Abstract

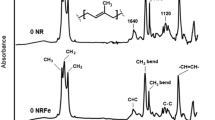

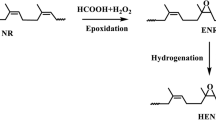

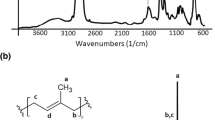

Partial degradation of high ammonia natural rubber (HANR) in the latex stage was successfully carried out in the presence of periodic acid as a water-soluble degrading agent at ambient temperatures, i.e. 30 °C. The number average molecular weight (Mn), weight average of molecular weight (Mw), gel content and Mooney viscosity were decreased as the periodic acid concentrations increased. The polydispersity was slightly increased with increasing periodic acid concentrations. The relationship between Mw, gel content and Mooney viscosity was established. Mw in the range of 8.0 × 105 g/mol to 1.2 × 106 g/mol, and gel content between 30 and 45 wt% successfully achieved the Mooney viscosity of raw natural rubber ranging from 60 to 85 MU. To obtain such properties, periodic acid concentration between 17 and 19 phr was used to partially degrade the natural rubber in the latex stage. The structural characterisations determined by Fourier transform infra-red (FTIR) and nuclear magnetic resonance (NMR) spectroscopies confirmed the occurrence of chain scission to form carbonyl terminal groups as a result of partial degradation. In summary, the Mooney viscosity of raw natural rubber can be controlled by partial degradation of natural rubber in the latex stage, contributed by a controlled decrease in molecular weight and gel content. Hence, this work may be useful in altering the properties of raw natural rubber that are suitable for processing of dry rubber products.

Similar content being viewed by others

References

Bristow GM, Westall B (1967) The molecular weight distribution of natural rubber. Polymer 8:609–617

Qu W, Zhu Y, Huang G, Huang C, Luo MC, Zheng J (2016) Study of molecular weight and chain branching architectures of natural rubber. J Appl Polym Sci 133(40). https://doi.org/10.1002/app.43975

Bhowmick AK, Cho J, MacArthur A, McIntyre D (1986) Influence of gel and molecular weight on the properties of natural rubber. Polymer 27(12):1889–1894

Tanaka Y, Tarachiwin L (2009) Recent advances in structural characterization of natural rubber. Rubber Chem Technol 82(3):283–314

Sakdapipanich JT, Rojruthai P (2012) Molecular structure of natural rubber and its characteristics based on recent evidence. In: Biotechnology-molecular studies and novel applications for improved quality of human life, p 213

Theamsawade P, Kumarn S, Sakdapipanich J (2020) Confirmation molecular structure of the Hevea rubber molecule and its effects in storage hardening. In: The International conference on materials research and innovation

Le Roux Y, Hhabe E, Sainte-Beuve J, Nkengafac J, Nkeng J, Ngolemasango FA, Gobina S (2000) Seasonal and clonal variations in the latex and raw rubber of Hevea brasiliensis. J Rubb Res 3(3):142–156

Moreno RMB, Ferreira M, Gonçalves PDS, Mattoso LHC (2005) Technological properties of latex and natural rubber of Hevea brasiliensis clones. Sci Agric 62(2):122–126

Sekhar BC (1962) Abnormal Groups in Rubber and Microgel. In: Proceedings of Fourth Rubber Technology Conference, London, pp 460–469

Kovuttikulrangsie S, Sakdapipanich JT (2005) The molecular weight (MW) and molecular weight distribution (MWD) of NR from different age and clone Hevea trees. Songklanakarin J Sci Technol 27:338–342

Ehabe EE, Bonfils F (2011) Novel insight into the gel phase of Hevea natural rubber. J Rubb Res 14(1):1–10

Subramaniam A (1975) Molecular weight and other properties of natural rubber: a study of clonal variations. In: Proceedings of the International Rubber Conference, Kuala Lumpur

Ong EL (2000) Characterization of new latex-timber clones of natural rubber. J Appl Polym Sci 78(8):1517–1520

Eng AH, Othman H, Hasma H, Ramli O, Masahuling B, Muniandy V, Kawahara S (2001) Some properties of natural rubber from latex-timber clones. J Rubb Res 4(3):164–176

Yip E (1990) Clonal characterization of latex and rubber properties. J Nat Rubb Res 5(1):52–80

Pasquini C, Figueiredo FC, Prince B (2005) Evaluation of the mooney viscosity of natural rubber by near-infrared spectroscopy. Spectrosc Lett 38(6):741–748

Sadaka F, Campistron I, Laguerre A, Pilard JF (2012) Controlled chemical degradation of natural rubber using periodic acid: application for recycling waste tyre rubber. Polym Degrad Stab 97(5):816–828

Fainleib A, Pires RV, Lucas EF, Soares BG (2013) Degradation of non-vulcanized natural rubber-renewable resource for fine chemicals used in polymer synthesis. Polímeros 23(4):441–450

Rooshenass P, Yahya R, Gan SN (2018) Preparation of liquid epoxidized natural rubber by oxidative degradations using periodic acid, potassium permanganate and UV-irradiation. J Polym Environ 26(4):1378–1392

Phinyocheep P, Phetphaisit CW, Derouet D, Campistron I, Brosse JC (2005) Chemical degradation of epoxidized natural rubber using periodic acid: preparation of epoxidized liquid natural rubber. J Appl Polym Sci 95(1):6–15

Pires RV, Pessoa LMB, Sant’Anna MDAD, Fainleib A, Nunes RDCP, Lucas EF, (2019) Synthesis and characterization of isoprene oligomers to compare different production chemical processes. Polímeros 29(1):e2019015. https://doi.org/10.1590/0104-1428.04418

Gillier-Ritoit S, Reyx D, Campistron I, Laguerre A, Pal Singh R (2003) Telechelic cis-1, 4-oligoisoprenes through the selective oxidolysis of epoxidized monomer units and polyisoprenic monomer units in cis-1, 4-polyisoprenes. J Appl Polym Sci 87(1):42–46

Thuong NT, Yamamoto Y, Nghia PT, Kawahara S (2016) Analysis of damage in commercial natural rubber through NMR spectroscopy. Polym Degrad Stab 123:155–161

Scholte TG, Meijerink NLJ, Schoffeleers HM, Brands AMG (1984) Mark-Houwink equation and GPC calibration for linear short-chain branched polyolefines, including polypropylene and ethylene–propylene copolymers. J Appl Polym Sci 29(12):3763–3782

Johansson EE, Lind J (2005) The general link between random scissions in linear polymers, changes in average chain length and the Mark–Houwink equation. Polym Degrad Stab 88(2):159–167

Yamamoto Y, Norulhuda SNB, Nghia PT, Kawahara S (2018) Thermal degradation of deproteinized natural rubber. Polym Degrad Stab 156:144–150

Zheng K, Duan H, Zhang L, Cui Y (2013) Synthesis of poly(4-methoxyphenol) by enzyme-catalyzed polymerization and evaluation of its antioxidant activity. New J Chem 37(12):4185

Pereira RFP, Valente AJM, Burrows HD, de Zea BV, Carvalho RA, Castro RAE (2013) Structural characterization of solid trivalent metal dodecyl sulfates: from aqueous solution to lamellar superstructures. RSC Adv 3(5):1420

Acknowledgements

This research was funded by the Malaysian Rubber Board for Scientific and Economic Advisory Council (SEAC) under Project Code S17SRP0653B. High appreciation to Dr Nghiem Thi Thuong from HUST, Hanoi, Vietnam for her sharing knowledge. Special thanks and appreciate to Mdm. Faezah Ismail, Mr. Hamdan Abu Bakar, Mdm. Haisah Usman, Miss Nur Aina Farina Mohd Rosli and Miss Nur Ain Zubaidah Ariffuddin for their great assistance throughout the work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yusof, N.H., Baratha Nesan, K.V. & Mohd Rasdi, F.R. Controlling the characteristics of raw natural rubber by partial degradation in the latex stage using a water-soluble degrading agent. J Rubber Res 23, 301–310 (2020). https://doi.org/10.1007/s42464-020-00058-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42464-020-00058-4