Kaiser N, Spannenberger S, Schmitt M, Cronau M, Kato Y, Roling B. Ion transport limitations in all-solid-state lithium battery electrodes containing a sulfide-based electrolyte. J Power Sources 2018;396:175.

Bielefeld A, Weber DA, Janek Jr. Modeling effective ionic conductivity and binder influence in composite cathodes for all-solid-state batteries. ACS Applied Mater Interfaces 2020;12:12821.

Dewald GF, Ohno S, Hering JG, Janek J, Zeier WG. Analysis of charge carrier transport toward optimized cathode composites for all-solid-state Li-S batteries. Batteries Supercaps 2021;4:183.

Song W, Scholtis ES, Sherrell PC, Tsang DK, Ngiam J, Lischner J, Fearn S, Bemmer V, Mattevi C, Klein N. Electronic structure influences on the formation of the solid electrolyte interphase. Energy Environ Sci 2020;13:4977.

Ryu J, Kang J, Kim H, Lee JH, Lee H, Park S. Electrolyte-mediated nanograin intermetallic formation enables superionic conduction and electrode stability in rechargeable batteries. Energy Storage Materials 2020;33:164.

Li Z, Zhang J, Wu HB, Lou XW. An improved Li-SeS2 battery with high energy density and long cycle life. Adv Energy Mater 2017;7:1700281.

Cui Y, Abouimrane A, Lu J, Bolin T, Ren Y, Weng W, Sun C, Maroni VA, Heald SM, Amine K. (De) Lithiation mechanism of Li/SeSx (x=0–7) batteries determined by in situ synchrotron X-ray diffraction and X-ray absorption spectroscopy. J Am Chem Soc 2013;135:8047.

Jiang M, Liu G, Zhang Q, Zhou D, Yao X. Ultrasmall Li2S-carbon nanotube nanocomposites for high-rate all-solid-state lithium-sulfur batteries. ACS Appl Mater Interfaces 2021;13:18666.

Li P, Zheng X, Yu H, Zhao G, Shu J, Xu X, Sun W, Dou SX. Electrochemical potassium/lithium-ion intercalation into TiSe2: kinetics and mechanism. Energy Storage Mater 2019;16:512.

Srout M, Kwon NH, Ben Youcef H, Semlal N, Fromm KM, Saadoune I. Li0.5Ni0.5Ti1.5Fe0.5(PO4)3/C electrode material for lithium ion batteries exhibiting faster kinetics and enhanced stability. ACS Appl Mater Interfaces 2020;12:18496.

Acknowledgements

This work is supported by the National Natural Science Foundation of China (No. 21975025, 21203008, 51772030), the National Key Research and Development Program of China “New Energy Project for Electric Vehicle” (No. 2016YFB0100204), and the Nature Science Foundation of Beijing Municipality (No. 2172051). State Key Laboratory also funds the project for Modification of Chemical Fibers and Polymer Materials, Donghua University. DTA, XRD, XPS, and NMR measurements were performed in the Analysis & Testing Center, Beijing Institute of Technology.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors state that there are no conflicts of interest to disclose.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

42765_2021_123_MOESM1_ESM.docx

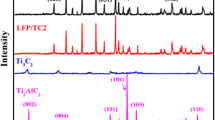

Supplementary XRD pattern of Li7P3S11, Li7P2.9W0.05S10.85 and Li7P2.8W0.1S10.7 glasses (Figure S1); Magnified XRD pattern of glass–ceramic samples (Figure S2); XPS spectra of Li7P2.9W0.05S10.85 glass–ceramic electrolyte (Figure S3); SEM image of Li7P3S11 glass–ceramic electrolyte (Figure S4); TEM image of Li7P3S11 glass–ceramic electrolyte (Figure S5); Schematic diagram of the preparation of composite cathode (Figure S6); SEM image of SeS2 and SeS2/CNT samples (Figure S7); XRD pattern of pristine SeS2 and SeS2/CNT samples (Figure S8); schematic diagram of all-solid-state Li-SeS2 battery (Figure S9); the first galvanostatic charge–discharge curve of the INCC/Li7P2.9W0.05S10.85/Li-In battery (Figure S10); the potential profile before, during, and after a constant current pulse with schematic labeling for CCC/Li7P2.9W0.05S10.85/Li-In (Figure S11) (DOCX 7323 KB)

Rights and permissions

About this article

Cite this article

Zhou, L., Tufail, M.K., Liao, Y. et al. Tailored Carrier Transport Path by Interpenetrating Networks in Cathode Composite for High Performance All-Solid-State Li-SeS2 Batteries. Adv. Fiber Mater. 4, 487–502 (2022). https://doi.org/10.1007/s42765-021-00123-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42765-021-00123-6